I've been doing a lot of thinking...

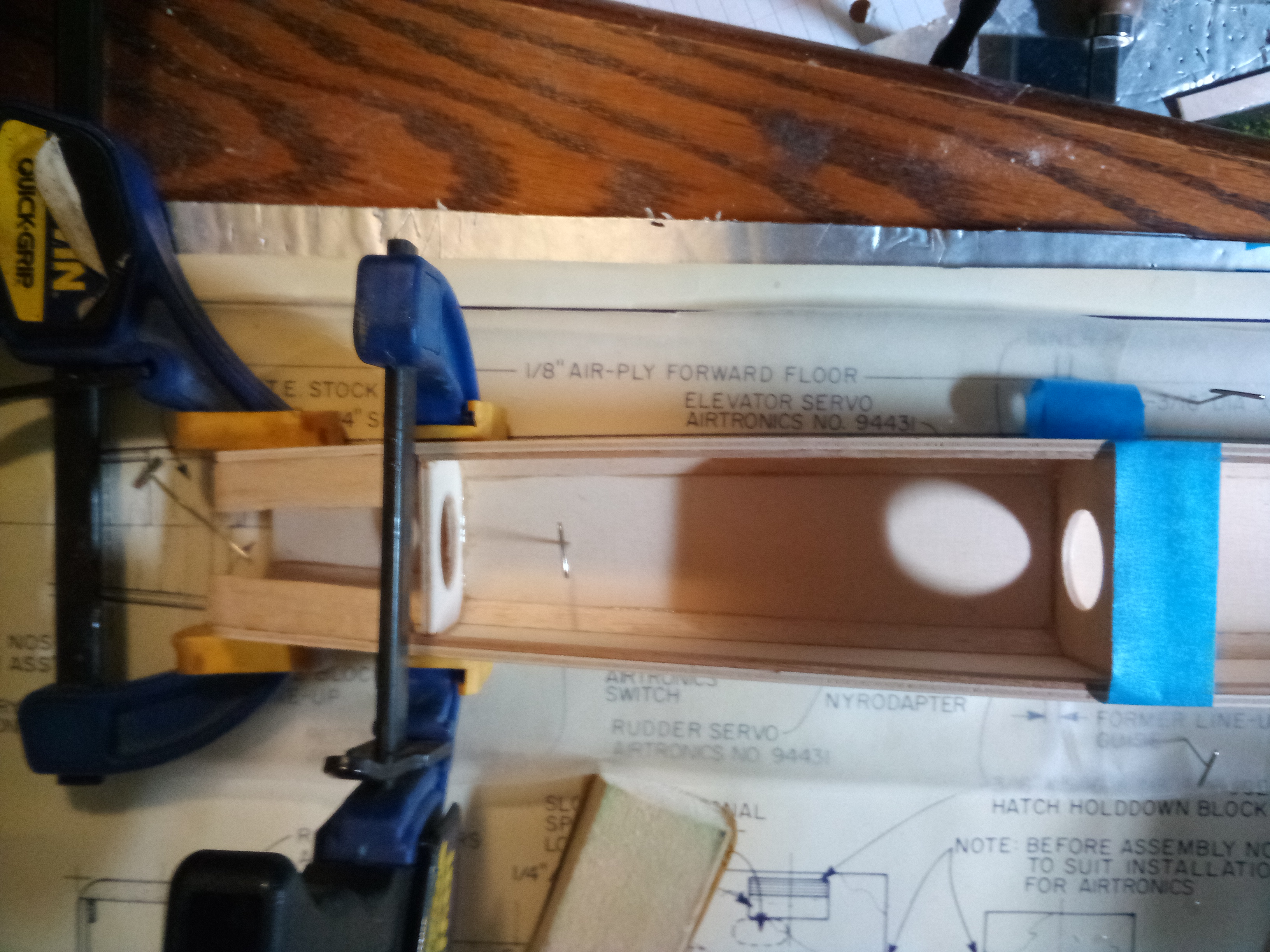

If I round the nose to match the spinner, then the nose block will have to be circular as well. My main goals for this build is for it to fly well, and to look good. But then how do I make it a hybrid glider? I can think of two options

Option 1:

Instead of a removable nose block, go with an entire removable nose. A similar setup like what you can see with flite test and their swappables, only make it look neater, of course. It would probably not be simple, or as strong as a one piece fuselage, but it would stick to the original plan.

Option 2:

Have no removable nose block, but just fly it off the winch without a propeller, letting the spinner be the "nose block". This is a lot simpler, and stronger perhaps, and easier. In other words, a pretty much not-hybrid glider. It would not stick to the original plan, but my intent is to build a well-flying thermal machine.

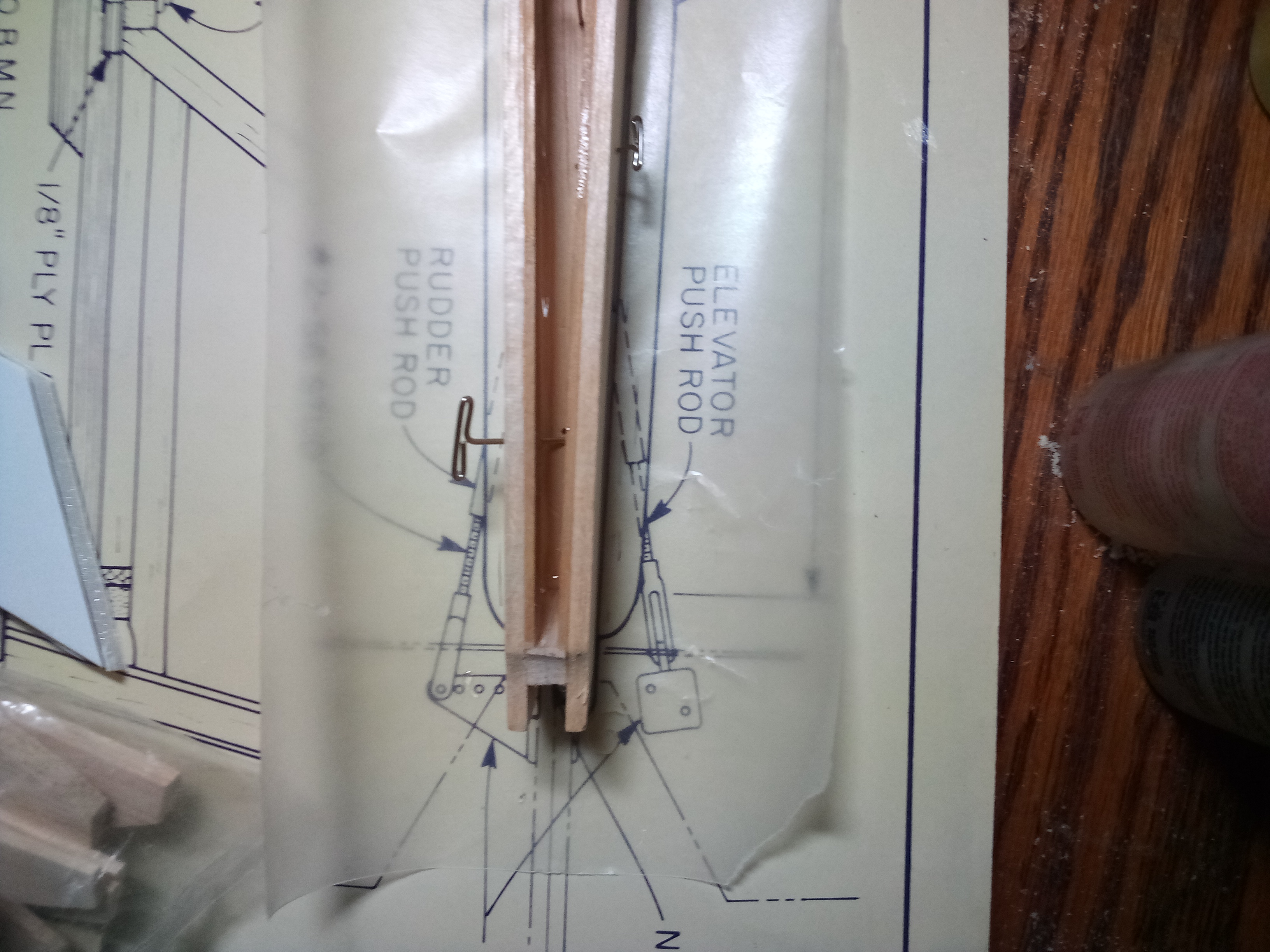

I am undecided yet, but am starting to lean more towards option two. I may have seen this coming when I started this build, thinking that a Hybrid Electric Sailplane may be a little unnecessary. It seemed a good idea at the time. Maybe my building skills were not as advanced as I thought they were, and complexity may affect performance.

In the trade-off between performance and versatility, I would choose performance.

Just as I was typing this, I thought up another possible downside, if I never (or even rarely) fly using the winch, then all the complexity of option 1 would be for naught.

That may have tipped the scale, I think I know what I will go with.