Mode 1

Active member

Hey All. Happy last day of 2018!

On my Mini Arrow I have unequal travel on my elevon. I get plenty of left but hardly any right. I did my best to make sure my control horn is over the seam. Electronics and servos are still pretty greek to me. Is there a fix for this? if it's a radio issue i'm flying frsky Qx7.

Any advice would be appreciated.

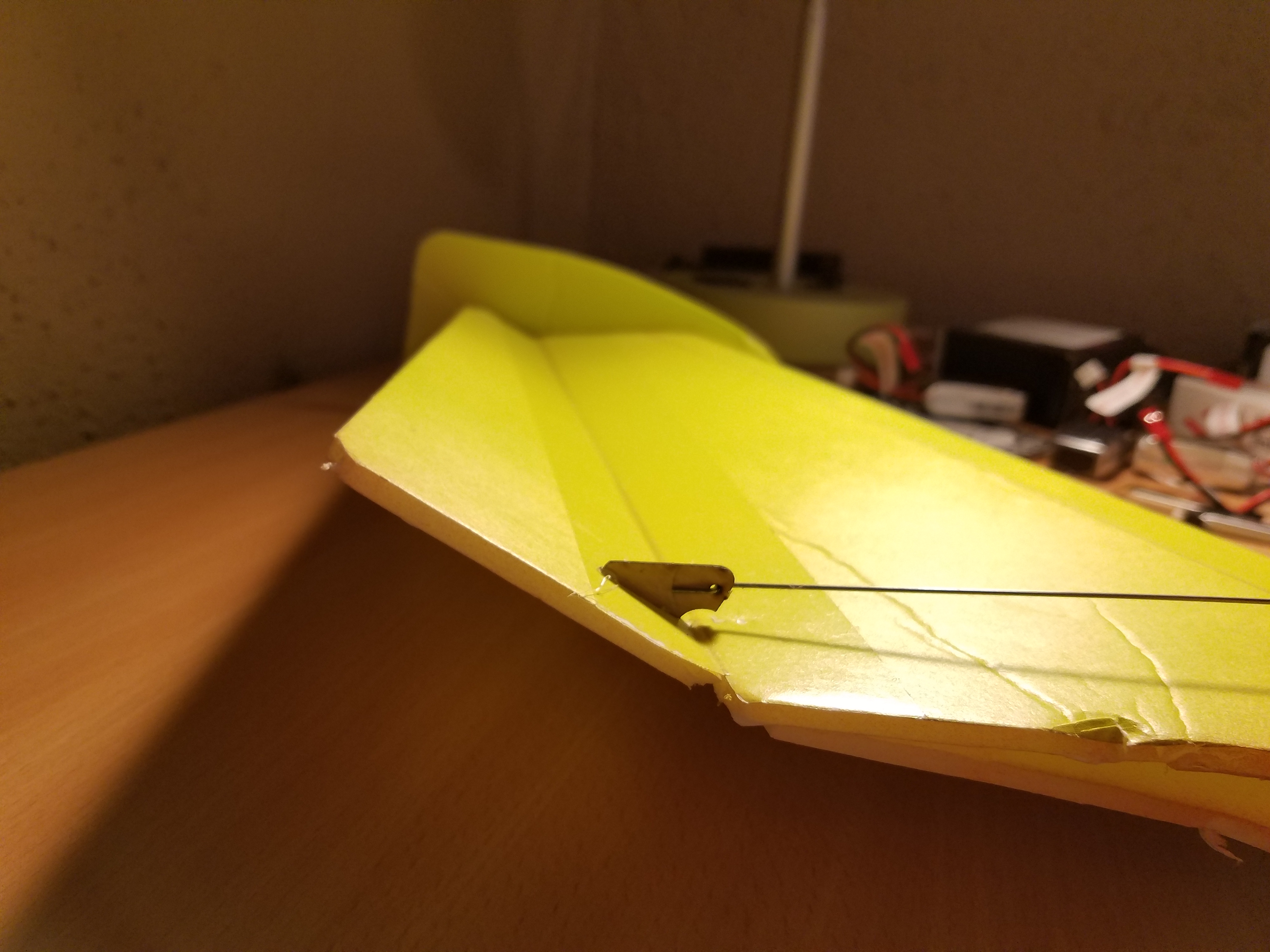

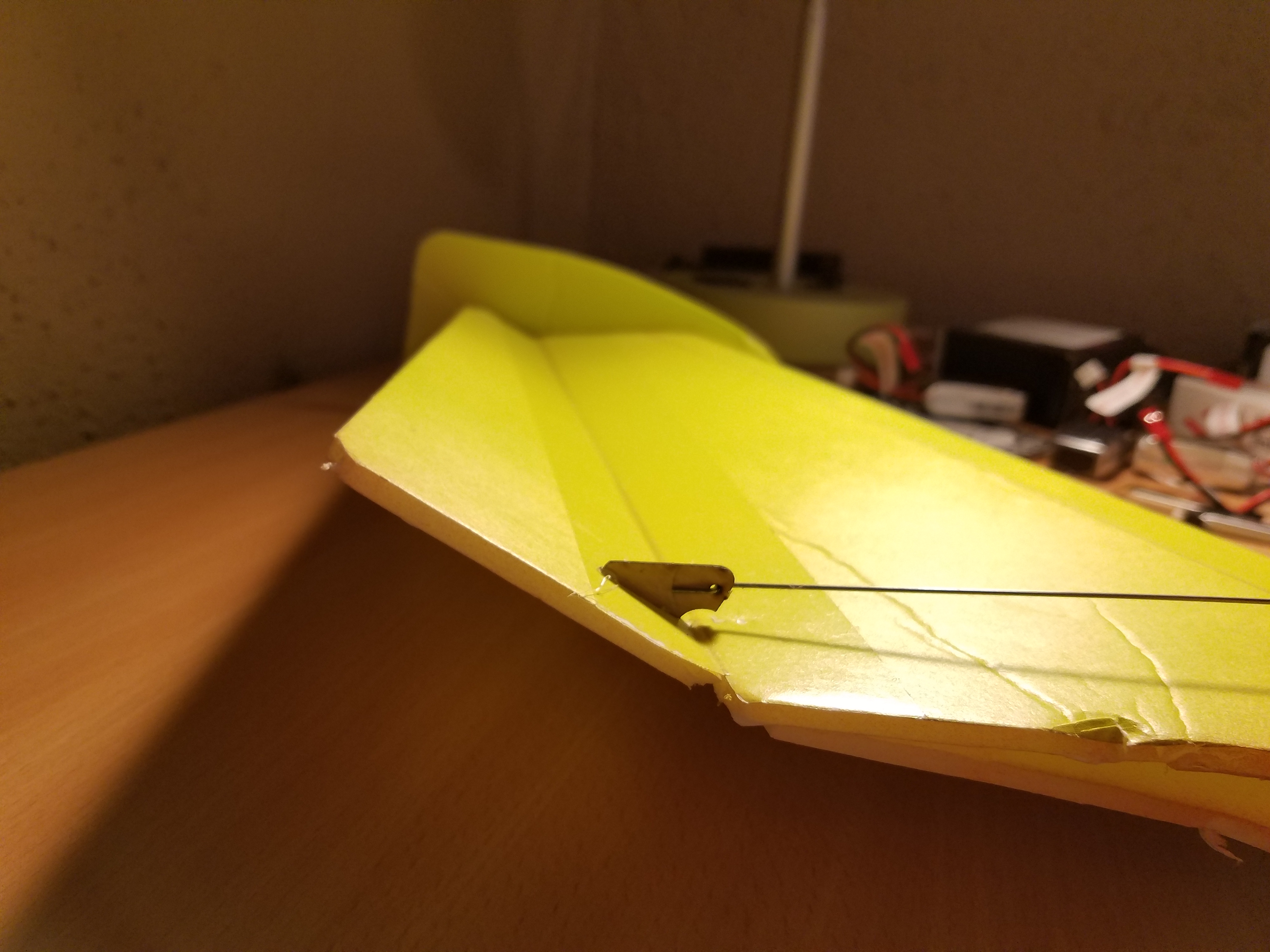

Sticks Centered

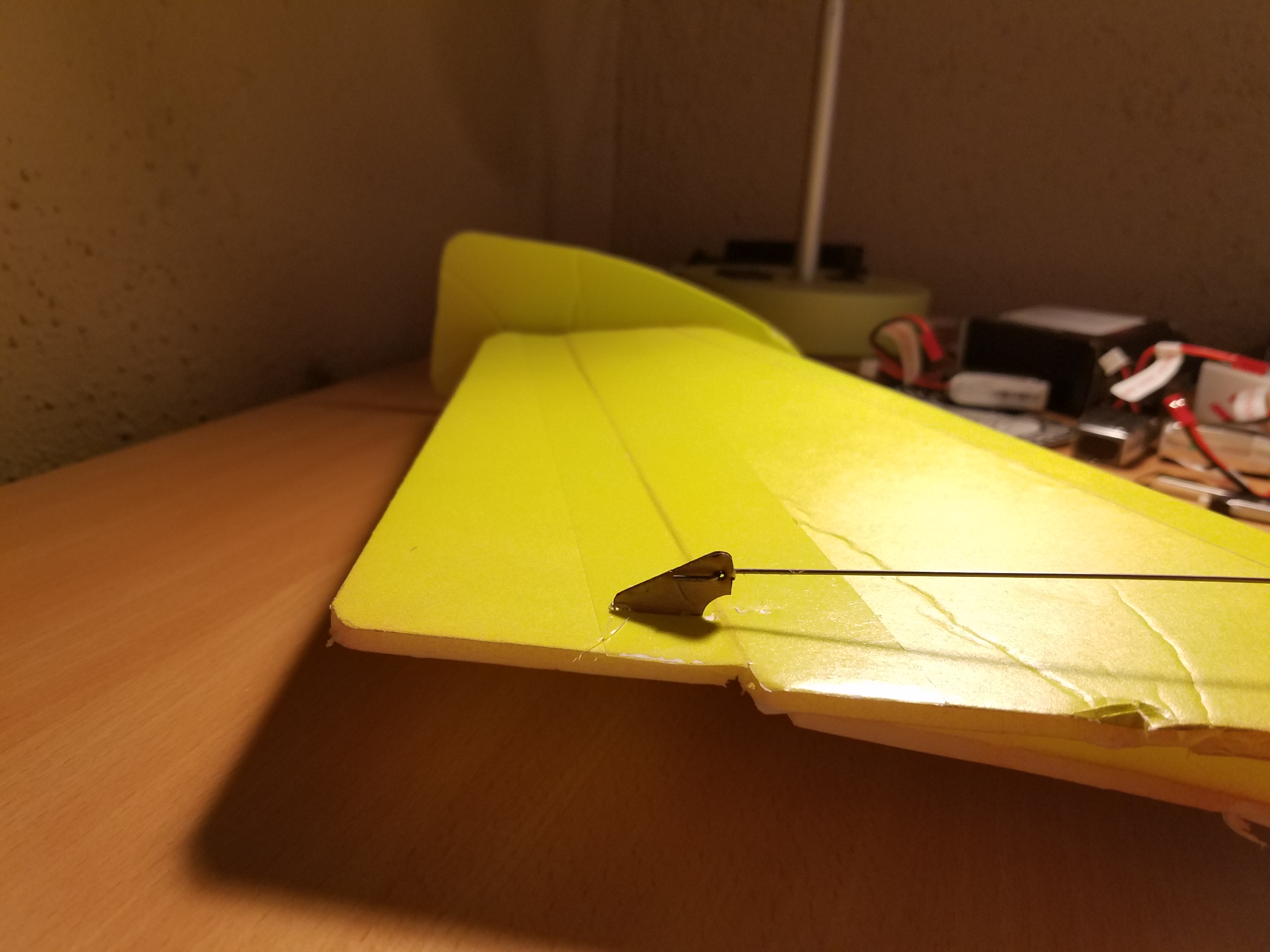

LEFT

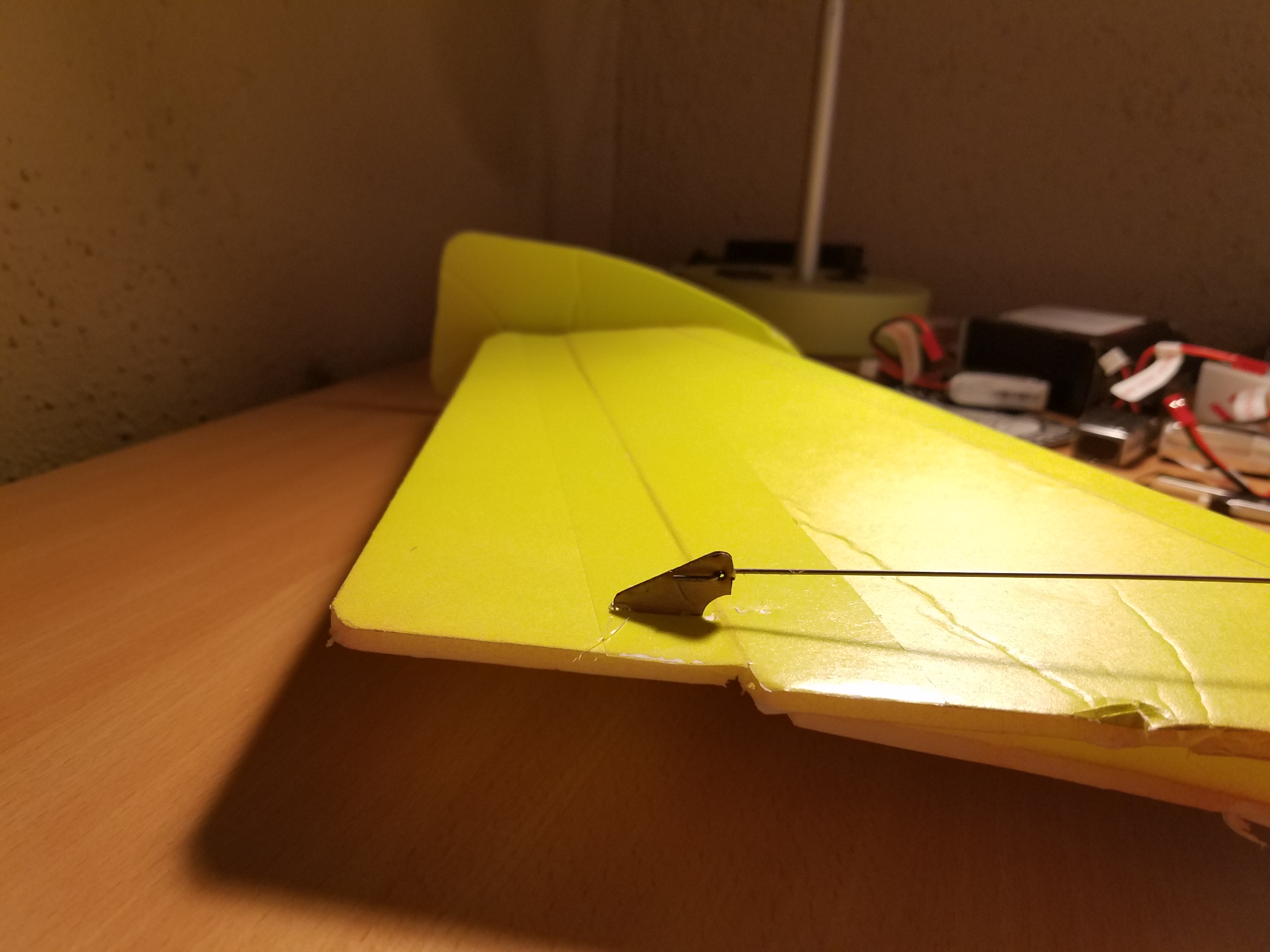

RIGHT

On my Mini Arrow I have unequal travel on my elevon. I get plenty of left but hardly any right. I did my best to make sure my control horn is over the seam. Electronics and servos are still pretty greek to me. Is there a fix for this? if it's a radio issue i'm flying frsky Qx7.

Any advice would be appreciated.

Sticks Centered

LEFT

RIGHT

Last edited: