AircPirateNinsei

airc-pirates.com

Thank you so much!

If questions arise during construction, please let me know!

If questions arise during construction, please let me know!

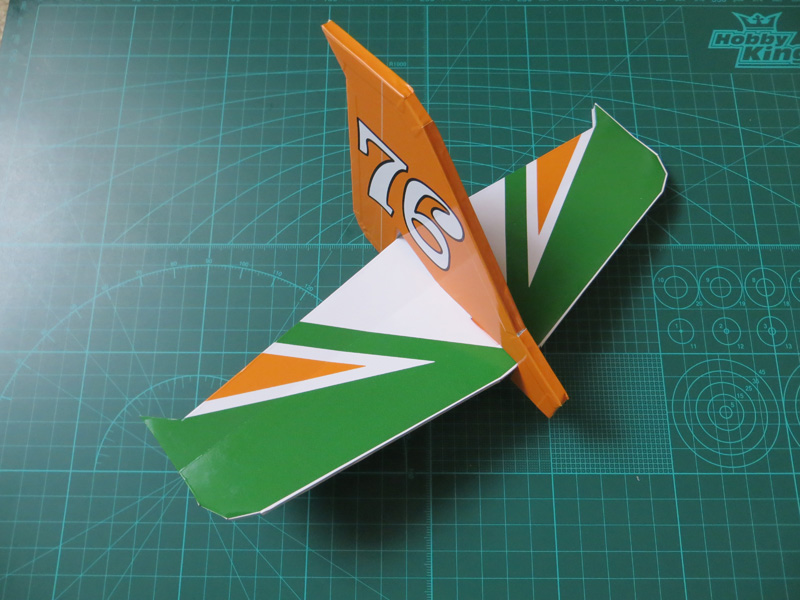

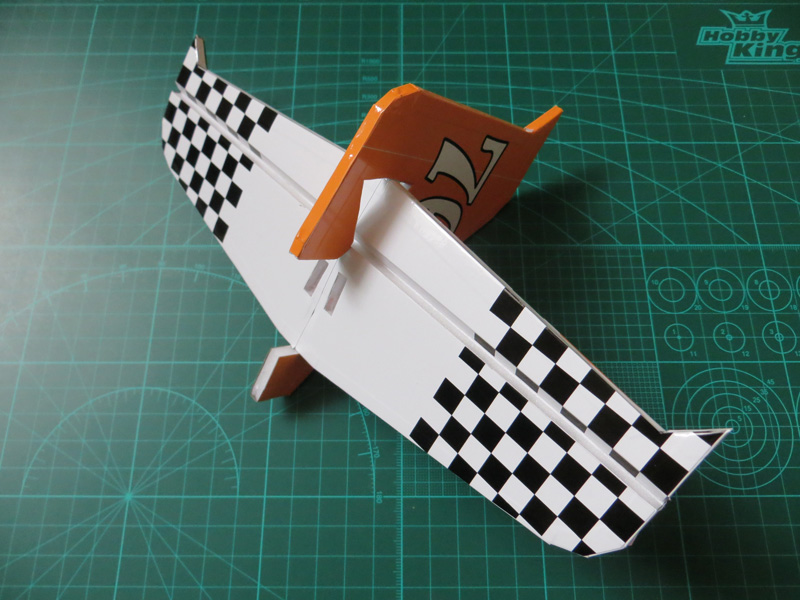

The weekend is coming up and the build plan and the sticker sheets of the AP Rascal Racer are now available for download!

Look here: http://airc-pirates.com/en_US/rr-download/

AircPirateNinsei

What are your thoughts on a slightly larger version with a power 10 motor?

What wingspan?

AircPirateNinsei

What are your thoughts on a slightly larger version with a power 10 motor?

What wingspan?

How about now for the plans.....the excitement is killing me.

The weekend is coming up and the build plan and the sticker sheets of the AP Rascal Racer are now available for download!

Look here: http://airc-pirates.com/en_US/rr-download/

Questions.

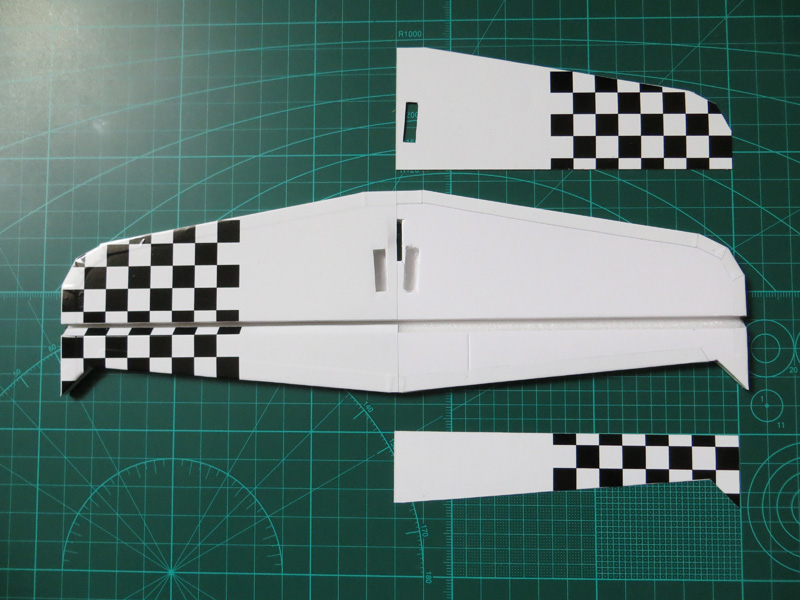

1. is the wing bottom supposed to be flat when complete?

2. would like a few pics of the wing assembly

3. would it be better to make the 2 inner spars full length to cross both wing halves?

4. wing could be done out of a single piece, is there a reason not to? or am i looking at things wrong.

I got everything sliced up on the laser this weekend, and will start on assembly this week.

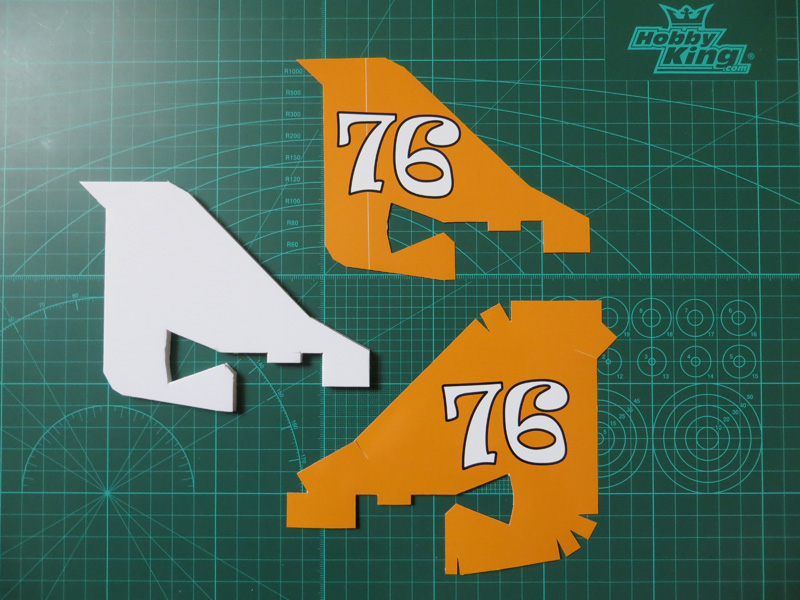

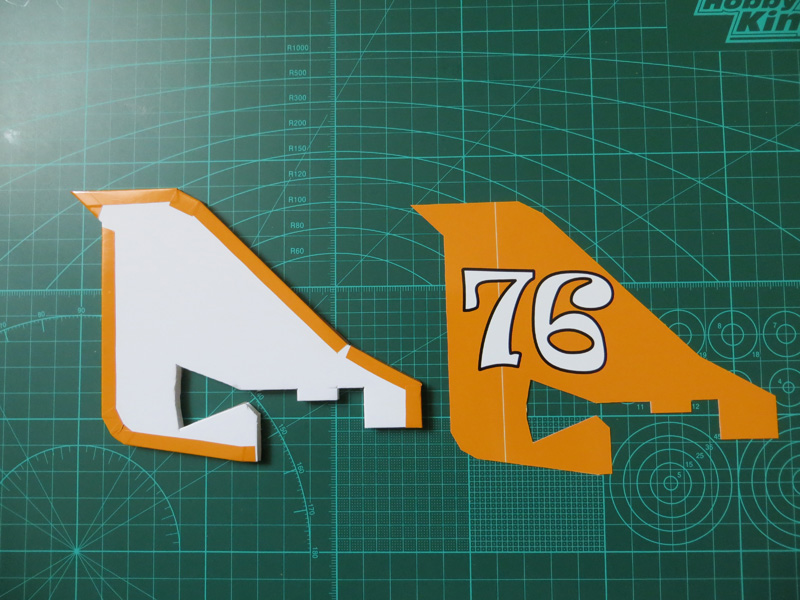

Question about the decals from a process perspective - do you typically pull the DTFB paper off, glue on the decal, and then fold and glue the plane up? Or do you like to add them at the end over the existing paper? I've seen people do both ways, and I usually do the first, but curious how you've been making these particular models.

Thanks,