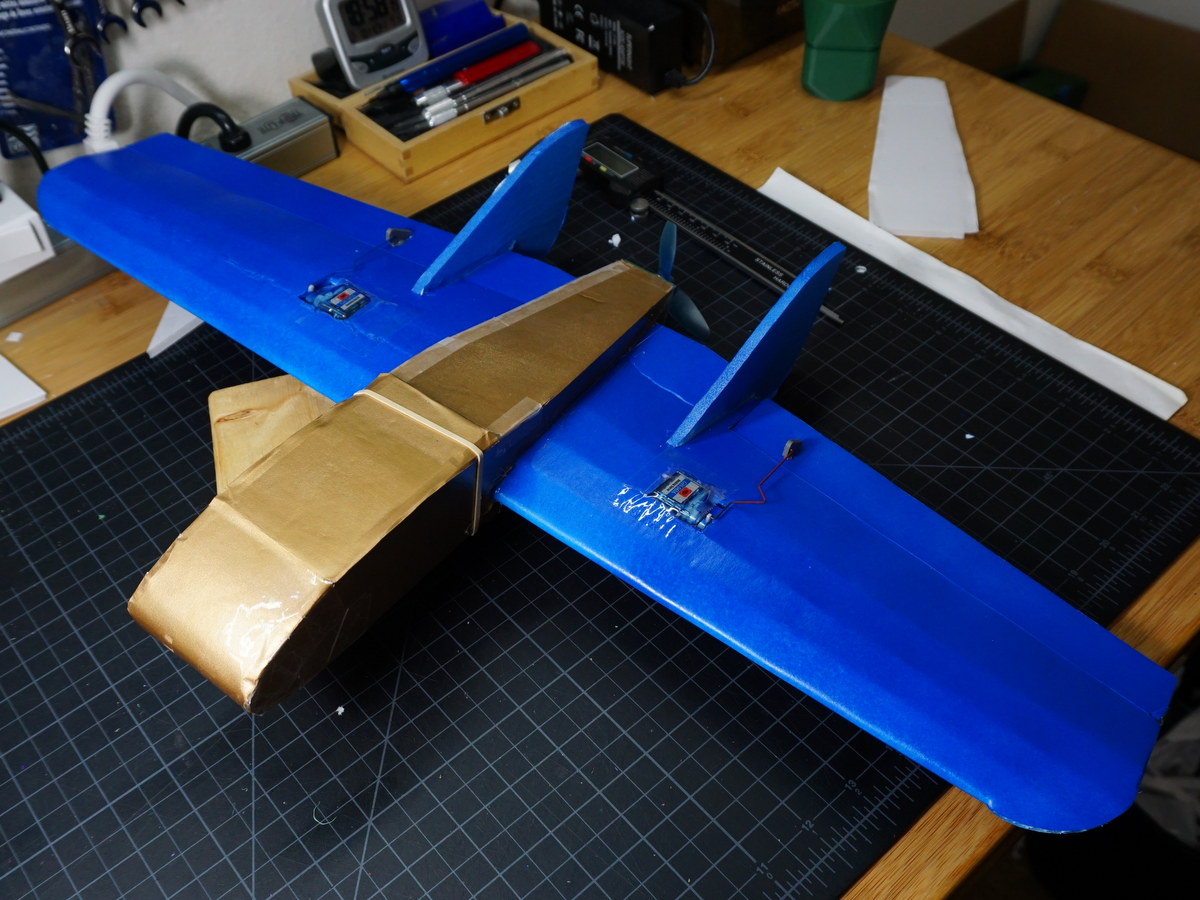

I did make another one, with an even lower effort paint job!

I made a few changes to the design.

ABS Fuselage Doubler - For one, I used 3D printed ABS doublers. They're 3mm thick and under 6g for the two of them. I removed the paper from the nose sides to compensate and used white gorilla glue to attach them so there's ~2g of difference in weight but a lot more strength. Now on a nose-crash, the energy is transferred back to the wing. I haven't had any really bad nose-ins yet to fully test it but it feels a lot stiffer. I did some snap tests on the bench and the weak point now is where the nose bit transitions to the long thin section, which could be reinforced in the 3D model.

Wingspan

Wingspan - I also extended the wingspan by 0.5" on each side, so 1" total addition, which adds 5% more effective wing area. I would have liked to have gone a full inch on each side, but the servo wires on my tiny 4.3g servos juuuust barely reach now and I didn't want to make new cables just go go a tiny bit further.

Reduced Vertical Stabilizers - Size reduced to 90% (just freehand cut 10% off the back and top). It still gets blown off the wind in a gust so I might reduce these to 80% size, but it has been so windy here that I'm waiting for more of a calm day to test before I say for sure.

Tail Taper - The motor end of the fuselage I reduced the width by 5mm to bring it to more of a point. It was like 39mm wide which is insanely too much for holding a 1407 motor and means 51% of the propeller is blocked by the firewall. This gives it a little a little cleaner air to spin in. In addition, because the gap at the back is narrower, there's less flex in the firewall from thrust (not that that is really an issue). I also cut the bottom off the firewall so it is only 26mm tall, again to allow better airflow to the prop. If I make another one of these, I'd reduce the taper further down by about 7mm, which is where the sides start to run into motor wires. I'd try to keep it this size for an 1806 motor.

Baked in Reflex - I cut the area between the fuselage and the vertical stabilizers, scored it, and bent it up so there's some reflex built into the wing itself rather than relying entirely on the eleveons. Having the reflex closer to the center of the craft also reduces roll induced by not having them exactly right, which is harder when the control surfaces are further out. I only raised them 4mm but I still needed a lot of reflex in the elevons so either this needs to be a lot more bent up, or it isn't very effective. (The left one was done first before I thought to score the bottom so it bent a bit weird).

Same setup as before except with a new larger battery.

FlySky FS-iA6 receiver

Cobra 1407 3500KV motor

3x4x3 (5A) or 3x5.2x3 (6.1A) prop

EMAX 12A ESC with 1A BEC

950mAh 2S battery (old was 850mAh)

2x 4.3g eBay servos

187g all up weight

After flying the Simple Cub for the past month, getting back to this tiny plank puts a grin on my face because it is a wholly different flying experience. I swear this thing can do a 180 degree turn in less than a meter of space which provides a lot of confidence that you can get out of virtually any jam as long as your fingers can tell the plane what to do fast enough.