You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Anet A8?

- Thread starter westy74

- Start date

quimney

Member

I've got one had it for a about a year now.... I think it's a great first printer. I have had too much fun learning about printing and how to improve my prints. If you want a turnkey machine and imagine this is that last printer you will ever buy then maybe you need to spend a lot more money. If you want a very credible and inexpensive printer that can make great parts then the A8 may be for you. It needs a better belt and nylon bearings but these parts are cheap, and you can use the printer itself to make the braces and tensioners it needs to perform even better. I have added automatic bed leveling and a octoprint to mine and I have no complaints.The upgrades have cost me less than $50 and it now does everything I need it to do. Right now I am getting ready to print my first plane and I believe this printer will be able to do the job very well.

Uncle Manuel

New member

These are true DIY kits, you have to assemble everything. I'm talking 12+ hours build time according to some folks. And you have to modify/upgrade the printer if you wanna have good and reliable prints. If you're not into that side of the coin you can buy preassembled kits like the well beloved Creality3D CR-10 or the improved model CR-10S. There are currently the CR-10 3S with 300 x 300 x 400 mm print space and the bigger versions 4S and 5S. I think that's better for getting started and not have to worry about if you have built the printer correctly. Just my 0,02€...

I recently went with the Prusa MK2s and it was so easy. I bought the kit and 8-9 hours of assembly I was printing. Not a difficult assembly at all. With all of the features it has I was able to get quality prints without a lot of tinkering and adjusting. I was willing to spend the extra money over some of the other DIY kits for these reasons.

Michael_jpm

New member

I recommend the Tevo Tarantula. Similar price, amazing prints and community and all metal frame. Took me 10 hours to put together.

quimney

Member

I hope I did not leave the wrong impression. I like the A8 and honestly I would buy it again. I printed 5 times a week for months before I changed anything... I'm an engineer, I love to tinker so there is no way I was going to leave it alone. I love to learn and having a solid printer is less than half the battle in my opinion. Learning how to make models that print well and how to slice the ones that wont is the second part of a very enjoyable journey. It's not turnkey and not for everyone, but if your willing to take the time to build it properly you will have to spend a lot of money to do better in my opinion.

Chuppster

Well-known member

I built my A8 in about 4 hours not quite a year ago. Since then it's racked up 70 days of printing and there haven't been any major failures. I have only replaced the mosfet for the hotbed. I did replace the hotend with an E3D V6, add a autolevel sensor, and do some other minor upgrades (printed upgrades, that is). I have a bowden version of the A8 (Tronxy P802e).

jaredstrees

Well-known member

Just got the A8. Honestly, probably the better way to go than a prebuilt. This way you'll know how it goes together and have a better understanding of how it works and how to address problems when they arise. I just got mine built Friday night and have already had successful prints. I bought upgraded belts and never opened the cheap ones that come with it. I wish I had done the bearings while assembling it, but oh well. Add a mosfet to the hot bed and don't look back!

DharanFlyer

Active member

I got a Tronxy first (by accident) and didn't like it and it fried it's board within the first few weeks.

Got a ANet A8 for Christmas and have been printing regularly for weeks now with 0 issues. Some minor tweaking of settings etc here and there and have a Y issue I have to sort out, but not affecting overall quality of prints. Installed a auto bed leveler before first print and upgraded to Skynet firmware to use it. Think my all-in build-to-print was 5 hours.

Just finished printing a cable chain for the Z that I am installing soon and next is cable tension items. Already printed a new case for MOSFET and board, frame braces, new filament roller, and a bunch of Star Wars Armada organizers to use.

Got a ANet A8 for Christmas and have been printing regularly for weeks now with 0 issues. Some minor tweaking of settings etc here and there and have a Y issue I have to sort out, but not affecting overall quality of prints. Installed a auto bed leveler before first print and upgraded to Skynet firmware to use it. Think my all-in build-to-print was 5 hours.

Just finished printing a cable chain for the Z that I am installing soon and next is cable tension items. Already printed a new case for MOSFET and board, frame braces, new filament roller, and a bunch of Star Wars Armada organizers to use.

TheWW1FlyingAce

Member

I have what's quickly turning into "The Anet A8 of Theseus" (https://en.wikipedia.org/wiki/Ship_of_Theseus). I've done the following modifications:

Some of these changes (MOSFETs, upgrading bed cables and power supply, switching to Marlin FW) were done for safety. The switch to Arduino+RAMPS was done because the hot end thermistor input on my Anet mainboard failed (the hot end thermistor would read 160C even when the hot end was dead cold.) Most of the other fixes are quality-of-life (extruder button, bed leveling thumbwheels, cable chains, PrintBite+ bed surface) or print quality improvements (better belts, belt tensioners, frame braces).

