speedbirdted

Legendary member

Lately thermals have started cropping up at my field more and more so the glider itch has returned. Unfortunately my Gentle Lady is no more (don't worry it's still flying just not with me holding the box anymore) so I have to build something to fill the void. Or maybe that's not so unfortunate?

I also set myself a challenge; a 2-meter sub-250 gram ship. It sounds impossible and... that's because I think it is, at least for a sport flier like me who's airplanes must put up with the rigors of transport and frequent usage. With lots of composite wizardry I'm sure you could do it and end up with an airframe that didn't splinter if you looked at it the wrong way, but balsa is more fun to build things with So the design requirements were scaled back a bit to a 60" span, and I think that's doable.

So the design requirements were scaled back a bit to a 60" span, and I think that's doable.

Obviously that light of an airframe is not going to take the violence of bungee launches for very long so I'm sticking a motor on it. And it's also just a nice luxury to have, if you get too low all you have to do is put in a little power.

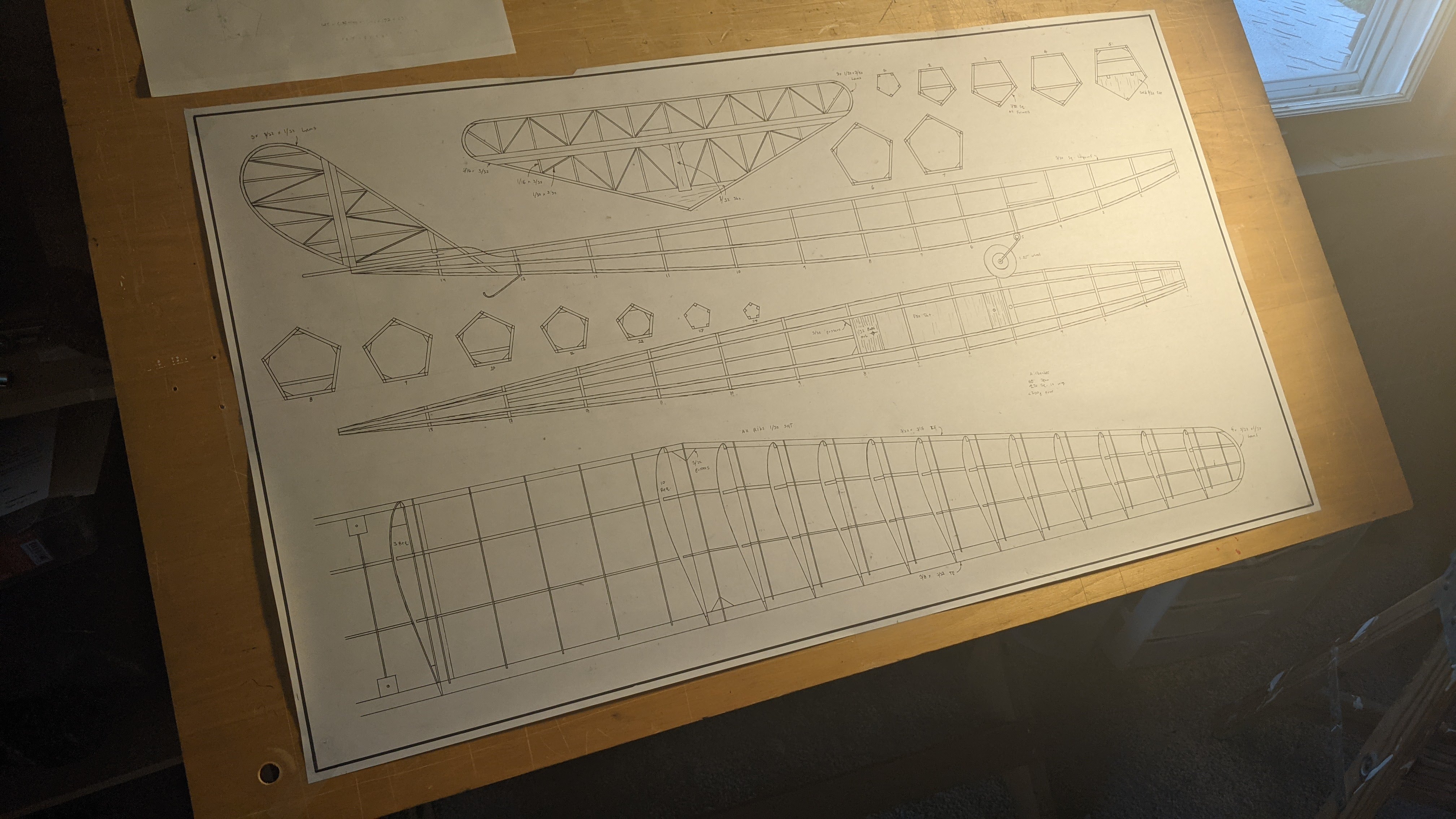

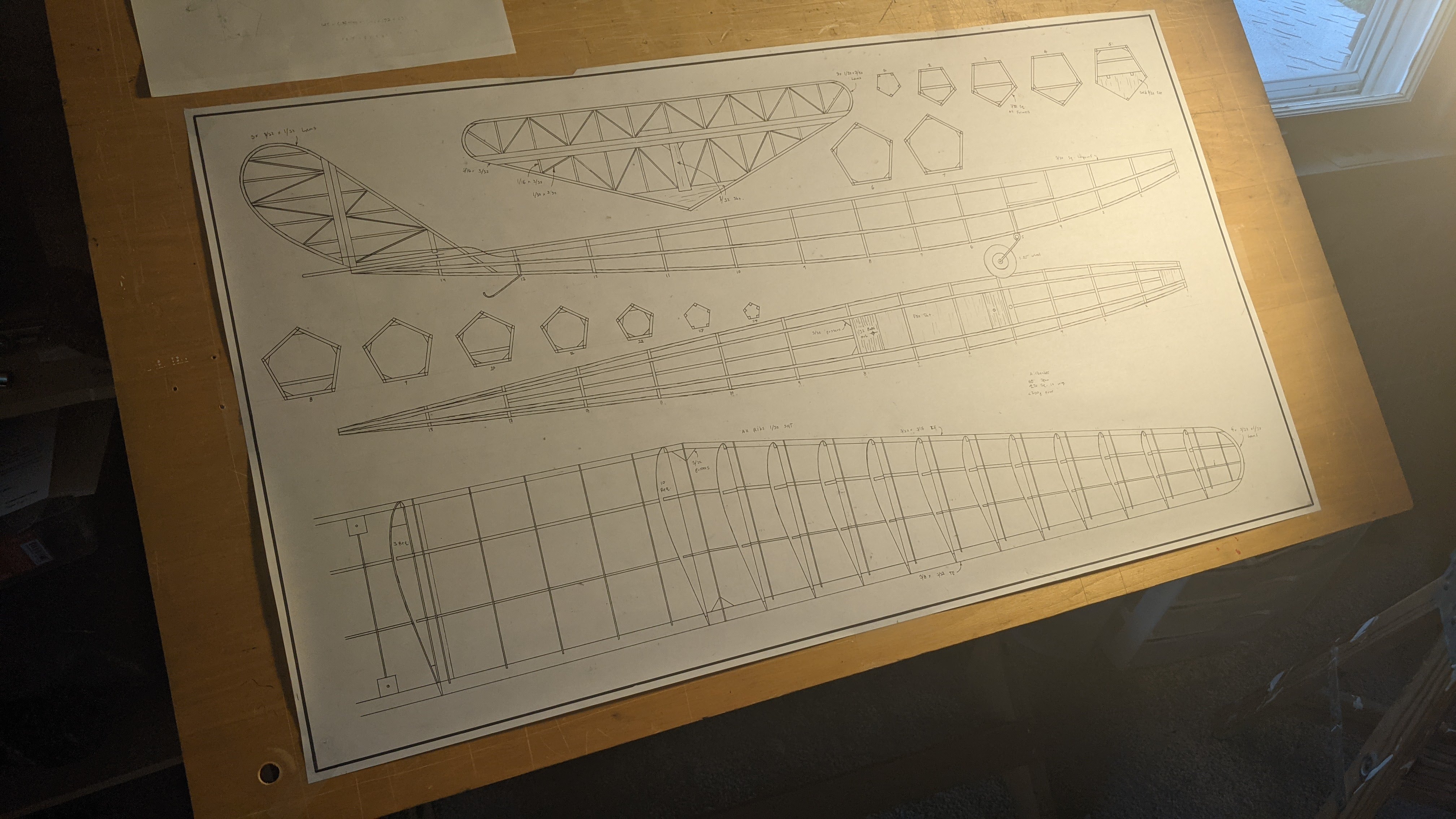

I had the design done from concept to finished plan in less than 48 hours. I didn't really employ any especially outlandish features, other than the pentagonal fuselage which you don't see too often. This was done just to make it look less generic, I guess. I had just enough time left today to run down to the print shop and get some copies made. Unfortunately I forgot to ask them to mirror one of them so I could build the left wing so I get to go do that tomorrow...

I really wanted to start with the wing but sadly a quick survey of the balsa I have resulted in the discovery that all the 1/32 sheets I have are far too heavy to be used for the wing ribs. Like, so damn heavy that the identically sized 3/32 sheet I stripped to make the fuse formers was significantly lighter. Looks like I get to buy some of that too...

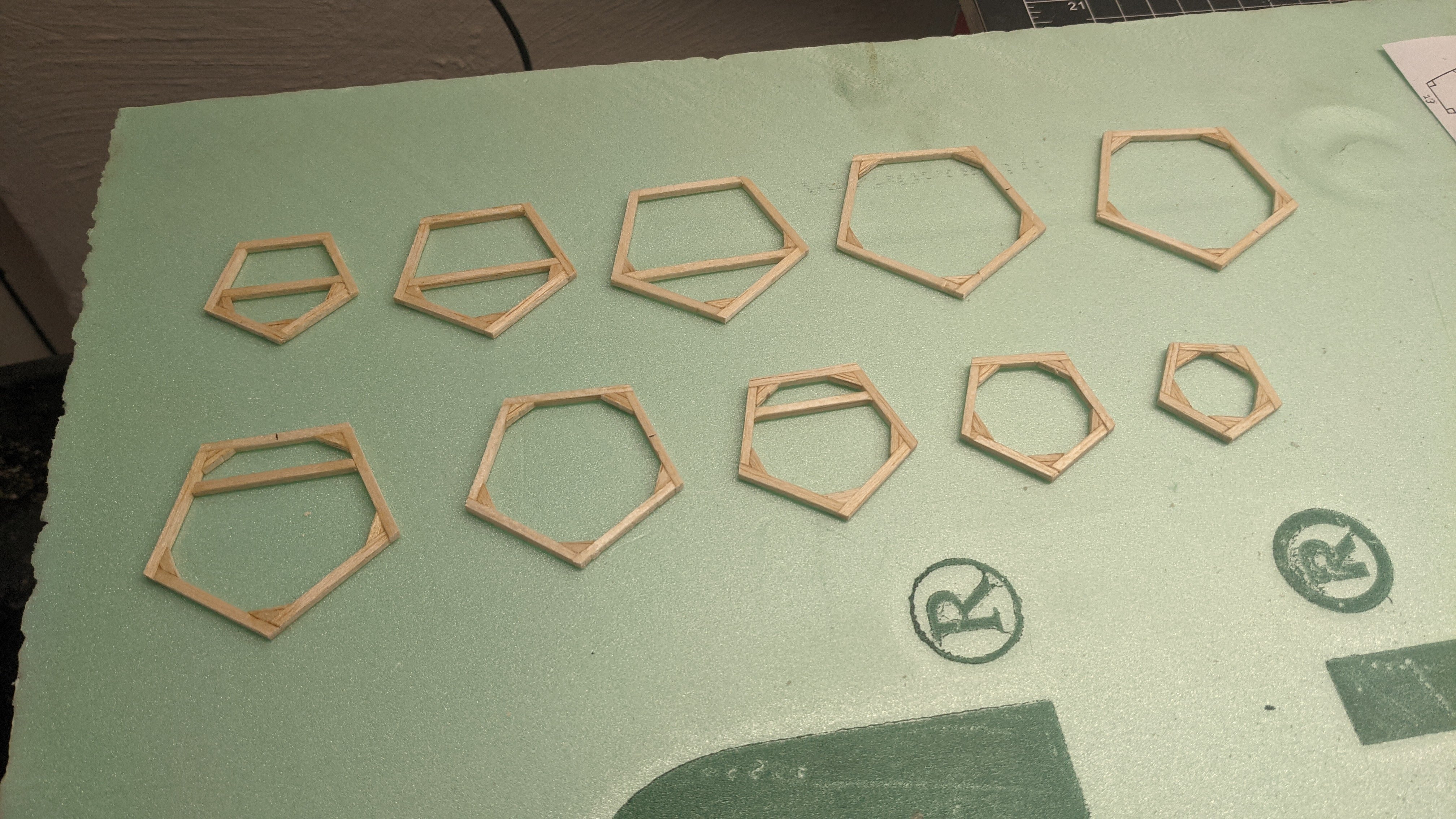

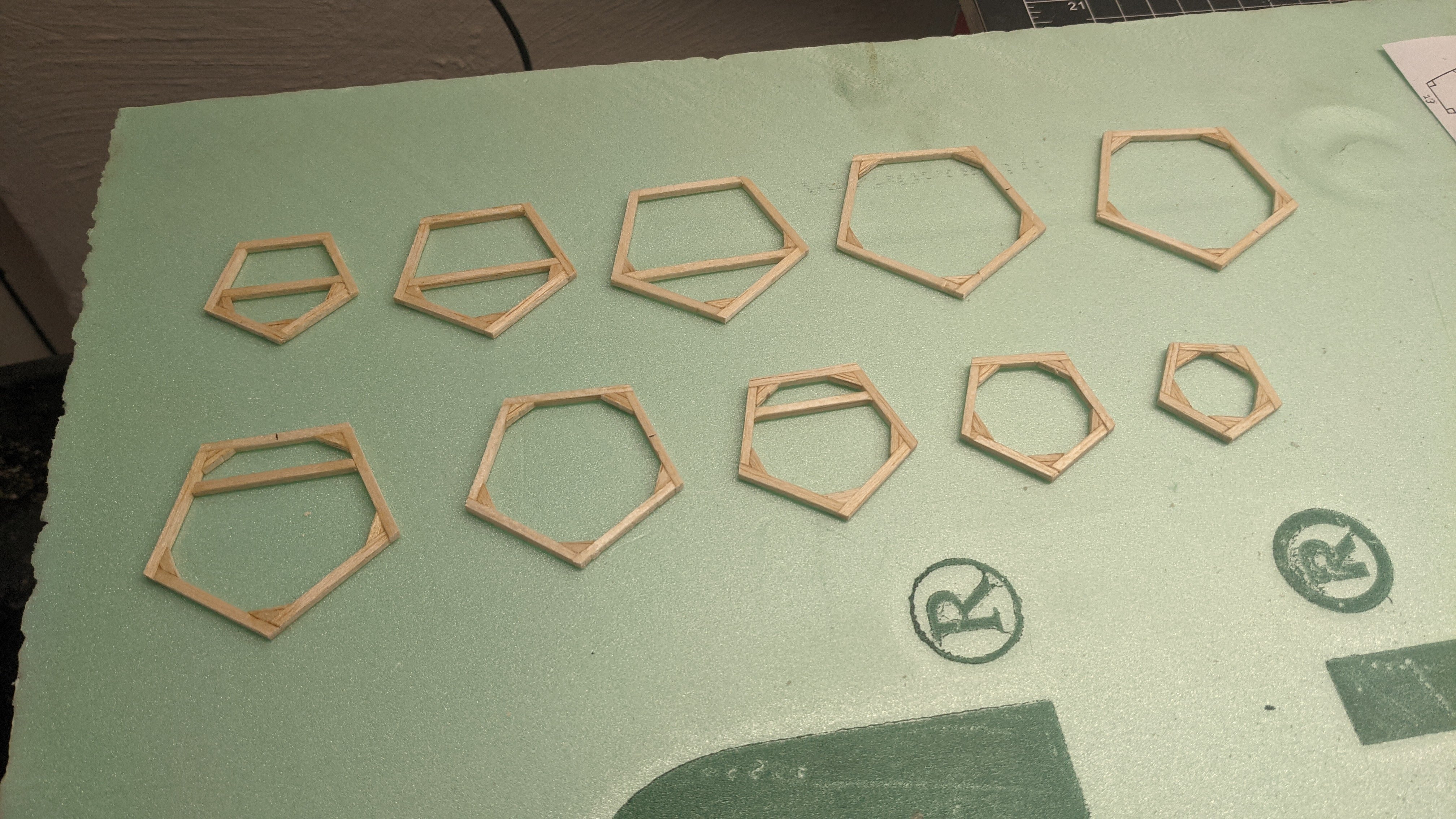

Speaking of those, that's what I have done for now, at least the ones that don't require the scroll saw to make (as my family banned me from using it when they're trying to sleep, either because it's too loud or they're just terrible at sleeping) I also have to cut the notches in them which I'm going to make some special sanding apparatus to do. The notches are actually meant to be cut at an angle which only requires one side of the longeron to be sanded flat, which will make it much easier to get it unformly smooth. It also allows me to build the fuselage without a jig directly over the plan, starting with the top longerons.

The electronics I bought from the Willy Nillies man arrived yesterday so other than the aforementioned wood problems I should have this done pretty fast. For covering I'm thinking tissue. I really don't want this thing ending up overweight...

