Introduction

This is the updated version of the Diamond. You can find the original thread here.

The plane has evolved along with my design and building style to incorporate some simpler approaches (for example the wings are FT-style-ish) and some non-traditional techniques (the score cut and gorilla glue hollow fuse sections).

Caveat emptor

Okay, the plans are free but "buyer beware" still applies. I consider this an intermediate build because some of the techniques are not traditional FT and also because the build log and plans do not aim to hold your hand while you build this. There is an assumption that you have experience building other planes and can figure some stuff out for yourself

Quia non habet esse perfectum

My favorite saying from Josh Bixler - it doesn't have to be perfect. This is a warts and all build log. I tend to apply what @rockyboy recently described as the "three foot rule" (if it looks okay from three feet away, its good) but I would broaden this to include four or even five feet.

The Plans

22 November 2018. 37 inch version is now attached to the bottom of this post. The plan package includes the sketchup model, the .DXF files, and tiled and full size PDFs.

37 Inch Specs

Wingspan = 37 inches

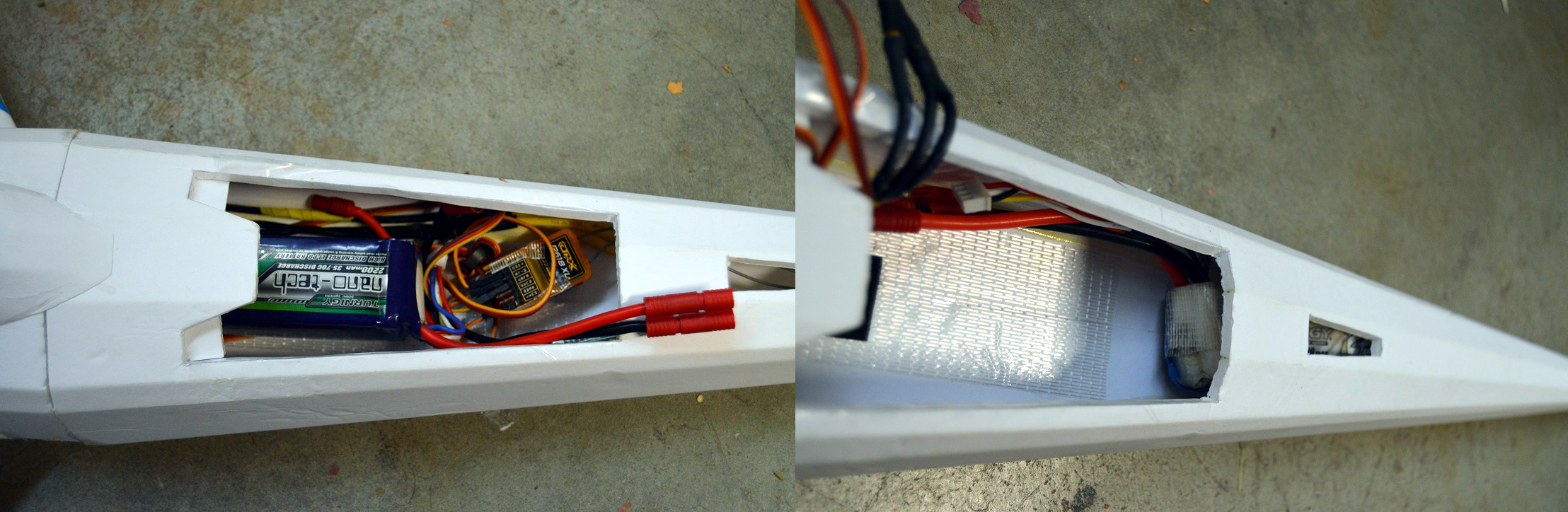

All up weight with 70mm EDF and 2200 mAh 4S = ~2lbs

CG is 3.5 inches back from the LE where the wing intersects with the fuse.

The Build

(I will be adding text to these over the next couple of days).

Plan Assembly

A - I always used tiled plans and try to optimize these, best I can, to ensure that each part fits on the minimum number of pages. I don't include cut marks (but if you use the full size plans, you can tell Adobe to add these when you print them as tiles).

B - the example shown are the wing pods. Note that in these pics the plans were not colorized yet but the final version will include standard FT color code (Black - cut through, Red - 50% score cute, Green - guide lines)

C - Almost all of the parts that are multiple sheets are drawn so that there are part lines that extend from one page to the other. Use the furthest apart pair of lines to align the sheets. Remove a tab of paper from the end of the line (page placed on pink foam to highlight the cut out tabs)

D - Lay the page with the tabs removed over its neighbor and align the pages. Depending on the quality of your printer, these may not always be 100% aligned, so get it as close as possible.

E - Use two small pieces of tape initially to join the two pages.

F - Finish with a single piece of tape across the seam.

Trim the excess paper from around each printed part to make it easier to mount to the foamboard. Note that in this build I only printed one set of wing parts (top and bottom surfaces are separate). I just turn these face down on the foamboard when I want to cut the mirror image. The final plans will contain both sets.

Frames

The build relies on using gorilla glue smeared into score cuts to provide strength and when the part is folded, hot glue is used to hold the seam together. Because the gorilla glue takes a couple of hours to set, the frames are needed to hold the part in the correct shape.

A - In this build each frame was printed once. The final plans will contain multiple images of frames if they are needed.

B - You can use scrap pieces of foamboard for the frames but ensure that you have at least 1 inch to spare all around the frame or it might rip when you use it to frame a part.

C - I almost always use the approach whereby I lay the plan on the foamboard, use a push pin to mark the corners of a part, remove the plan and use a straight edge to cut the part using a "join-the-dots" approach. It allows me to use the same set of printed plans multiple times.

D - You can see the pattern of pin holes that mark the piece on the foamboard.

E - The frame fully cut. Try not to extend your cuts beyond the points on the plan as this will weaken the frame

F - All the the frames ready for use. Note that these frames can be used for multiple builds so keep them when you are finished building the plane

Wing Box Support

Earlier versions of the design suffered a little from an issue where the inlets for the EDF needed to be big enough to feed air to the EDF while not removing too much foamboard from the fuselage side wall in order to support the wing. In this version, a box is constructed and inserted under the wing with glue on the top and bottom surfaces. This means the wing is affixed to the floor of the plane so that the fuselage side wall is no longer needed to hold the wing.

A - The part laid on a piece of foam. In the final plan versions the "B-Folds" will be clearly marked. I use push pins to hold the plan onto the foamboard then work my way around with another pin to mark the corners that I need to cut.

B - The piece is cut and the trenches for the B-Folds are removed FT style.

C - Dry fit of the part to make sure it fits together properly

D - Like good tableware etiquette, work your way from the outside to the inside when gluing the B-Folds, and try to keep the folds square.

E - The final part glued up.

F - Added some extreme packing tap across the seam. If you do this, remove the tape that obstructs one of the channels as your EDF wires will run down under the wing into the nose.

Vertical Stabilizer Cut and Fold

A - Cut the part per the plans and add the score cuts

B - Use a blunt ended BBQ skewer to open up the score cuts slightly

C - Fold the part and ensure that the trailing edges align well.

Horizontal Stabilizer

A - Cut the part and score and bevel the aileron hinge. I always add a strip of tape on the top surface of control surfaces to reinforce the paper and always follow the FT technique of adding some hot glue to the bevel and then scraping it off to strengthen the hinge and stop the paper from delaminating

B, C, D - Although not 100% necessary, I like to add wood support to the HS. Trench the foam to match whatever spar you choose to use and hot glue in place (not included in plans) Later you will see I added another piece of wood to the elevator in the same fashion.

Canopy / Turtle Deck

A, B - Cut and score the piece per the plans. Slightly widen the score cuts with a blunt tipped BBQ skewer. Note that I marked all of my pin holes with a pencil. Sometimes when cutting the pieces I lose the pin hole which means I one end of the score cut. The pencil mark serves as a backup.

C - Fold over each section of the part to establish its shape - You can overfold it to help it hold its shape a little while gluing together

D - Working your way from the front, use hot glue to join the sides of each adjacent section. You should try to keep the piece folded in its approximate shape to make it easier to align the sections. The finished part will likely try to spring back to a flat piece when you are done - don't worry, the tabs will pull it back to the correct shape when you install in onto the fuse.

Rear Fuse

A, B - When marking and cutting this part you will see holes marked in green with the instruction "Transfer to other side". These outline holes that you will cut later in the build process, from the outside of the assembled piece (when the gorilla glue is set). You will see this feature on a number of parts. To transfer, use a push pin to push through the foamboard to the other side (you can place a scrap piece of foamboard underneath to make this easier). Flip the piece over and join the dots with pencil to mark the hole you will cut out later.

C - Widen the score cuts with a blunt tipped BBQ skewer. Note that some of the score cuts (normally the ones closest to the edge (which will be the seam when the part is finished) will need extra widening to help the piece fold properly. To do this, hold the BBQ skewer at an angle and to the side and drag it down the length of the score cut, almost making a bevel.

D - Dry fit the folded part into its frames (one at the front and one at the rear). Try to ensure that the part fills the frame, taking on the correct shape. If some of the sides don't sit flush with the frame, you may need the widen the score cuts a little more to allow the part to "relax" into the frame.

Center Fuse

A - The part is constructed the same as the rear fuse. On this part, the "Transfer To Other Side" instructions mark out the wing hole and the EDF inlet. Note that in panel A, only the outline of the combined wing hole and inlet are drawn. In the plans the two are marked separately and you should draw both as such. This is because when installing the wing, you should only remove the wing hole part first, install the wing, and later remove the EDF inlet.

B - Here you can see how the outer score cut was widened, almost to a bevel, to allow the piece to fold correctly.

Nose

The nose is a bit of a pain to construct, mostly because there is too much foam competing for not enough space right at the tip. For previous builds I just kept manipulating and crushing foam until I could get it to fold. In the current plans I have included a couple of small trenches to help to nose fold a little easier. Warning - the following is a bit of a hack job.

A - As part of this build I tried quite a few approaches to optimize how the last 6 or 7 inches of the nose would fold and eventually came up with a set of steps that seems to work repeatedly.

B - On the plans there will be guidelines marked across the tip of the nose part.

C - remove foam from the two marked trenches.

D - Roll a pencil or pen from the mark to the tip to crush the foamboard. Repeat a couple of times.

E - Remove the very tip of the nose as indicate in the plans

F - Dry fit the folded nose into the appropriate frames. Note that in this picture, the frames were cut a little large and therefore fit close to the base of the nose. These are updated in the finished plans to better cover the length of the nose. in reality, only the frame at the base is critical because it creates the shape of the interface between the nose and the rest of the fuselage

Assembling the Fuselage and Nose Parts

I suggest setting the fuse parts up first before assembling the wings. The glue in the center fuse section should be set before trying to install the wings.

All three sections are glued and assembled the same way. Wear gloves when using gorilla glue, it doesn't wash off well. I prefer the original gorilla glue to the newer white stuff which I don't think is as strong (could just be my opinion). Note also that gorilla glue ages, like a good wine. The glue will flow more freely and foam up more than older stuff, so if you glue is fresh try not to use too much.

A - Get organized so that you have your parts ready to go. I collect scraps of foam throughout the build and cut into approx 1/2 strips that I used to smear the gorilla glue into the score cuts.

B - Tape a scrap piece of foam to the bench and pour a health dipping pool of gorilla glue. Open up the part to be glued so that the score cuts open up and you can get the glue in there.

C - Score cuts prepped. Now run a bead of hot glue along one edge of the part and fold it over. I find it easiest to bring the two edges together with the part sitting seam-down on the bench - just slide it around a little so the part doesn't stick to your working surface. Then put the part back in its frames and wait for it to set. All three fuselage pieces are glued in this fashion

A - When hot gluing the nose, try doing it in two steps, leaving about 5 inches of the tip until last. Even then you may not end up with a perfectly flush seam, don't worry about it.

B - If your seam is a little open, like mine, just fill the gap with some hot glue.

Wing Construction

The wing is like many of the FT wing builds with a couple of small differences. It is a thin wing (3 foamboard thicknesses max height).

A - In the tiled version of the plans the wing panels (four of them) are separate pieces. Cut and score according to the plans and cut and bevel the ailerons.

B - Turn the pieces upside down (so you can no longer see the score cuts and spar guide lines) and tape the two halves together. Focus on the alignment of the wing tips and not so much the roots

C - Turn the joined pieces back (right side up). Widen the score cuts slightly with a blunt tipped BBQ skewer and bevel the leading edge (LE). Note that I no longer blade cut these LE bevels, I just use a BBQ skewer held at an angle to "crush" the bevel in. Works fine and is fast and safe. Hot glue the spar in place making sure the the spar sits approx 1/8 inch away from the root edge which will allow the servo wires to run through to the front of the wing. Note that although the spars are included in the plans, you just need to cut a 1/2 inch wide strip of foam, 20 inches long, and trim it to fit.

D - using your wing spar reinforcement of choice (I use a strip of 12 inch paint stirrer stick that is 2 foamboard thicknesses wide) mark a trench on the bottom surface and the LE side of the spar. Score cut, remove the foam, and hot glue in your spar. Again, leave the spar approx 1/8 inch short of the root edge for the servo wires to pass.

E - Servo placement is not marked on the plans. I place the servo so that the arm is approximately in the center of the aileron. The pocket for the servo is on the trailing edge (TE) side of the foam spar. Make the pocket large enough to include the servo arm and ensure that when your servo is powered up it will center by pushing the arm down through the bottom surface of the wing (you can cut a relief for the arm if you wish).

F - when you have the servo glued into the pocket, use a felt tip pen / sharpie to mark the edges of the servo and fold the wing so that the upper panel touches the servo. This will leave an imprint on the upper wing surface that you also need to pocket so that the wing will fold properly.

A - Install servo extensions. After applying hot glue to the spar, top of servo, and trailing edge of the lower surface, fold the wing FT style. The only specific thing that I watch for at this point is that the wing tip stays flat on the bench while I am folding and holding the wing. Note that sometimes there is a slight overhang at the root and tip. Don't worry about it, just trim of the excess.

B - Repeat for the second half of the wing

C - Take a piece of stir stick, typically 6 inches long and 1/2 inch wide and apply glue to one half. Slide it into one of the wing roots in a position where it is snug. Make sure that the stick points perpendicular to the root edge.

D - Make sure the servo extensions run forward and exit the wing at the nose. Apply glue to the root edge of the wing and to the remaining spar and join the wing halves FT style. You might want to dry fit this first.

Wing Installation

Don't attempt to install the wing until the gorilla glue in the fuselage section is set.

A - Using a sharp blade cut out the wing hole. These are a little tight and you may need to rub the upper wing surface with sand paper to open up the slot. Don't widen the lower wing surface part of the hole unless you know the holes on either side of the fuse are not level.

B - Push the servo wires back inside the wing. Install the wing. This will take a bit of pushing and rocking back and forth. Once it is in, take some time to confirm it is square with the fuselage. The length from the wing tip to the fuse should be the same either side (red lines) and the length from the TE wing tip to the front of the fuse section should be the same (green lines). Once the wing is square, glue the wing in place FT style noting that you should not glue the wing where the EDF inlet is marked

C - Dry fit the wing box under the wing. This will be tight, you don't have to push it in all the way for dry fit. Put a thin layer of gorilla glue on to the top and bottom surfaces of the wing box and slide it under the wing. Push it back under the wing until it feels like it will not go back any further. Tidy up / remove excess gorilla glue.

Pusher Motor Mount

A - The pusher mount is made in two pieces that are double thickness. Score, add hot glue and fold to make each piece

B - The two pieces made

C - The pieces interlock. Apply hot glue to all contacting surfaces and assemble the mount. At this point you may want to add your firewall and add tape to reinforce the firewall attachment to the mount.

D - The pusher mount just slips into the end of the rear fuselage part. Note the markings on the plans as to which way the parts should be oriented. Hot glue the mount in place.

EDF Holder

A - Parts ready to cut and mount. This EDF has a removable front lip which makes installing into the foamboard holder easier. If your EDF does not have a removable lip and you need to bring the holder from the rear, you will need to split it to go around the wires.

B - When cutting the EDF holder, cut the circle first and ensure that it fits easily onto your EDF before cutting the holder part completely

C - Holder part is cut and dry fit into the rear fuselage part.

D - Align the EDF in the holder so that the wires will come out through the bottom slot which was not in these original plans but is included in the final version). Add your motor extension wires (they need to cover the distance from the EDF to the hatch. Hot glue the EDF into the holder by running a bead of glue all around the circumference at the junction between the EDF and holder.

Just exceeded the 20,000 character limit for a post! Continued on next post.

Final product of this build:

DamoRC

This is the updated version of the Diamond. You can find the original thread here.

The plane has evolved along with my design and building style to incorporate some simpler approaches (for example the wings are FT-style-ish) and some non-traditional techniques (the score cut and gorilla glue hollow fuse sections).

A recent build for a friend at my local field

Now for some latin

Caveat emptor

Okay, the plans are free but "buyer beware" still applies. I consider this an intermediate build because some of the techniques are not traditional FT and also because the build log and plans do not aim to hold your hand while you build this. There is an assumption that you have experience building other planes and can figure some stuff out for yourself

Quia non habet esse perfectum

My favorite saying from Josh Bixler - it doesn't have to be perfect. This is a warts and all build log. I tend to apply what @rockyboy recently described as the "three foot rule" (if it looks okay from three feet away, its good) but I would broaden this to include four or even five feet.

The Plans

22 November 2018. 37 inch version is now attached to the bottom of this post. The plan package includes the sketchup model, the .DXF files, and tiled and full size PDFs.

37 Inch Specs

Wingspan = 37 inches

All up weight with 70mm EDF and 2200 mAh 4S = ~2lbs

CG is 3.5 inches back from the LE where the wing intersects with the fuse.

The Build

(I will be adding text to these over the next couple of days).

Plan Assembly

A - I always used tiled plans and try to optimize these, best I can, to ensure that each part fits on the minimum number of pages. I don't include cut marks (but if you use the full size plans, you can tell Adobe to add these when you print them as tiles).

B - the example shown are the wing pods. Note that in these pics the plans were not colorized yet but the final version will include standard FT color code (Black - cut through, Red - 50% score cute, Green - guide lines)

C - Almost all of the parts that are multiple sheets are drawn so that there are part lines that extend from one page to the other. Use the furthest apart pair of lines to align the sheets. Remove a tab of paper from the end of the line (page placed on pink foam to highlight the cut out tabs)

D - Lay the page with the tabs removed over its neighbor and align the pages. Depending on the quality of your printer, these may not always be 100% aligned, so get it as close as possible.

E - Use two small pieces of tape initially to join the two pages.

F - Finish with a single piece of tape across the seam.

Trim the excess paper from around each printed part to make it easier to mount to the foamboard. Note that in this build I only printed one set of wing parts (top and bottom surfaces are separate). I just turn these face down on the foamboard when I want to cut the mirror image. The final plans will contain both sets.

Frames

The build relies on using gorilla glue smeared into score cuts to provide strength and when the part is folded, hot glue is used to hold the seam together. Because the gorilla glue takes a couple of hours to set, the frames are needed to hold the part in the correct shape.

