ThomasMartino

Elite member

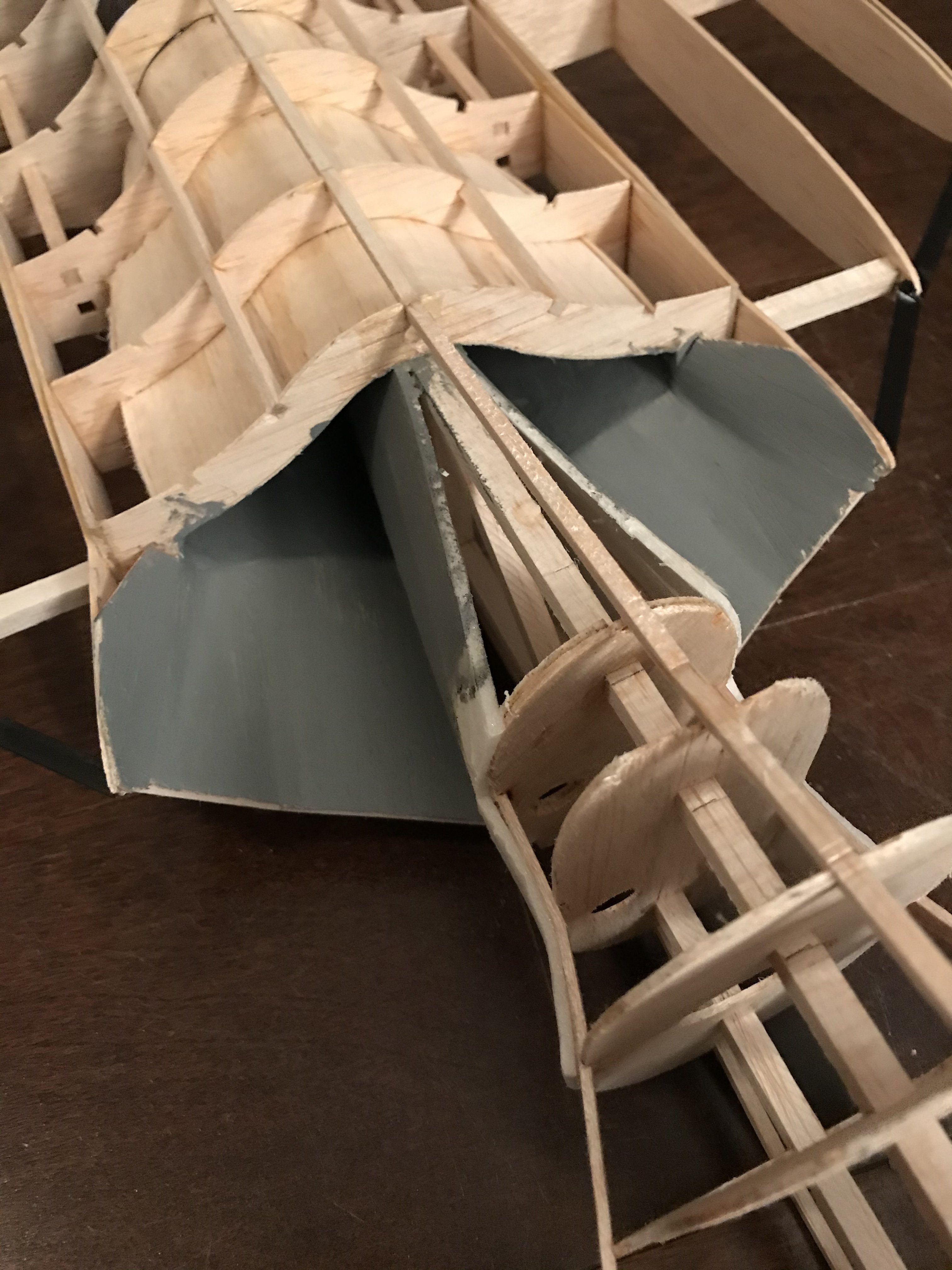

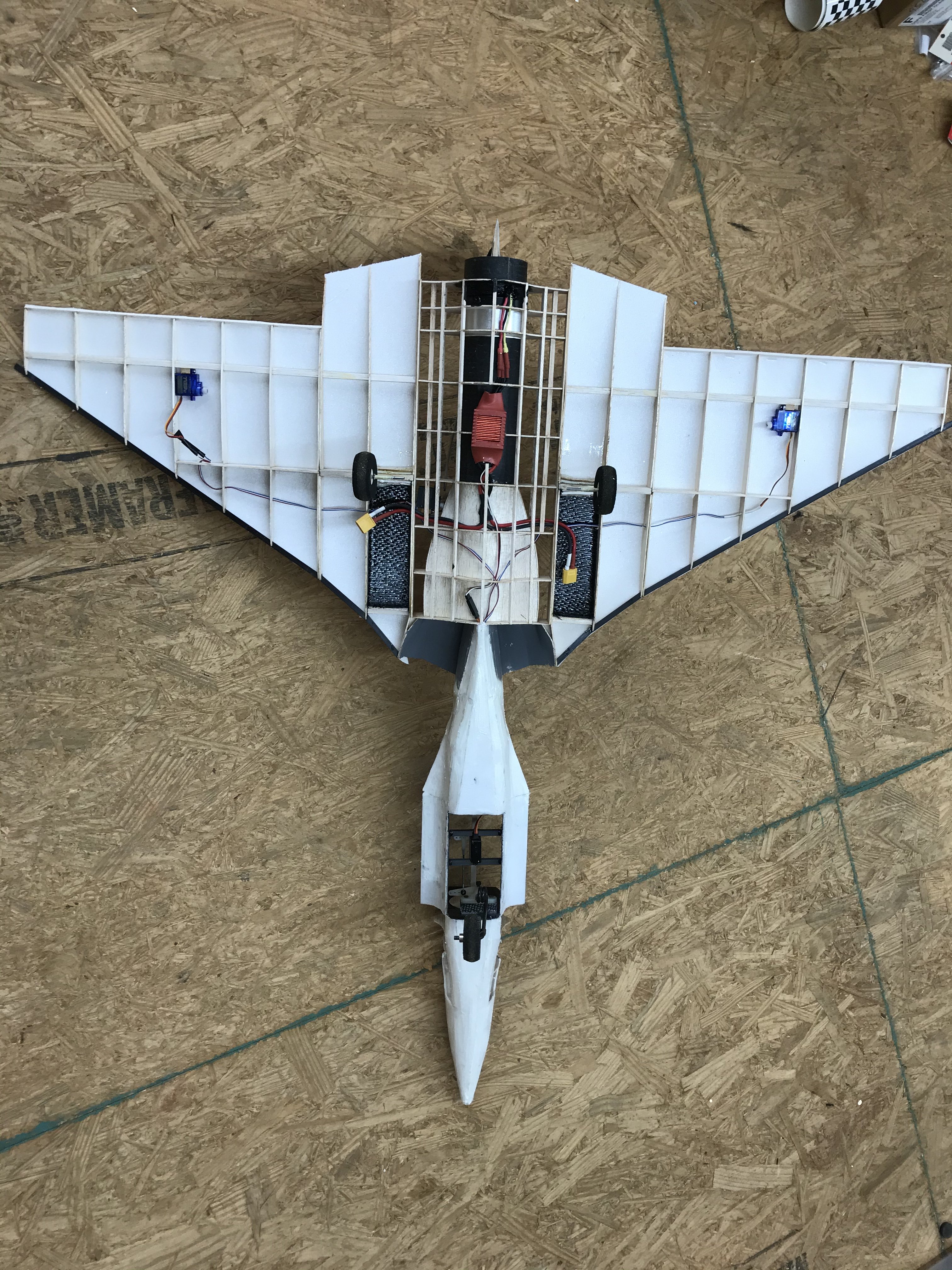

I’m five days into this project and I’m very happy with it, so I decided to make a build thread to share the process and get opinions from the community. This is my first EDF so advice is appreciated. The frame is balsa. It will be sheeted in balsa and 3mm foam then fiberglassed. I’m vacuum bagging as many of the composite parts as possible to keep the weight down and strength up. It will have elevons, full moving canards, and rudder. I decided I’ll make a fixed landing gear instead of retracts, so the top speed may suffer, but since I’m new to EDFs I’m more concerned with keeping the wing loading down so slow speed performance isn’t terrible.

Wingspan: 39 inches

Length: 39 inches

Powerplant: 64mm EDF, 800 Watts

Battery: two 4S 1,300mAh in parallel

Estimated AUW: 40 ounces

Wingspan: 39 inches

Length: 39 inches

Powerplant: 64mm EDF, 800 Watts

Battery: two 4S 1,300mAh in parallel

Estimated AUW: 40 ounces