Joe M

Member

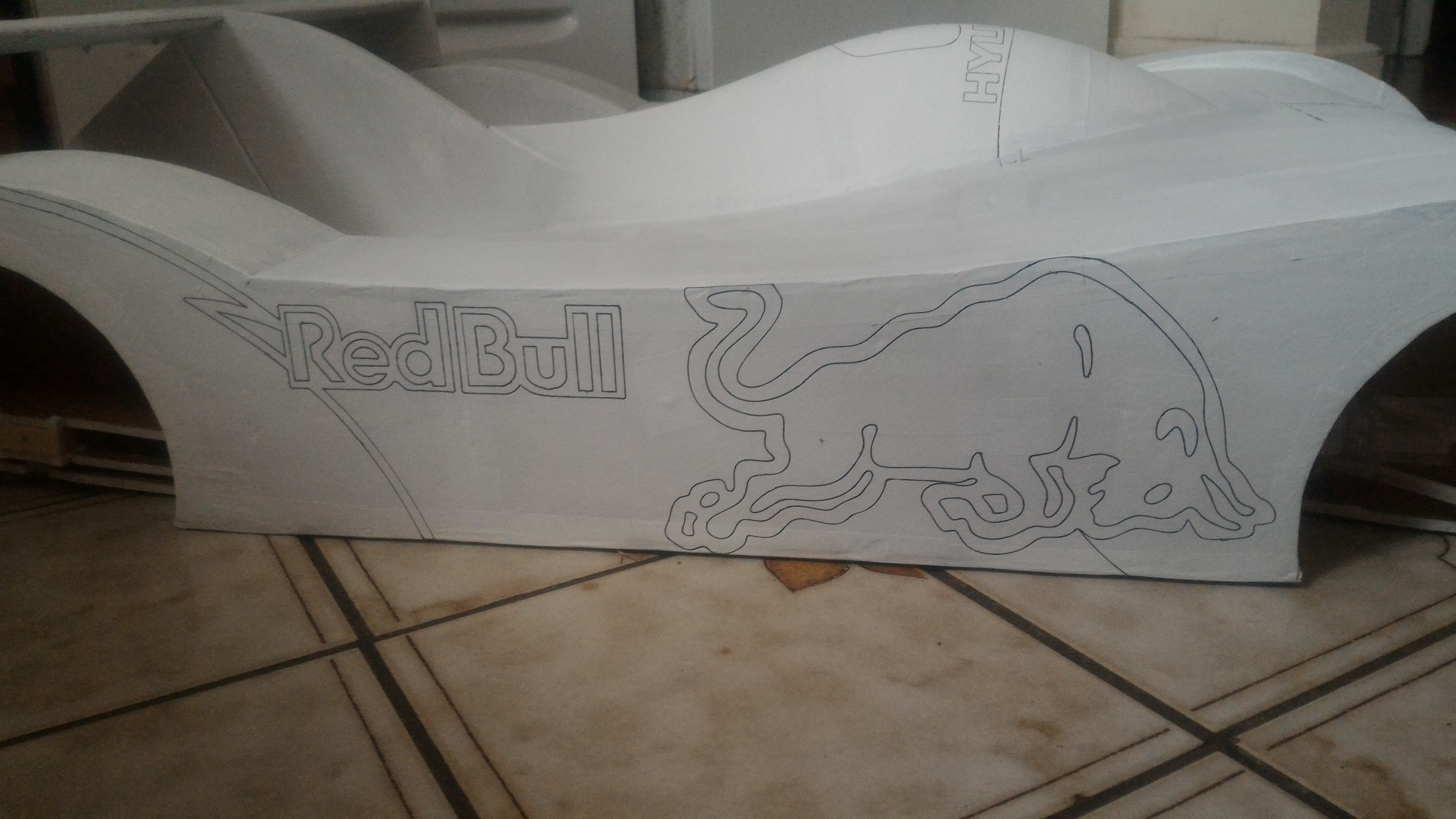

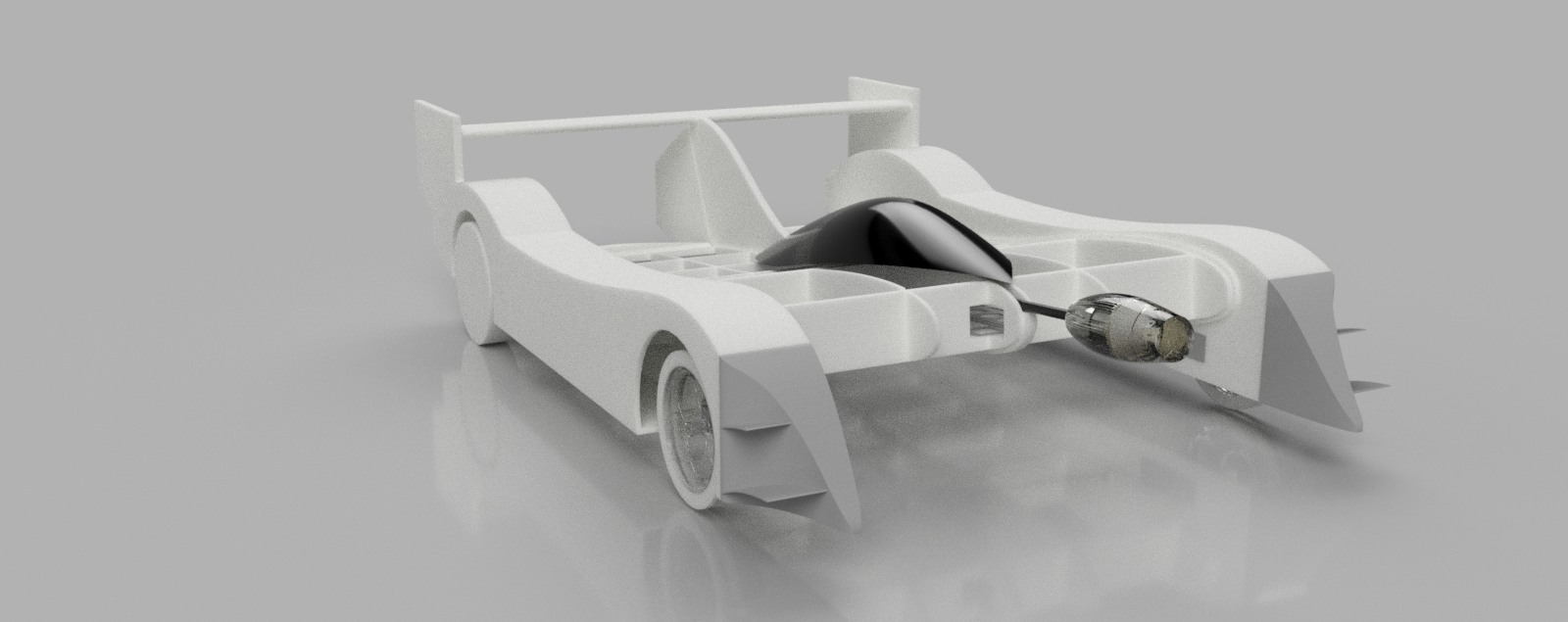

I've been planning on building a new flying car based on the RMR PM580 Pikes Peak racer for a while now. I even made a prototype a few years ago that never got off the ground. Since then I've learned a bit about 3D CAD/CAM and 3D printing and I figure it's as good a time as any to tackle this project again.

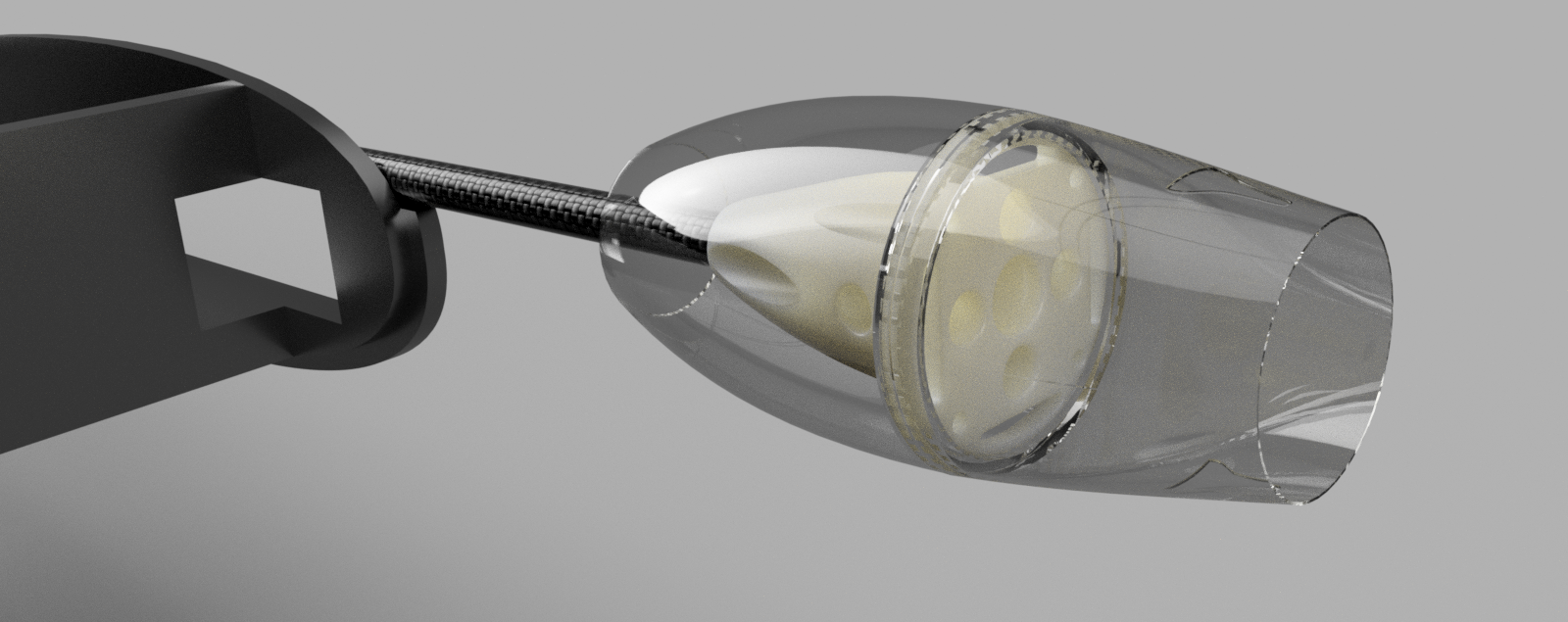

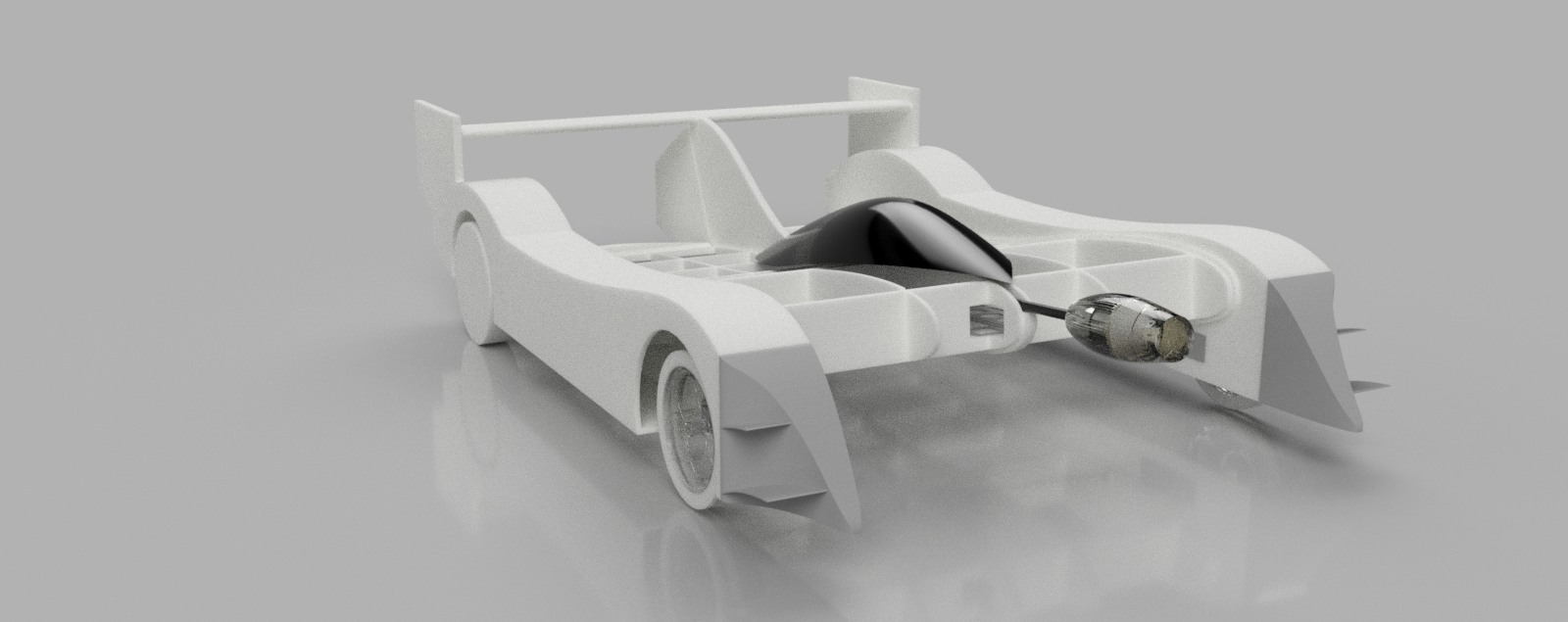

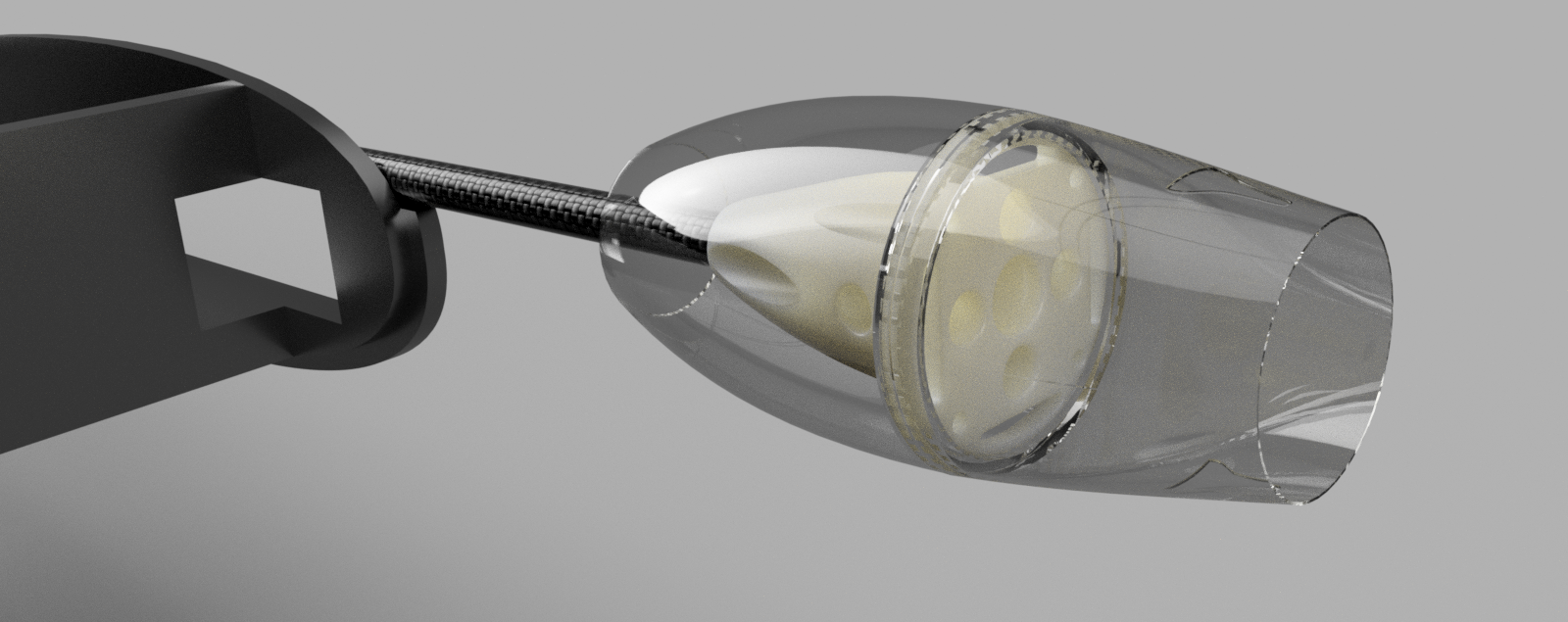

Here are some renders of what I've got in Fusion 360:

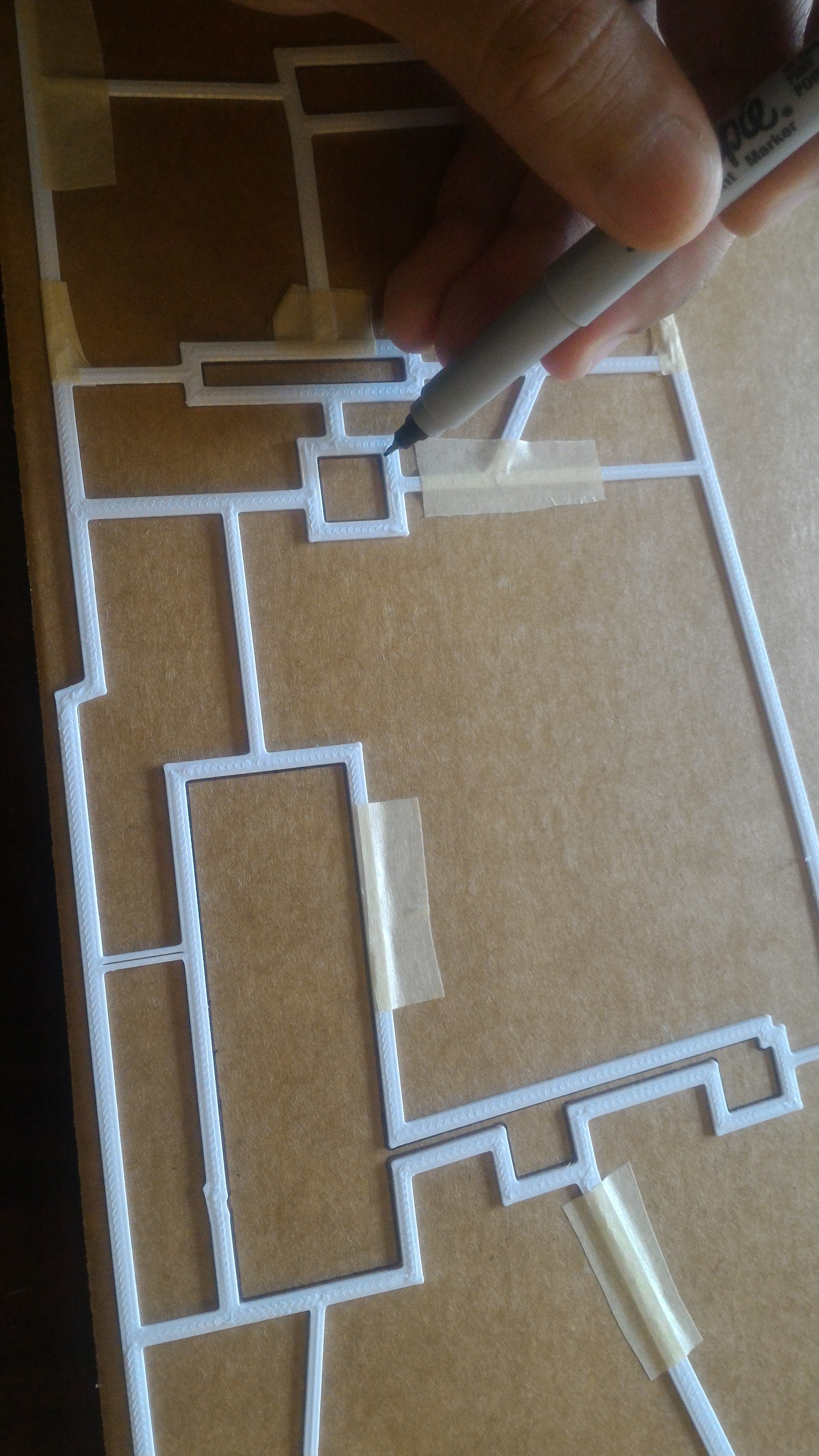

I'll be 3D printing stencils for the foam parts to save time.

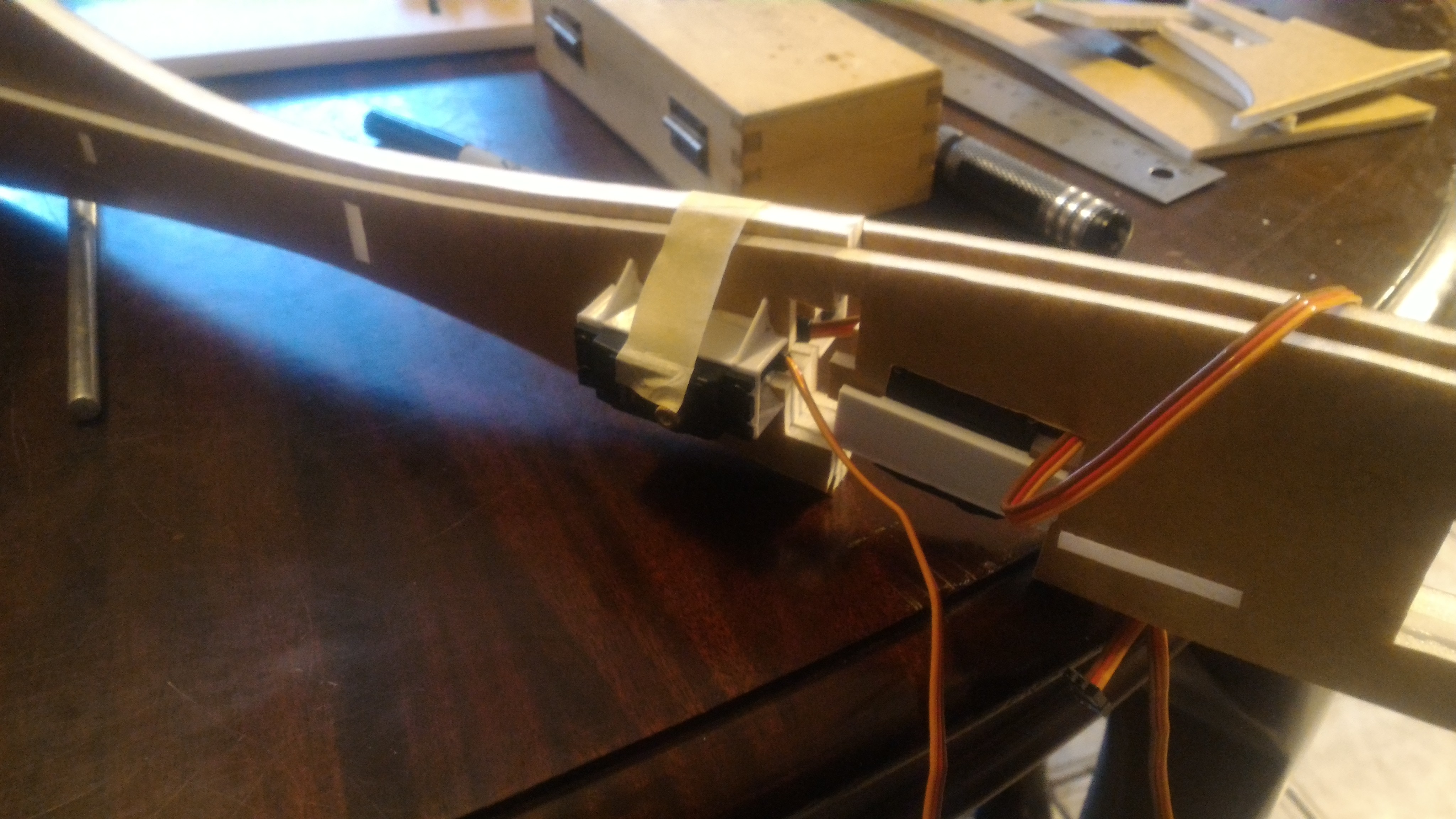

The motor pylon can be moved forwards and backwards to adjust the CG. I'll be flying this on two 4S 2200 packs, which should fit easily in the large battery bay.

The motor pylon on the front will swing a 10x6 prop. Flying time should be about 10 minutes with the power setup I've got on hand. Wing loading will be very low, around 4 to 4.5 lbs with 900 square inches of wing area.

Most of the construction will be FT foam with a carbon motor tube and a few extruded carbon flat rods for bracing. The complicated bits will be 3D printed in PLA and PETG. Assuming it builds and flies alright and there's interest I might do a redesign and post plans. If all goes smoothly I'm also planning on making some buoyant pontoon wheels for flying off water.

I am partway into the build now, so I'll start posting regular updates tonight as I get pictures and information together.

-Joe

Here are some renders of what I've got in Fusion 360:

I'll be 3D printing stencils for the foam parts to save time.

The motor pylon can be moved forwards and backwards to adjust the CG. I'll be flying this on two 4S 2200 packs, which should fit easily in the large battery bay.

The motor pylon on the front will swing a 10x6 prop. Flying time should be about 10 minutes with the power setup I've got on hand. Wing loading will be very low, around 4 to 4.5 lbs with 900 square inches of wing area.

Most of the construction will be FT foam with a carbon motor tube and a few extruded carbon flat rods for bracing. The complicated bits will be 3D printed in PLA and PETG. Assuming it builds and flies alright and there's interest I might do a redesign and post plans. If all goes smoothly I'm also planning on making some buoyant pontoon wheels for flying off water.

I am partway into the build now, so I'll start posting regular updates tonight as I get pictures and information together.

-Joe