At this point the print quality I'm getting is close to the limits of the technology.

Do you need to do all of these updates? No. But I would recommend at least the physical safety upgrades (MOSFETs, bed cables and power supply) and adding the extruder button and belt tensioners to start out with.

Also, all machines of this design have a "feature" that can cause problems. There are two Z-axis motors, and the Z-axis lead screws have a pretty steep pitch. This means that if the motors are off you can easily push the axis up or down. However the two Z-axis screws are not connected in any way which means that you can easily push one side down more than the other leaving you with a skewed X-axis. This tends to happen very easily when you are changing filament. So I recommend printing out and using Anet A8/Prusa i3 - Z-Axis Alignment Tool. This will save you a lot of bed leveling

Hope this helps. Please don't hesitate to ask any questions.

- Safety improvements:

- Added power MOSFETs for the bed and hotend.

- Removed the heated bed connector and soldered 14AWG silicone wire directly to the bed.

- Replaced the power supply with an HP DPS-600PB 47A server power supply.

- Replaced standard firmware with Marlin 1.1.8

- Replaced the X and Y linear bearings with Igus Drylin polymer bearings.

- Replaced the motherboard with an Arduino 2560 clone + RAMPS 1.4

- Added an 18mm diameter 8mm sensing distance inductive sensor.

- Put two layers of dollar tree foamboard under the bed as insulation.

- Printed out a whole lot of upgrade parts:

- Anet A8 X Axis Cable Chain with Z Stop Adjustment

- Y cable chain

- I only use the end pieces and the long piece from the above - for the actual chain pieces I use Loose and Light Cable Chain

- Holder for the Arduino/RAMPS and MOSFETs with a 80mm fan to cool the stepper drivers (modified from https://www.thingiverse.com/thing:1796052)

- Holder for the inductive sensor

- Semicircular fan nozzle

- Mounts for the DPS-600PB (designed by yours truly)

- Y-axis back frame brace

- Y-axis front frame brace

- X-axis belt tensioner

- Y-axis belt tensioner

- X-belt holder (mine is actually a remix of the linked one with countersunk holes for M3 cap-head screws)

- Y-belt holder

- Bed leveling screw thumbwheels

- "Hulk" frame braces

- Extruder button

- Installed a PrintBite+ (https://flex3drive.com/printbite/) print surface

- Hooked up a Raspberry Pi running OctoPrint so I can control the printer from a web browser.

- Replaced the belts with higher quality ones (https://smile.amazon.com/gp/product/B00YMM6IQW)

- Replaced the Z-axis couplings with Plum Couplings

Some of these changes (MOSFETs, upgrading bed cables and power supply, switching to Marlin FW) were done for safety. The switch to Arduino+RAMPS was done because the hot end thermistor input on my Anet mainboard failed (the hot end thermistor would read 160C even when the hot end was dead cold.) Most of the other fixes are quality-of-life (extruder button, bed leveling thumbwheels, cable chains, PrintBite+ bed surface) or print quality improvements (better belts, belt tensioners, frame braces).

At this point the print quality I'm getting is close to the limits of the technology.

Do you need to do all of these updates? No. But I would recommend at least the physical safety upgrades (MOSFETs, bed cables and power supply) and adding the extruder button and belt tensioners to start out with.

Also, all machines of this design have a "feature" that can cause problems. There are two Z-axis motors, and the Z-axis lead screws have a pretty steep pitch. This means that if the motors are off you can easily push the axis up or down. However the two Z-axis screws are not connected in any way which means that you can easily push one side down more than the other leaving you with a skewed X-axis. This tends to happen very easily when you are changing filament. So I recommend printing out and using Anet A8/Prusa i3 - Z-Axis Alignment Tool. This will save you a lot of bed leveling

Hope this helps. Please don't hesitate to ask any questions.

Last edited:

bhursey

The Geeky Pilot

I looked at it for weeks. I decided to go a Monoprice Maker select V2.1 .. I got it on Amazon Sale for 269. I am glad I did. I literally had it printing out of the box in about 30 min.. I have upgraded to an all metal hot end and installed a mosfet for safety. However it prints awesome!!!! Right now printing a Plane from 3dlabprint. However I woudl say the microswiss all metal hotend upgrade is a must.. Im not trying to necessarily sway you but it is definitely out of the box a superior printer. It has an all metal gantry also. Although I did add a zbrace.. https://www.monoprice.com/product?p_id=13860

Michael9865

Elite member

Built my A8 about a week ago. It has been a fun machine for me to enter into the 3D printer world.

sumone

Active member

I bought an Anet A8 a few weeks ago. (I have not owned or used a 3d printer before)

I new it was a kit but looking at all the parts laid out on the floor i have to admit it was a little bit intimidating .

But i grabbed a stack of small disposable party plates and emptied each bag of screws onto its own plate with the bags label and put on the install video and after 2 evenings of work had it all assembled. (I also ordered the seperate mosfet for the heat bed when i ordered the printer from ebay)

I found it quite fun to put together.

I had watched a few you tube clips that recommended glass on the heat bed so i grabbed a $3 picture frame from a reject shop a used the glass from it.(clamped the glass on with 2 folder clips)

I gave it a light mist of $3 hair spray (outside not while its on the bed)

plugged it in , Leveled the bed loaded up cura and did a test print.

no real issues at all.

I move my prints around the bed in cura so i don't have to apply hair spray all the time .

When it needs it i unclip the glass from the bed wipe it down with methylated spirits apply another fine coat of hair spray and I'm good to go again.

I have since bought the auto level $13 from china but leveling the bed isn't as tedious i thought it would be and takes me less than a minute so i haven't bothered installing it yet.

I think its a great entry level printer if you like to tinker and learn .

I new it was a kit but looking at all the parts laid out on the floor i have to admit it was a little bit intimidating .

But i grabbed a stack of small disposable party plates and emptied each bag of screws onto its own plate with the bags label and put on the install video and after 2 evenings of work had it all assembled. (I also ordered the seperate mosfet for the heat bed when i ordered the printer from ebay)

I found it quite fun to put together.

I had watched a few you tube clips that recommended glass on the heat bed so i grabbed a $3 picture frame from a reject shop a used the glass from it.(clamped the glass on with 2 folder clips)

I gave it a light mist of $3 hair spray (outside not while its on the bed)

plugged it in , Leveled the bed loaded up cura and did a test print.

no real issues at all.

I move my prints around the bed in cura so i don't have to apply hair spray all the time .

When it needs it i unclip the glass from the bed wipe it down with methylated spirits apply another fine coat of hair spray and I'm good to go again.

I have since bought the auto level $13 from china but leveling the bed isn't as tedious i thought it would be and takes me less than a minute so i haven't bothered installing it yet.

I think its a great entry level printer if you like to tinker and learn .

TheWW1FlyingAce

Member

I have since bought the auto level $13 from china but leveling the bed isn't as tedious i thought it would be and takes me less than a minute so i haven't bothered installing it yet.

One easy thing I can recommend to help avoid needing to level as often is to print out some Z-axis alignment gizmos (Anet A8/Prusa i3 - Z-Axis Alignment Tool. This will help ensure that both sides of the Z-axis are at the same level every time (they can easily go out of alignment when the motors are disabled). With those I think you'll find that you very rarely need to adjust your bed level. Another cheap and easy bed-leveling improvement is to get rid of the springs and use a rigid bed connection. What I did was print out four thumbwheels (Thumbwheel M3 with scale 0.01 mm with grip (Nut on bottom). Then I drilled out the holes in the Y-axis frame (the H-frame that has the Y-axis bearings attached to it) with a 5/16" drill bit. Then I used a nylon washer and a nut to rigidly attach the four screws to the bed, then threaded the thumbwheel with a nut on it onto the bottom of the screw, fed the screw through the hole in the Y-axis frame, and finally put the wing nut on the bottom. The bed is now rigidly held in place and wobbles less when changing direction, and it holds level very well. In fact, I've stopped using automatic bed leveling because I've found I don't really need it as long as I use the Z-axis alignment tools whenever the motors have been disabled or the printer has been powered down.

One easy thing I can recommend to help avoid needing to level as often is to print out some Z-axis alignment gizmos (Anet A8/Prusa i3 - Z-Axis Alignment Tool. This will help ensure that both sides of the Z-axis are at the same level every time (they can easily go out of alignment when the motors are disabled). With those I think you'll find that you very rarely need to adjust your bed level. Another cheap and easy bed-leveling improvement is to get rid of the springs and use a rigid bed connection. What I did was print out four thumbwheels (Thumbwheel M3 with scale 0.01 mm with grip (Nut on bottom). Then I drilled out the holes in the Y-axis frame (the H-frame that has the Y-axis bearings attached to it) with a 5/16" drill bit. Then I used a nylon washer and a nut to rigidly attach the four screws to the bed, then threaded the thumbwheel with a nut on it onto the bottom of the screw, fed the screw through the hole in the Y-axis frame, and finally put the wing nut on the bottom. The bed is now rigidly held in place and wobbles less when changing direction, and it holds level very well. In fact, I've stopped using automatic bed leveling because I've found I don't really need it as long as I use the Z-axis alignment tools whenever the motors have been disabled or the printer has been powered down.