A - In this build each frame was printed once. The final plans will contain multiple images of frames if they are needed.

B - You can use scrap pieces of foamboard for the frames but ensure that you have at least 1 inch to spare all around the frame or it might rip when you use it to frame a part.

C - I almost always use the approach whereby I lay the plan on the foamboard, use a push pin to mark the corners of a part, remove the plan and use a straight edge to cut the part using a "join-the-dots" approach. It allows me to use the same set of printed plans multiple times.

D - You can see the pattern of pin holes that mark the piece on the foamboard.

E - The frame fully cut. Try not to extend your cuts beyond the points on the plan as this will weaken the frame

F - All the the frames ready for use. Note that these frames can be used for multiple builds so keep them when you are finished building the plane

Wing Box Support

Earlier versions of the design suffered a little from an issue where the inlets for the EDF needed to be big enough to feed air to the EDF while not removing too much foamboard from the fuselage side wall in order to support the wing. In this version, a box is constructed and inserted under the wing with glue on the top and bottom surfaces. This means the wing is affixed to the floor of the plane so that the fuselage side wall is no longer needed to hold the wing.

A - The part laid on a piece of foam. In the final plan versions the "B-Folds" will be clearly marked. I use push pins to hold the plan onto the foamboard then work my way around with another pin to mark the corners that I need to cut.

B - The piece is cut and the trenches for the B-Folds are removed FT style.

C - Dry fit of the part to make sure it fits together properly

D - Like good tableware etiquette, work your way from the outside to the inside when gluing the B-Folds, and try to keep the folds square.

E - The final part glued up.

F - Added some extreme packing tap across the seam. If you do this, remove the tape that obstructs one of the channels as your EDF wires will run down under the wing into the nose.

Vertical Stabilizer Cut and Fold

A - Cut the part per the plans and add the score cuts

B - Use a blunt ended BBQ skewer to open up the score cuts slightly

C - Fold the part and ensure that the trailing edges align well.

Horizontal Stabilizer

A - Cut the part and score and bevel the aileron hinge. I always add a strip of tape on the top surface of control surfaces to reinforce the paper and always follow the FT technique of adding some hot glue to the bevel and then scraping it off to strengthen the hinge and stop the paper from delaminating

B, C, D - Although not 100% necessary, I like to add wood support to the HS. Trench the foam to match whatever spar you choose to use and hot glue in place (not included in plans) Later you will see I added another piece of wood to the elevator in the same fashion.

Canopy / Turtle Deck

A, B - Cut and score the piece per the plans. Slightly widen the score cuts with a blunt tipped BBQ skewer. Note that I marked all of my pin holes with a pencil. Sometimes when cutting the pieces I lose the pin hole which means I one end of the score cut. The pencil mark serves as a backup.

C - Fold over each section of the part to establish its shape - You can overfold it to help it hold its shape a little while gluing together

D - Working your way from the front, use hot glue to join the sides of each adjacent section. You should try to keep the piece folded in its approximate shape to make it easier to align the sections. The finished part will likely try to spring back to a flat piece when you are done - don't worry, the tabs will pull it back to the correct shape when you install in onto the fuse.

Rear Fuse

A, B - When marking and cutting this part you will see holes marked in green with the instruction "Transfer to other side". These outline holes that you will cut later in the build process, from the outside of the assembled piece (when the gorilla glue is set). You will see this feature on a number of parts. To transfer, use a push pin to push through the foamboard to the other side (you can place a scrap piece of foamboard underneath to make this easier). Flip the piece over and join the dots with pencil to mark the hole you will cut out later.

C - Widen the score cuts with a blunt tipped BBQ skewer. Note that some of the score cuts (normally the ones closest to the edge (which will be the seam when the part is finished) will need extra widening to help the piece fold properly. To do this, hold the BBQ skewer at an angle and to the side and drag it down the length of the score cut, almost making a bevel.

D - Dry fit the folded part into its frames (one at the front and one at the rear). Try to ensure that the part fills the frame, taking on the correct shape. If some of the sides don't sit flush with the frame, you may need the widen the score cuts a little more to allow the part to "relax" into the frame.

Center Fuse

A - The part is constructed the same as the rear fuse. On this part, the "Transfer To Other Side" instructions mark out the wing hole and the EDF inlet. Note that in panel A, only the outline of the combined wing hole and inlet are drawn. In the plans the two are marked separately and you should draw both as such. This is because when installing the wing, you should only remove the wing hole part first, install the wing, and later remove the EDF inlet.

B - Here you can see how the outer score cut was widened, almost to a bevel, to allow the piece to fold correctly.

Nose

The nose is a bit of a pain to construct, mostly because there is too much foam competing for not enough space right at the tip. For previous builds I just kept manipulating and crushing foam until I could get it to fold. In the current plans I have included a couple of small trenches to help to nose fold a little easier. Warning - the following is a bit of a hack job.

A - As part of this build I tried quite a few approaches to optimize how the last 6 or 7 inches of the nose would fold and eventually came up with a set of steps that seems to work repeatedly.

B - On the plans there will be guidelines marked across the tip of the nose part.

C - remove foam from the two marked trenches.

D - Roll a pencil or pen from the mark to the tip to crush the foamboard. Repeat a couple of times.

E - Remove the very tip of the nose as indicate in the plans

F - Dry fit the folded nose into the appropriate frames. Note that in this picture, the frames were cut a little large and therefore fit close to the base of the nose. These are updated in the finished plans to better cover the length of the nose. in reality, only the frame at the base is critical because it creates the shape of the interface between the nose and the rest of the fuselage

Assembling the Fuselage and Nose Parts

I suggest setting the fuse parts up first before assembling the wings. The glue in the center fuse section should be set before trying to install the wings.

All three sections are glued and assembled the same way. Wear gloves when using gorilla glue, it doesn't wash off well. I prefer the original gorilla glue to the newer white stuff which I don't think is as strong (could just be my opinion). Note also that gorilla glue ages, like a good wine. The glue will flow more freely and foam up more than older stuff, so if you glue is fresh try not to use too much.

A - Get organized so that you have your parts ready to go. I collect scraps of foam throughout the build and cut into approx 1/2 strips that I used to smear the gorilla glue into the score cuts.

B - Tape a scrap piece of foam to the bench and pour a health dipping pool of gorilla glue. Open up the part to be glued so that the score cuts open up and you can get the glue in there.

C - Score cuts prepped. Now run a bead of hot glue along one edge of the part and fold it over. I find it easiest to bring the two edges together with the part sitting seam-down on the bench - just slide it around a little so the part doesn't stick to your working surface. Then put the part back in its frames and wait for it to set. All three fuselage pieces are glued in this fashion

A - When hot gluing the nose, try doing it in two steps, leaving about 5 inches of the tip until last. Even then you may not end up with a perfectly flush seam, don't worry about it.

B - If your seam is a little open, like mine, just fill the gap with some hot glue.

Wing Construction

The wing is like many of the FT wing builds with a couple of small differences. It is a thin wing (3 foamboard thicknesses max height).

A - In the tiled version of the plans the wing panels (four of them) are separate pieces. Cut and score according to the plans and cut and bevel the ailerons.

B - Turn the pieces upside down (so you can no longer see the score cuts and spar guide lines) and tape the two halves together. Focus on the alignment of the wing tips and not so much the roots

C - Turn the joined pieces back (right side up). Widen the score cuts slightly with a blunt tipped BBQ skewer and bevel the leading edge (LE). Note that I no longer blade cut these LE bevels, I just use a BBQ skewer held at an angle to "crush" the bevel in. Works fine and is fast and safe. Hot glue the spar in place making sure the the spar sits approx 1/8 inch away from the root edge which will allow the servo wires to run through to the front of the wing. Note that although the spars are included in the plans, you just need to cut a 1/2 inch wide strip of foam, 20 inches long, and trim it to fit.

