telnar1236

Elite member

I've been toying with the idea of a modular plane for a while. The two big advantages are that it would give a similar versatility to Flite Test Swappables for experimenting with different configurations, and, if a part was broken, you could just replace that part instead of rebuilding large parts of the aircraft. There are also a number of challenges to overcome, with the largest two being weight and the durability of the connections. That said, I think I've built up enough experience with 3D printed planes to make it work. If this system works as I hope it will, I plan to use it for all of my future designs. I've been working on this for quite a while in the background, but didn't want to post a thread about it until I was pretty confident I could make it work.

I have a few goals with this project.

1. Make a modular system able to be used for many different designs

2. Make it easy to print (limited use of supports, normal PLA, fits on an Ender 3 or equivalent)

3. Make it able to be used for prop or 64mm EDF or 70mm EDF

4. Make the propulsion system removable and compatible with foam board power pods (via an adapter)

5. Design it for 3s or 4s to make the batteries more affordable and safer

6. Design a number of planes for the system ranging from a trainer to warbirds to 6 channel + EDFs

7. Design connection hardware that can be printed independent of the rest of the system to allow for experimentation with foam board parts

8. Make flight-tested STLs available on this forum

9. Continue to refine the design based on experience to make it as simple as possible to use

10. Design/build data logging hardware/software that can be installed in multiple configurations

11. Actually take video of each design flying (probably onboard RunCam on the tail)

The design I am currently working with uses circular connection hardware that twists together and locks in place with two screws per joint for the fuselage. For the wings and tail I decided not to reinvent the wheel and am using connections very similar to what you'll see on commercially available RC planes. All of the fuselage sections for the initial tests are cylindrical and fit tightly around the internal components, but I plan on designing additional fuselage shapes in the future. I took some inspiration from the appearance of @Power_Broker 's modular design ( https://forum.flitetest.com/index.php?threads/large-modular-uav-design.69987/ )without really knowing the geometry of the internal structure.

I am now on my fourth set of test hardware and the first that should be flight-capable. My first design was mostly to experiment with fits and connection system geometries. It never even got printed. My initial thought was also to make the wing sections modular to allow for as much versatility as possible, but I couldn't make the aerodynamics work.

My second iteration was meant to experiment with fits for the connection hardware and got partially printed. It took me several hours to get everything to go together right for just two pieces, so it definitely needed some optimization. It was also too heavy.

Version three was the first that would probably have been flight-capable had I finished the design. However, I still wasn't happy with how everything fit together, and I did some back of the envelope calculations that left me concerned with the strength of the connections (the margin of safety was about 0.02 for a 10g maneuver which was too close for comfort). The connection hardware fit better and only took about 30 minutes to get to fit, but still required post processing with a hand saw.

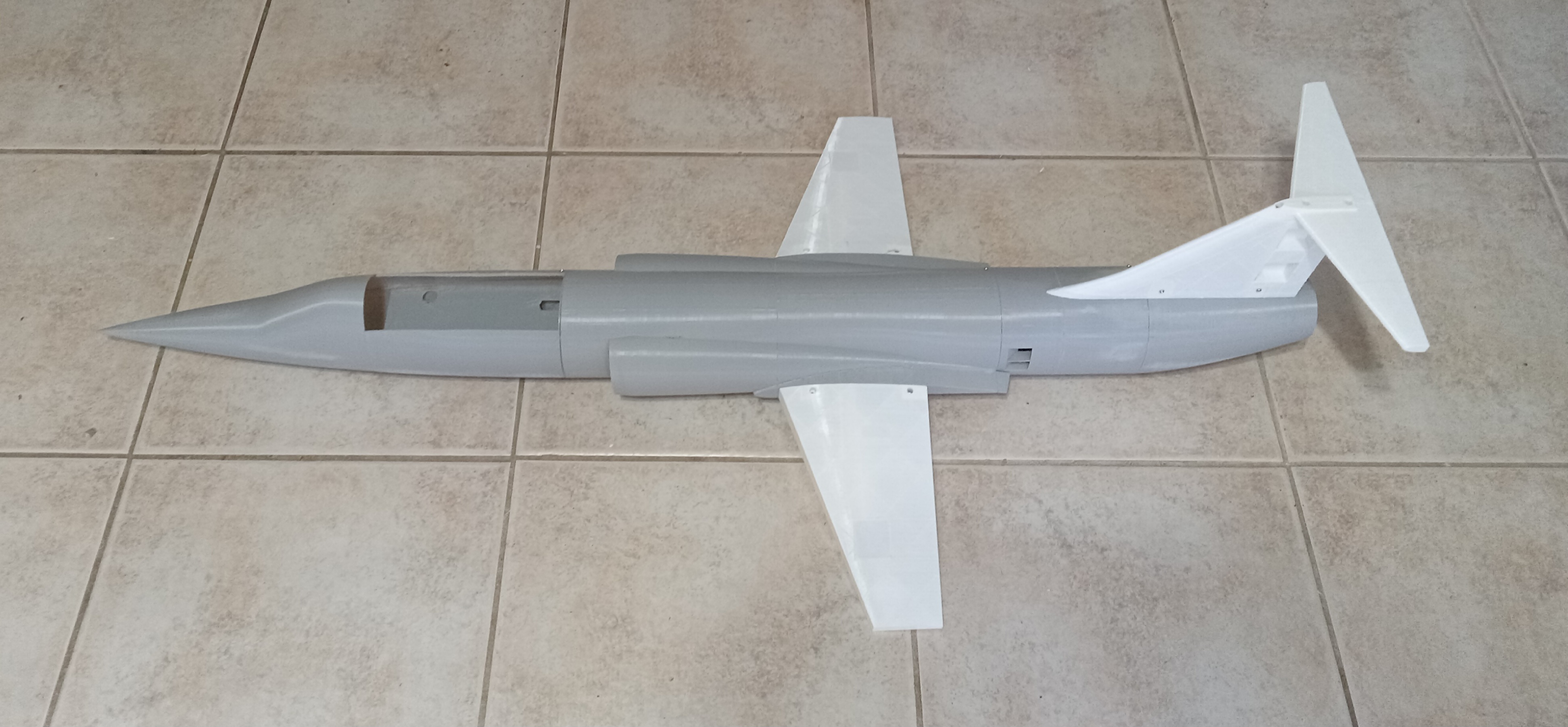

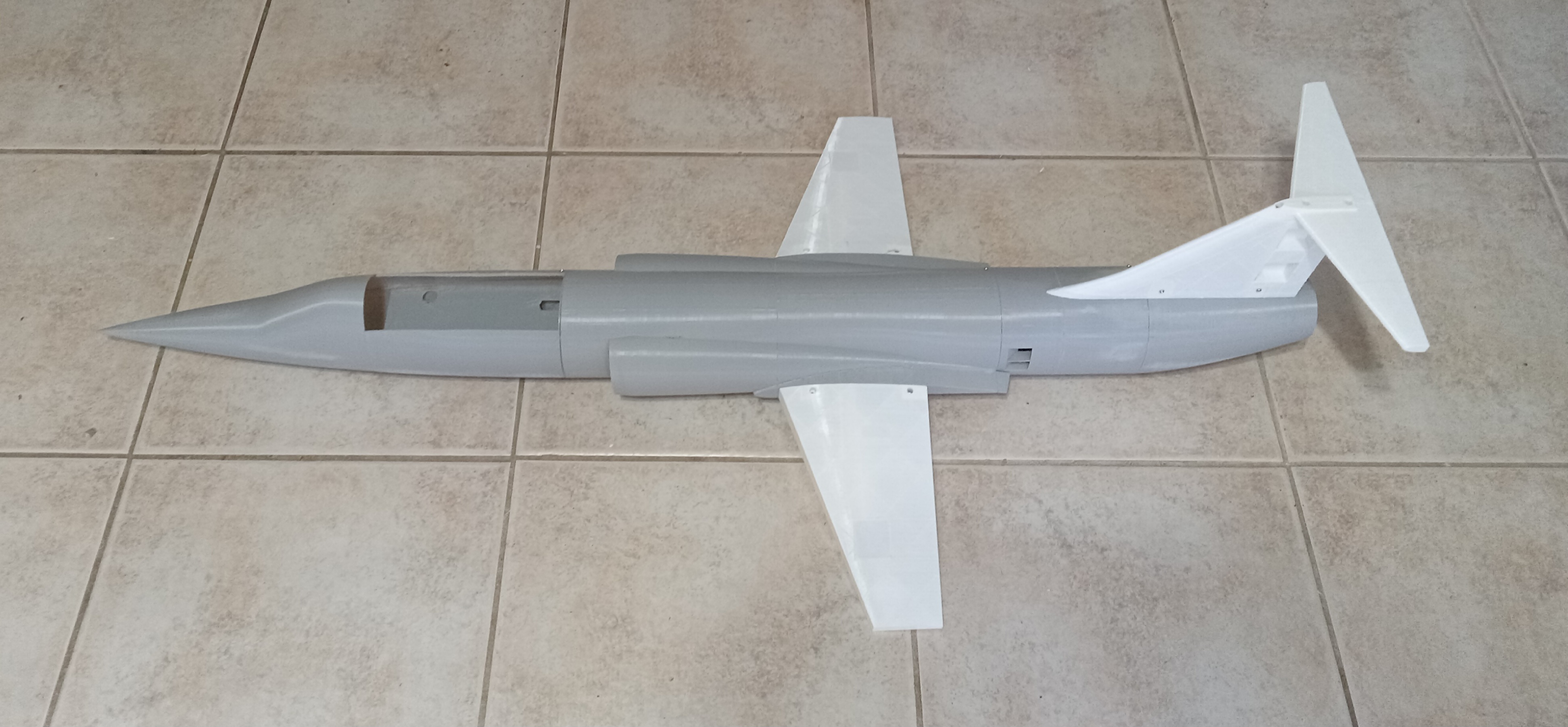

Which brings me to version 4 - the current version. I changed the orientation of the print for the connection hardware which almost doubles the strength and improves the tolerances I can achieve but requires it to be printed in 6 parts instead of 2. However, it's an enormous improvement and the time to assemble a connection is about 10 minutes plus the time for the CA to harden. The only post processing required is breaking all the edges with a knife. I decided to build the first model in the shape of an F-104 (I have a reputation to keep up after all). The real advantage is the enormous amount of time I spent characterizing the design of the F-104 for my 50mm EDF and 80mm EDF versions which saves a lot of time. However, I expect a trainer jet with different wings and a tail optimized as a jet trainer to be ready to fly about a week after I first test the F-104 version. Then some prop designs will follow and then more and more varying jets.

Another big improvement over the previous versions is that the cheater inlet is now 130% FSA for a typical 70mm EDF (I went and measured all the 70mm EDFs in my possession) which means that additional conventional inlets are strictly optional which will make experimenting with widely varying designs simpler. This F-104 in particular has inlets worth 215% FSA and I didn't measure any noticeable change in thrust between having the fan installed and in free air which is a first for me. The final AUW should be about 1550 grams and the EDF (a Powerfun 70mm 4s unit running on a 3600 mAh 4s pack) outputs about 1600 grams so the final TWR should be about 1, even if the weight grows a bit (as it always does). Built light with fixed gear and 4 channels, this plane should weigh in at about 1 kg so it should also be possible to fly it on a strong 64mm EDF which I will eventually test.

I have a few goals with this project.

1. Make a modular system able to be used for many different designs

2. Make it easy to print (limited use of supports, normal PLA, fits on an Ender 3 or equivalent)

3. Make it able to be used for prop or 64mm EDF or 70mm EDF

4. Make the propulsion system removable and compatible with foam board power pods (via an adapter)

5. Design it for 3s or 4s to make the batteries more affordable and safer

6. Design a number of planes for the system ranging from a trainer to warbirds to 6 channel + EDFs

7. Design connection hardware that can be printed independent of the rest of the system to allow for experimentation with foam board parts

8. Make flight-tested STLs available on this forum

9. Continue to refine the design based on experience to make it as simple as possible to use

10. Design/build data logging hardware/software that can be installed in multiple configurations

11. Actually take video of each design flying (probably onboard RunCam on the tail)

The design I am currently working with uses circular connection hardware that twists together and locks in place with two screws per joint for the fuselage. For the wings and tail I decided not to reinvent the wheel and am using connections very similar to what you'll see on commercially available RC planes. All of the fuselage sections for the initial tests are cylindrical and fit tightly around the internal components, but I plan on designing additional fuselage shapes in the future. I took some inspiration from the appearance of @Power_Broker 's modular design ( https://forum.flitetest.com/index.php?threads/large-modular-uav-design.69987/ )without really knowing the geometry of the internal structure.

I am now on my fourth set of test hardware and the first that should be flight-capable. My first design was mostly to experiment with fits and connection system geometries. It never even got printed. My initial thought was also to make the wing sections modular to allow for as much versatility as possible, but I couldn't make the aerodynamics work.

My second iteration was meant to experiment with fits for the connection hardware and got partially printed. It took me several hours to get everything to go together right for just two pieces, so it definitely needed some optimization. It was also too heavy.

Version three was the first that would probably have been flight-capable had I finished the design. However, I still wasn't happy with how everything fit together, and I did some back of the envelope calculations that left me concerned with the strength of the connections (the margin of safety was about 0.02 for a 10g maneuver which was too close for comfort). The connection hardware fit better and only took about 30 minutes to get to fit, but still required post processing with a hand saw.

Which brings me to version 4 - the current version. I changed the orientation of the print for the connection hardware which almost doubles the strength and improves the tolerances I can achieve but requires it to be printed in 6 parts instead of 2. However, it's an enormous improvement and the time to assemble a connection is about 10 minutes plus the time for the CA to harden. The only post processing required is breaking all the edges with a knife. I decided to build the first model in the shape of an F-104 (I have a reputation to keep up after all). The real advantage is the enormous amount of time I spent characterizing the design of the F-104 for my 50mm EDF and 80mm EDF versions which saves a lot of time. However, I expect a trainer jet with different wings and a tail optimized as a jet trainer to be ready to fly about a week after I first test the F-104 version. Then some prop designs will follow and then more and more varying jets.

Another big improvement over the previous versions is that the cheater inlet is now 130% FSA for a typical 70mm EDF (I went and measured all the 70mm EDFs in my possession) which means that additional conventional inlets are strictly optional which will make experimenting with widely varying designs simpler. This F-104 in particular has inlets worth 215% FSA and I didn't measure any noticeable change in thrust between having the fan installed and in free air which is a first for me. The final AUW should be about 1550 grams and the EDF (a Powerfun 70mm 4s unit running on a 3600 mAh 4s pack) outputs about 1600 grams so the final TWR should be about 1, even if the weight grows a bit (as it always does). Built light with fixed gear and 4 channels, this plane should weigh in at about 1 kg so it should also be possible to fly it on a strong 64mm EDF which I will eventually test.