This time no video update but just some text and a couple pictures. I prettymuch started from scratch for this build from a cad perspective.

It's not that I made all the parts again but I did start over with the assemblies. The file I worked in untill now was a mess, just as you'd expect

with a proof of concept. But now that I've made some nice steps with the design the file and design structure really needed an update.

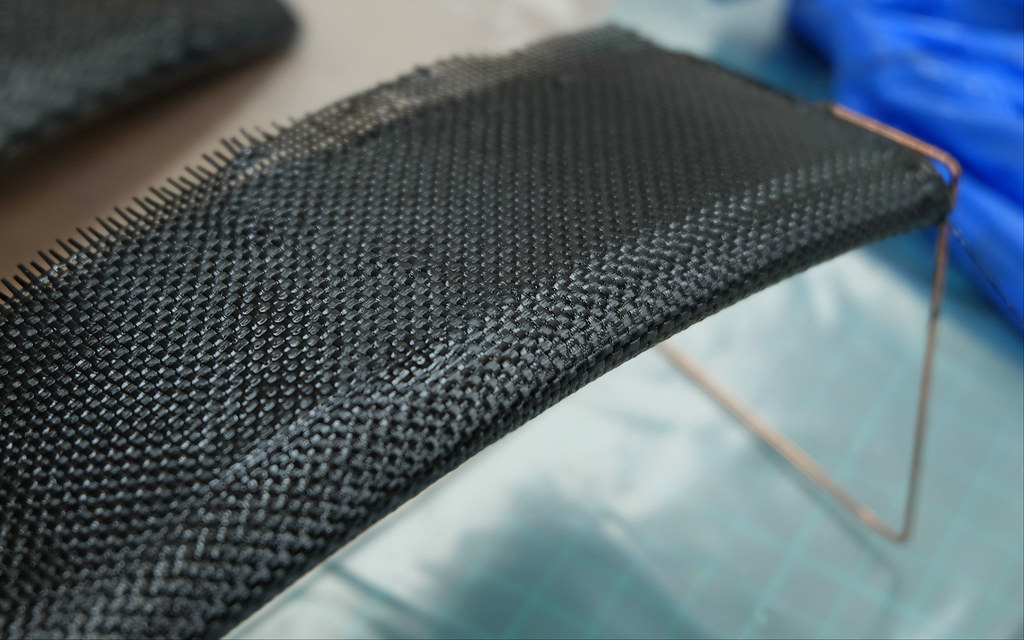

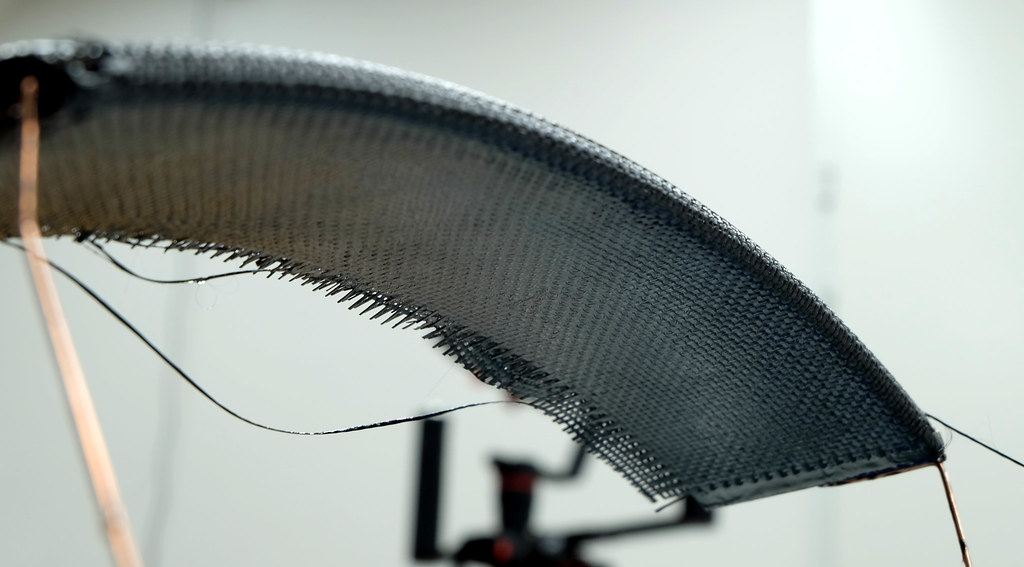

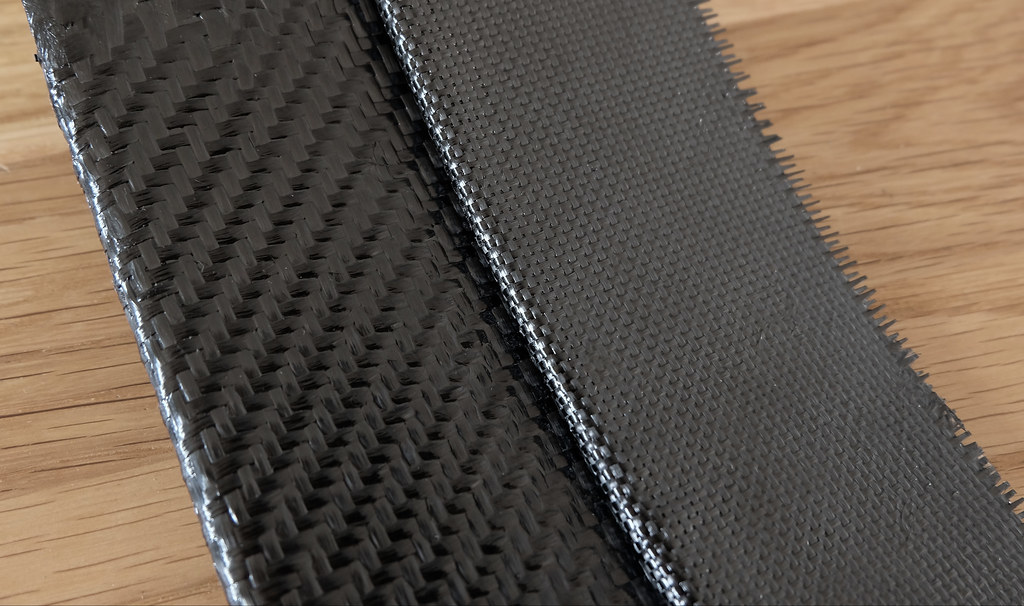

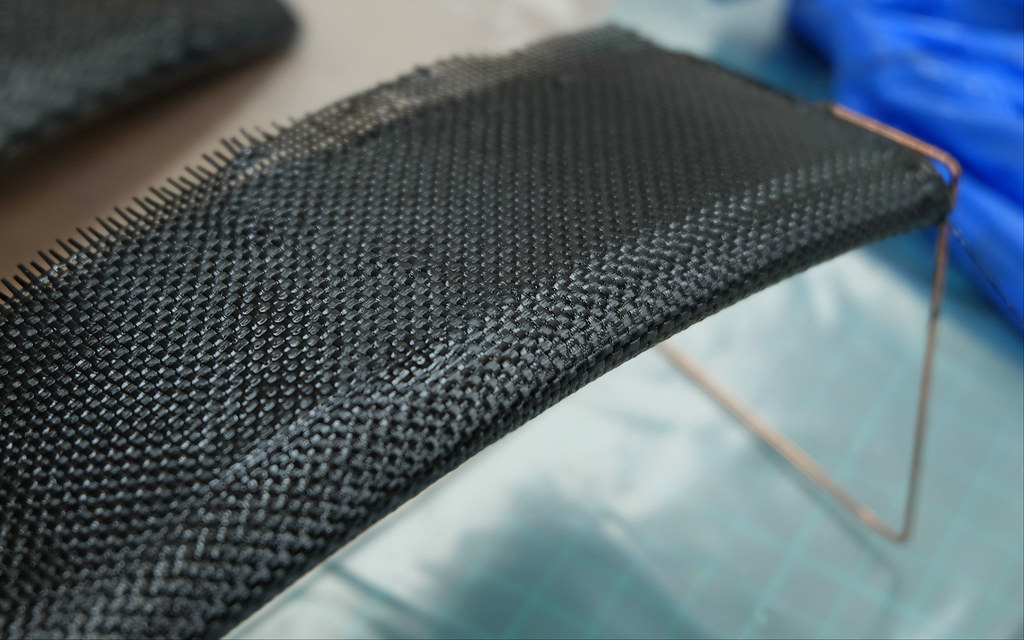

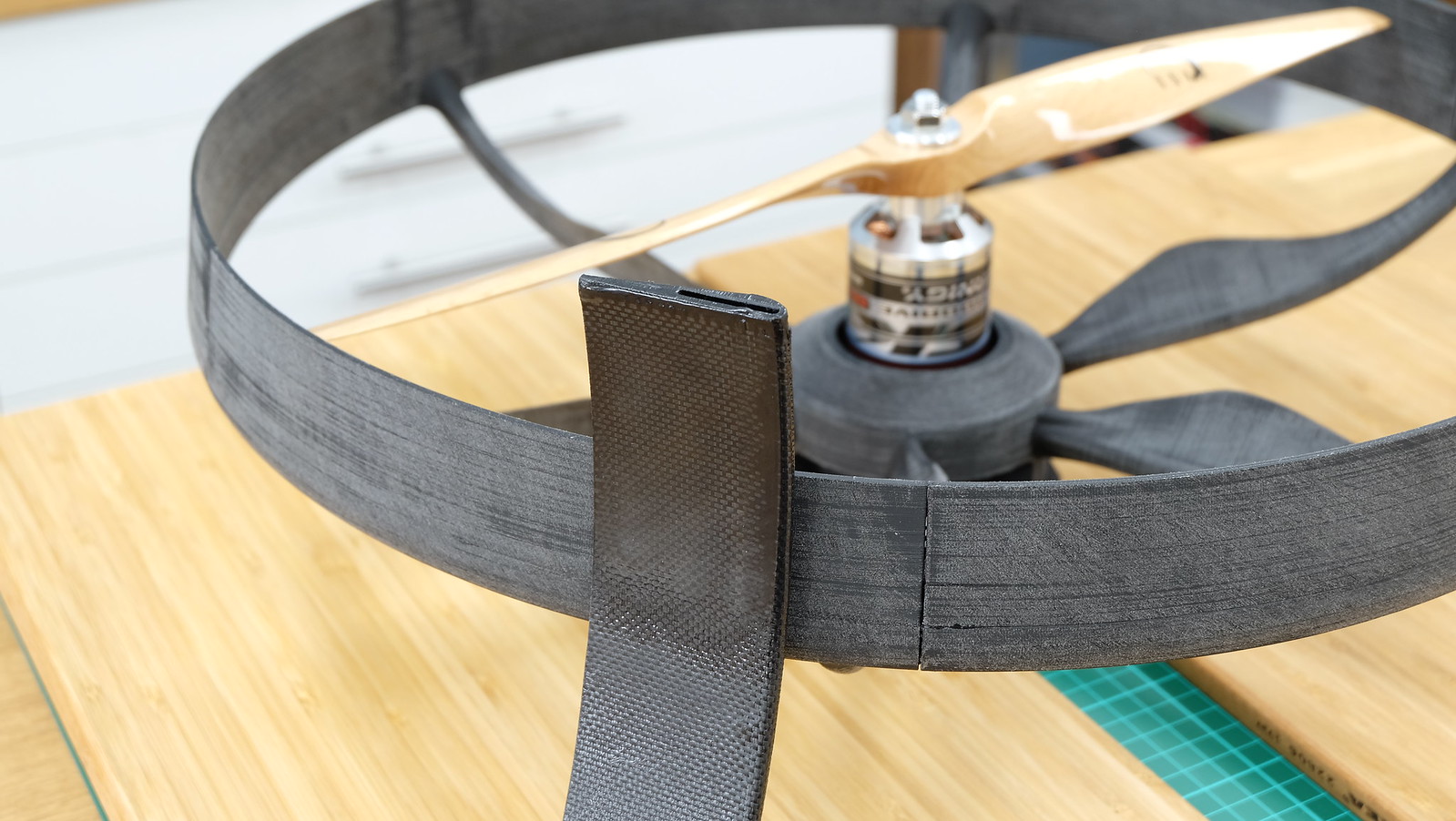

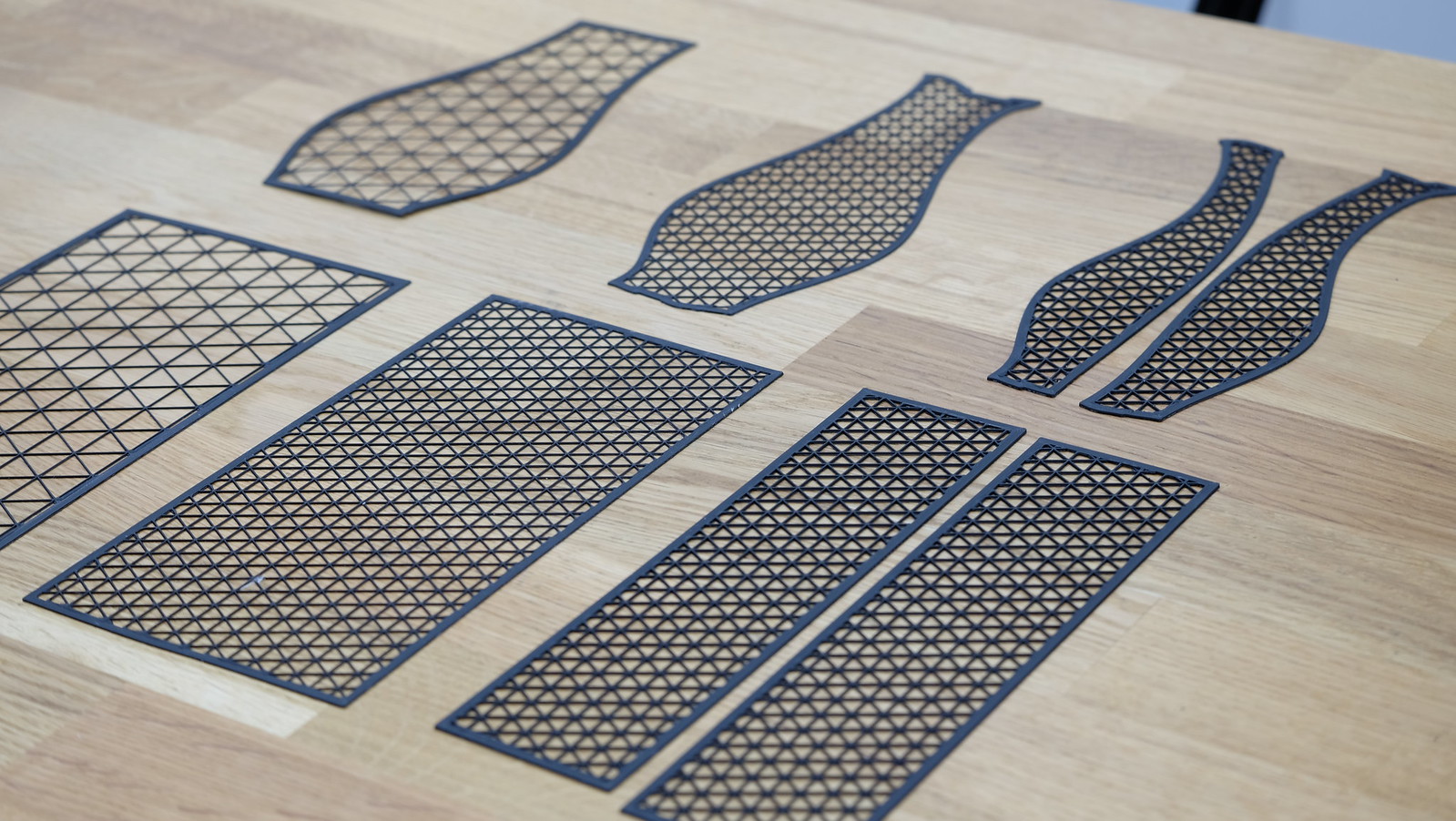

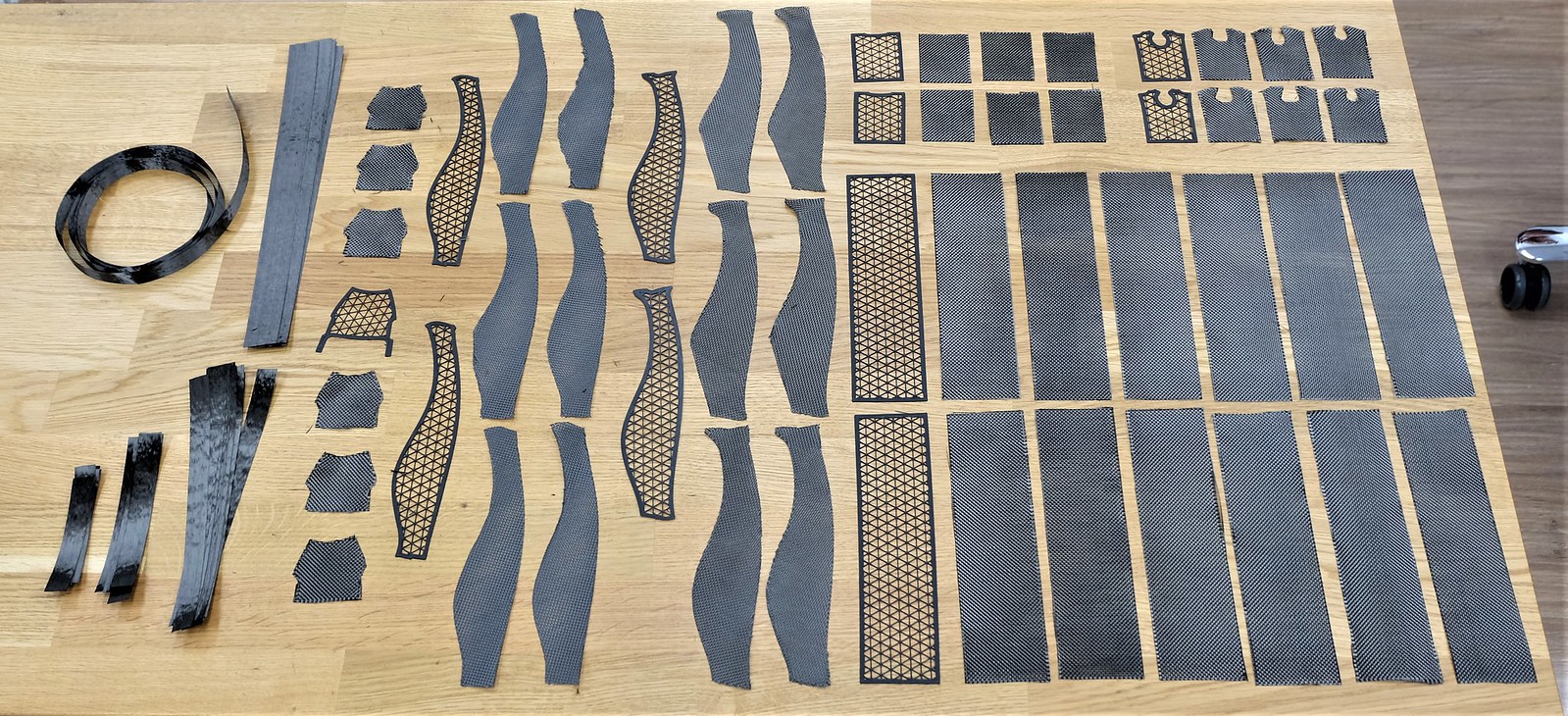

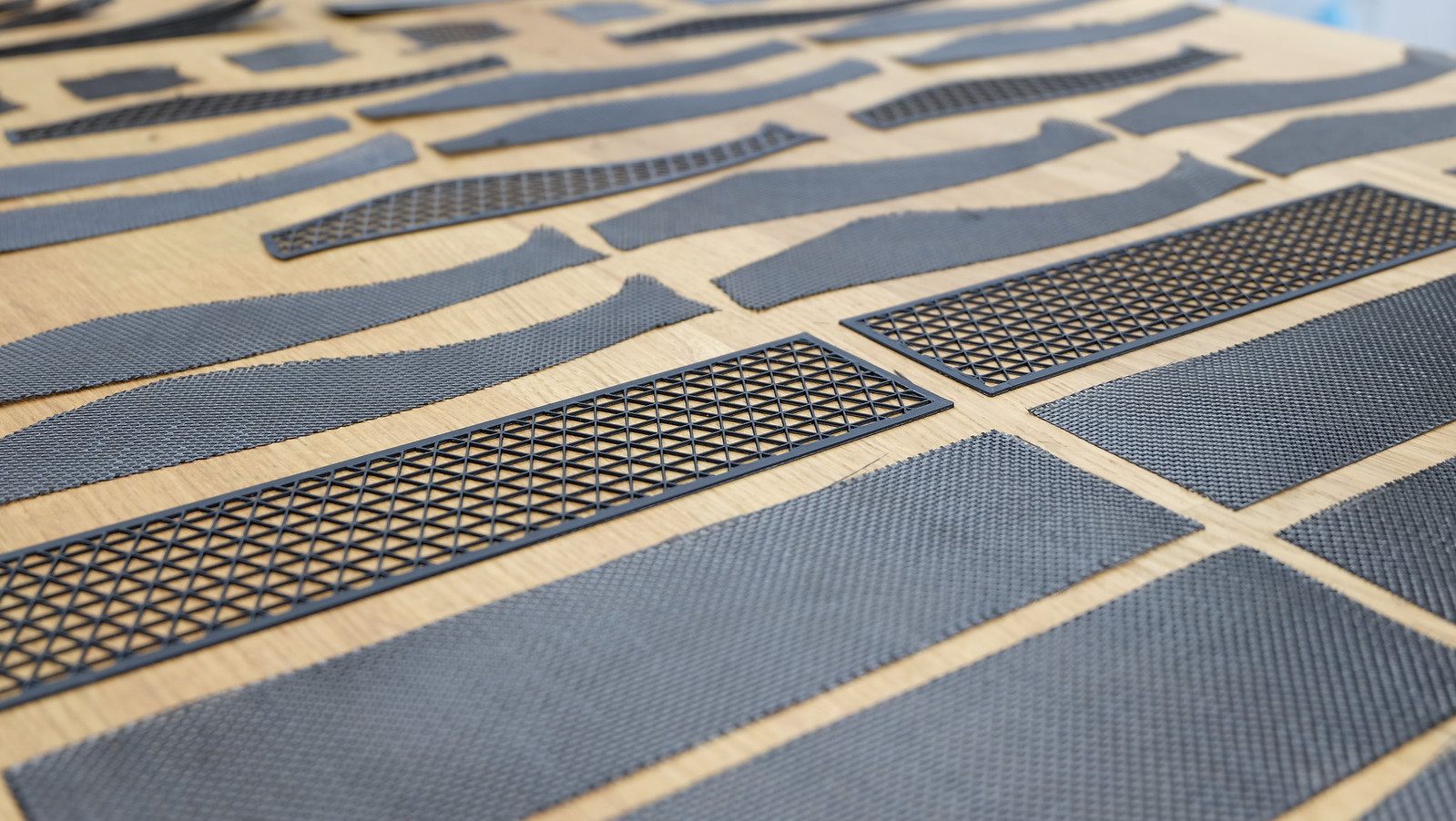

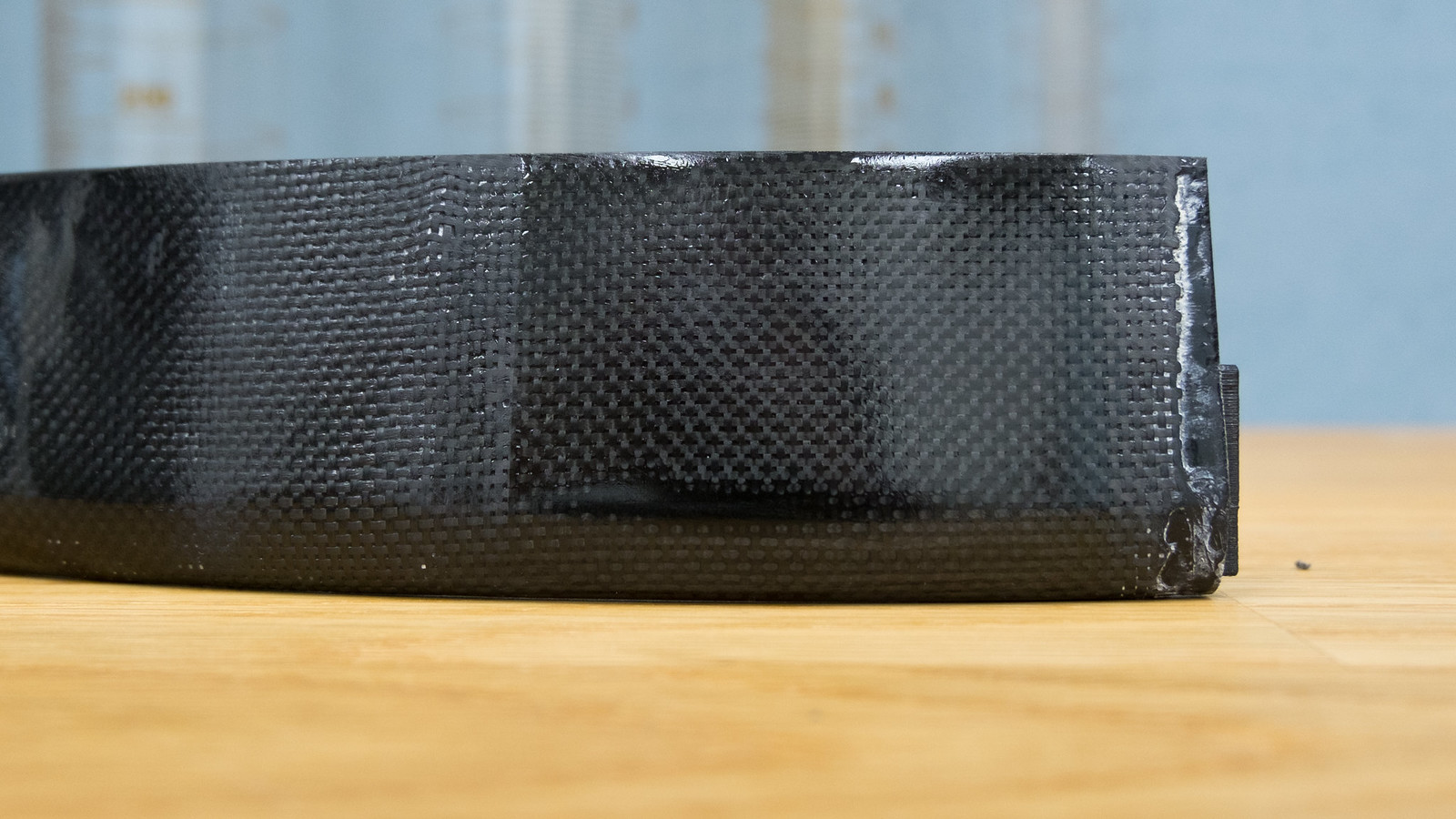

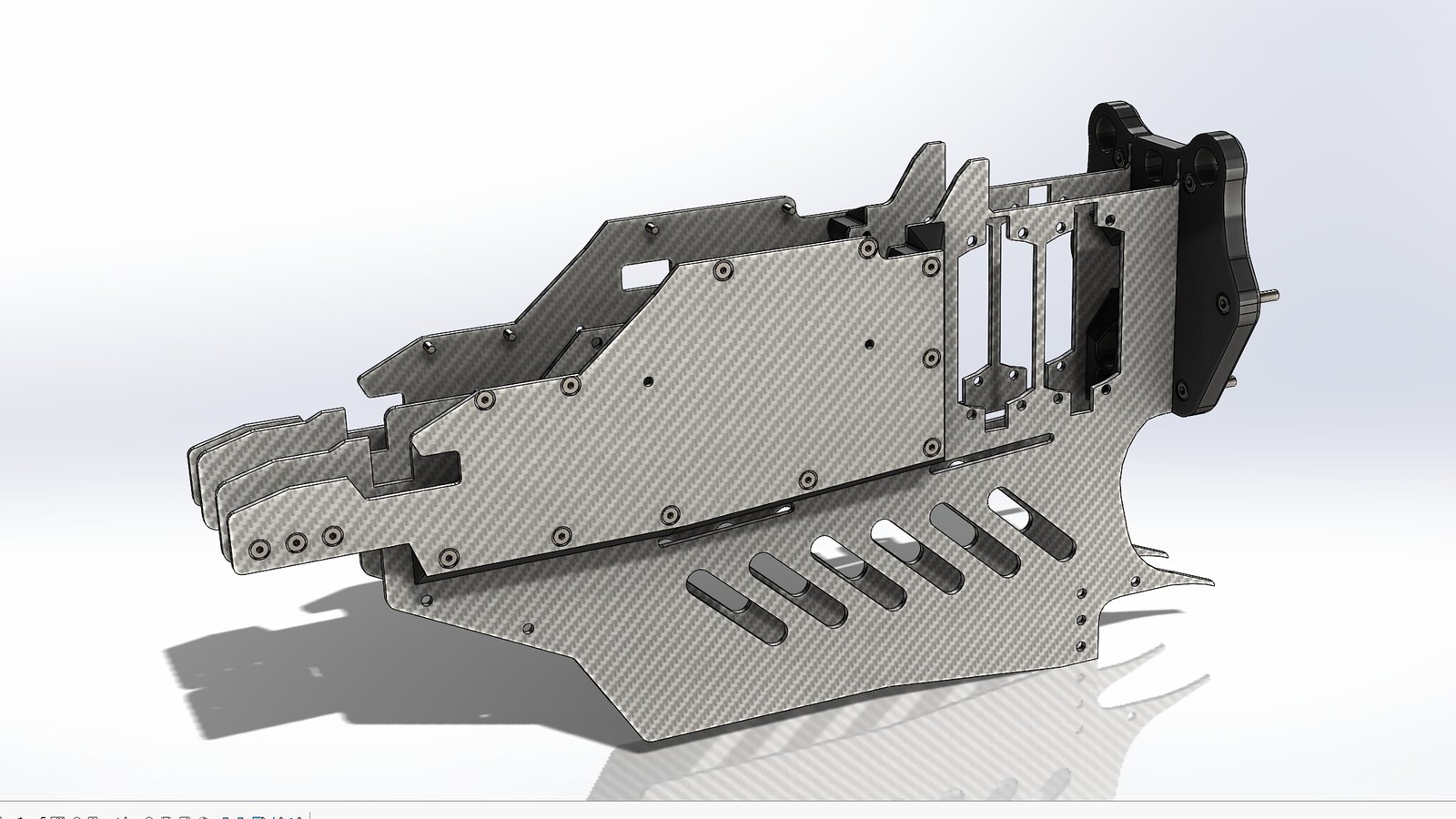

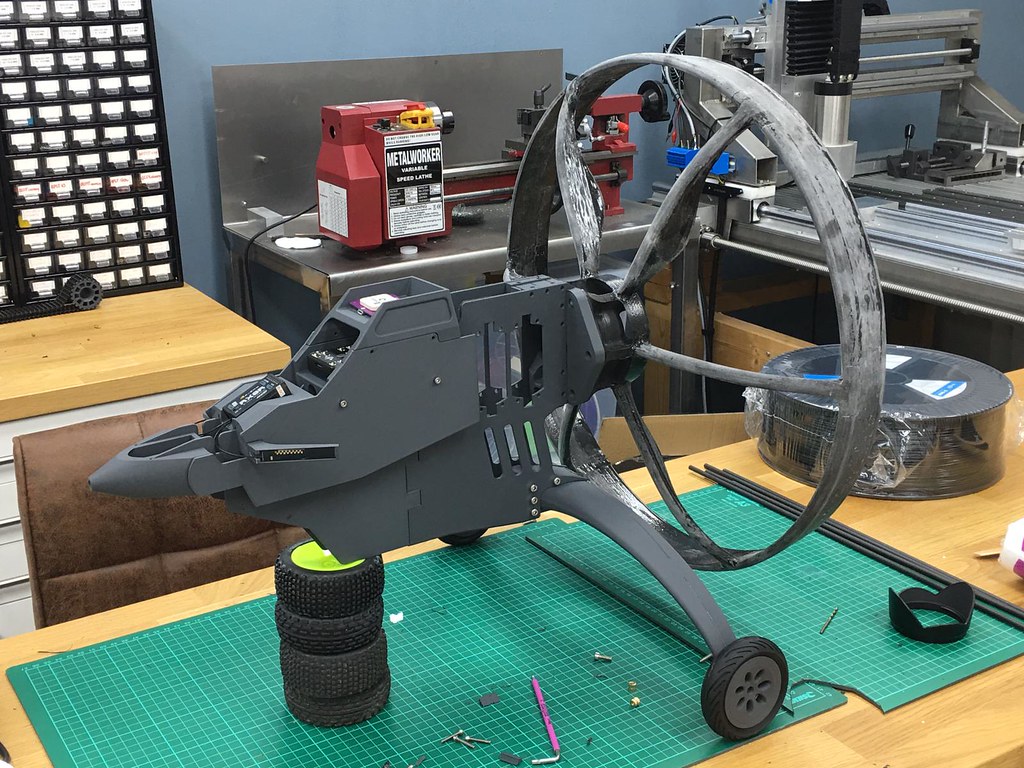

As I explained in the last video, I decided to take the classic frame approach (just like RC helicopters) for this build. I'm going to make a couple

carbon frames that make up the backbone of the model and all components are bolted to this backbone. I made about half of the mounts and

am testfitting the parts in preparation of cutting the frameplates. I'm going to make those as the final step when I am sure that the positions of

the parts are correct, I obviously don't want to mess up a nice sheet of carbon fiber if I can testfit and troubleshoot in advance.

So on to the pictures!

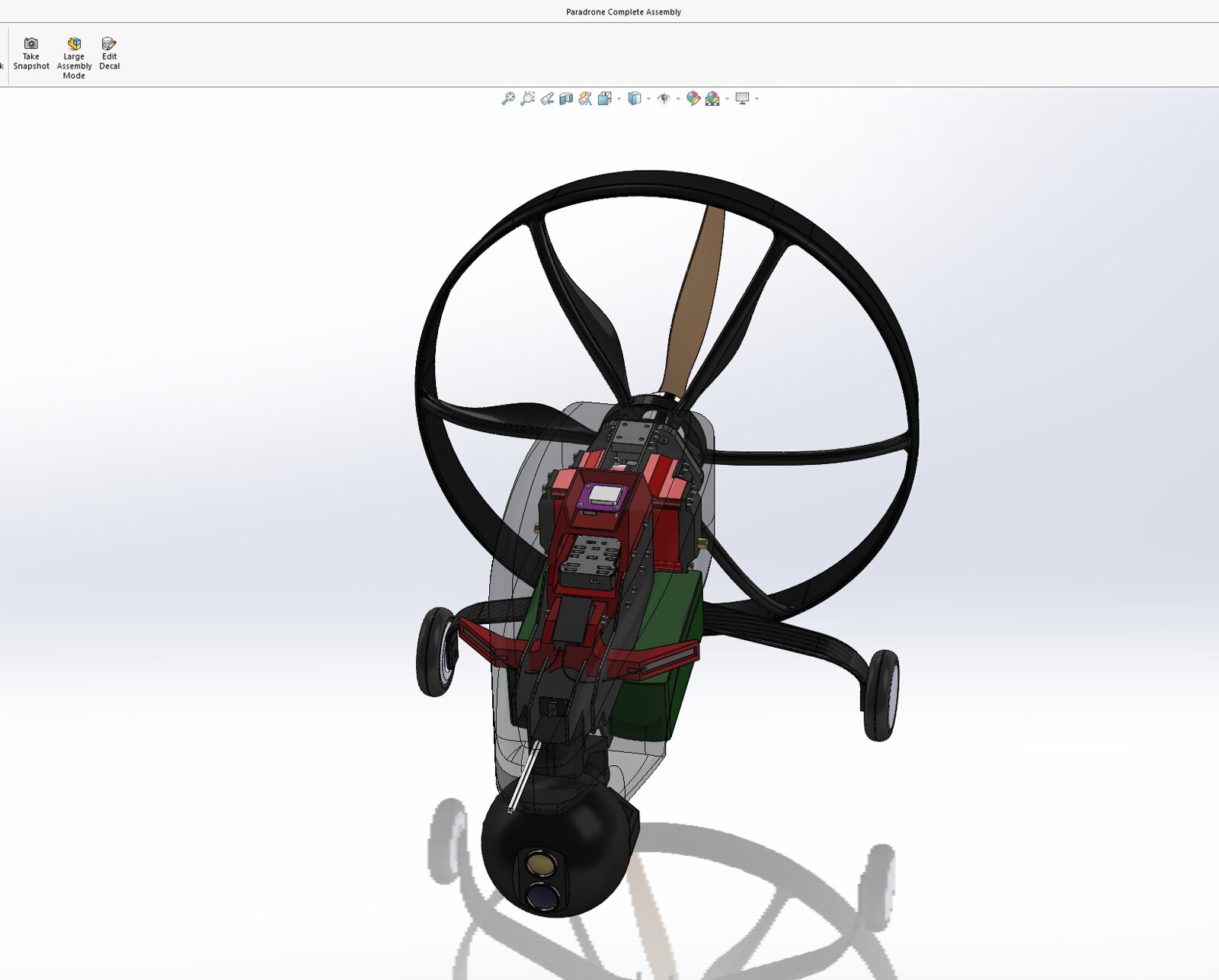

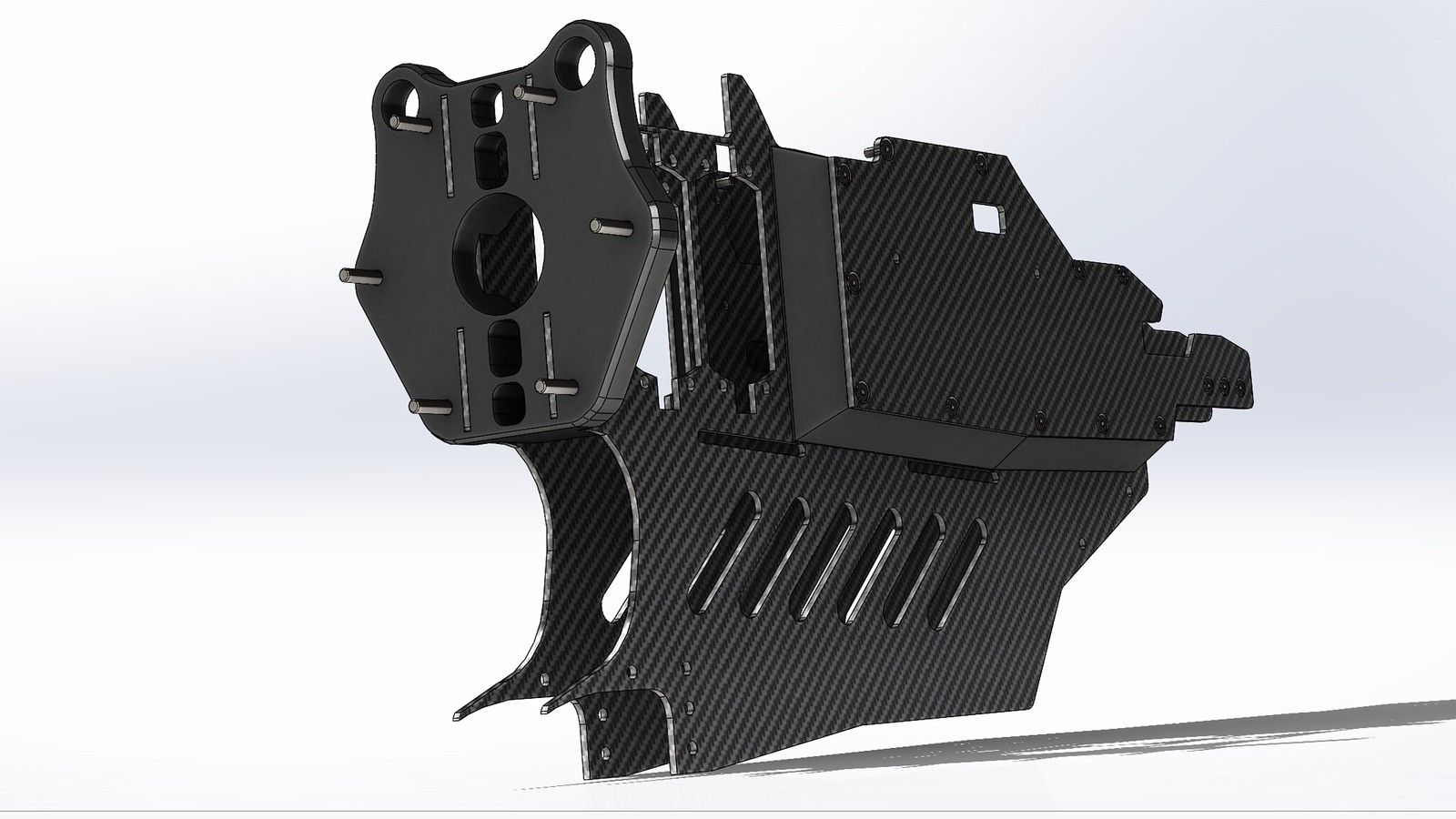

Front/side view without canopy

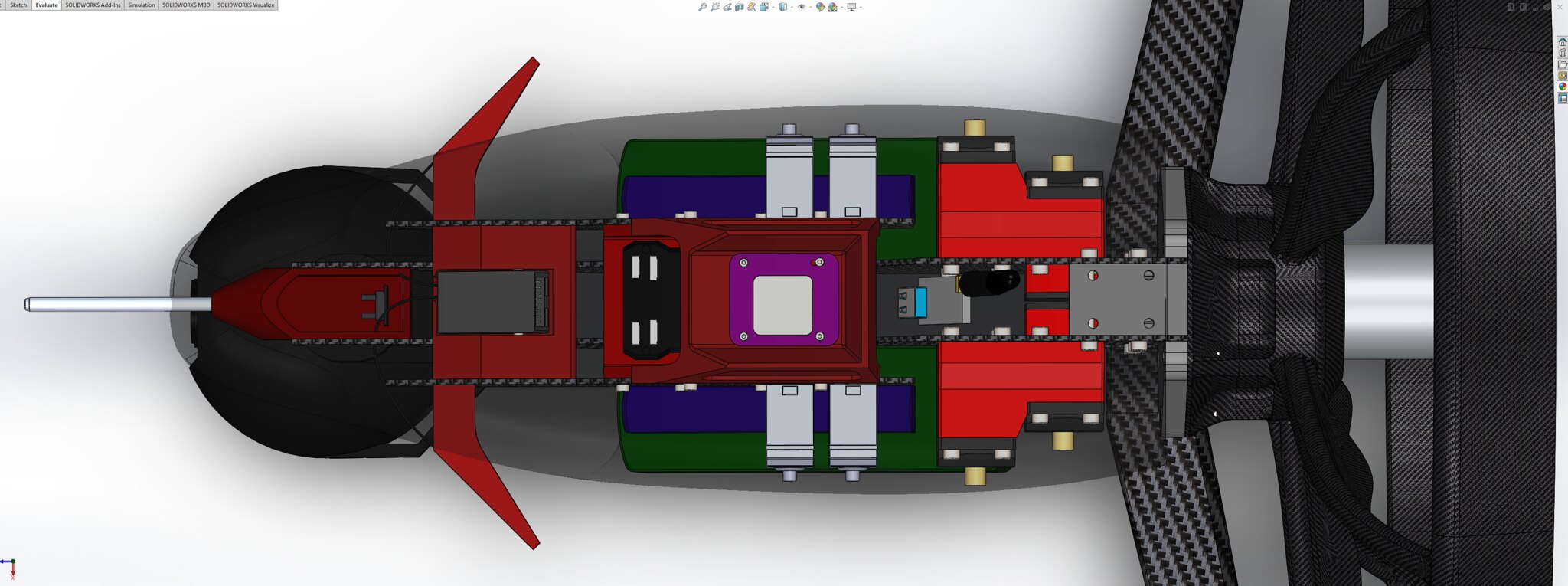

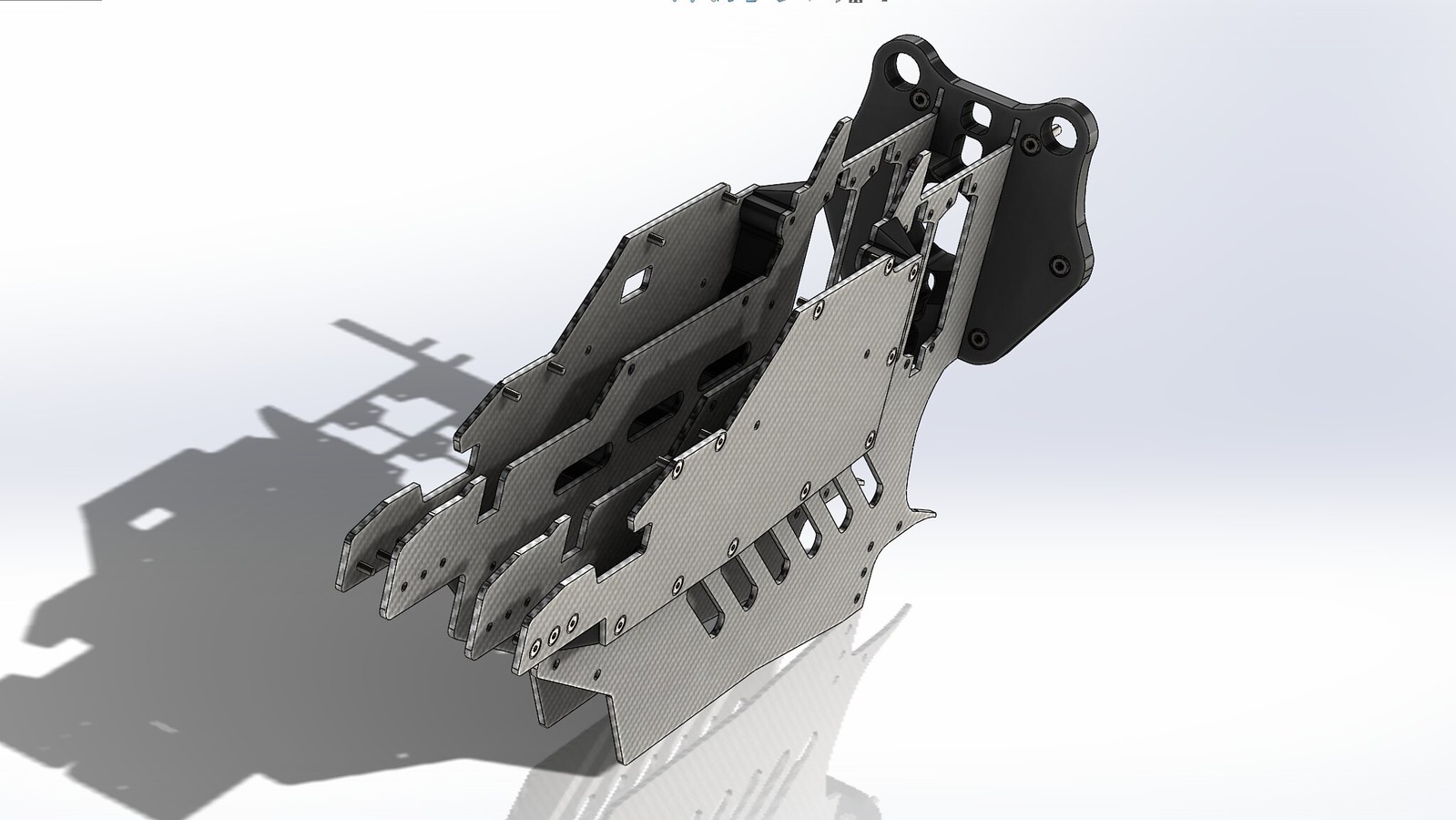

Topview with a nice view of the component layout

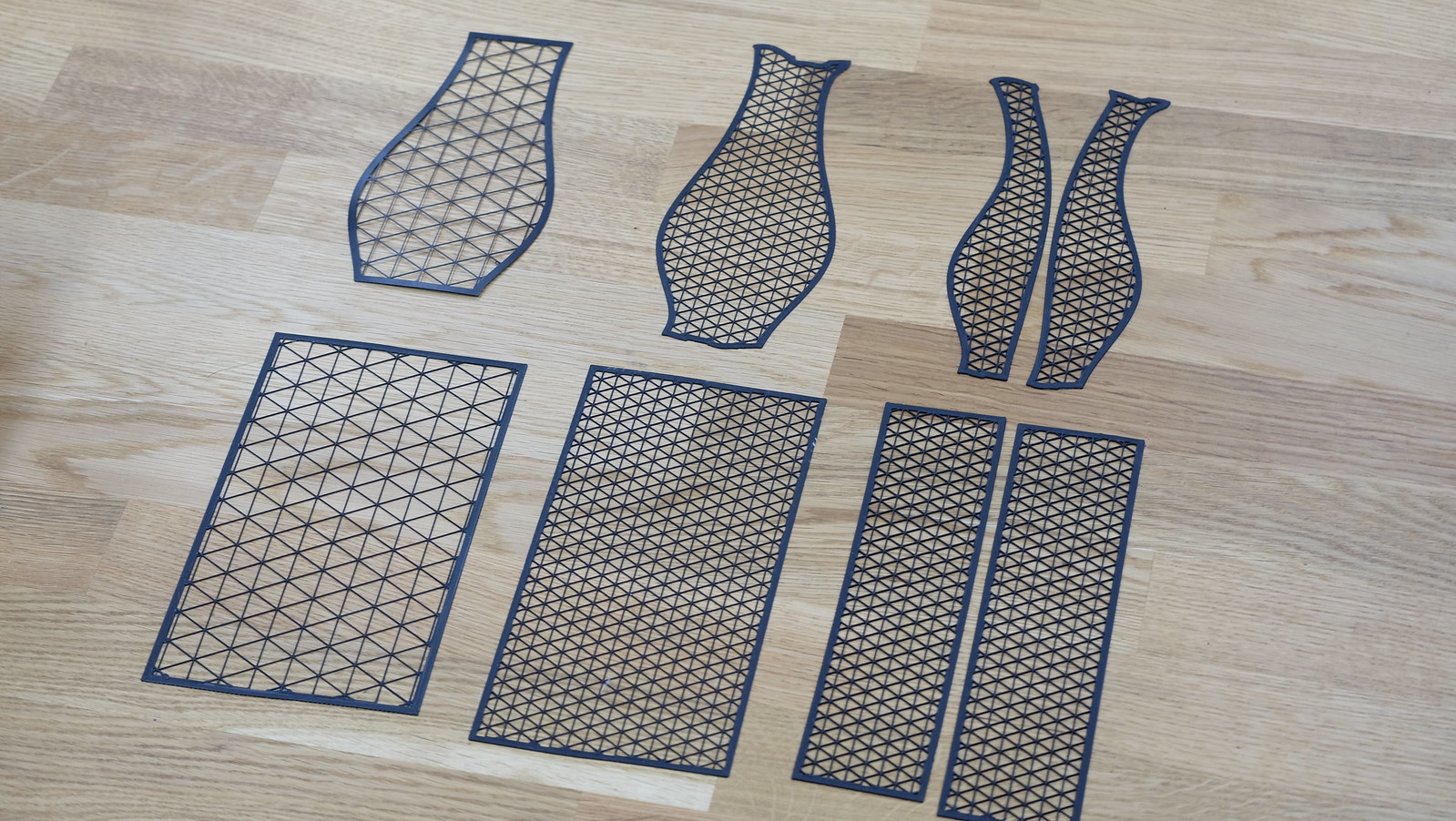

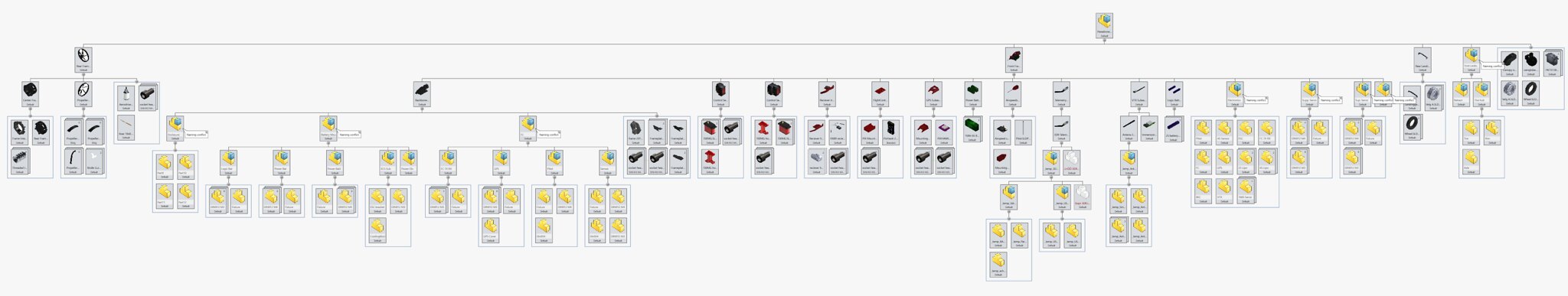

As I said, I'm fixing the assemblies and am trying to create some structure. This means that the parts are put in subassemblies that make sense and those subassemblies are mated in the final complete assembly. Solidworks has a nice tool that helps visualize the structure of the model called "treehouse"

This overview isn't complete but does give a realistic pretty accurate view of the build.