TooJung2Die

Master member

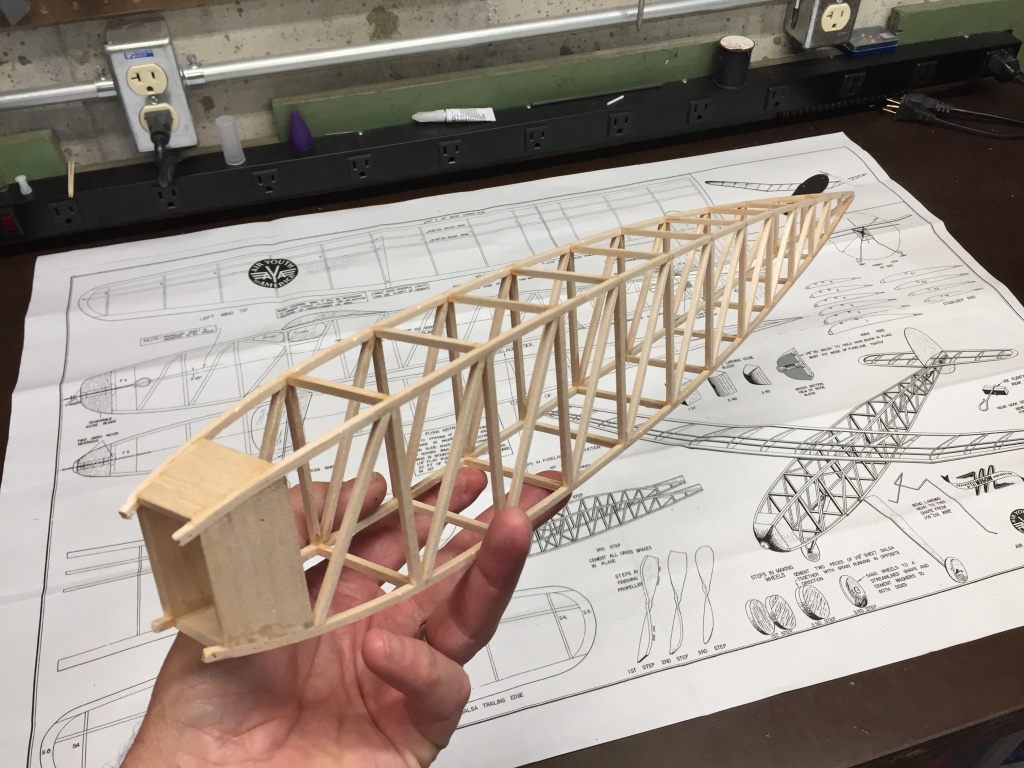

Odd name for an airplane. It's a 1930's era rubber powered design. Project #5 in "Air Youth of America" organization of the same period. I got it from Penn Valley Hobby Center. They closed their store after 50+ years in business. They were selling their remaining stock on eBay. It was a fascinating collection of vintage and old timer kits. Last time I checked even the eBay store was closed. I'm glad I bought a few before they were all gone.

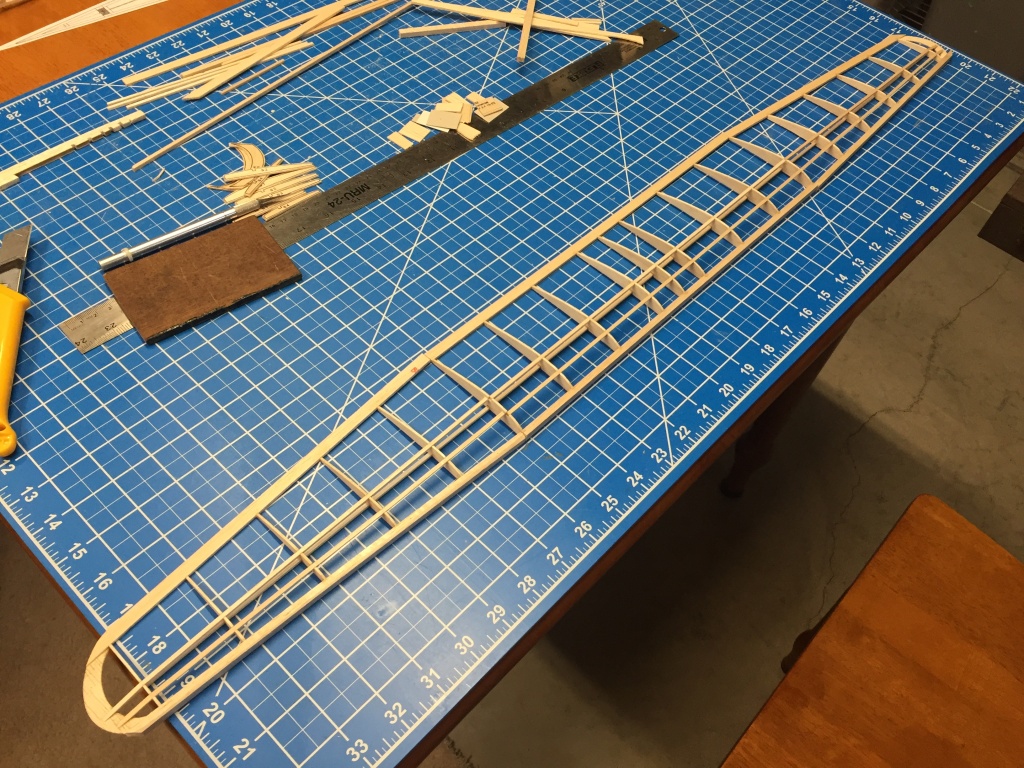

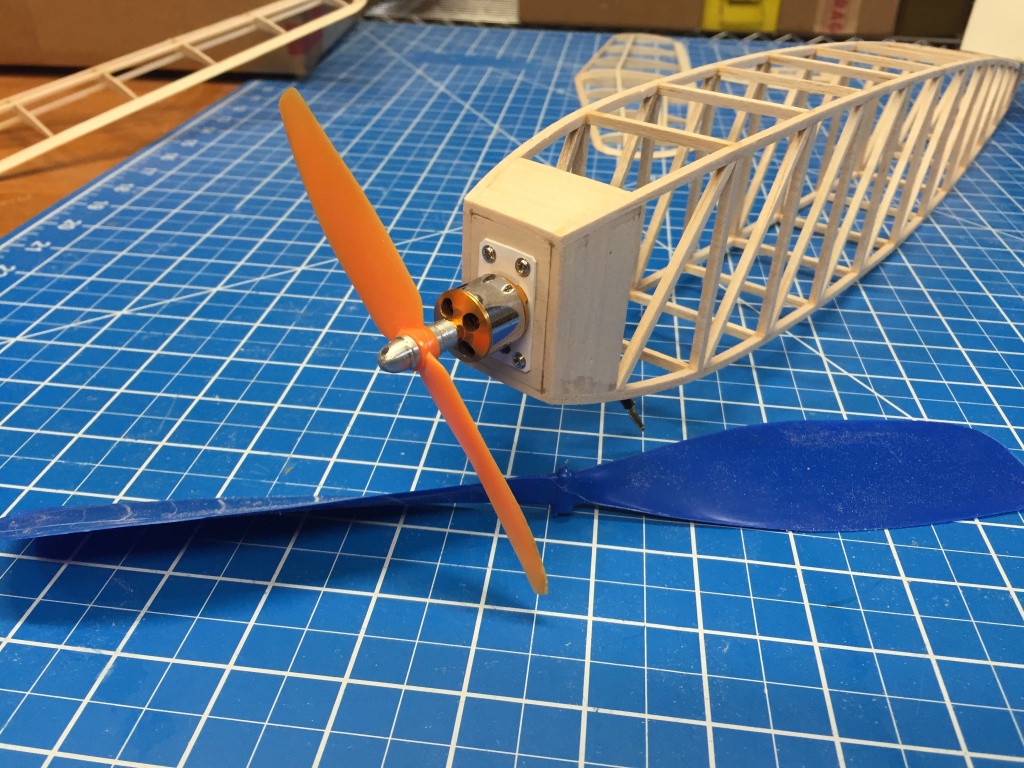

I'll be modifying the kit for electric motor RC, 3 channel, RET. I expect it will be a super light weight motor glider using the lightest RC components I have on hand. Here's a look at the kit contents. As you can see nothing is pre-cut. It is good old time printed balsa. Most of the construction is stick so there's not a lot to cut out. Look at the size of that propeller.

A close up of the plan 3D view.

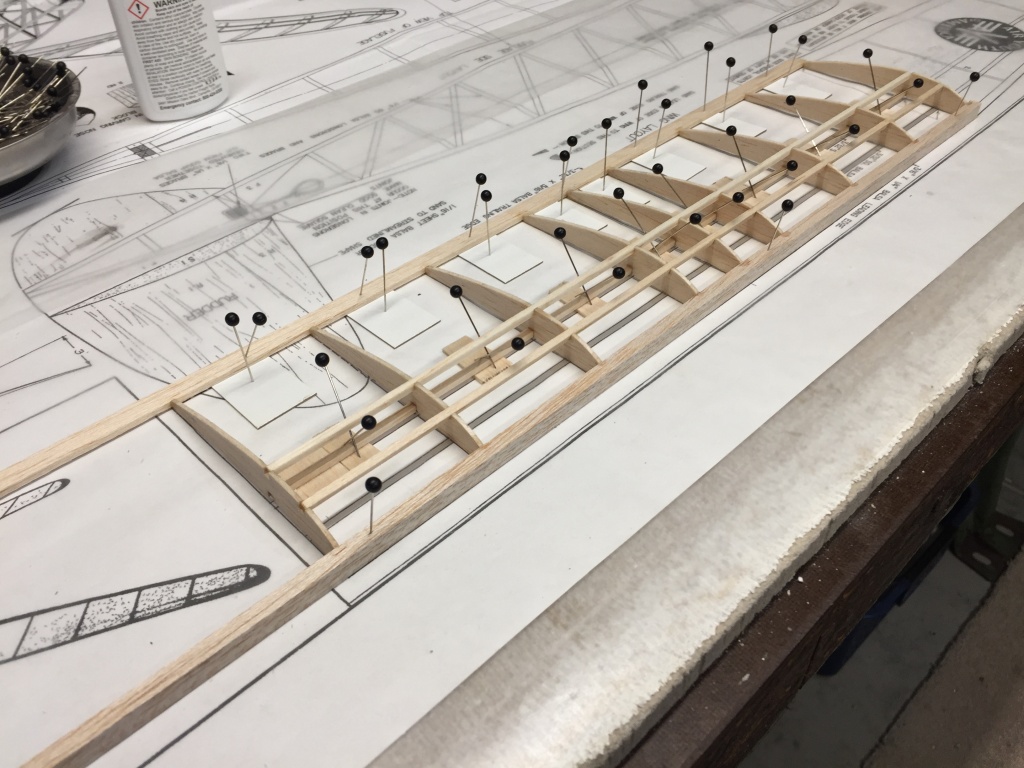

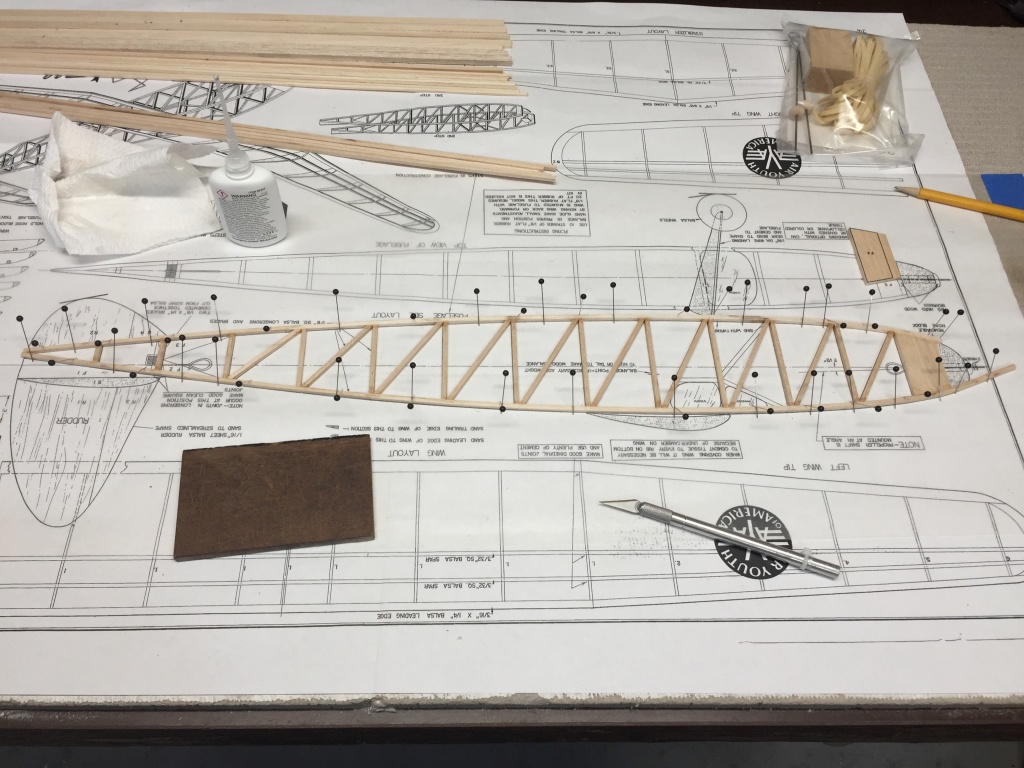

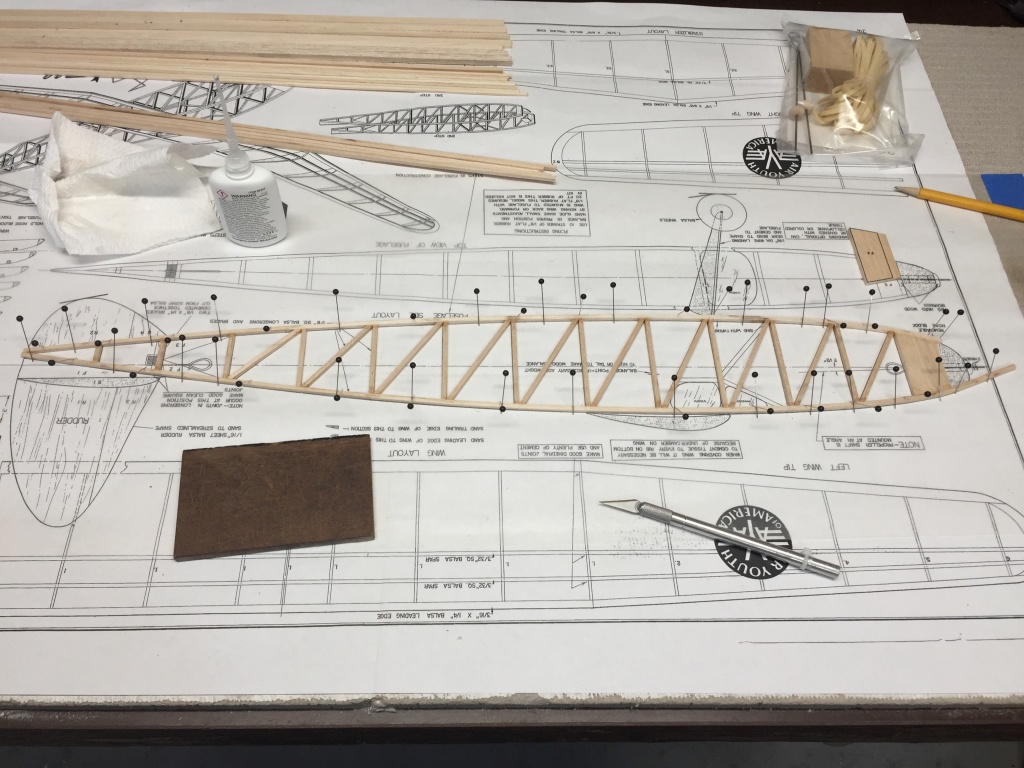

First fuselage side pinned down and glued.

I'll be taking my time, enjoying the build and post here as the project progresses.

Jon

I'll be modifying the kit for electric motor RC, 3 channel, RET. I expect it will be a super light weight motor glider using the lightest RC components I have on hand. Here's a look at the kit contents. As you can see nothing is pre-cut. It is good old time printed balsa. Most of the construction is stick so there's not a lot to cut out. Look at the size of that propeller.

A close up of the plan 3D view.

First fuselage side pinned down and glued.

I'll be taking my time, enjoying the build and post here as the project progresses.

Jon

Last edited: