Mad_Mechanic

Well-known member

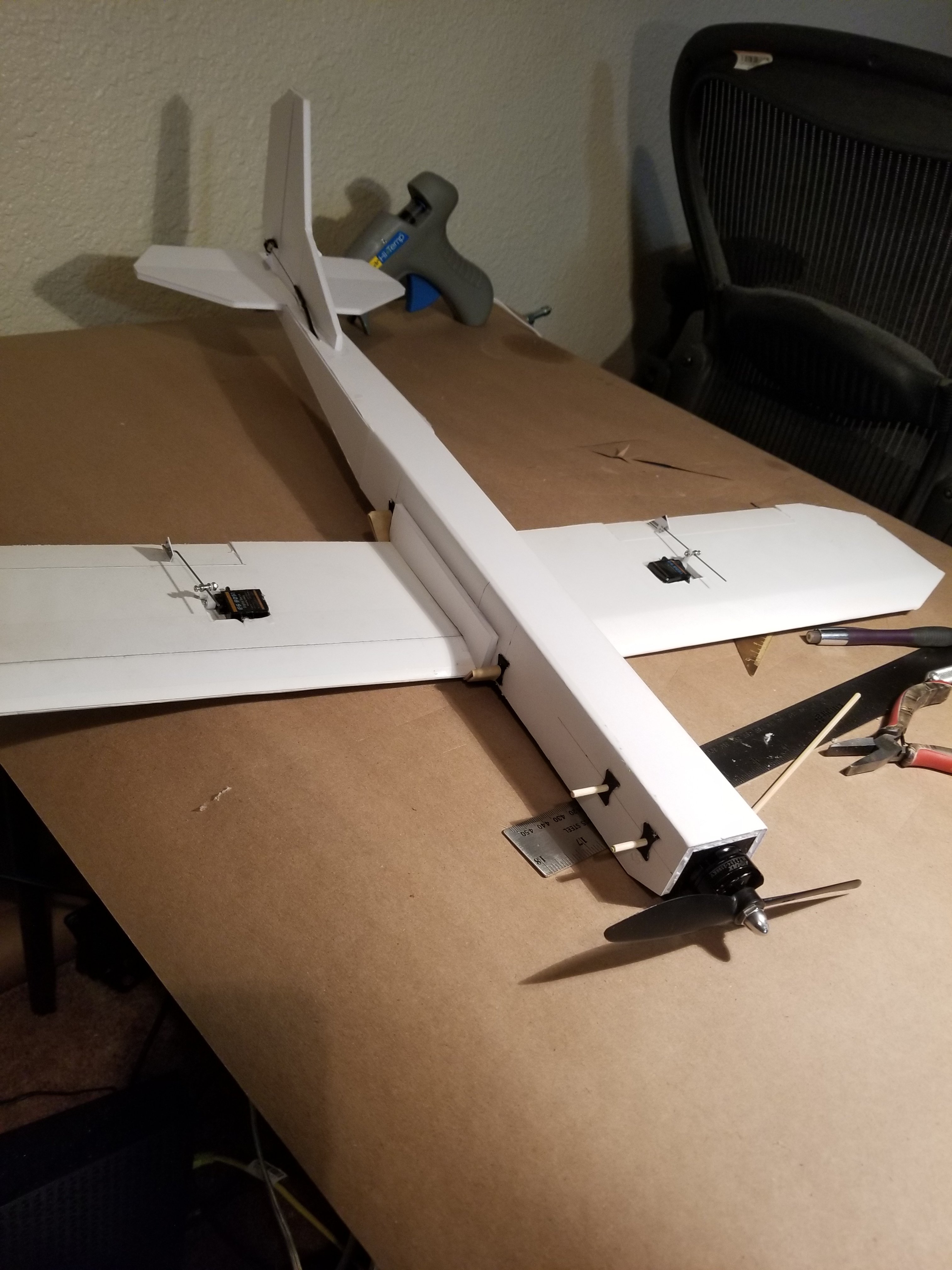

Yes, you read the title correctly. I'm sure this has been done, but I wanted to challenge myself to design a plane that only needs 1 sheet of dollar tree/store foam board to make the airframe, thus making the airframe 1$.

I created a list of design constraints:

> Bottom Wing

> 3 or 4 channel

> No flying wing design (I know FliteTest already has a flying wing from 1 sheet)

> All structural components must be included in the 1 sheet, no using scraps from another left over board!

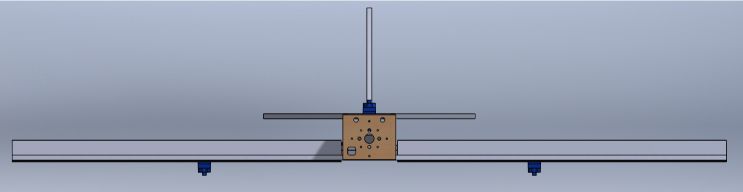

> Utilize an FT Firewall

> DO NOT use an FT swappable power pod as this would add foamboard and weight.

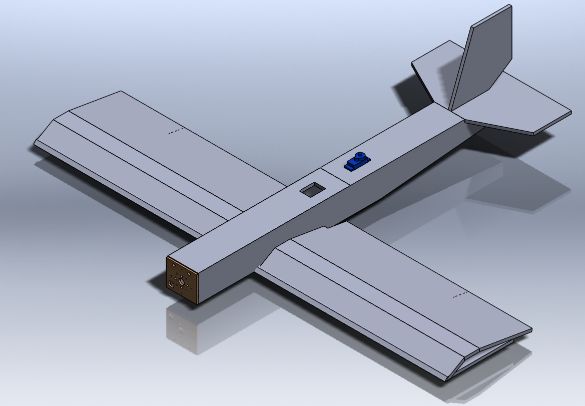

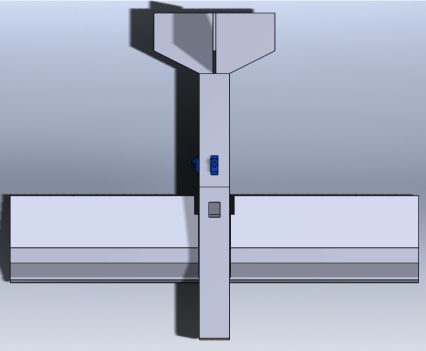

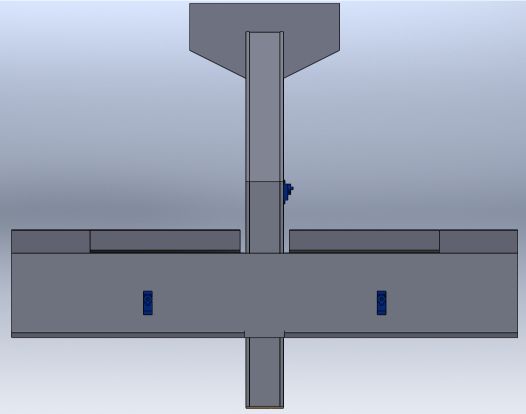

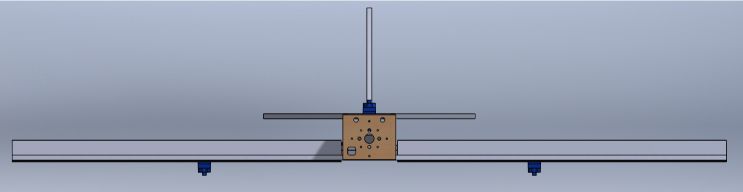

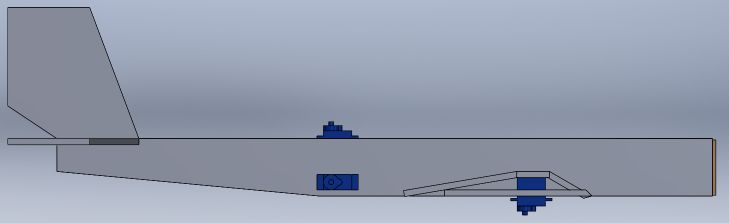

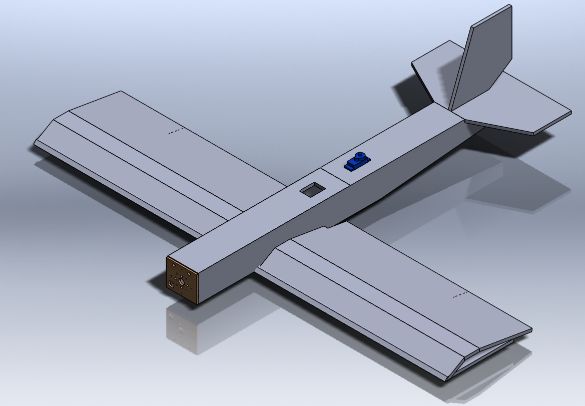

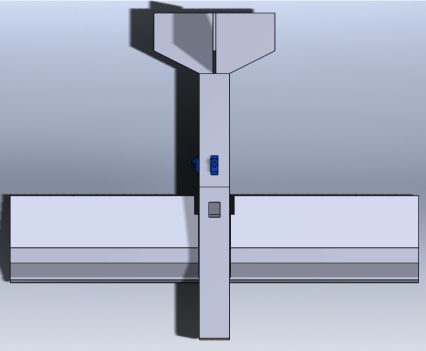

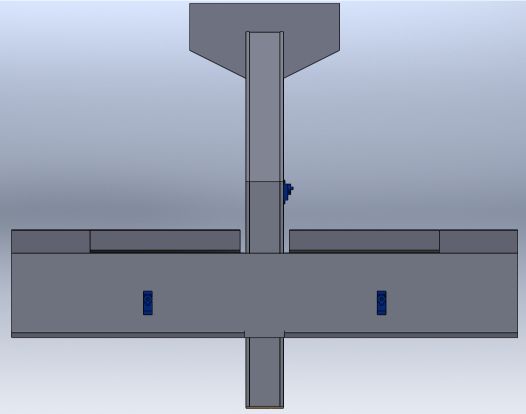

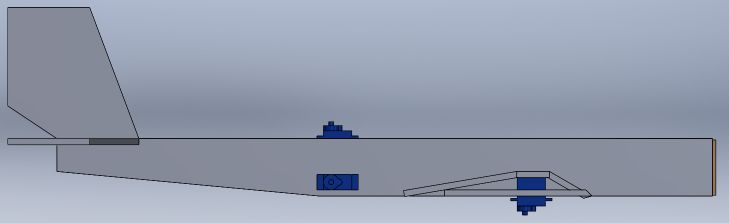

Here is what I've designed thus far:

Wingspan: 27 in

Elevator width: 8 in

Rudder Height: 4in

Overall length (no motor): 21.6in

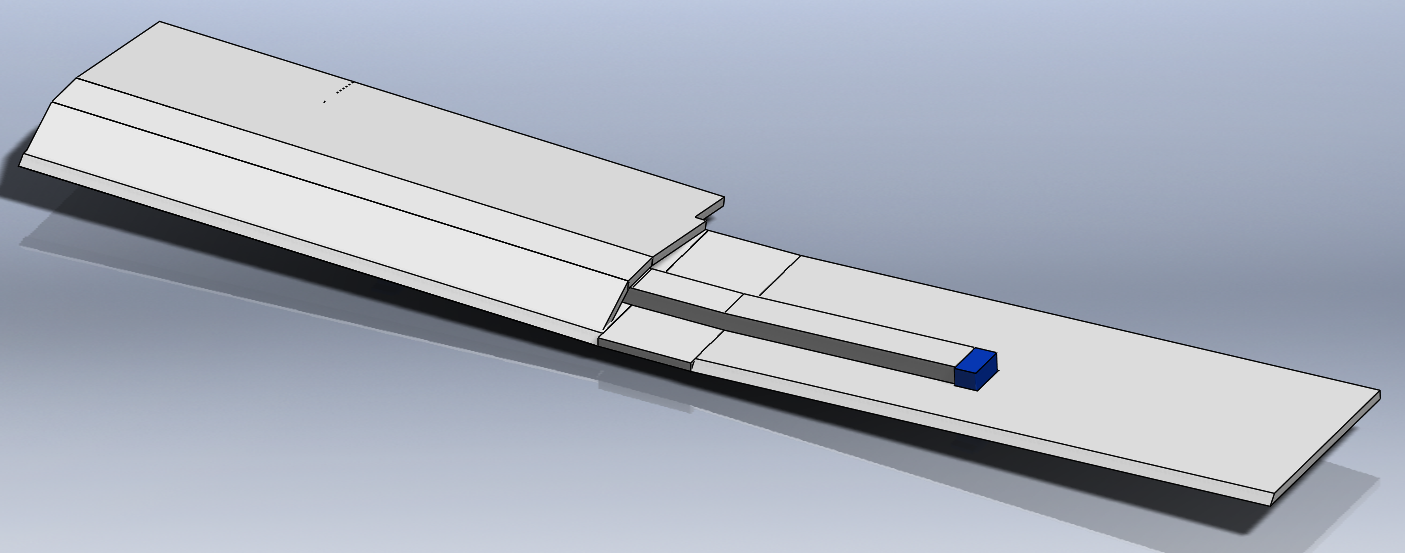

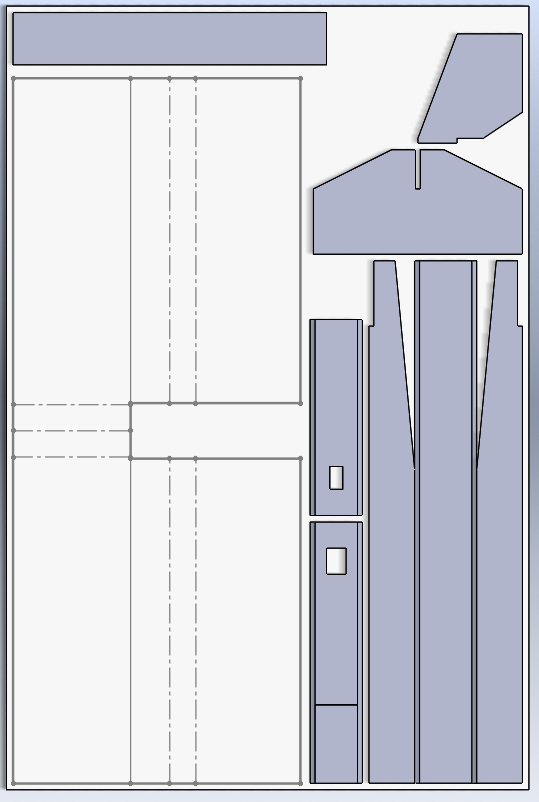

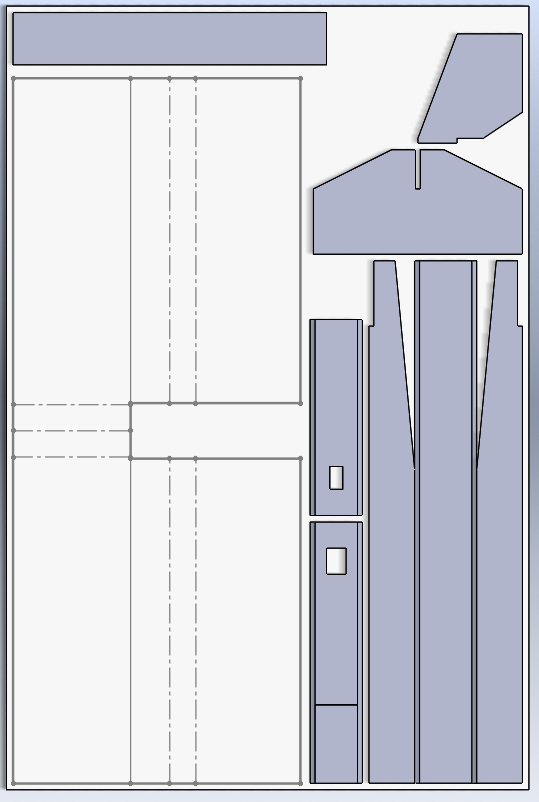

Here is the board layout thus far:

My concerns at this time are the tail surfaces, I fear they might be a bit small.

Thoughts? Concerns? Ideas?

Once I finalize my version 1 design I plan to have this printed at a local staples office supply print center for ~$3 (they can print up to a 24"x36" sheet of paper).

I currently do not have an motor, propeller or battery spec'd, any thoughts on those? Perhaps a 6in prop?

I created a list of design constraints:

> Bottom Wing

> 3 or 4 channel

> No flying wing design (I know FliteTest already has a flying wing from 1 sheet)

> All structural components must be included in the 1 sheet, no using scraps from another left over board!

> Utilize an FT Firewall

> DO NOT use an FT swappable power pod as this would add foamboard and weight.

Here is what I've designed thus far:

Wingspan: 27 in

Elevator width: 8 in

Rudder Height: 4in

Overall length (no motor): 21.6in

Here is the board layout thus far:

My concerns at this time are the tail surfaces, I fear they might be a bit small.

Thoughts? Concerns? Ideas?

Once I finalize my version 1 design I plan to have this printed at a local staples office supply print center for ~$3 (they can print up to a 24"x36" sheet of paper).

I currently do not have an motor, propeller or battery spec'd, any thoughts on those? Perhaps a 6in prop?