quorneng

Master member

It has been done before as an EDF but from what I can tell some sort of scale sacrifice had to be made with EDF installation and/or the wing section.

My intention is to keep to true scale including the inlet and exhaust by using extreme light weight materials . The exhaust is actually a slot far from ideal for an EDF.

The original was intended to be a coal fired ram jet but only a full scale glider was completed by students under the direction of Lippisch immediately after the was and was promptly 'acquired' by the US and taken to the USA along with Lippisch. NACA tested the glider in their full size wind tunnel but showed its low speed characteristics to be poor, although previous war time tests in Germany on a small model indicated it was stable in a super sonic wind tunnel.

Lippisch as a well respected aeronautical engineer advised Convair on the XF82 delta interceptor but the Convair design team disagreed with Lippisch and selected a thin delta wing rather than the thick one of the P13a.

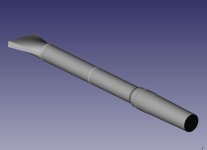

My first task is to design and make the EDF duct. It will be printed in LW-PLA

It looks impossible long and narrow let alone the effect of the slot exhaust.

The complete printed duct with a 50 mm EDF doesn't look any better!

Testing showed the end of the slot tended to vibrate.

You can hear the 'drone' on this video so it required extra stiffening.

I fear this is not going to be easy, let alone fly properly.