dkj4linux

Elite member

Thank you, Miles, for your kind words... and for sharing your work. Welcome!Hello all and hello David,

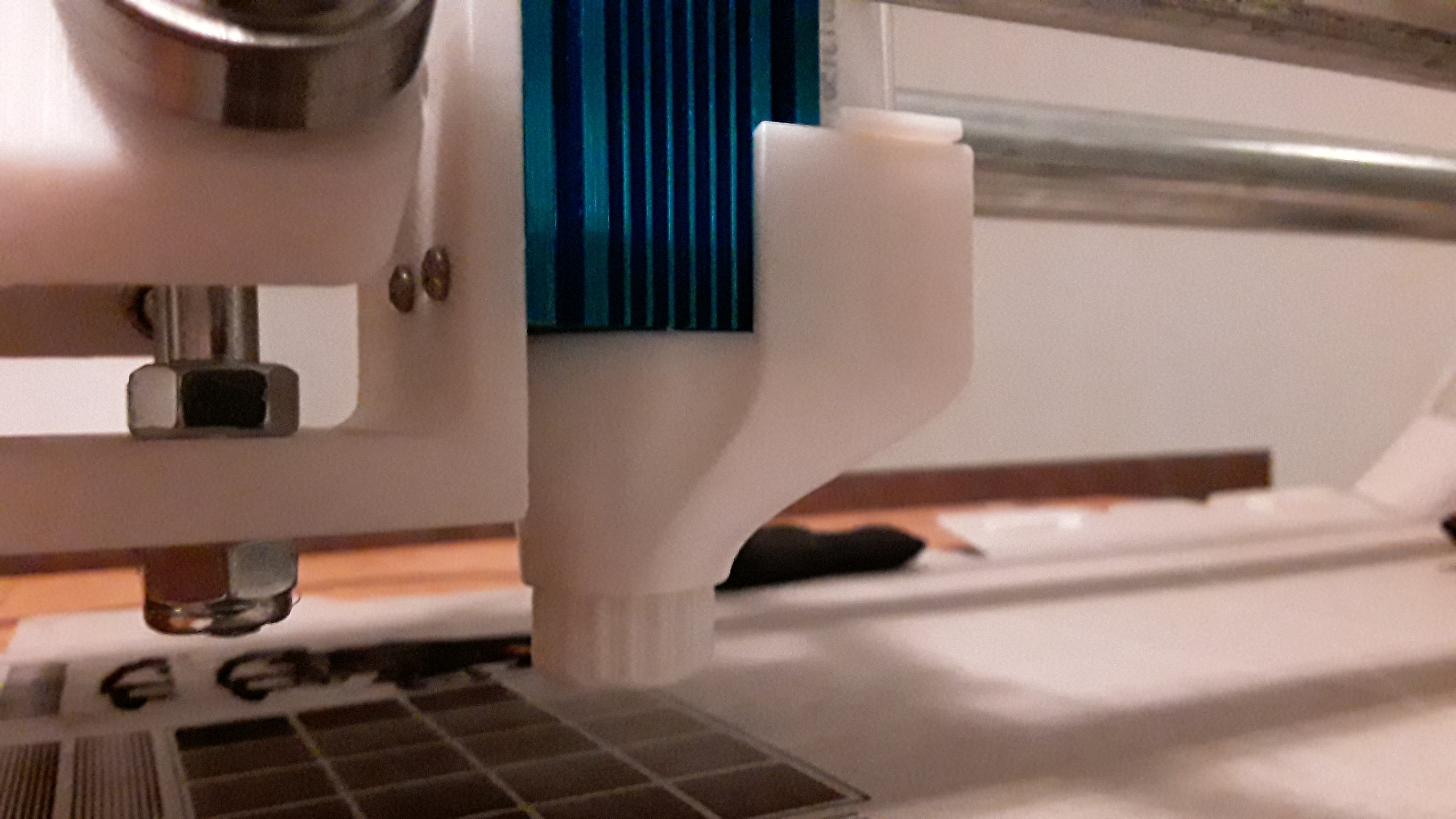

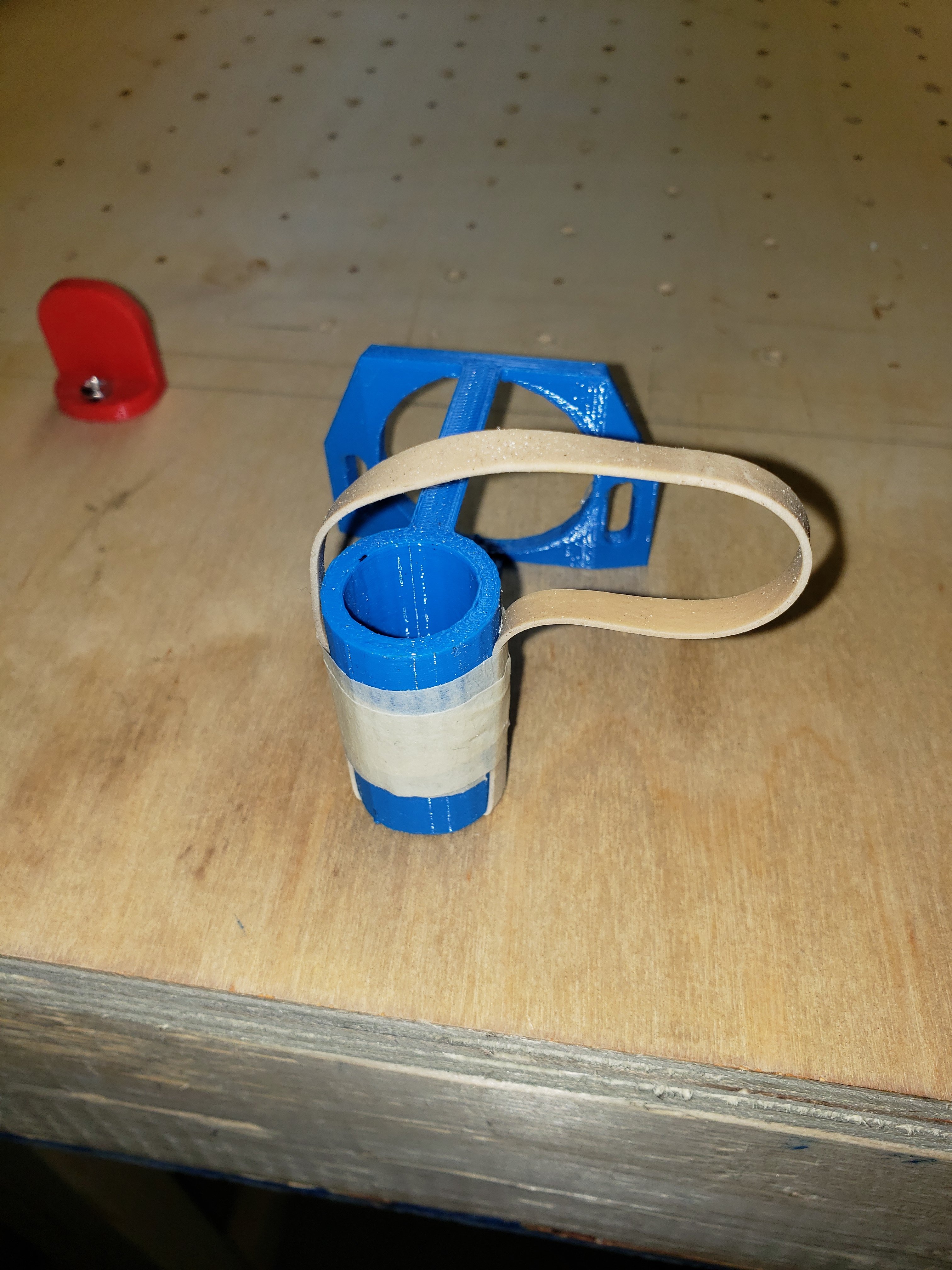

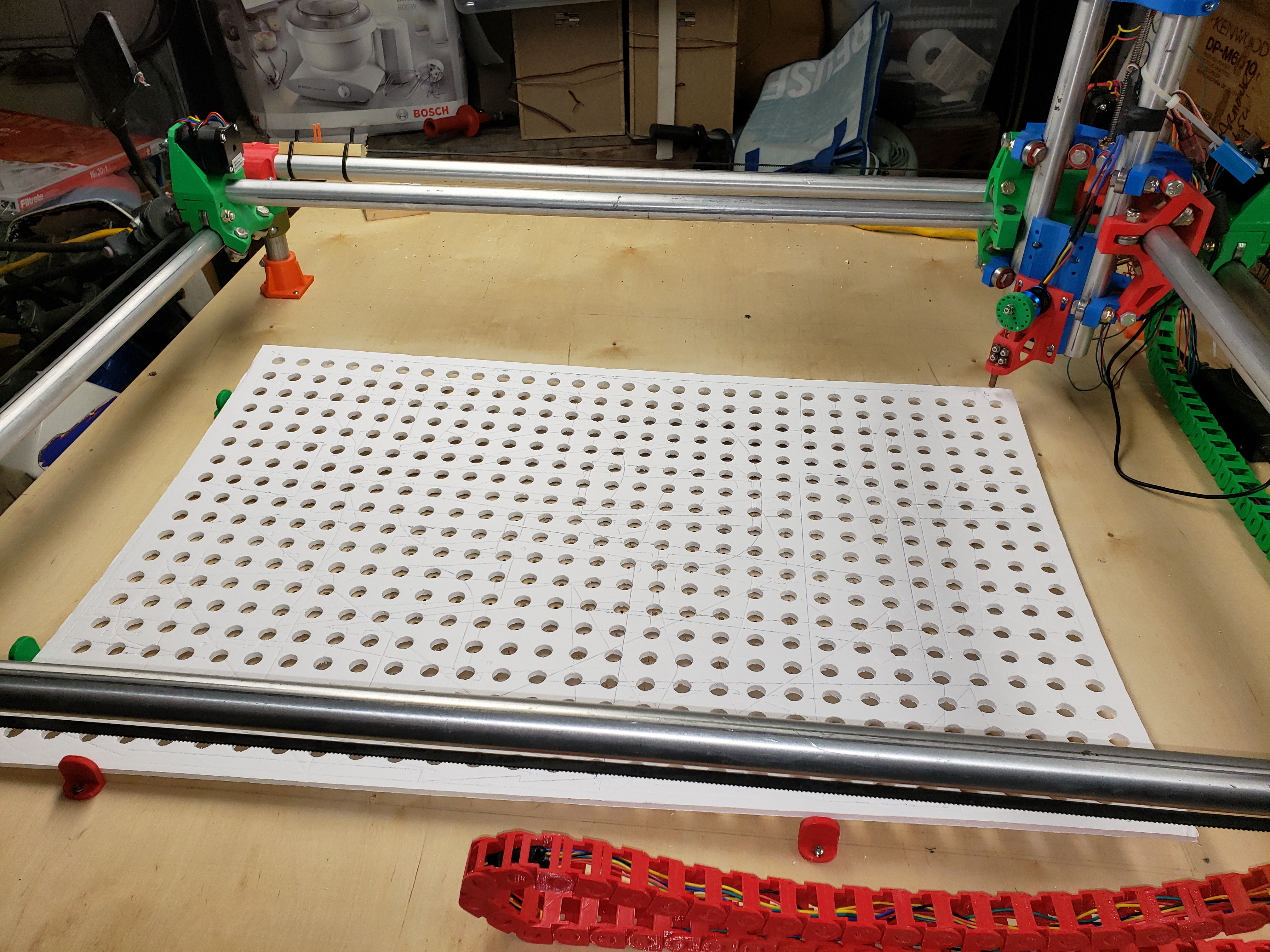

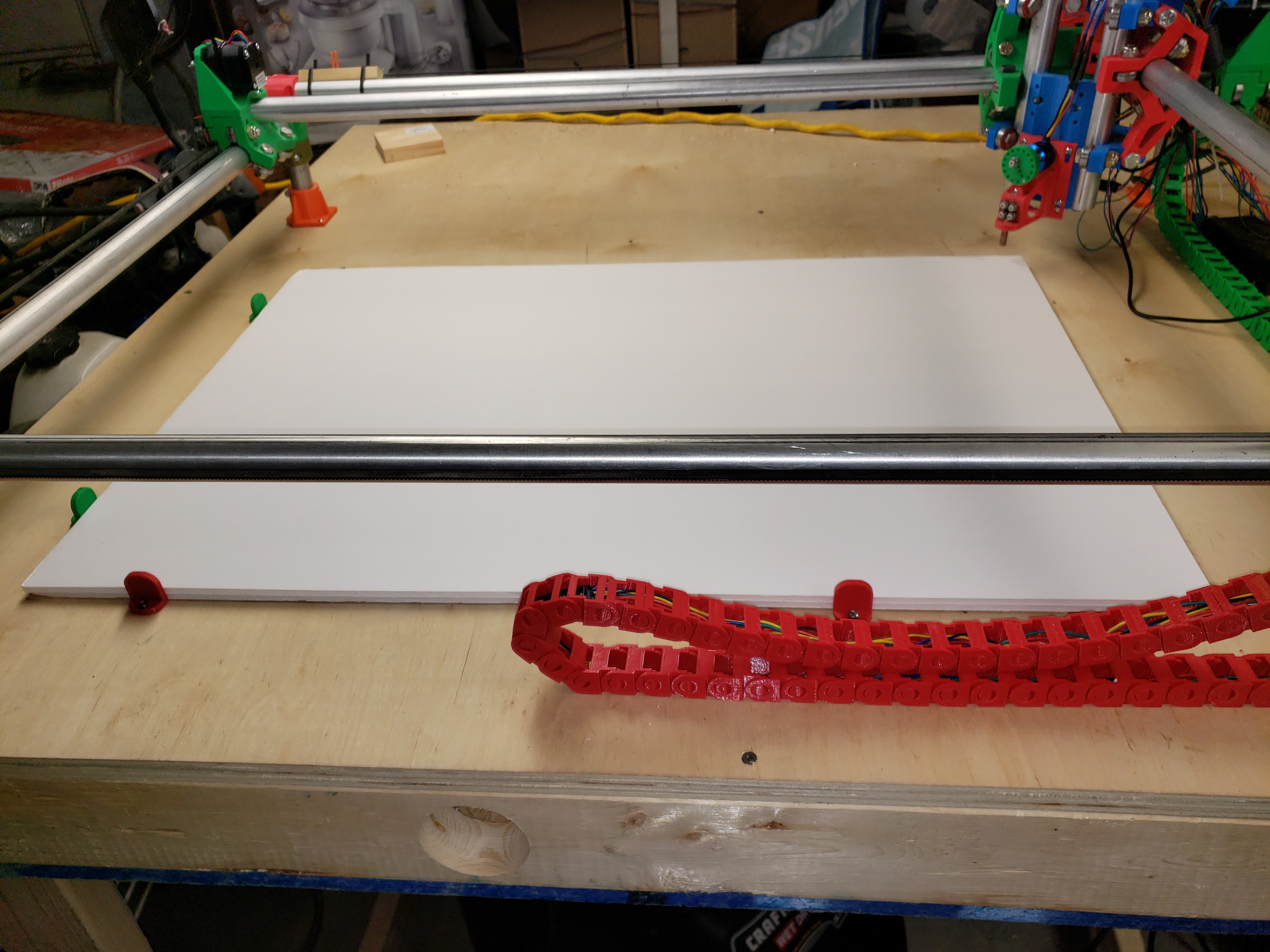

The concept of a needle cutter intrigued me for a long time. I have a working machine and I wanted to share my experiences.

I haven't followed the recent postings and I can't even claim to have read the majority of the older stuff. Still, I've found what I have read