Thank you - I will look into that when I get to fixing my heat bed.

TheWW1FlyingAce

Member

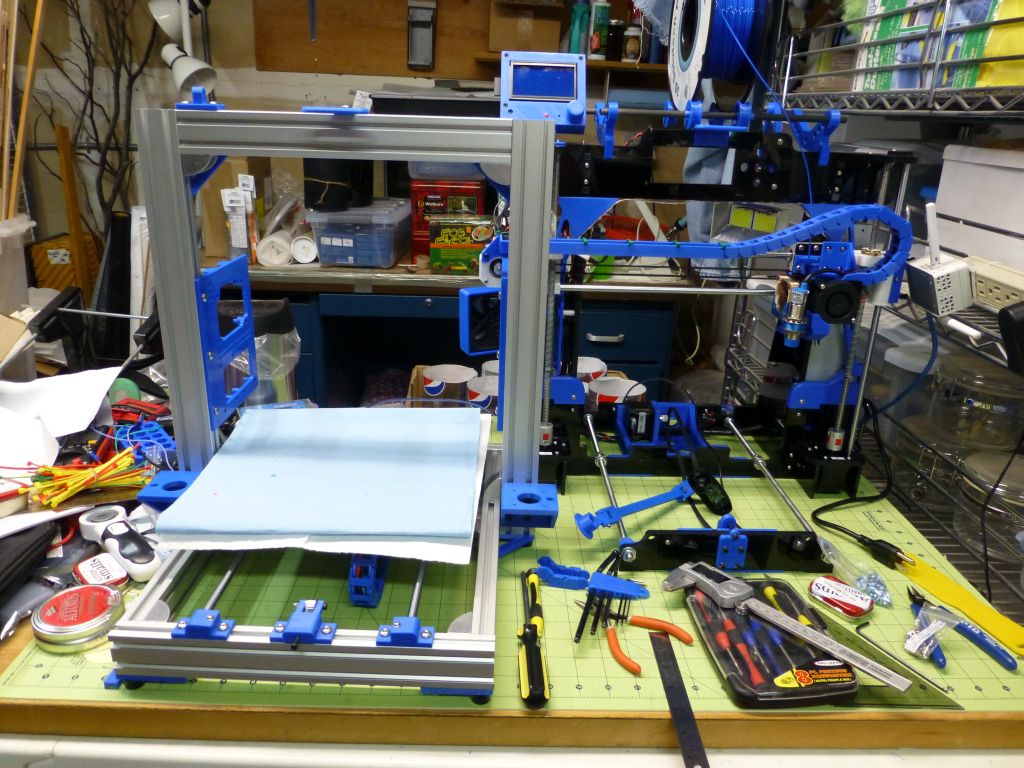

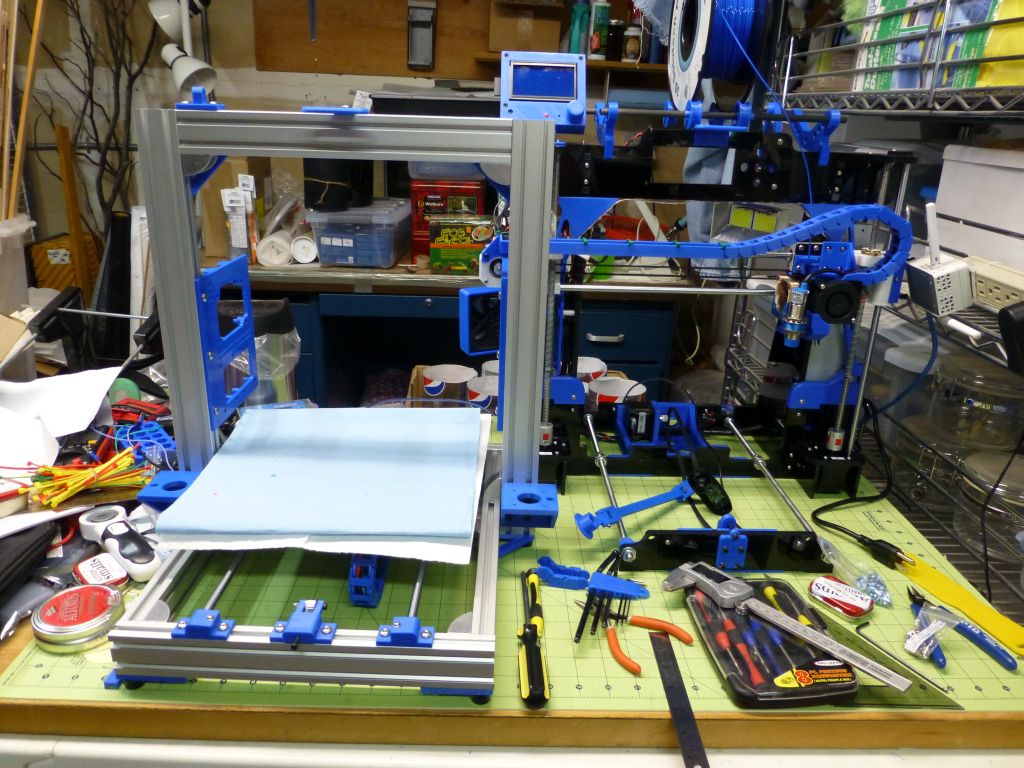

Just wanted to post some pictures of my AM8 - the metal frame (aluminum extrusions) upgrade to the A8. This has made the frame extremely rigid.

CMS_1961

CMS_1961

Anet A8 is a good first printer!! It is cheap enough to get into 3D printing. You will see that a lot of people have suggested upgrades and I am sure they will make it better. One thing to remember is to NEVER leave this printer unattended -- I have read and seen some serious issues that occur (fires). With all that said, I run mine stock the way it came with no upgrades and I am always there during printing!!!

I have found to get the best prints for your first layer --use glass with diluted wood or Elmer's glue as a painted thin layer and dried on the glass--it has not failed me yet and I have tried a bunch!!! Keep the bed level and use the paper under nozzle and five point (center and 4 corners) method of leveling. My prints come out really good and repeatable using PLA. I have not tried ABS or any other materials yet. I am currently making all the attachments for the MPCNC I just built--I ordered the printed parts because I just could not see watching 150 hours of printing when the kit was $135.

I believe I used the print doctor (on Youtube) for the settings for CURA--I can send mine if you need them.

Good luck!!

I have found to get the best prints for your first layer --use glass with diluted wood or Elmer's glue as a painted thin layer and dried on the glass--it has not failed me yet and I have tried a bunch!!! Keep the bed level and use the paper under nozzle and five point (center and 4 corners) method of leveling. My prints come out really good and repeatable using PLA. I have not tried ABS or any other materials yet. I am currently making all the attachments for the MPCNC I just built--I ordered the printed parts because I just could not see watching 150 hours of printing when the kit was $135.

I believe I used the print doctor (on Youtube) for the settings for CURA--I can send mine if you need them.

Good luck!!

CMS_1961

CMS_1961

Westy74

One more thing,

The reason I have not done all the upgrades/improvements to my ANET A8 is you can see suggested in the WW1 Flying ACE feedback to you, by the time you do all that stuff you could just go out and by a really good--significantly higher priced printer. Grant it a lot of the upgrades can be printed right on the A8 itself. The MOSFETs are one upgrade I plan to make--just for the safety aspect. I believe everything else is just nice to have unless it does some significant improvement it the print quality. There was a video on Youtube where a guy made a bunch of upgrades and they had no affect on the quality of print--they looked good though!! This is a cheap printer but it actually has the capability to make great prints with the correct CURA settings and a level print bed, in my opinion. I am happy with my prints and once you dial it in--it will work great.

One more thing,

The reason I have not done all the upgrades/improvements to my ANET A8 is you can see suggested in the WW1 Flying ACE feedback to you, by the time you do all that stuff you could just go out and by a really good--significantly higher priced printer. Grant it a lot of the upgrades can be printed right on the A8 itself. The MOSFETs are one upgrade I plan to make--just for the safety aspect. I believe everything else is just nice to have unless it does some significant improvement it the print quality. There was a video on Youtube where a guy made a bunch of upgrades and they had no affect on the quality of print--they looked good though!! This is a cheap printer but it actually has the capability to make great prints with the correct CURA settings and a level print bed, in my opinion. I am happy with my prints and once you dial it in--it will work great.

Similar threads

- Replies

- 9

- Views

- 436

- Replies

- 14

- Views

- 557

- Replies

- 17

- Views

- 4K

- Replies

- 1

- Views

- 554