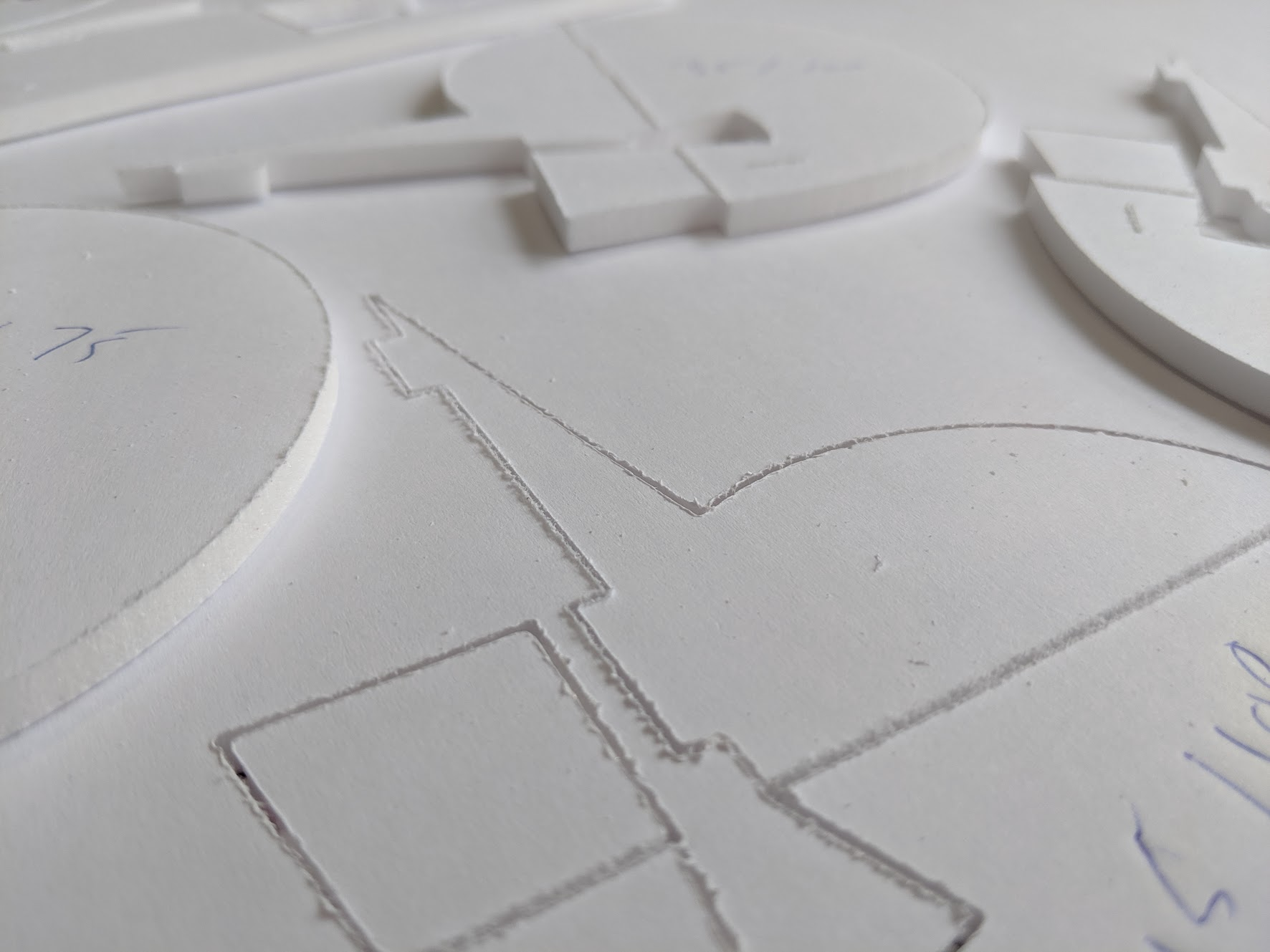

I started with the mpcnc and needle cutter but recently moved to the dewalt spindle with a 1/32" dia 1/4" depth bit. Much faster for me and way better cuts. I got my bits from a US company on Ebay for $6 each, but just ordered a set from the rascal CNC list with a new account coupon for 10 bits for $1.79. So I'll be comparing the $6/bit with these $0.18/bit in a couple months.

Laser works well for thin hobby plywood and poasterboard, I'm running a cheap setup with like a 2.8watt laser mostly off ebay. It won't cut foam though. As for speeds, I've been slowly increasing mine with pretty good success. I'm using the dewalt spindle, which doesn't have a speed control, so I've got it run through a router speed controller. I run it around 70% mostly for noise reduction. I'm currently up to 25mm/s cut rate with no issues, doing the full 5.5mm in a single pass. I've been upping it by 1-2mm/s every sheet I cut.