It seemed like it took a lot longer, but just over a week later Mike's Slick is done. Well, he needs to program it with his new Spektrum I12 (?) transmitter and I'm waiting for a new black spinner to arrive, but MY work is complete!

As mentioned previously, it's a pretty decent kit although the instructions are the weak-link. Mike installed the elevator servos in the tail where a rudder servo would normally go, but I was able to move them forward of the horizontal stab and cover the holes in the covering nicely. You can also see a couple green lights near the nose. The top one is the ignition light - on is a live ignition and off is ignition killed, all from the transmitter. Nice and visible, important when trying to start a gas engine...!

Under that is a bigger green light, which is actually a light around the power flag/pin. Pull the flag/pin off the plane and the electronics go live (except for the ignition if that is turned off at the transmitter).

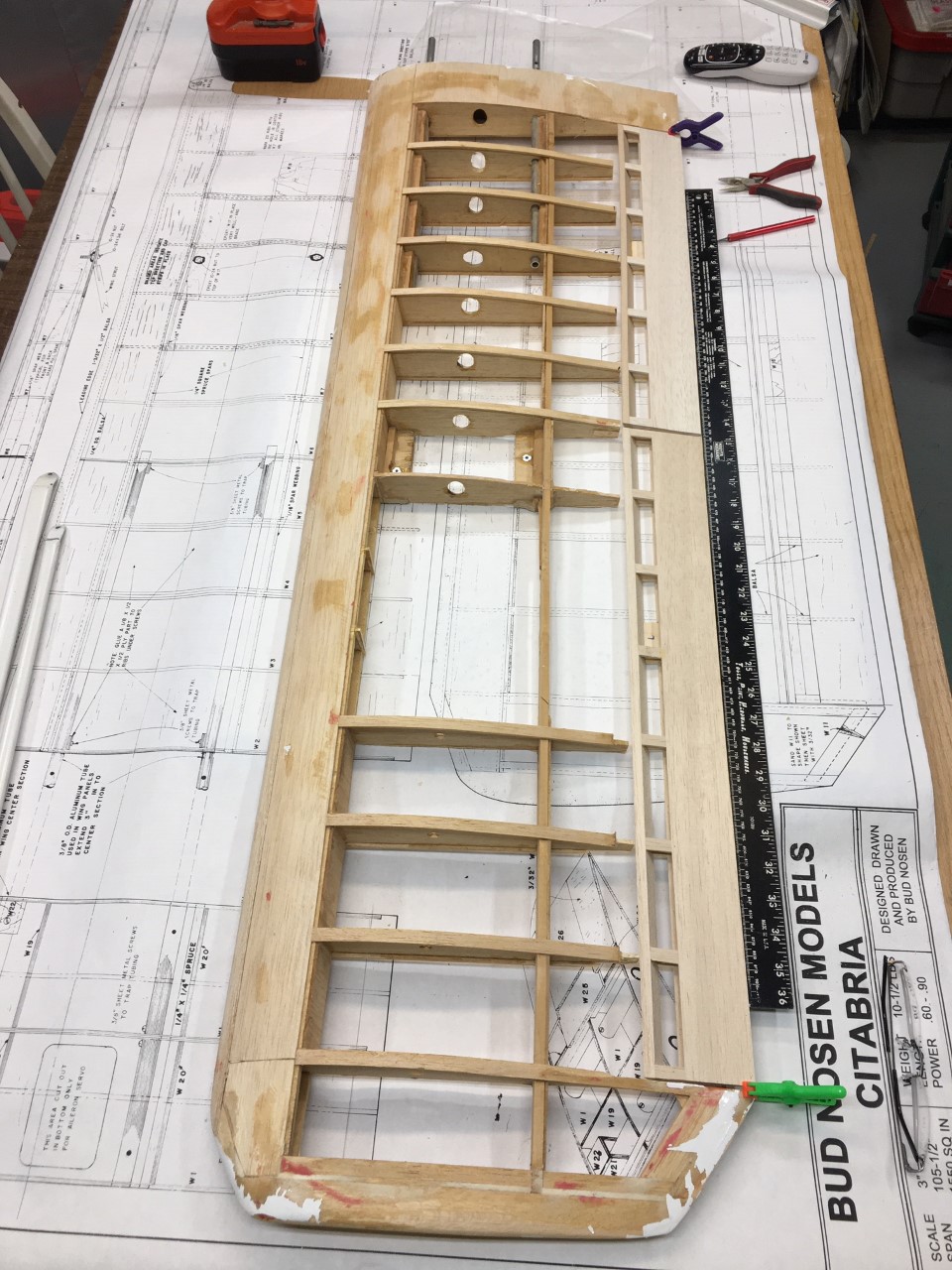

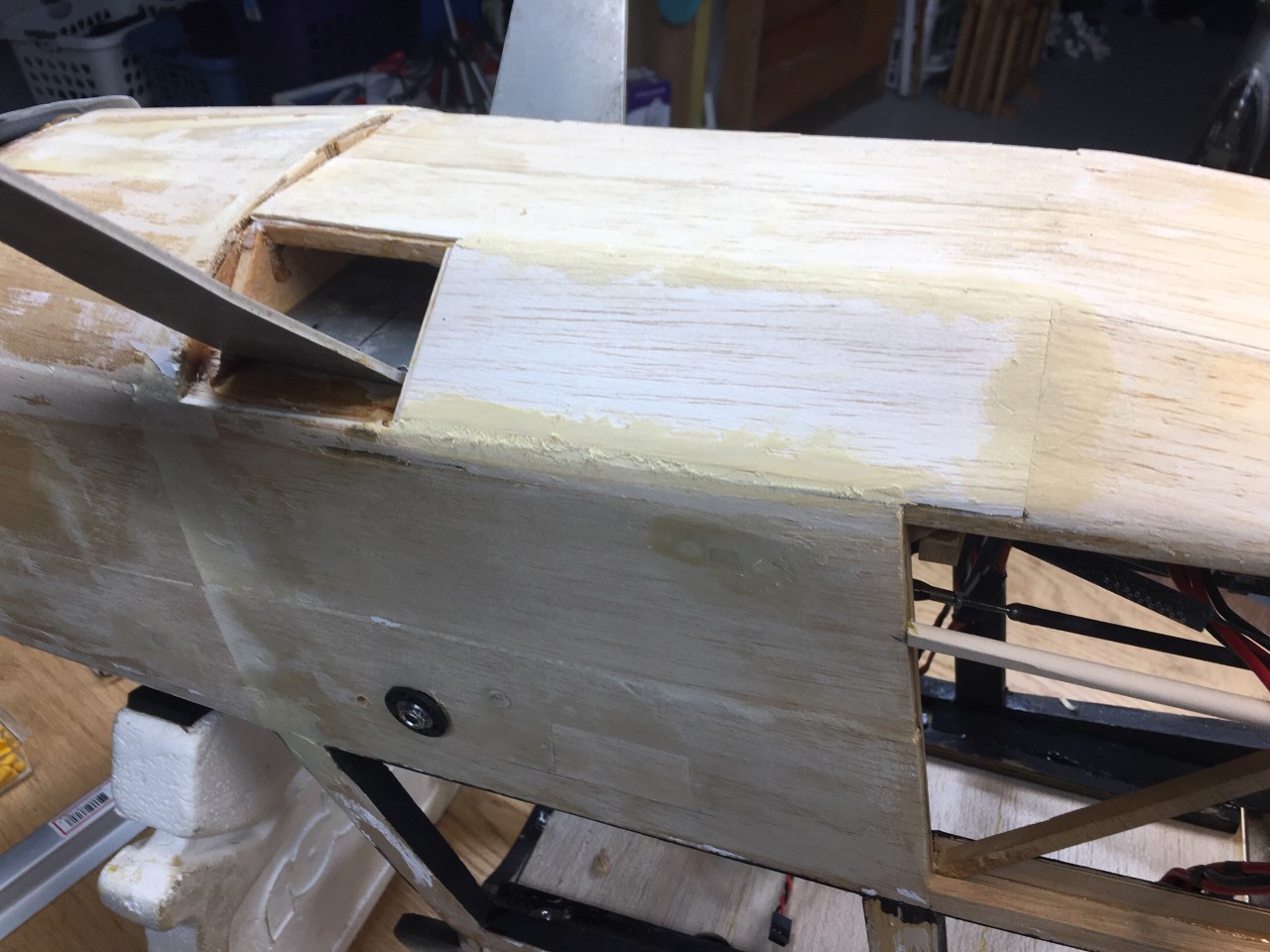

The ignition kill switch and power switch used in Mike's plane are the same as I've started installing in my Rascal 110. I like them enough so far that I'm also going to install them in the Citabria, so here it all is laid out to show how it all goes together. Two batteries plug in to the "Dualsky VR Pro Duo" regulator on the right. These feed into a voltage regulator (5v, 6v, or 7v) which also has a kill switch for the entire system (red flag/pin to the right). Pull the pin and the entire system goes live. Both batteries work together to power all electronics, but if one battery dies, the other takes over to power it all. The green light by the flag/pin starts flashing to notify you of a battery problem. Lights on the regulator also tell you if the battery is good, getting low, or low (green, yellow, and red lights). Notice my receiver is plugged into the regulator for channels 1-4, and that there are 4 spots on the regulator marked for servos. On a simple 4-channel plane all servos will be powered by the regulator instead of getting power through the receiver. In theory this should help avoid issues from powering 8+ standard servos through the receiver. Not sure how big of an issue that really is, but it sounds legit!

So that takes care of the throttle, ailerons (on a Y-harness), elevators, and rudder, but what about flaps, landing gear, or other servos? The easy answer is I'll just run the remainder through the receiver. In my case it'll just be two flap servos and one of the elevator servos plus the ignition kill module shown to the left, so power draw through the receiver will be fairly low.

Confusing? Yeah, it took me a while to get it all sorted out in my head, but after setting it up on a couple planes so far I'm liking it more and more. I'd like it more if it handled 6 or 8 channels, but can live with 4.