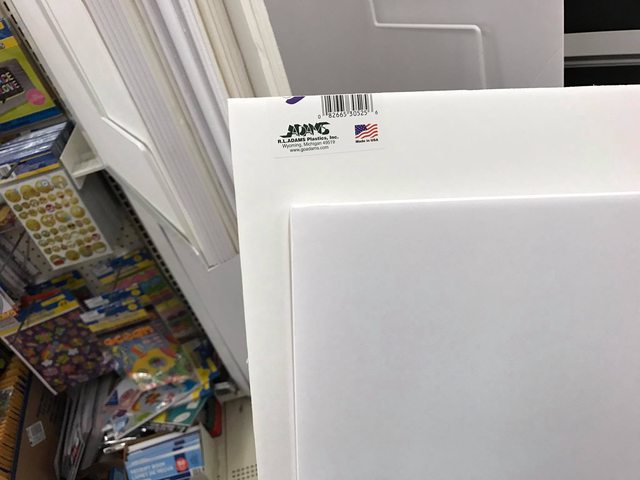

I buy my Adams foam board at my local Phoenix Dollar Tree stores. Lately I have found the foam board is different. The paper is whiter, smoother and the board is flatter. It looks and feels identical to the Ross foam board I got at Wal-Mart. The label still says Adams. As with the Ross board, it takes paint better but the knife cuts are not as clean as with the older product and also seems to be less ridged. Has anyone else seen this new Adams product in their stores?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New Adams foam board?

- Thread starter richb2599

- Start date

flyinggreek

Member

I'm new to using this foam and have noticed that there are different colors of white and the foam seems to be softer.

Very interesting. I'll have to pick some new stuff up to have a look. I really hope that the board hasn't changed to be more like Ross. Adams is much more durable than Ross board.

I agree. But that seems to be the case, at least with what I have purchased lately.

flyinggreek

Member

Might have to invest in a case of FT foam

Might have to invest in a case of FT foam

Haha,not a bad idea Flyinggreek!

Seriously though... we have had a few issues recently with the WHITE FOAM from Adams with warpage and other concerns... THE Water Resistant foam is GREAT and has not given us any issues, but the white version has been a little awkward as of late. We are in talks with them about having a better quality assurance with the white, but things in the business world always move slowly! ha

Have a blessed and merry christmas and may your days be filled with wonderful, non-warped, durable, white or Water-Resistant FOAM!!

Stefan

jpot1

Elite member

I buy my Adams foam board at my local Phoenix Dollar Tree stores. Lately I have found the foam board is different. The paper is whiter, smoother and the board is flatter. It looks and feels identical to the Ross foam board I got at Wal-Mart. The label still says Adams. As with the Ross board, it takes paint better but the knife cuts are not as clean as with the older product and also seems to be less ridged. Has anyone else seen this new Adams product in their stores?

Interesting as I was wondering if it was just me. The sheets are noticeably whiter. I did not notice any issues with stiffness. Plan to use it over the holidays, fingers crossed.

ofiesens2

Professional noob

I think the switch over from the more yellowish foam to the more white stuff you mention happened in spring of 2016, if not earlier. I was fairly dormant in terms of flying and building this year, and I haven't bought any foam before a couple weeks ago, but I've had a few sheets of the newer style foam in my closet all year.

I bought a box of FT foam from graupner and are greatly disappointed with the product. Every single board in this box is heavily warped and as so useless for many models.

Hey na1pir,

did you contact Graupner with that problem? It shouldn't be that way.

Keno

Well-known member

It does appear that Adam’s Corp has made quality improvements to its foam board as noted. A couple of problems exist, our local $tree in-store handling needs improvement. The second problem is unwanted delamination. Adams could make improvements in the manufacturing, but at dollar a board whats expected? The delamination issue appears to be caused by paint products when applied heavy, accidentally or otherwise. Paint solvents appear to attack the foam to paper adhesive. Petroleum based Minwax, as we know, is a good primer coating and rub-on Minwax appears to work best as lighter controlled coatings can be applied.

@Balu I sent them a mail this morning, I do not know why I have not think of that before...

All sheets low look something like that.

But I have not seen that in first two sheets...

Is it possible that I am storing it the wrong way? I have it flat down in dry room at 18°C. Should I put box with short side up?

All sheets low look something like that.

But I have not seen that in first two sheets...

Is it possible that I am storing it the wrong way? I have it flat down in dry room at 18°C. Should I put box with short side up?

Last edited:

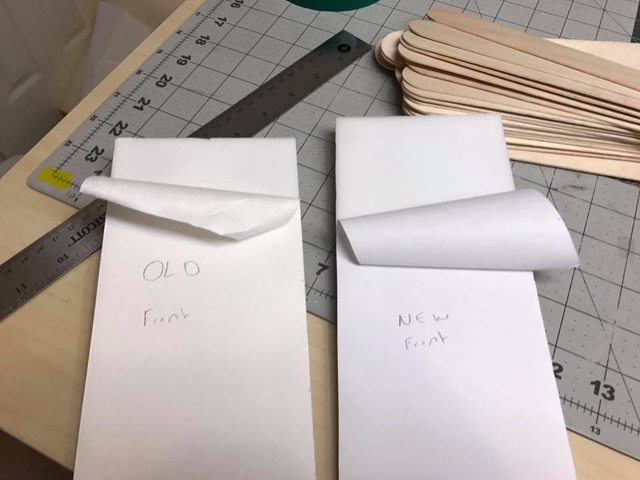

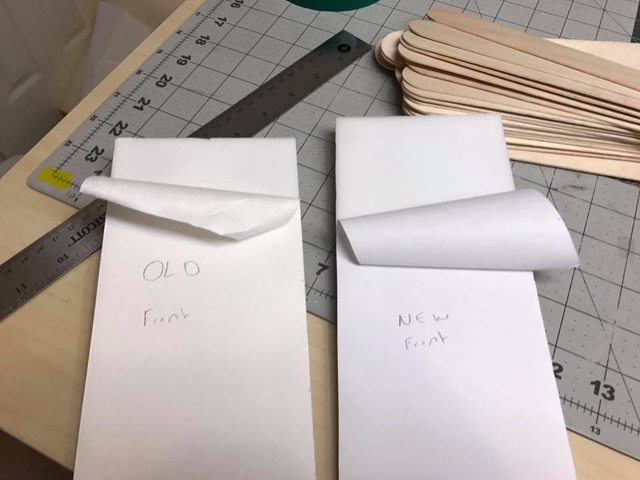

The NEW version is bright white and has a different texture. From the 3 boxes worth I saw in the store, the boards seem to be more consistent in their flatness. I didn't really see any that were warped like the OLD board is sometimes. The NEW board feels a little more 'spongy' in your hand, I'm not sure how to measure this but it's noticeable.

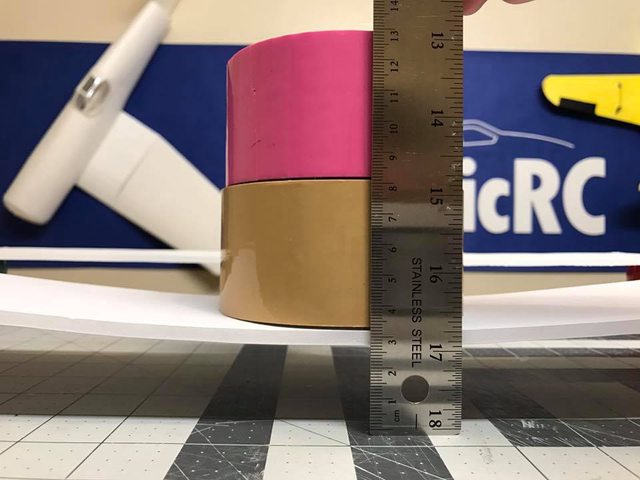

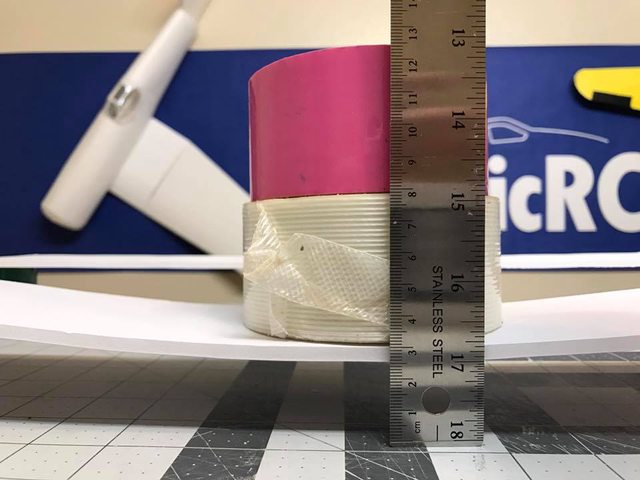

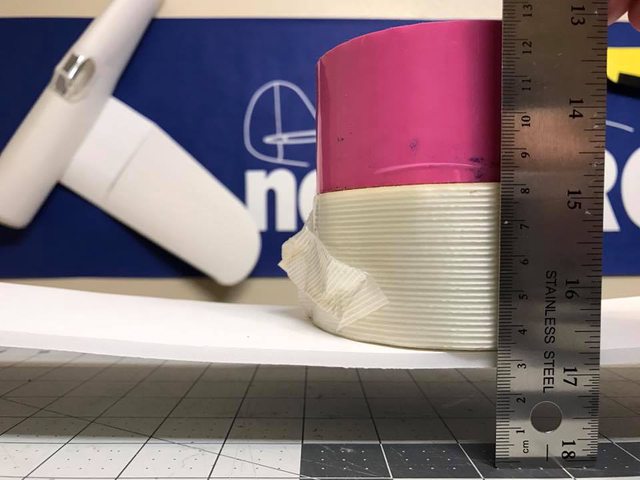

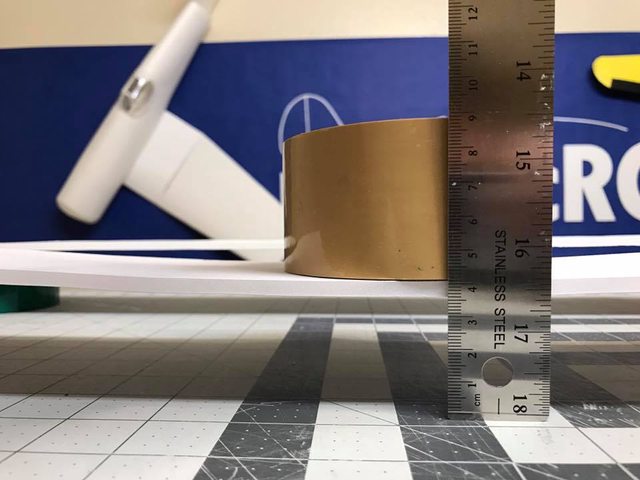

SHEET WEIGHT

Original = 112g

New = 115g

TESTING

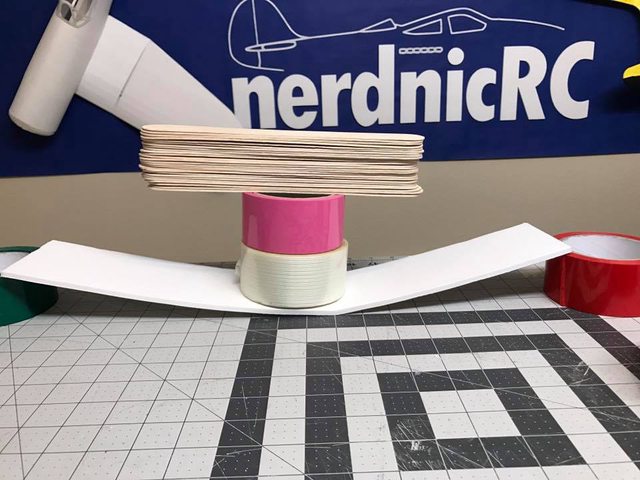

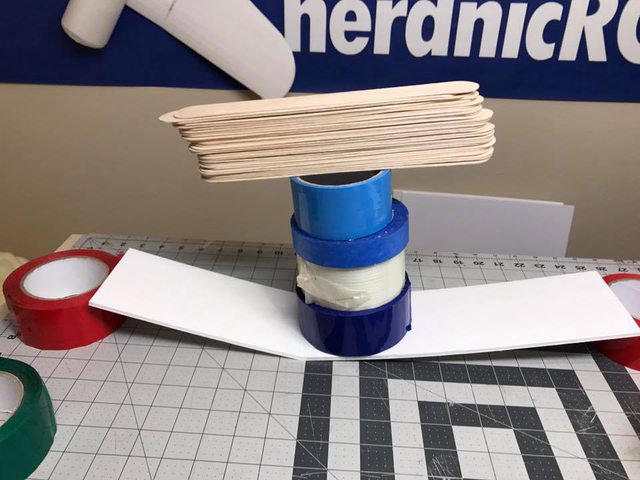

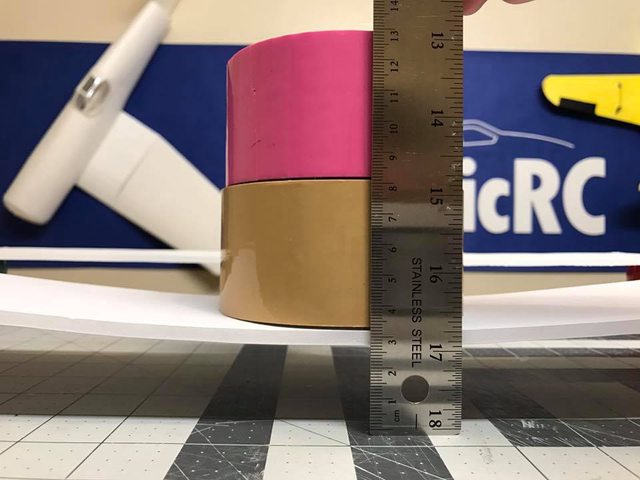

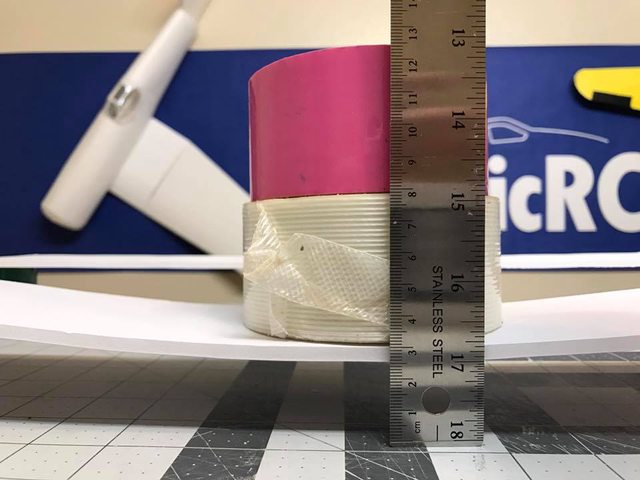

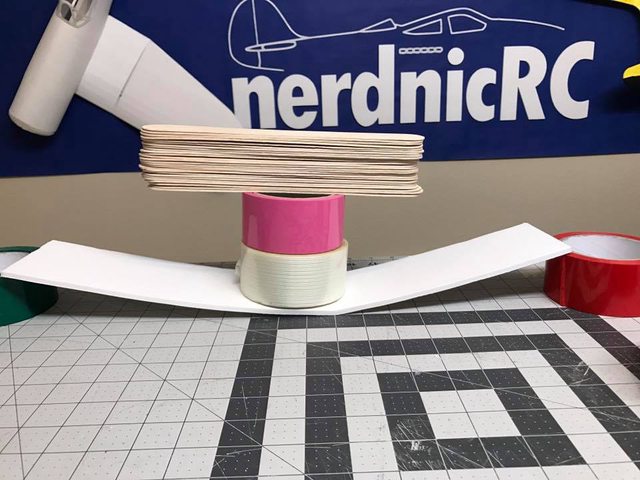

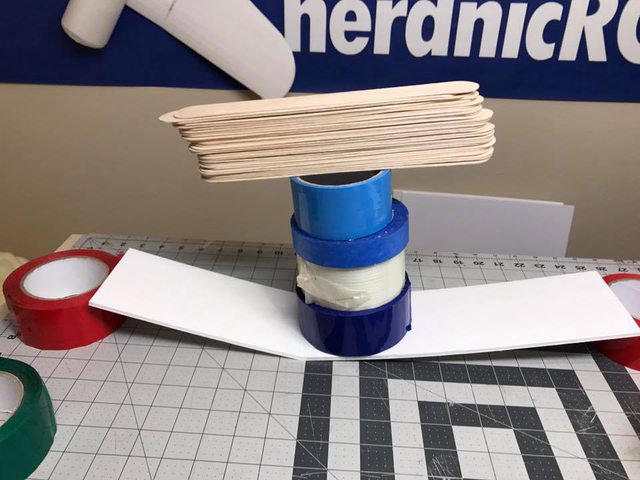

I will be using rolls of tape of various weights and large popsicle sticks at 8g each. To keep this from being too large of a post, all weights were verified off camera on a digital scale.

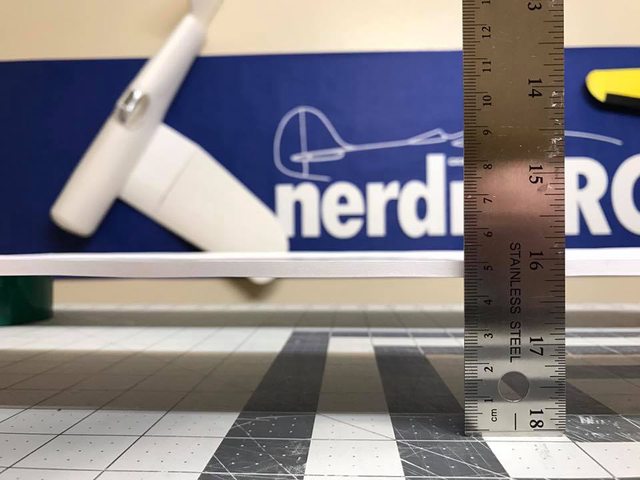

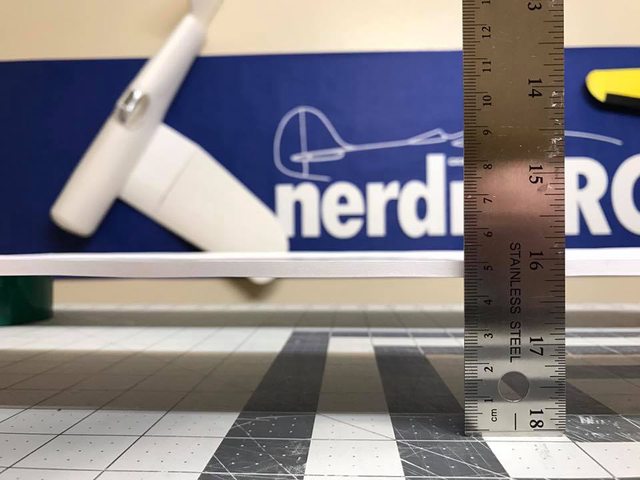

TEST 1 - Failure test on width cut

I cut 4 inch strips out of the width of the foam. So 4x20. The new foam feels more bendy in my hands. Due to the grain of the foam (for both sheets) a strip cut out of the width of the foam will be weaker than one cut from the length, I'm not sure by how much, but we'll see.

How does the new foam hold up compared to the old in a failure test?

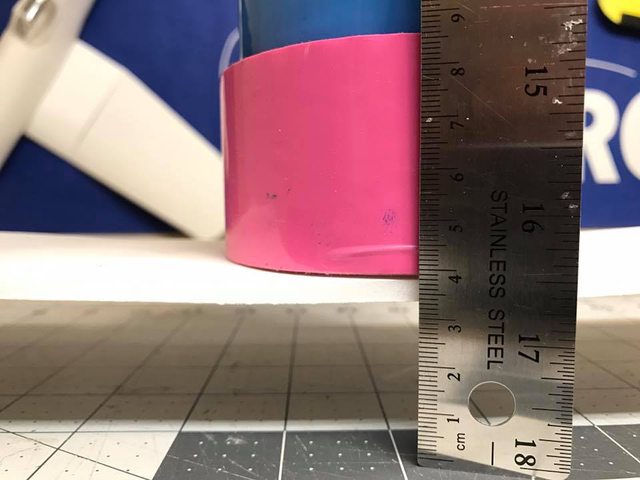

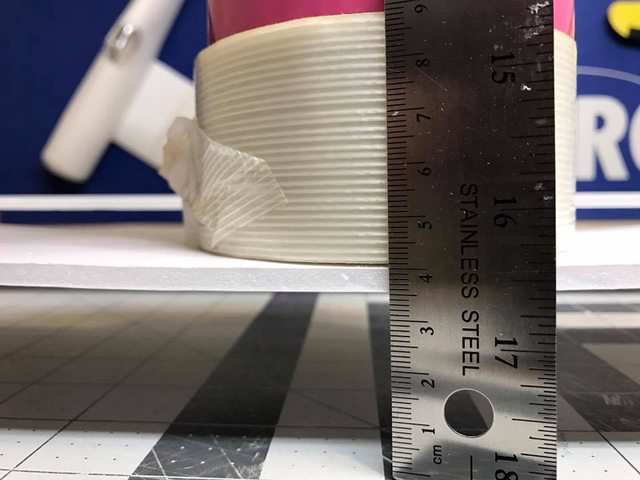

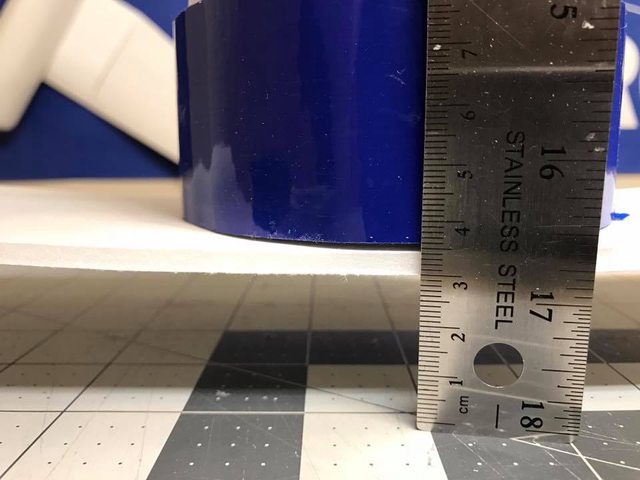

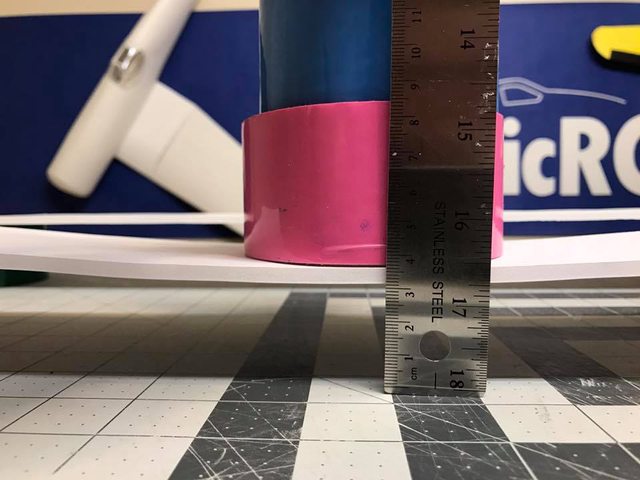

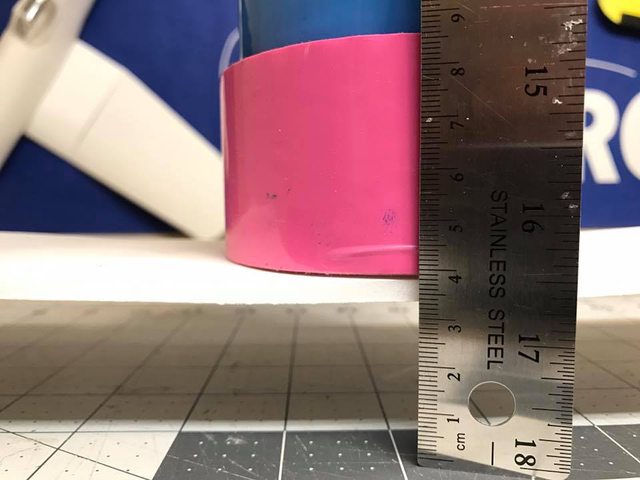

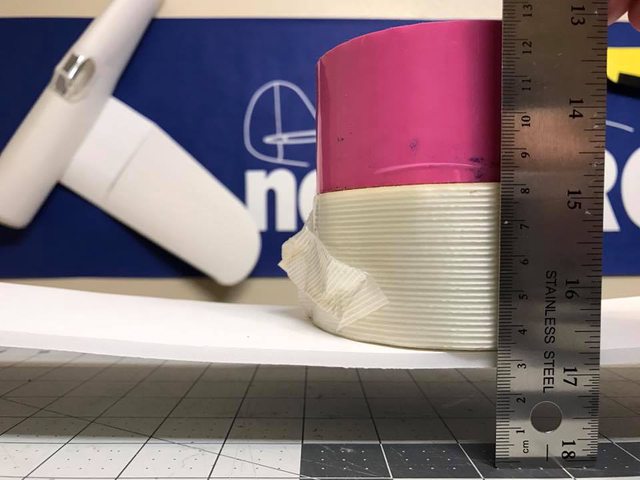

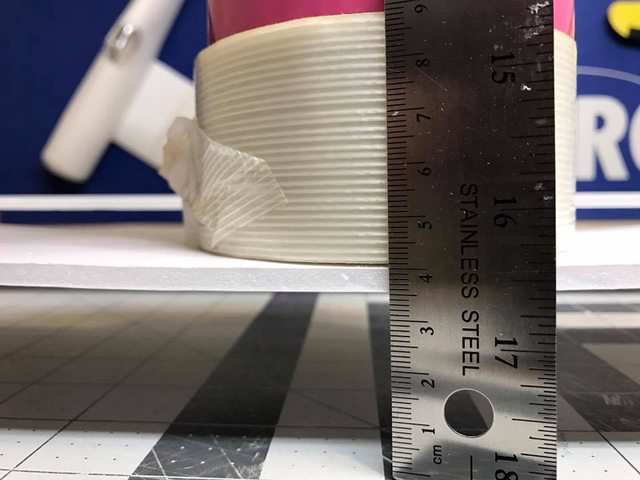

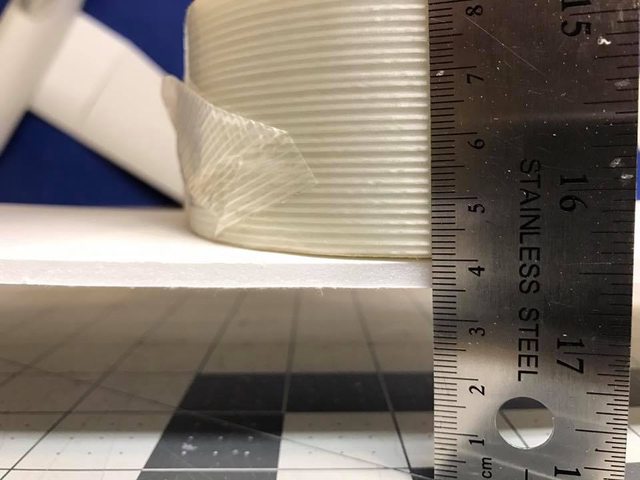

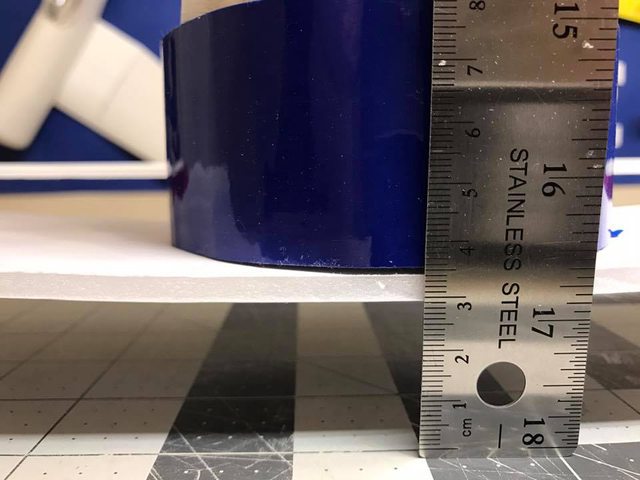

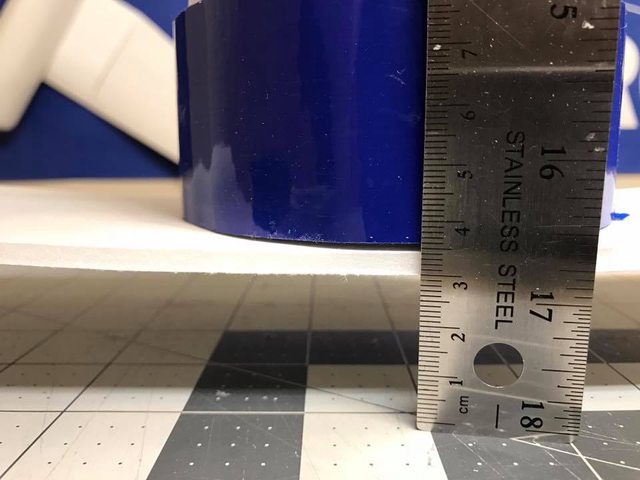

No load control. Foam sits 4.6cm off the table.

144g load - NEW FOAM

144g load - OLD FOAM

NEW foam deflected 1cm and the OLD .9cm.

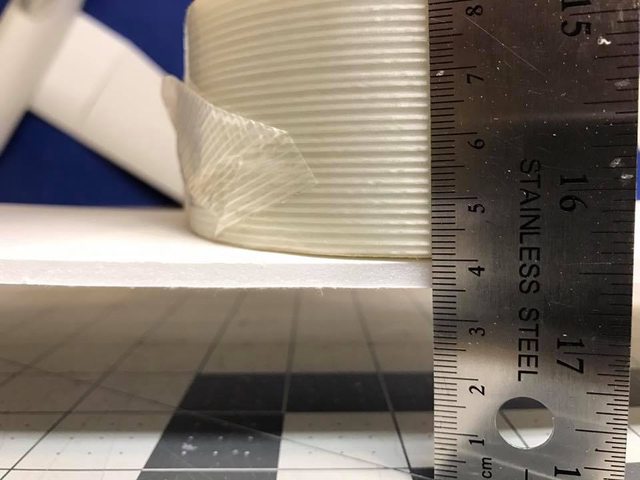

200g load - NEW FOAM

200g load - OLD FOAM

NEW foam deflected 1.5cm and the OLD 1.3cm.

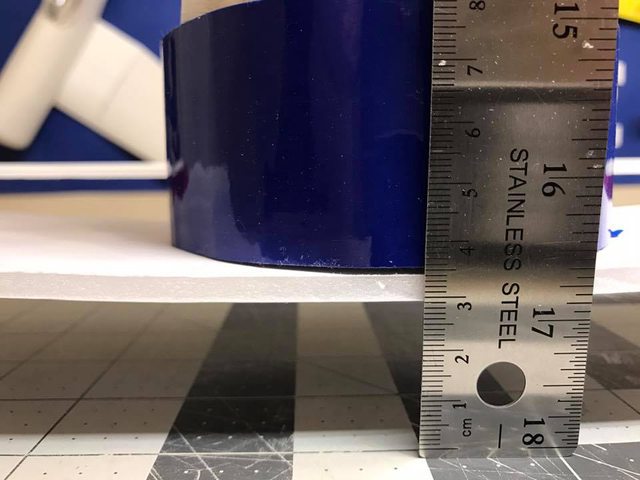

220g load - NEW FOAM

220g load - OLD FOAM

NEW foam deflected 1.55 and the OLD 1.4cm.

270g load - NEW FOAM

270g load - OLD FOAM

NEW foam deflected 1.9cm and the OLD 1.65cm.

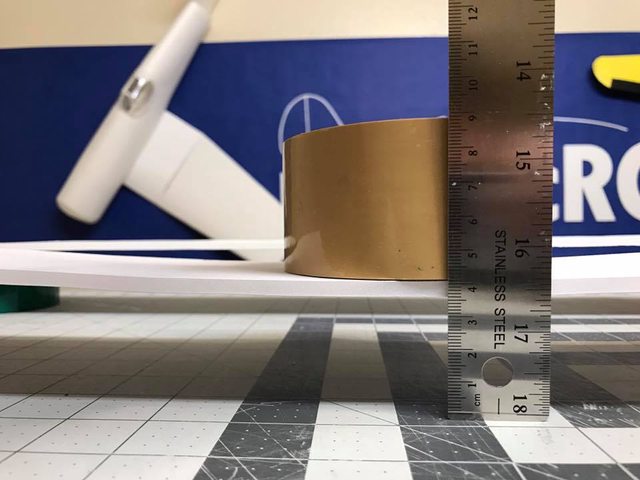

300g load - NEW FOAM

300g load - OLD FOAM

New foam deflected 2.05cm and the OLD 1.8cm.

460g load - NEW FOAM

460g load - OLD FOAM

The NEW board produced a bent board that deflected all the way to the table without immediate failure. By the time I was able to grab a picture it had failed completely. With the NEW foam failed I will continue to find the OLD foams failure point.

508g load - OLD FOAM

OLD foam held 500g and then failed at 508g.

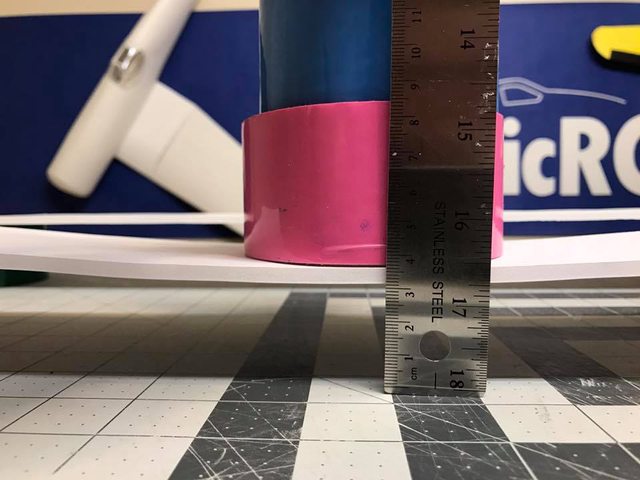

TEST 2 - Failure test on length cut

I am now going to do the same test but from the length of the board, I'll start at 400g. No load control is 4.6cm as before.

400g load - NEW FOAM

400g load - OLD FOAM

Similar results but as you can see length cut is WAY stronger than width. I always keep this in mind for my builds, wings, stabs and fuse should ALWAYS run length wise.

600g load - NEW FOAM

600g load - OLD FOAM

Again, similar results. The NEW foam is holding up better with the length cut.

800g load - NEW FOAM

NEW held at 792g and then failed at 800g.

822g load - OLD FOAM

OLD held at 814g and then failed at 822g

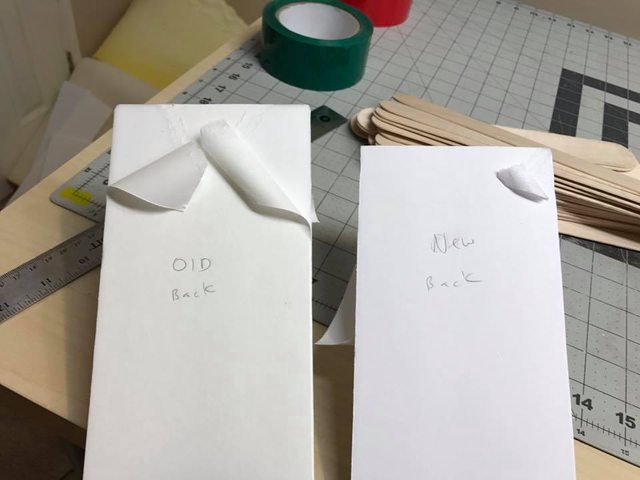

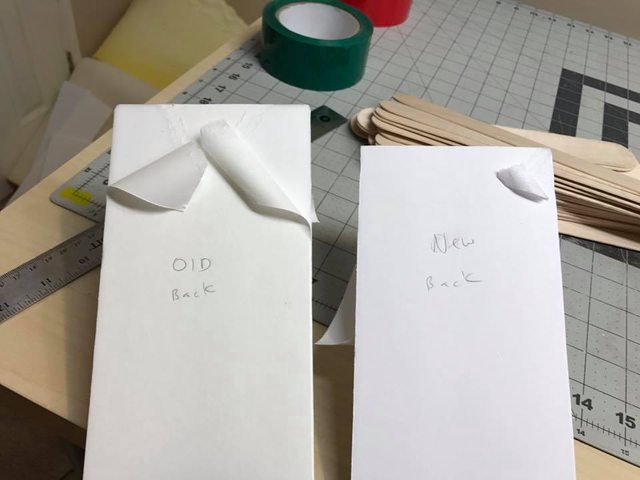

TEST 3 - Paper removal

Grabbing the corner and peeling back produced the same results on one side of the NEW board. It looks like one side of the NEW board has better adhesion though. This was consistent with 5 other boards I bought from the same batch.

To my understanding Adams doesn't use an adhesive on these boards. The paper is rolled/pressed onto the foam while it's still hot. Because of this lack of adhesive, Adams board suffers greatly from moisture exposure. Will this be the same for the NEW board?

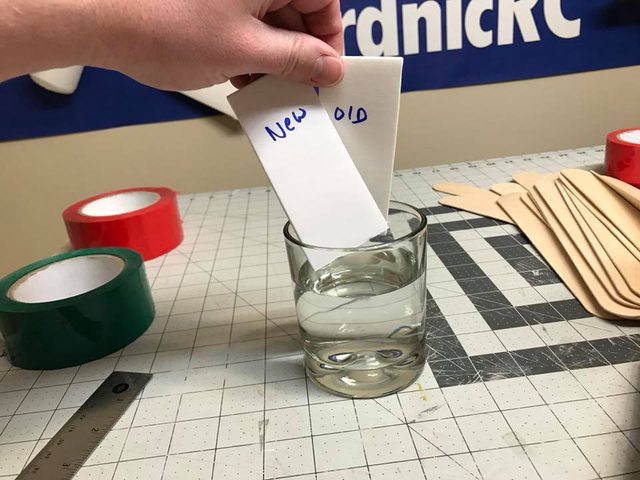

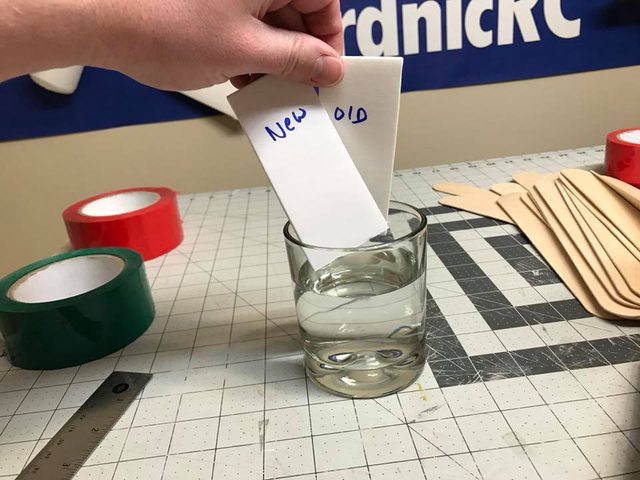

TEST 4 - Water

I left the foam pieces in water for 10 minutes. Then I took them out and let them dry for 30 minutes.

The paper nearly fell off both NEW and OLD foam. It looks like there is no change here in the bonding method.

Let me know what other tests you guys would like to see!

SHEET WEIGHT

Original = 112g

New = 115g

TESTING

I will be using rolls of tape of various weights and large popsicle sticks at 8g each. To keep this from being too large of a post, all weights were verified off camera on a digital scale.

TEST 1 - Failure test on width cut

I cut 4 inch strips out of the width of the foam. So 4x20. The new foam feels more bendy in my hands. Due to the grain of the foam (for both sheets) a strip cut out of the width of the foam will be weaker than one cut from the length, I'm not sure by how much, but we'll see.

How does the new foam hold up compared to the old in a failure test?

No load control. Foam sits 4.6cm off the table.

144g load - NEW FOAM

144g load - OLD FOAM

NEW foam deflected 1cm and the OLD .9cm.

200g load - NEW FOAM

200g load - OLD FOAM

NEW foam deflected 1.5cm and the OLD 1.3cm.

220g load - NEW FOAM

220g load - OLD FOAM

NEW foam deflected 1.55 and the OLD 1.4cm.

270g load - NEW FOAM

270g load - OLD FOAM

NEW foam deflected 1.9cm and the OLD 1.65cm.

300g load - NEW FOAM

300g load - OLD FOAM

New foam deflected 2.05cm and the OLD 1.8cm.

460g load - NEW FOAM

460g load - OLD FOAM

The NEW board produced a bent board that deflected all the way to the table without immediate failure. By the time I was able to grab a picture it had failed completely. With the NEW foam failed I will continue to find the OLD foams failure point.

508g load - OLD FOAM

OLD foam held 500g and then failed at 508g.

TEST 2 - Failure test on length cut

I am now going to do the same test but from the length of the board, I'll start at 400g. No load control is 4.6cm as before.

400g load - NEW FOAM

400g load - OLD FOAM

Similar results but as you can see length cut is WAY stronger than width. I always keep this in mind for my builds, wings, stabs and fuse should ALWAYS run length wise.

600g load - NEW FOAM

600g load - OLD FOAM

Again, similar results. The NEW foam is holding up better with the length cut.

800g load - NEW FOAM

NEW held at 792g and then failed at 800g.

822g load - OLD FOAM

OLD held at 814g and then failed at 822g

TEST 3 - Paper removal

Grabbing the corner and peeling back produced the same results on one side of the NEW board. It looks like one side of the NEW board has better adhesion though. This was consistent with 5 other boards I bought from the same batch.

To my understanding Adams doesn't use an adhesive on these boards. The paper is rolled/pressed onto the foam while it's still hot. Because of this lack of adhesive, Adams board suffers greatly from moisture exposure. Will this be the same for the NEW board?

TEST 4 - Water

I left the foam pieces in water for 10 minutes. Then I took them out and let them dry for 30 minutes.

The paper nearly fell off both NEW and OLD foam. It looks like there is no change here in the bonding method.

Let me know what other tests you guys would like to see!

flyinggreek

Member

Thank you for the tests. Pretty interesting. I wonder how much stronger it would be if the paper was bonded?

Thank you for the tests. Pretty interesting. I wonder how much stronger it would be if the paper was bonded?

That's how Elmers board is, the kind standard 'paper board' in the UK and AUS. I haven't tested it before but Elmers is about twice as strong and twice the weight.

ROSS board is similar in weight to Adams and they use a glue adhesive but their foam cells are weaker. I'll have to test that.

@Balu I sent them a mail this morning, I do not know why I have not think of that before...

All sheets low look something like that.

View attachment 79011

But I have not seen that in first two sheets...

Is it possible that I am storing it the wrong way? I have it flat down in dry room at 18°C. Should I put box with short side up?

I have a whole new box that looks just like this. Sad. I wish they were not wavy.

Waywiness does not bother me, but that twistiness does. I tried to do ft nutball an ft flyer and both were warped so much that I could not fly them it straight (rolling automatically). Trimming did not help because they do not have ailerons. Worst thing that this twisted foam does is that it returns to this twisted state, so fuselage is the most problematic part of the plane. More complex wings handle warpage better.

Any tip for getting them straight?

Any tip for getting them straight?

Similar threads

- Replies

- 26

- Views

- 2K

- Replies

- 3

- Views

- 630

- Replies

- 0

- Views

- 581