I also set myself a challenge; a 2-meter sub-250 gram ship. It sounds impossible and... that's because I think it is, at least for a sport flier like me who's airplanes must put up with the rigors of transport and frequent usage. With lots of composite wizardry I'm sure you could do it and end up with an airframe that didn't splinter if you looked at it the wrong way, but balsa is more fun to build things with

Obviously that light of an airframe is not going to take the violence of bungee launches for very long so I'm sticking a motor on it. And it's also just a nice luxury to have, if you get too low all you have to do is put in a little power.

I had the design done from concept to finished plan in less than 48 hours. I didn't really employ any especially outlandish features, other than the pentagonal fuselage which you don't see too often. This was done just to make it look less generic, I guess. I had just enough time left today to run down to the print shop and get some copies made. Unfortunately I forgot to ask them to mirror one of them so I could build the left wing so I get to go do that tomorrow...

I really wanted to start with the wing but sadly a quick survey of the balsa I have resulted in the discovery that all the 1/32 sheets I have are far too heavy to be used for the wing ribs. Like, so damn heavy that the identically sized 3/32 sheet I stripped to make the fuse formers was significantly lighter. Looks like I get to buy some of that too...

Speaking of those, that's what I have done for now, at least the ones that don't require the scroll saw to make (as my family banned me from using it when they're trying to sleep, either because it's too loud or they're just terrible at sleeping) I also have to cut the notches in them which I'm going to make some special sanding apparatus to do. The notches are actually meant to be cut at an angle which only requires one side of the longeron to be sanded flat, which will make it much easier to get it unformly smooth. It also allows me to build the fuselage without a jig directly over the plan, starting with the top longerons.

The electronics I bought from the Willy Nillies man arrived yesterday so other than the aforementioned wood problems I should have this done pretty fast. For covering I'm thinking tissue. I really don't want this thing ending up overweight...