to be incredibly interesting. Also, kudos to David on how supporting and positive you are with everyone and every idea. A discouraging word is not just seldom heard. it's not heard at all. My compliments to you.

Here's the video:

Miles

And congratulations on getting your machine running so well. I must admit I was taken aback by the twisted needle you're using... what kind of wire are you using? I notice it comes in a spool... the 0.025" (0.635mm) music-/piano-wire I use comes as straight pieces of varying lengths. This piano-wire, in 36" lengths, is similar to what I use and provides for many needles... and is far easier to work with.

A possibility -- though I've not tried it with piano-wire -- I've "twist-straightened" spooled, solid, 0.025" Mig-wire to make needles, early on, that worked quite well. Take a length of wire to be straightened -- 24" to 36" will do -- and form a small eye in one end. Take a short length of wire coat hanger and make a small hook that can be chucked up into a power hand drill... like a cup hook. Tightly clamp the end of the wire to be straightened -- without the eye -- in a small vice and place it on the floor. Stand on it and then hook the eye in the wire to be straightened with the coat hanger hook and pull up on it until taut. Turn on the drill and twist the wire... either direction, while maintaining the tension... for 10, 15, 20 seconds or more... or until the wire breaks. The wire will work-harden to some degree and be perfectly straight. I've made many needles that way... and since you're twisting your wire to some degree, it will probably "twist-straighten" as well?

Please keep us posted on your progress. And, thanks again!

-- David

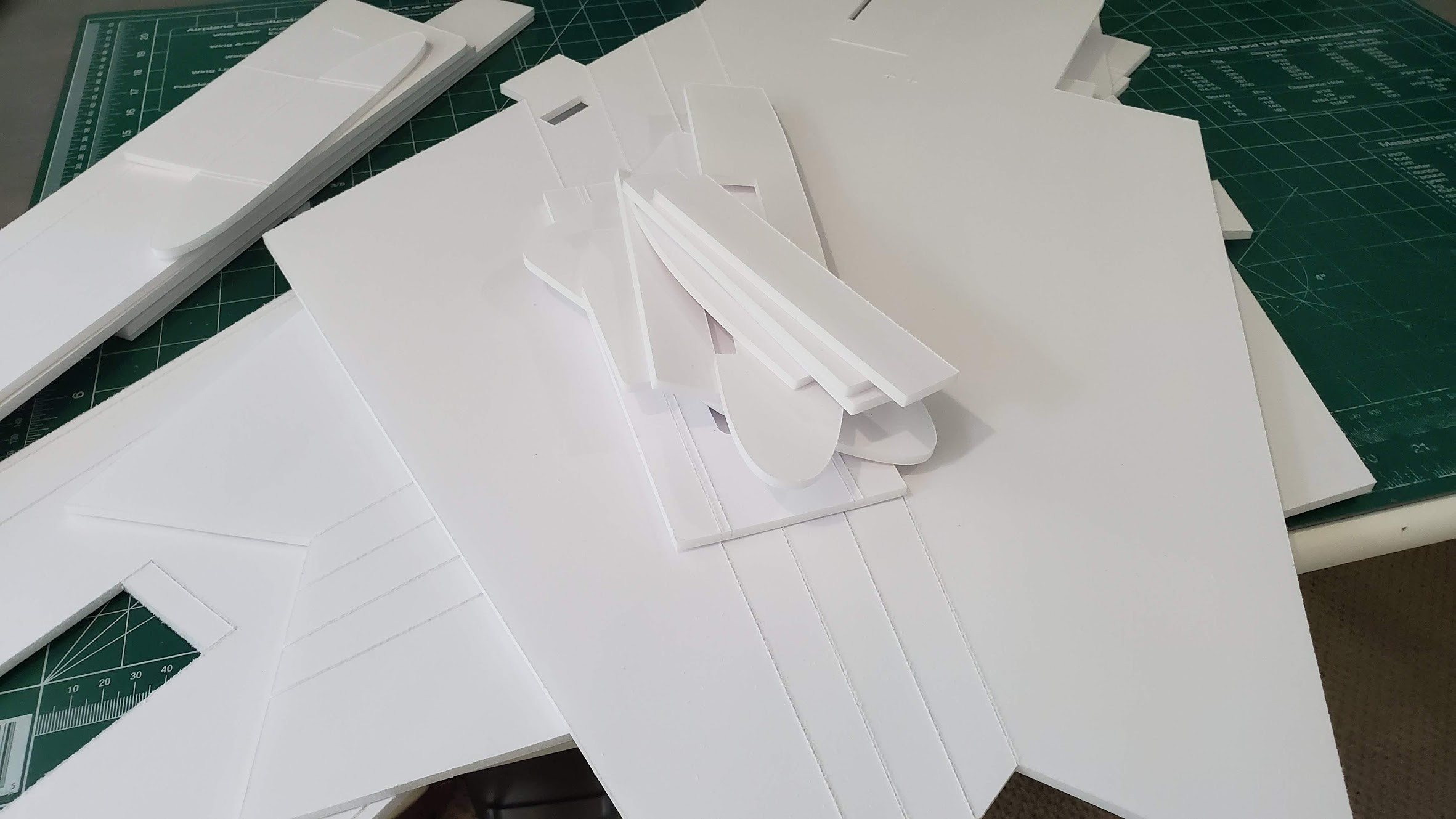

![IMG_20190701_193604269[1].jpg IMG_20190701_193604269[1].jpg](https://ftforumx2.s3.amazonaws.com/2019/07/236428_75b23738d4aa0f4943d5ae46928c1cbf.jpg)

![IMG_20190701_193557877[1].jpg IMG_20190701_193557877[1].jpg](https://ftforumx2.s3.amazonaws.com/2019/07/236430_577498268161b52fdb78d61f1832cbd6.jpg)