D - using your wing spar reinforcement of choice (I use a strip of 12 inch paint stirrer stick that is 2 foamboard thicknesses wide) mark a trench on the bottom surface and the LE side of the spar. Score cut, remove the foam, and hot glue in your spar. Again, leave the spar approx 1/8 inch short of the root edge for the servo wires to pass.

E - Servo placement is not marked on the plans. I place the servo so that the arm is approximately in the center of the aileron. The pocket for the servo is on the trailing edge (TE) side of the foam spar. Make the pocket large enough to include the servo arm and ensure that when your servo is powered up it will center by pushing the arm down through the bottom surface of the wing (you can cut a relief for the arm if you wish).

F - when you have the servo glued into the pocket, use a felt tip pen / sharpie to mark the edges of the servo and fold the wing so that the upper panel touches the servo. This will leave an imprint on the upper wing surface that you also need to pocket so that the wing will fold properly.

A - Install servo extensions. After applying hot glue to the spar, top of servo, and trailing edge of the lower surface, fold the wing FT style. The only specific thing that I watch for at this point is that the wing tip stays flat on the bench while I am folding and holding the wing. Note that sometimes there is a slight overhang at the root and tip. Don't worry about it, just trim of the excess.

B - Repeat for the second half of the wing

C - Take a piece of stir stick, typically 6 inches long and 1/2 inch wide and apply glue to one half. Slide it into one of the wing roots in a position where it is snug. Make sure that the stick points perpendicular to the root edge.

D - Make sure the servo extensions run forward and exit the wing at the nose. Apply glue to the root edge of the wing and to the remaining spar and join the wing halves FT style. You might want to dry fit this first.

Wing Installation

Don't attempt to install the wing until the gorilla glue in the fuselage section is set.

A - Using a sharp blade cut out the wing hole. These are a little tight and you may need to rub the upper wing surface with sand paper to open up the slot. Don't widen the lower wing surface part of the hole unless you know the holes on either side of the fuse are not level.

B - Push the servo wires back inside the wing. Install the wing. This will take a bit of pushing and rocking back and forth. Once it is in, take some time to confirm it is square with the fuselage. The length from the wing tip to the fuse should be the same either side (red lines) and the length from the TE wing tip to the front of the fuse section should be the same (green lines). Once the wing is square, glue the wing in place FT style noting that you should not glue the wing where the EDF inlet is marked

C - Dry fit the wing box under the wing. This will be tight, you don't have to push it in all the way for dry fit. Put a thin layer of gorilla glue on to the top and bottom surfaces of the wing box and slide it under the wing. Push it back under the wing until it feels like it will not go back any further. Tidy up / remove excess gorilla glue.

Pusher Motor Mount

A - The pusher mount is made in two pieces that are double thickness. Score, add hot glue and fold to make each piece

B - The two pieces made

C - The pieces interlock. Apply hot glue to all contacting surfaces and assemble the mount. At this point you may want to add your firewall and add tape to reinforce the firewall attachment to the mount.

D - The pusher mount just slips into the end of the rear fuselage part. Note the markings on the plans as to which way the parts should be oriented. Hot glue the mount in place.

EDF Holder

A - Parts ready to cut and mount. This EDF has a removable front lip which makes installing into the foamboard holder easier. If your EDF does not have a removable lip and you need to bring the holder from the rear, you will need to split it to go around the wires.

B - When cutting the EDF holder, cut the circle first and ensure that it fits easily onto your EDF before cutting the holder part completely

C - Holder part is cut and dry fit into the rear fuselage part.

D - Align the EDF in the holder so that the wires will come out through the bottom slot which was not in these original plans but is included in the final version). Add your motor extension wires (they need to cover the distance from the EDF to the hatch. Hot glue the EDF into the holder by running a bead of glue all around the circumference at the junction between the EDF and holder.

Just exceeded the 20,000 character limit for a post! Continued on next post.

Final product of this build:

DamoRC

Attachments

Last edited: