L Edge

Master member

As the winds get higher and more gusty, fewer fly. The 2 keys to this type of flying relies on the plane as well as the skill of the pilot. Looking at the plane, the more stable it is, the higher the winds and turbulence it can handle.

So looking at the design of the bird, I chose to explore Sponz's "wonder series" with his approval and adapt it with devices. I also wanted it to fly low and near me rather than high and far distances within an enclosed tree area that causes wind havoc (unseen turbulence) and crosswinds. You can learn a lot more when the model is up close. Grant it, the closer to the ground, the odds go up in favor to the ground gods. I still do test myself and have paid the price at times.

Devices:

1) Use of 4 large end caps to slow the roll rate down and help control the airflow.

2) I am adding the "UDDER RUDDER" just behind the prop which adds yaw control of crosswinds and high resolution at very high AOA at slow speeds and counteracting wing roll overs. Since the end caps essentially are a good length of the plane, the udder rudder was added at the nose for a quicker response time in yaw.

3) I am adding a modified leading edge slot found in early NACA videos that is used to increase stabilization of the wing.

Specs of my avain bird:

Eflite 370 motor Outrunner 920KV 3S 1300 lipo

APC 9x3/8SF prop with 20Amp ESC

L= 24"

Width = 33"

Fuse is 2" square

CG is 1" from leading edge.

5 servos with rudder, and 2 sets of elevons in wing and tail

Weight with battery 415.6 grams

Using just one layer of flat plate foam (no airfoil or k stuff)

Footnote:

I am being hampered by the fact I am running out of foam. So it is using 2 types of foam to finish it off. So far I have used 4 bundles of FFF (each 50 ft long by 4 ft high), 1 FFF bundle given to me (that is 1 sided re-enforced-same dimensions) and a 10 pack of dupron of different thicknesses and 28" wide by 42. That is a lot of models I have made.

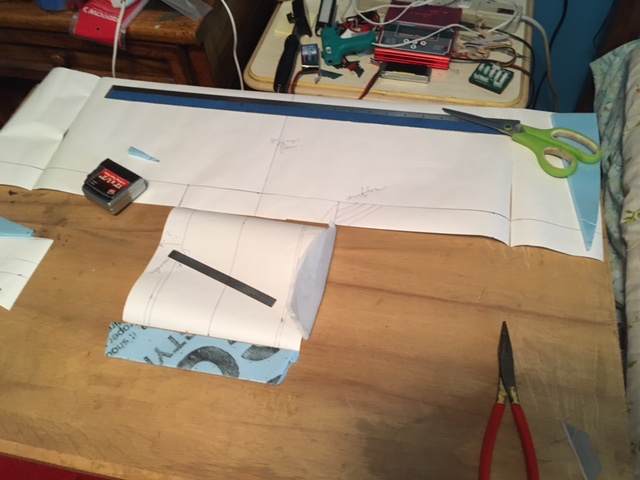

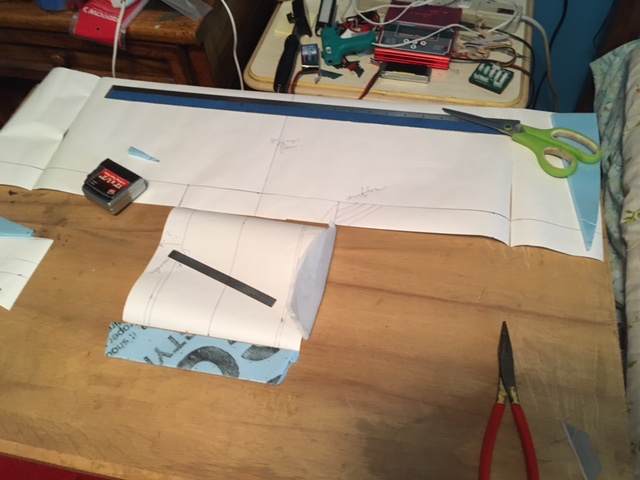

This controlled my dimensions, so I eyed Sponz's and being old school, made my cuts out of paper until I felt "it looks good".

So cut the wing out and the back plate and hot glued them together. Again, going for a light weight plane.

Notice the small dimension between back plate and front wing and ailerons. That is for the end plates. Ailerons are 1 1/2" wide by 12" long. Elevator is 8 1/4" wide by (modified) 2 1/2" long.

Turning it over:

The strength of the wing is increased by using a carbon hollow rod(31" long) and notching out a groove in the foam and hot gluing it in place at 3 1/2 ' from LE. The rest of black crap is ink added by Dow, hard to get off,

Fuse is designed 2" wide by 2 3/8 down. At 2nd plate glue joint, it is narrowed down to 1 1/4 exit.

An opening behind motor mount is added so there is an airflow to remove heat from battery and ESC and flow out end. Added two servos to bottom of wing to be 1/2 the control surfaces which will be programmed as 2 sets of elevons. Reason that the 2 sets of end plates(large in size) slow the roll of the plane, so to overcome and gain rotational speed, 2 surfaces are better than one. Motor is 5" from leading edge of wing.

Position of 2nd set of elevons servos is using outer tube to eliminate bowing of wire.

So looking at the design of the bird, I chose to explore Sponz's "wonder series" with his approval and adapt it with devices. I also wanted it to fly low and near me rather than high and far distances within an enclosed tree area that causes wind havoc (unseen turbulence) and crosswinds. You can learn a lot more when the model is up close. Grant it, the closer to the ground, the odds go up in favor to the ground gods. I still do test myself and have paid the price at times.

Devices:

1) Use of 4 large end caps to slow the roll rate down and help control the airflow.

2) I am adding the "UDDER RUDDER" just behind the prop which adds yaw control of crosswinds and high resolution at very high AOA at slow speeds and counteracting wing roll overs. Since the end caps essentially are a good length of the plane, the udder rudder was added at the nose for a quicker response time in yaw.

3) I am adding a modified leading edge slot found in early NACA videos that is used to increase stabilization of the wing.

Specs of my avain bird:

Eflite 370 motor Outrunner 920KV 3S 1300 lipo

APC 9x3/8SF prop with 20Amp ESC

L= 24"

Width = 33"

Fuse is 2" square

CG is 1" from leading edge.

5 servos with rudder, and 2 sets of elevons in wing and tail

Weight with battery 415.6 grams

Using just one layer of flat plate foam (no airfoil or k stuff)

Footnote:

I am being hampered by the fact I am running out of foam. So it is using 2 types of foam to finish it off. So far I have used 4 bundles of FFF (each 50 ft long by 4 ft high), 1 FFF bundle given to me (that is 1 sided re-enforced-same dimensions) and a 10 pack of dupron of different thicknesses and 28" wide by 42. That is a lot of models I have made.

This controlled my dimensions, so I eyed Sponz's and being old school, made my cuts out of paper until I felt "it looks good".

So cut the wing out and the back plate and hot glued them together. Again, going for a light weight plane.

Notice the small dimension between back plate and front wing and ailerons. That is for the end plates. Ailerons are 1 1/2" wide by 12" long. Elevator is 8 1/4" wide by (modified) 2 1/2" long.

Turning it over:

The strength of the wing is increased by using a carbon hollow rod(31" long) and notching out a groove in the foam and hot gluing it in place at 3 1/2 ' from LE. The rest of black crap is ink added by Dow, hard to get off,

Fuse is designed 2" wide by 2 3/8 down. At 2nd plate glue joint, it is narrowed down to 1 1/4 exit.

An opening behind motor mount is added so there is an airflow to remove heat from battery and ESC and flow out end. Added two servos to bottom of wing to be 1/2 the control surfaces which will be programmed as 2 sets of elevons. Reason that the 2 sets of end plates(large in size) slow the roll of the plane, so to overcome and gain rotational speed, 2 surfaces are better than one. Motor is 5" from leading edge of wing.

Position of 2nd set of elevons servos is using outer tube to eliminate bowing of wire.

Last edited: