Bought one of those little Dart planes from RMRC at Flite Fest Ohio, it's a mini Cuda clone type plane. Flew great for being small, so I thought I'd make it 3D printable and a bit bigger to account for the weight of 3D printed parts.

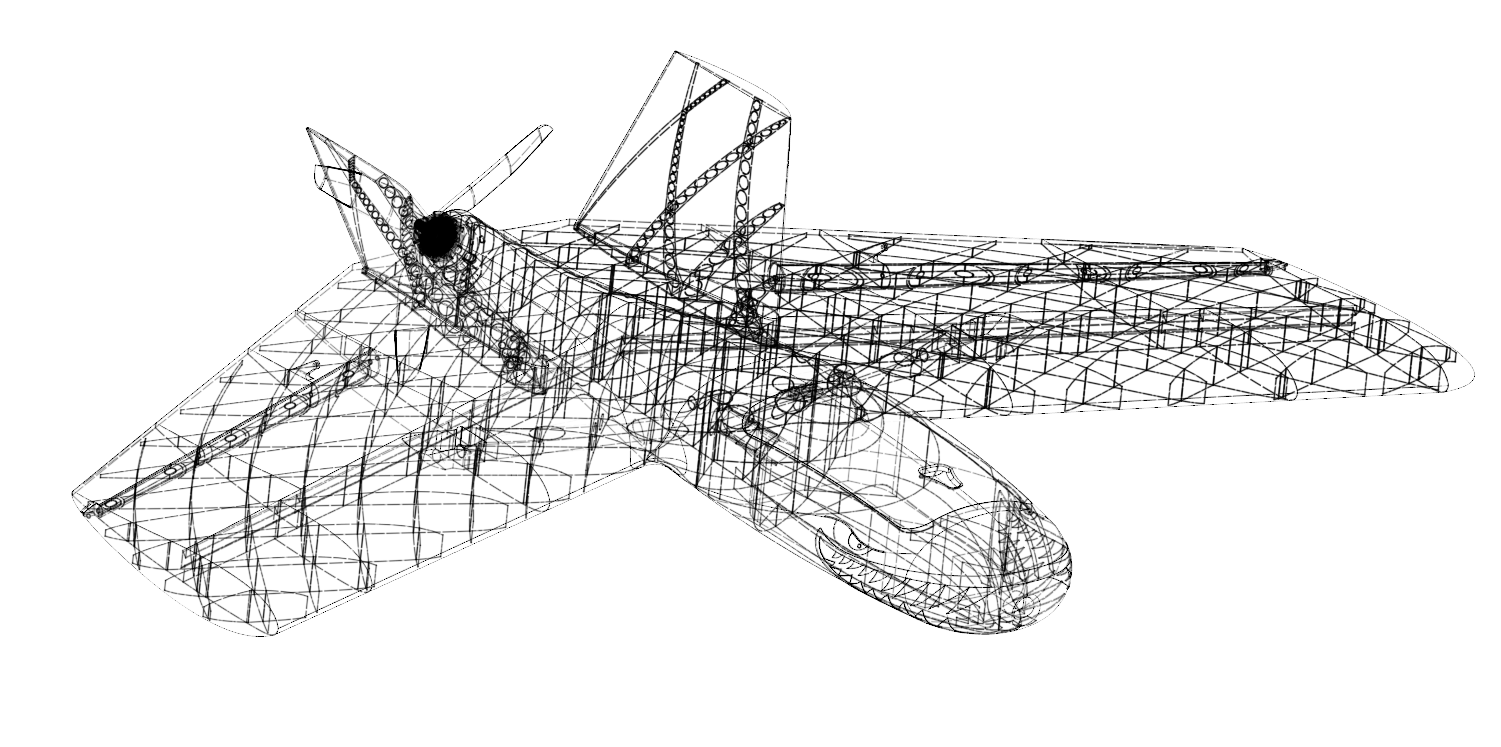

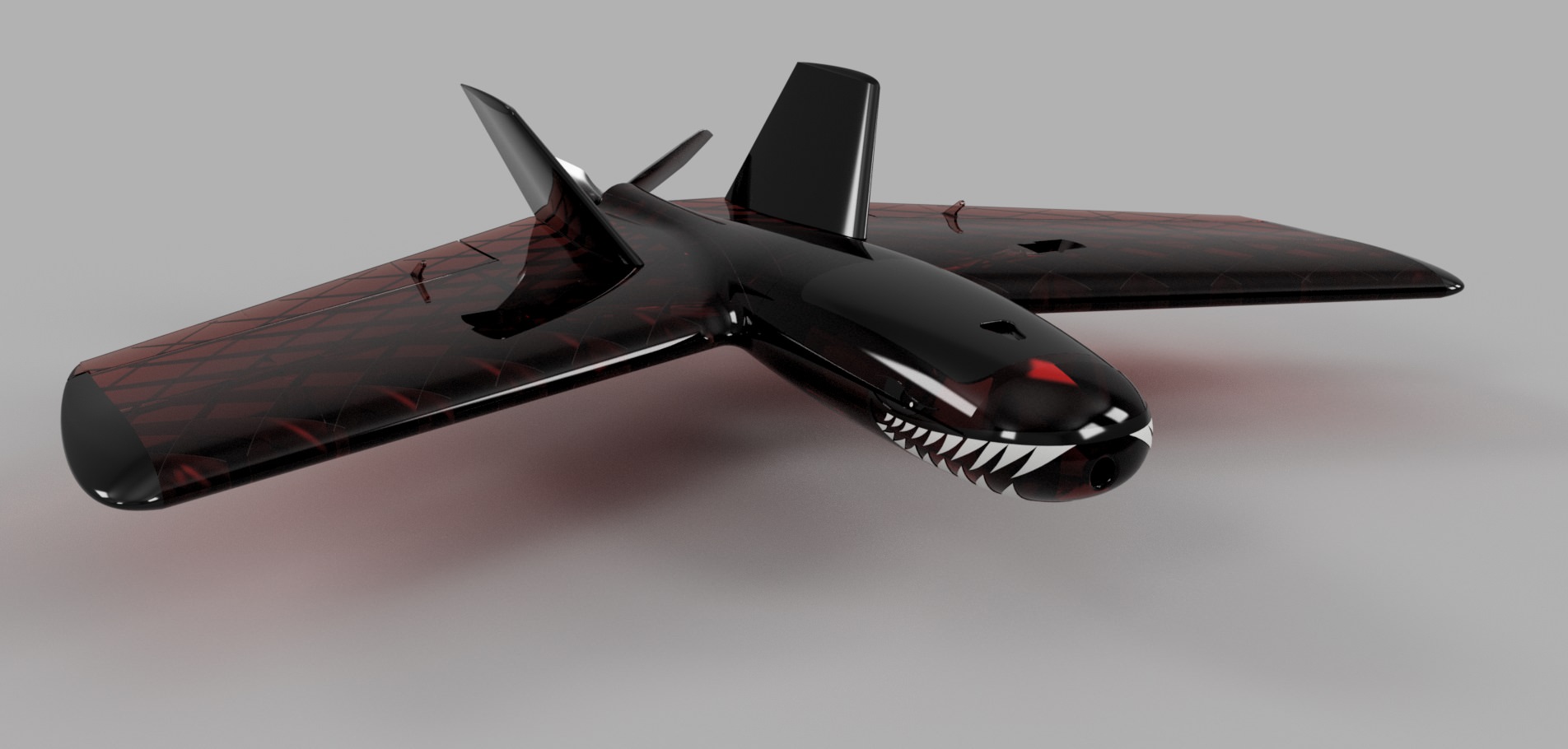

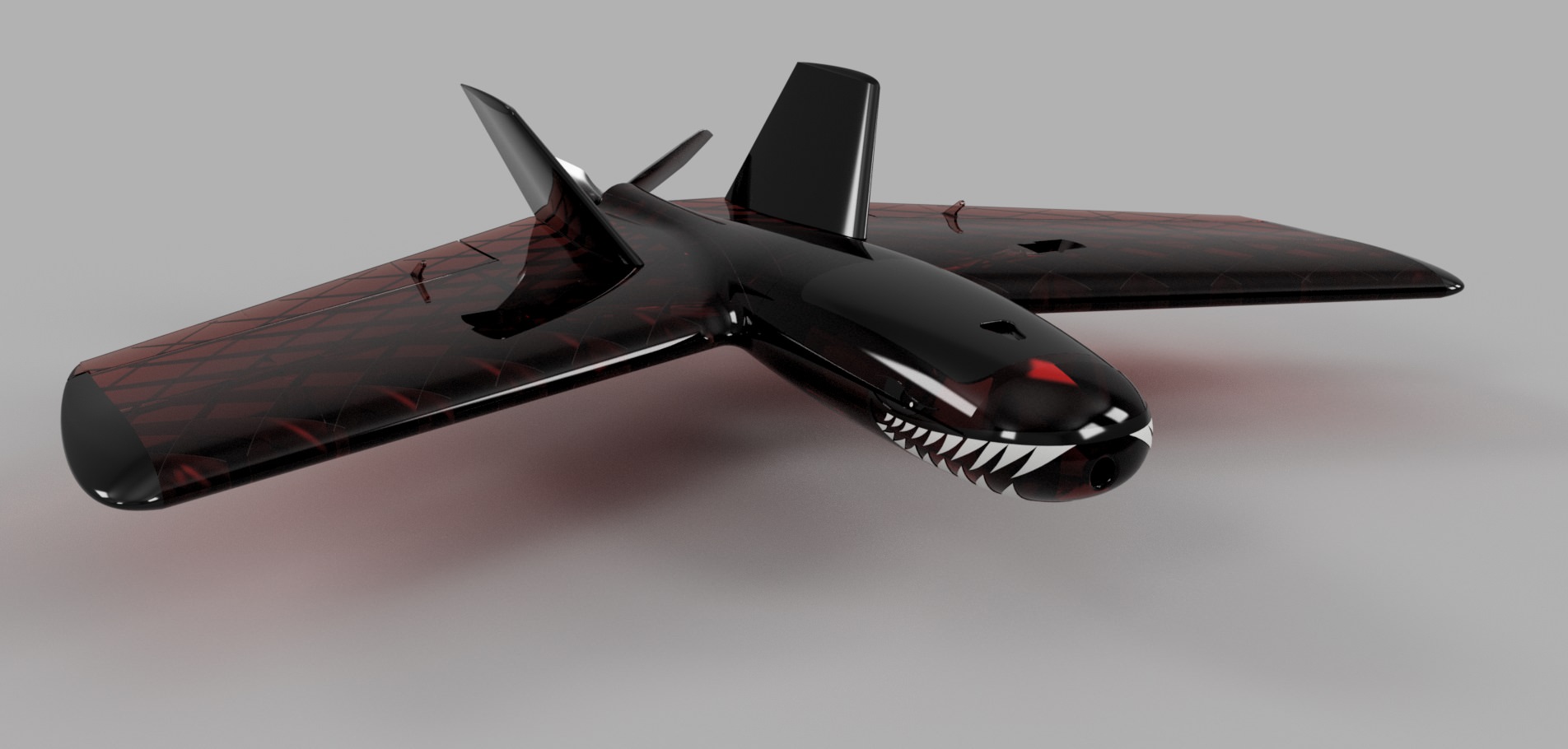

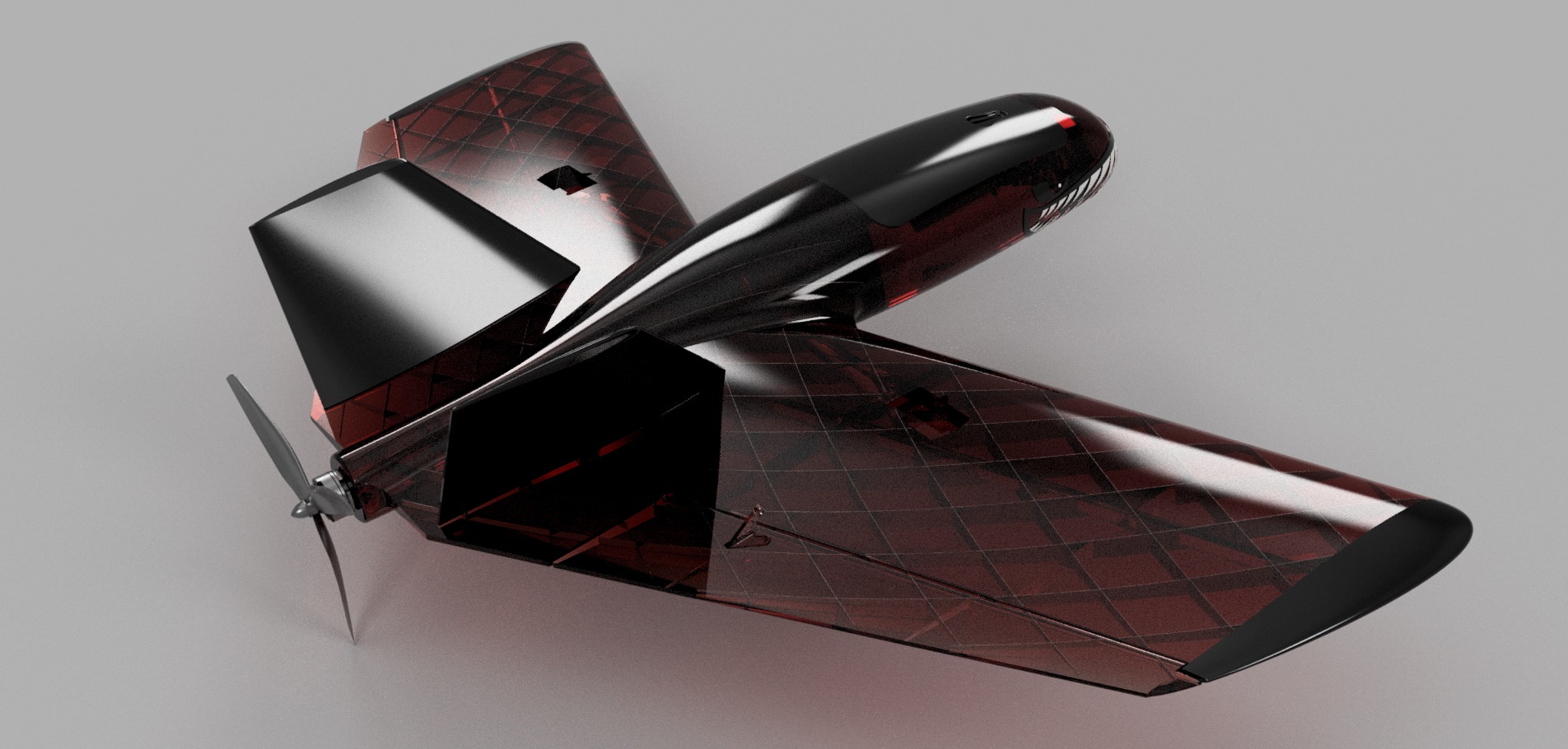

Started drawing stuff up yesterday and here's what I've got.

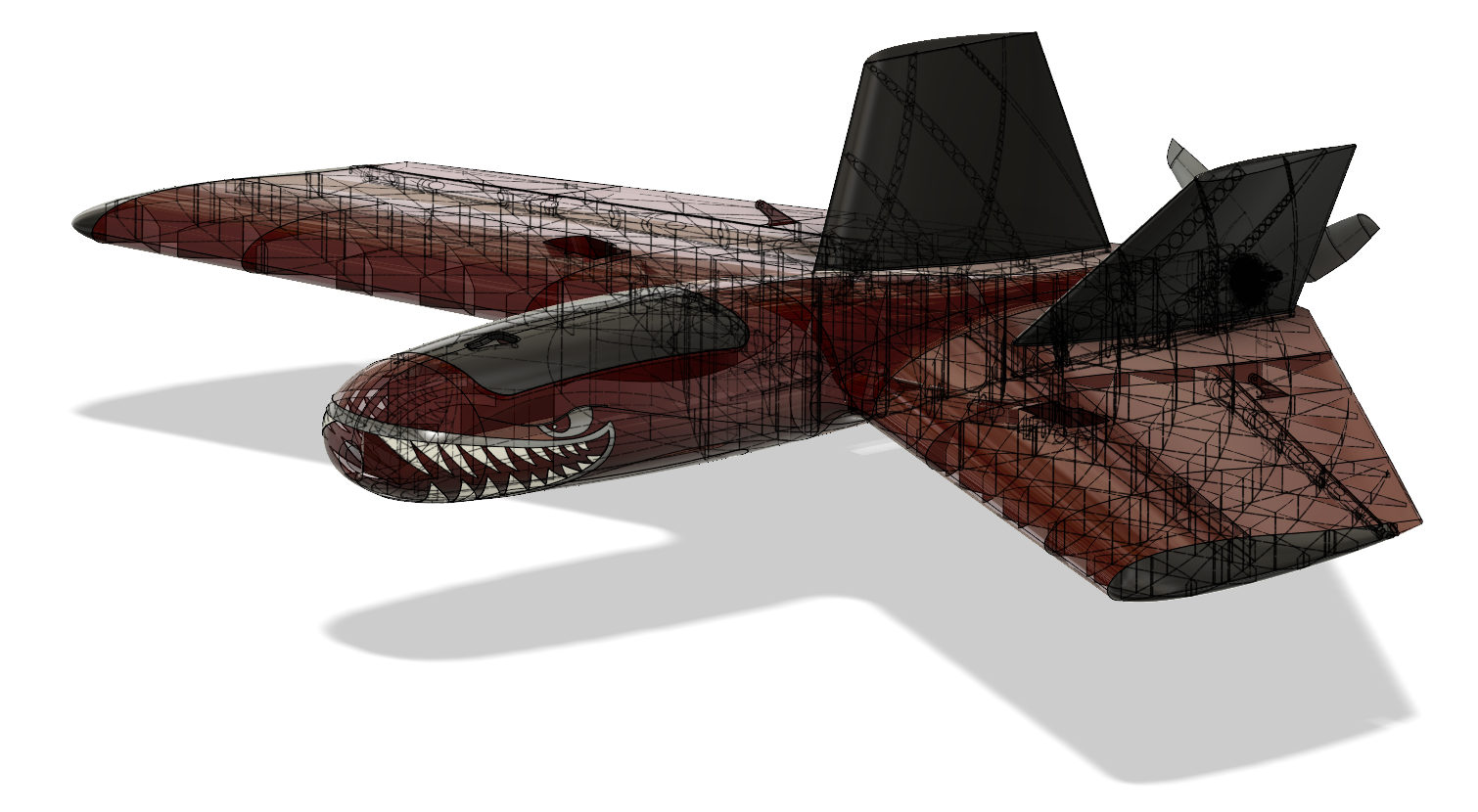

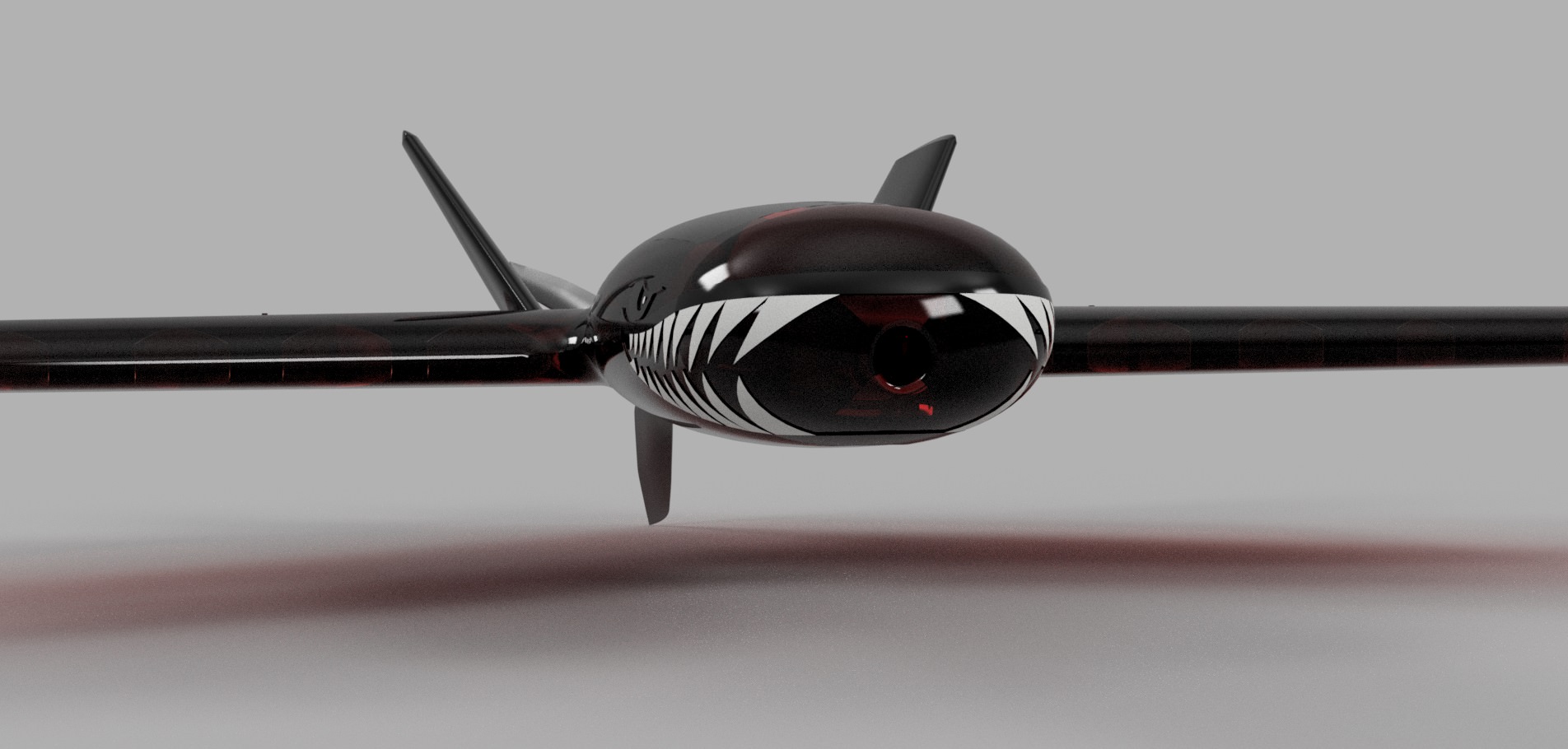

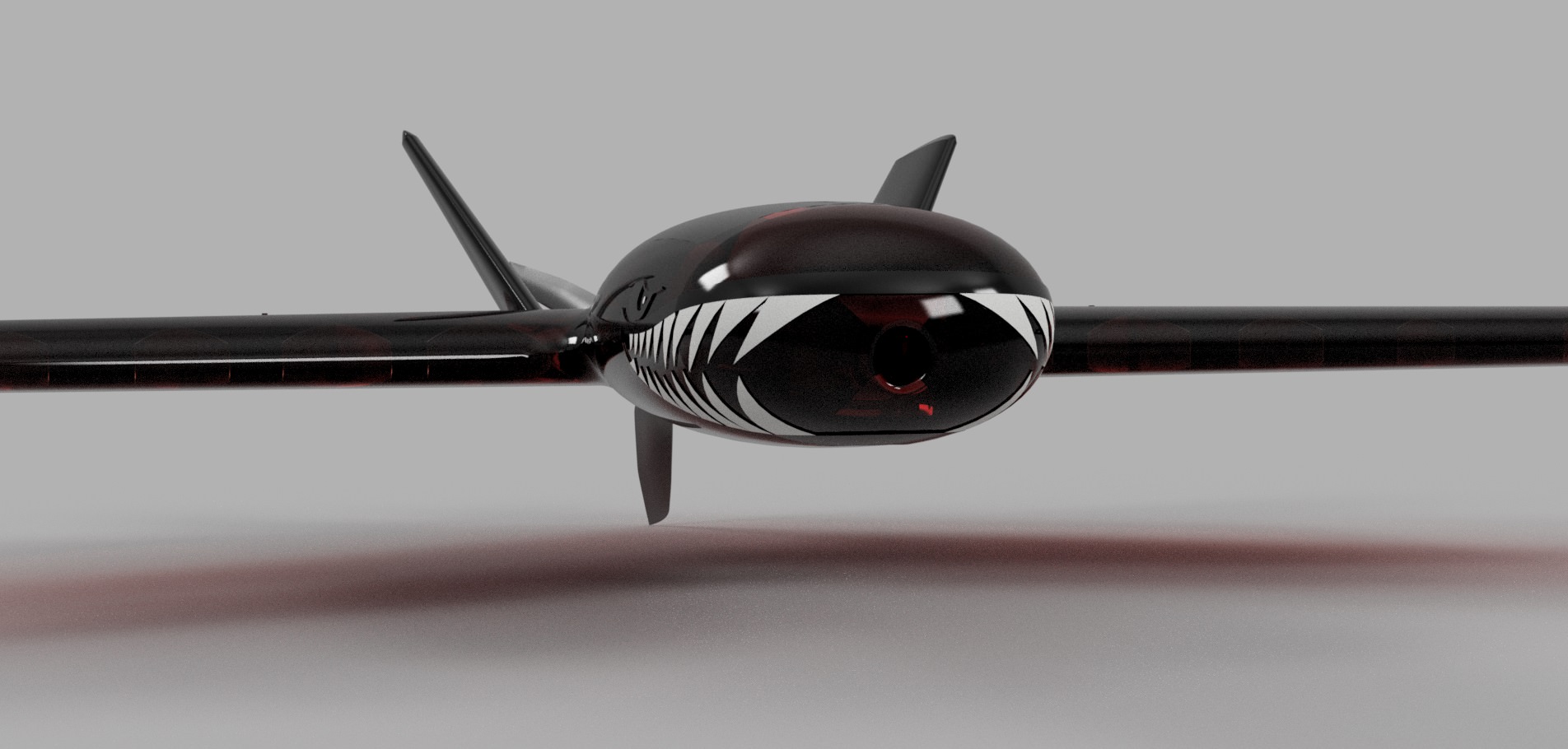

The eyes, mouth, and teeth are all part of the model, and will show up when printing. Should make it very easy to paint, or add some tape or something.

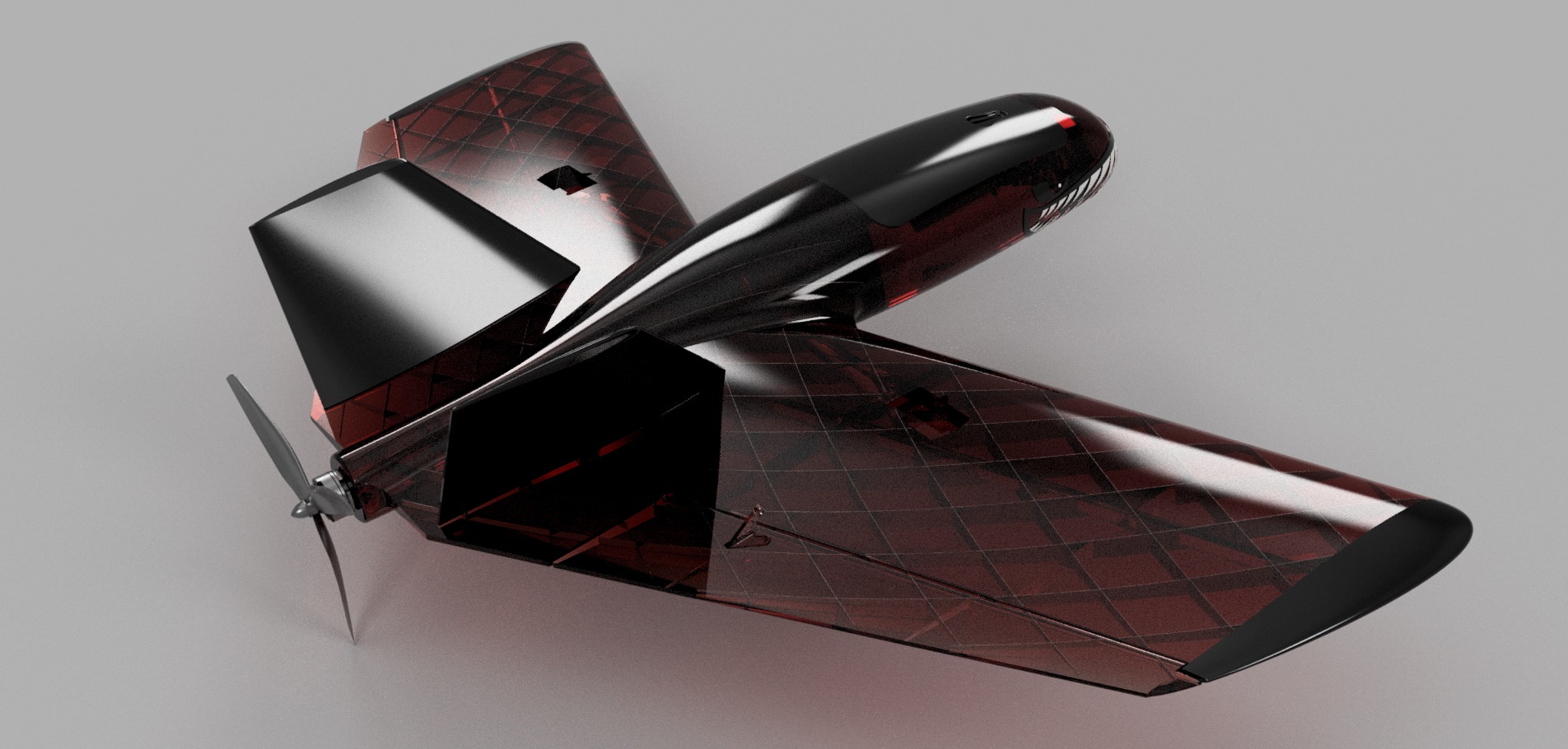

We'll have to see where final weights line up, but I'm hoping to run an F to B pack sized motor on either 3 or 4 s. The nose has been lengthened a good bit from standard cuda configurations to try and make balancing easier. I think a couple 1300mah batts side by side up in the nose will do the job. If not, there's provisions for an FPV camera to add a bit more nose weight. Worst comes to worst, I can always make the nose a bit longer.

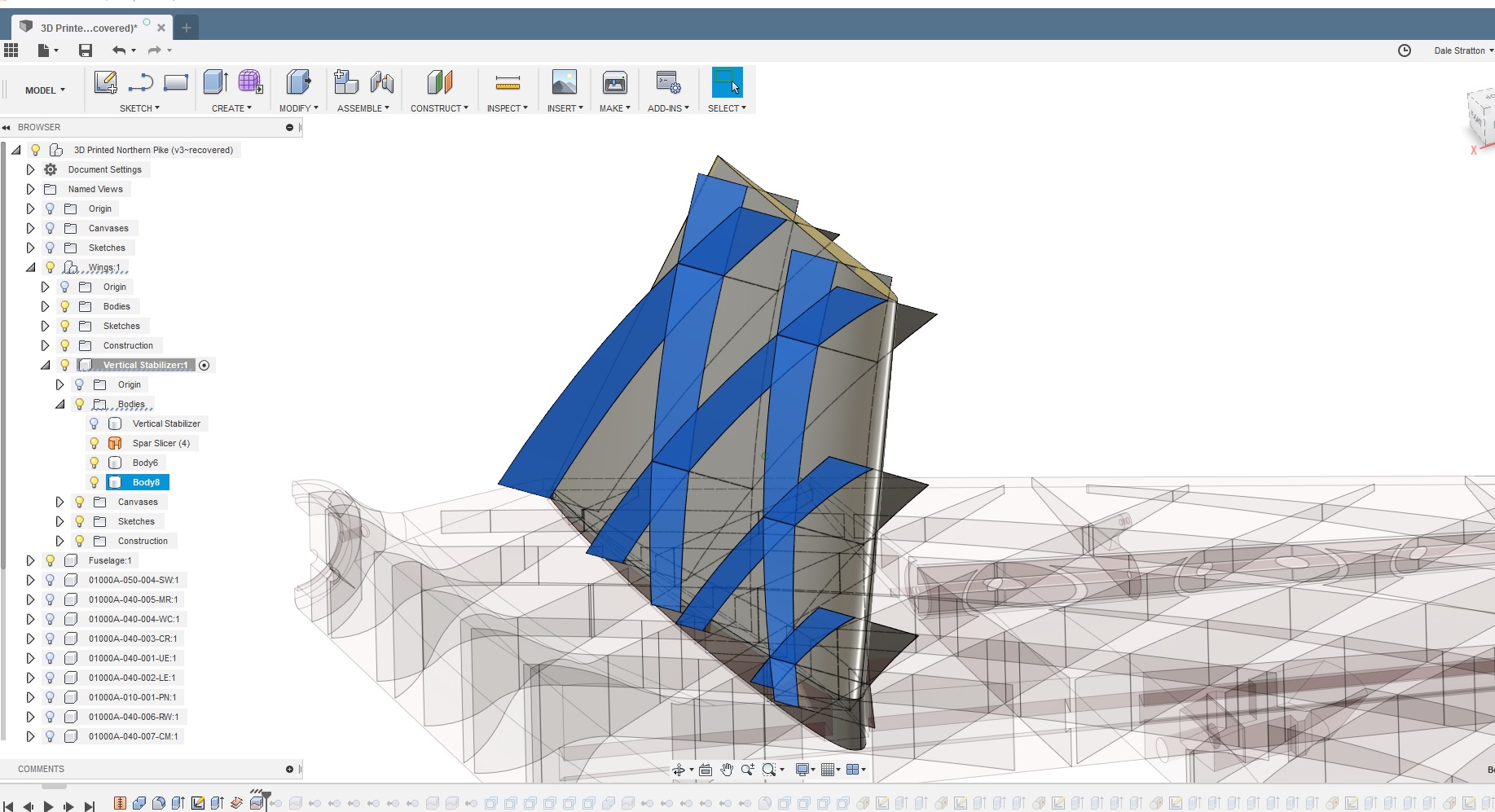

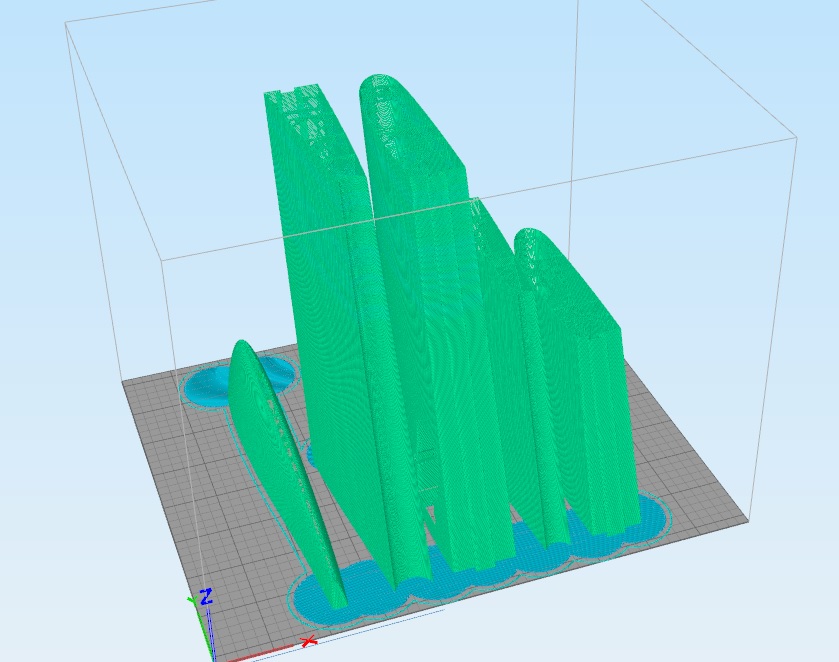

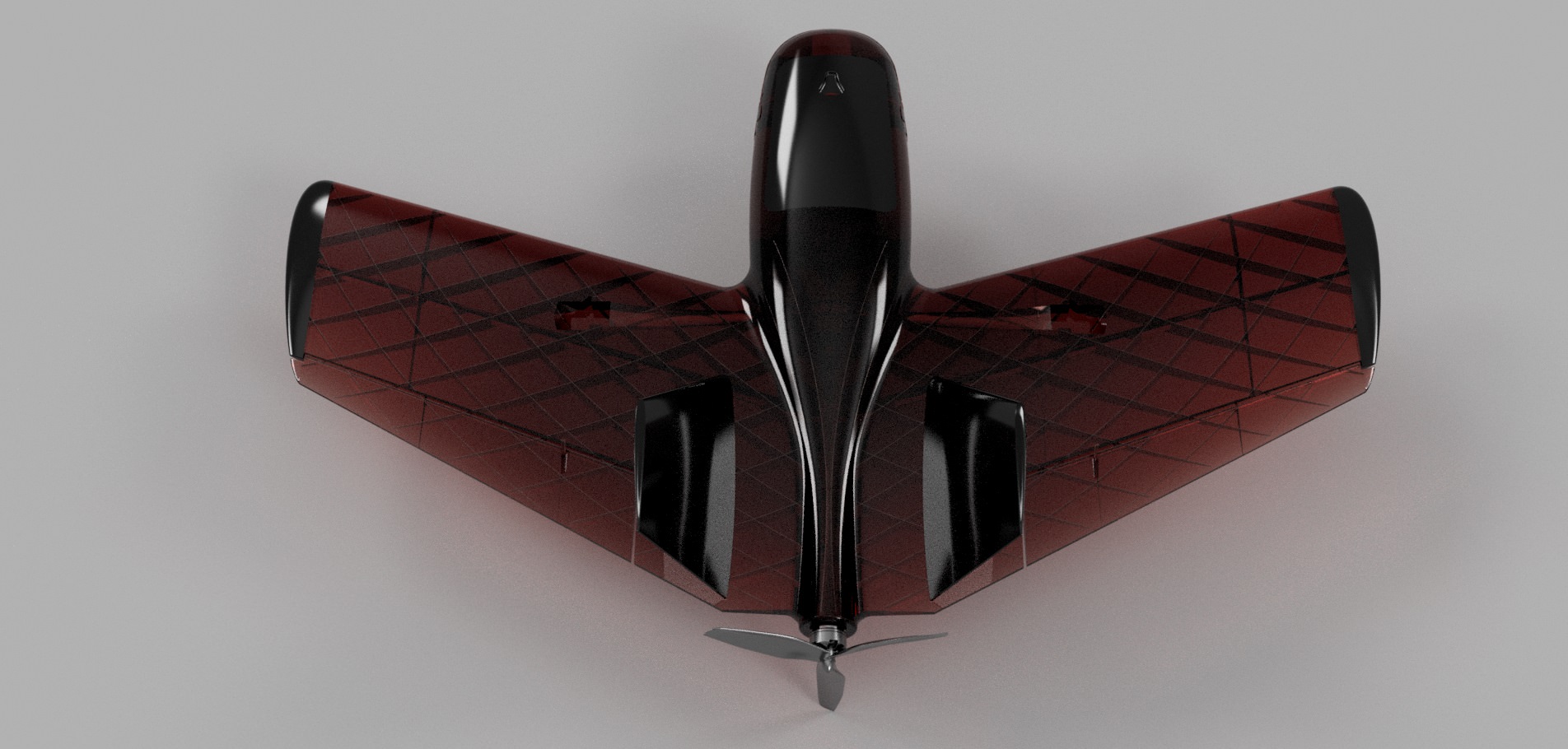

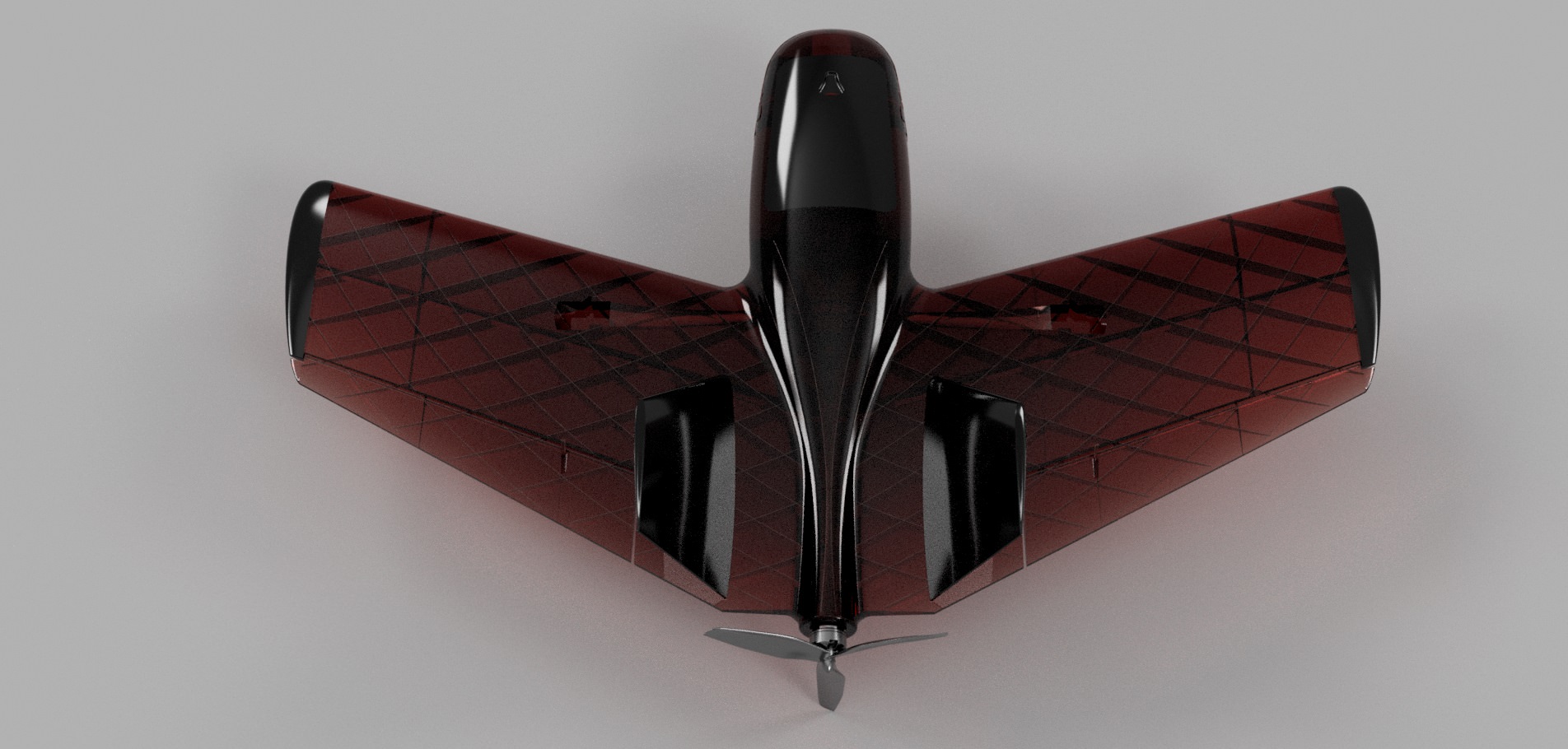

The majority of the fiddly bits on the model are done, but I am going to have to set aside something like 5-6 hours to complete the lightening holes in the spars. Hole cutting aside, it's amazing how much easier it is to draw up a simple plane like this compared to a scale aircraft. I'll also be trying out a new cad technique here to try and make the file manageable and not bog down my PC. I'm doing everything possible to get it ready for printing before cutting spar holes. Once all the groundwork is done, I can make each printable section it's own component, and then cut holes. That should hopefully make my life easier from a processor bottleneck standpoint.

************************************************************************************

ETA: Latest Flight is the Maiden of the PETG version.

ETA: It Flies!!

I've posted the files over on Thingiverse for the 36" version. They're free, but if you want to donate something via paypal or tip me on thingiverse I won't say no.

https://www.thingiverse.com/thing:3040294

Started drawing stuff up yesterday and here's what I've got.

The eyes, mouth, and teeth are all part of the model, and will show up when printing. Should make it very easy to paint, or add some tape or something.

We'll have to see where final weights line up, but I'm hoping to run an F to B pack sized motor on either 3 or 4 s. The nose has been lengthened a good bit from standard cuda configurations to try and make balancing easier. I think a couple 1300mah batts side by side up in the nose will do the job. If not, there's provisions for an FPV camera to add a bit more nose weight. Worst comes to worst, I can always make the nose a bit longer.

The majority of the fiddly bits on the model are done, but I am going to have to set aside something like 5-6 hours to complete the lightening holes in the spars. Hole cutting aside, it's amazing how much easier it is to draw up a simple plane like this compared to a scale aircraft. I'll also be trying out a new cad technique here to try and make the file manageable and not bog down my PC. I'm doing everything possible to get it ready for printing before cutting spar holes. Once all the groundwork is done, I can make each printable section it's own component, and then cut holes. That should hopefully make my life easier from a processor bottleneck standpoint.

************************************************************************************

ETA: Latest Flight is the Maiden of the PETG version.

ETA: It Flies!!

I've posted the files over on Thingiverse for the 36" version. They're free, but if you want to donate something via paypal or tip me on thingiverse I won't say no.

https://www.thingiverse.com/thing:3040294

Last edited: