L Edge

Master member

While going thru FT thread's, ran across JGplanes-White Diamond". Simplistic, strong, fast and being a different designed airplane, wondered if it could be adapted to my 64mm EDF and add a thrust vectoring unit to it.

https://forum.flitetest.com/index.php?threads/white-diamond-revealed-single-sheet-dtfb-flier.57931/

So,after conversing with JG, here is the story of how I am attempting how to do it.

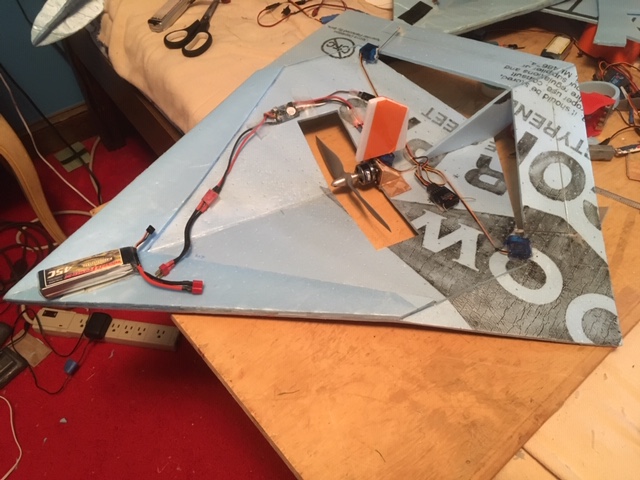

Decided that in order to accomplish that, needed to expand size. Being old school, laid it out on paper(see his simple 1 page drawing) and using same angles, ended up with a length of 30 inches and a width of 26 1/4". I use blue FFF with a double sided film on it and black markings that over a period of years, will not come off entirely. Hence your model needs to be painted at which I am not talented. I use packing tape instead.

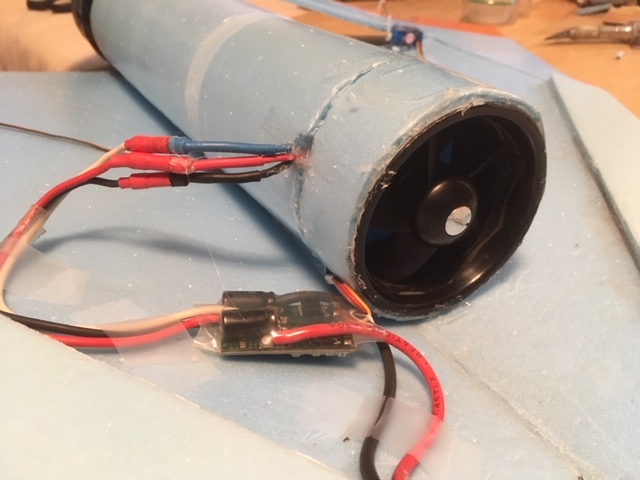

Having a fleet of 64mm EDF's planes ranging from FSWings, Bobcat's, F-22 with thruster's, transports, STOL's, etc., so when I saw the total area, knew it would be the right size. I have purchased and used 70 and 80 EDF's as well, but looked at weight verses wing area, I chose the 64. Being totally unsure on how it would fly, decided to make two. Start with a prop driven and then switch to the 64.

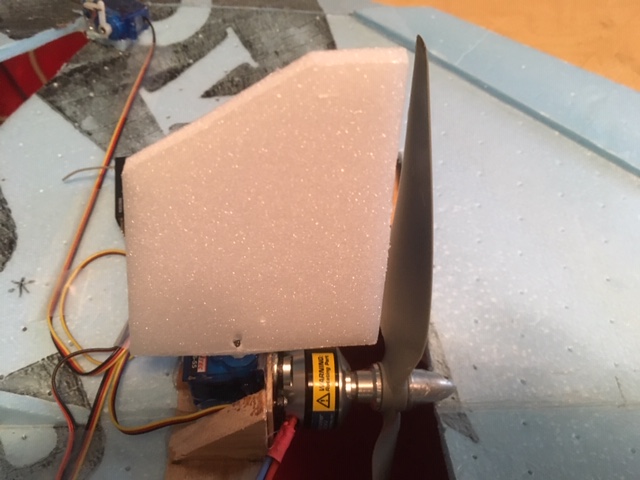

Over the years, my "go to" motor is an E-Flite park 370 1360kv using a prop from 7-9" prop and the one I am using is a APC 9 x 4.5 MRotor since it act differently than the SF's. JGplanes speed is much faster than mine, and I did not feel the need for speed, but can I adapt it to an EDF?

Problem 1:

Where is CG? -- Looking at it, I knew my motor had to be behind the prop so knew I had to jockey all electronics, servos, (not battery) to make it come out right, so I don't have to add weight. First thing I did was cut out pattern following JG's video. Here is his build.

https://forum.flitetest.com/index.php?threads/white-diamond-revealed-single-sheet-dtfb-flier.57931/

So,after conversing with JG, here is the story of how I am attempting how to do it.

Decided that in order to accomplish that, needed to expand size. Being old school, laid it out on paper(see his simple 1 page drawing) and using same angles, ended up with a length of 30 inches and a width of 26 1/4". I use blue FFF with a double sided film on it and black markings that over a period of years, will not come off entirely. Hence your model needs to be painted at which I am not talented. I use packing tape instead.

Having a fleet of 64mm EDF's planes ranging from FSWings, Bobcat's, F-22 with thruster's, transports, STOL's, etc., so when I saw the total area, knew it would be the right size. I have purchased and used 70 and 80 EDF's as well, but looked at weight verses wing area, I chose the 64. Being totally unsure on how it would fly, decided to make two. Start with a prop driven and then switch to the 64.

Over the years, my "go to" motor is an E-Flite park 370 1360kv using a prop from 7-9" prop and the one I am using is a APC 9 x 4.5 MRotor since it act differently than the SF's. JGplanes speed is much faster than mine, and I did not feel the need for speed, but can I adapt it to an EDF?

Problem 1:

Where is CG? -- Looking at it, I knew my motor had to be behind the prop so knew I had to jockey all electronics, servos, (not battery) to make it come out right, so I don't have to add weight. First thing I did was cut out pattern following JG's video. Here is his build.

Last edited: