Duck

Active member

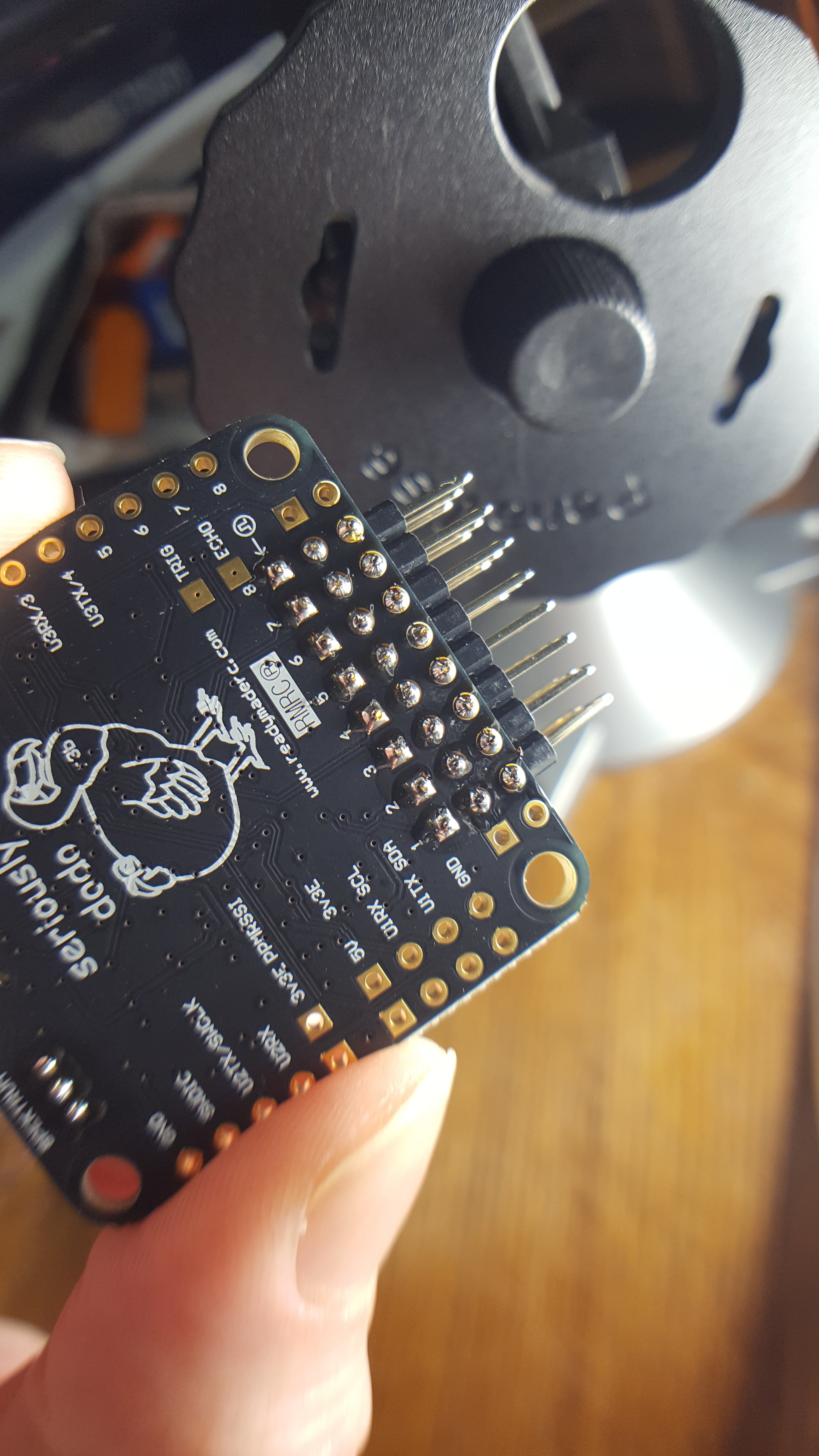

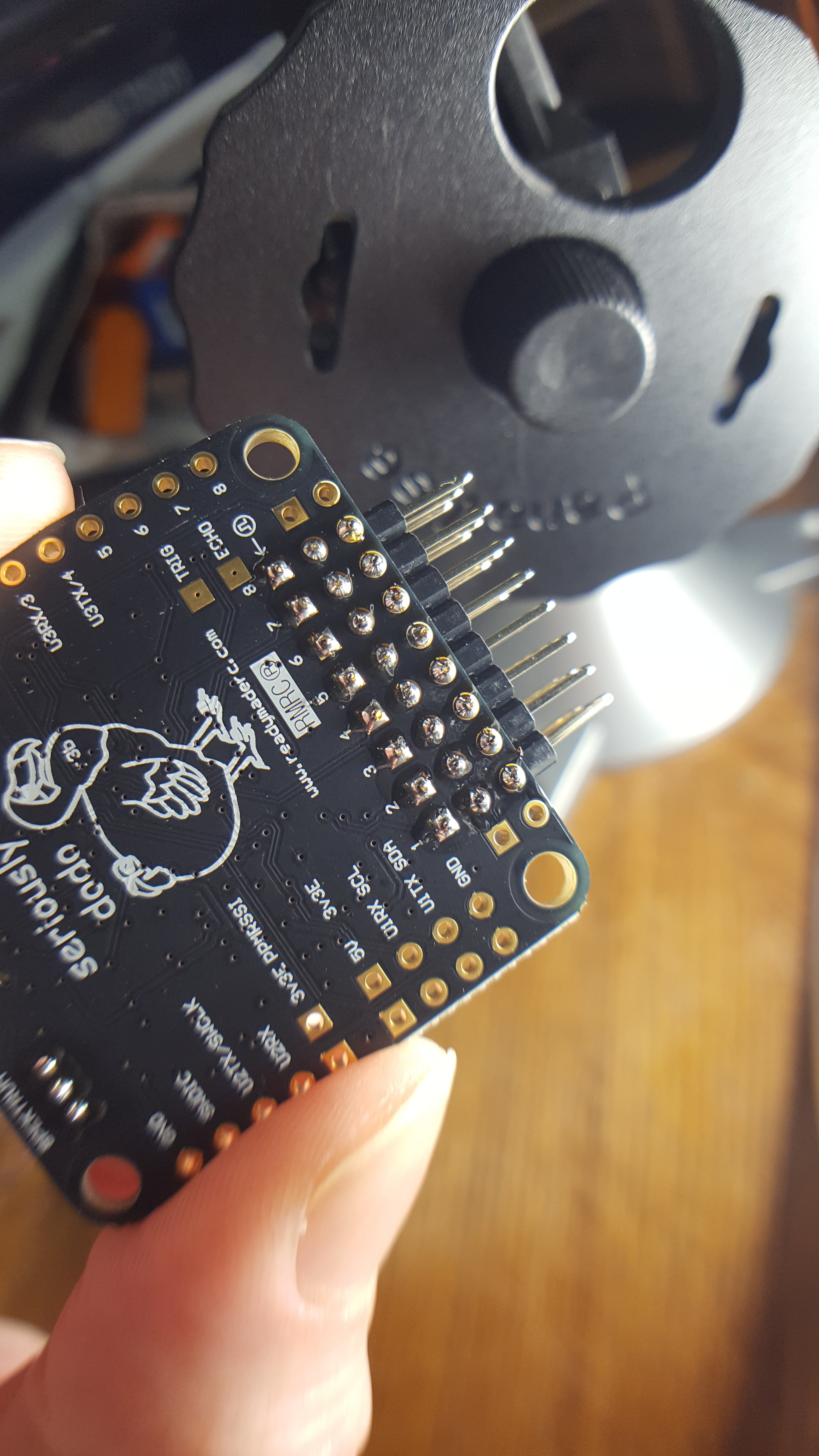

I picked up a pair of RMRC Dodp 3b boards while they were on sale with the goal of it being my first FC. Soldering the through hole connections for receiver and servos went fine. I've tested the receiver wth it connected to cleanflight.

I actually think the solder looks great for my first through-hole attempt.

I had planned on soldering a JST pigtail to the vbat pins and running that to a JST tap on an xt60. This would let me move the FC around or put in an extender without resoldering. The board would power off that and also drive the servos.

The problem I ran into was that even my 20 guage JST pigtail with braided wires wont fit the VBat through-holes. I assume this is the situation where you want a flat pad instead. What are the best ways to connect these on the FC? Is my JST pigtail idea silly? How would this normally be hooked up for a wing?

I came up with a few options but each has drawbacks. I was hoping to get some sage advice to point me in the right direction.

1. Do I just need higher gauge pigtails?

2. Should I trim some braid off and make it fit?

3. Should I just use some solid copper wire that fits and splice that to the pigtail?

Board

https://www.readymaderc.com/products/details/rmrc-seriously-dodo-flight-controller-rev-3b

Thanks!

I actually think the solder looks great for my first through-hole attempt.

I had planned on soldering a JST pigtail to the vbat pins and running that to a JST tap on an xt60. This would let me move the FC around or put in an extender without resoldering. The board would power off that and also drive the servos.

The problem I ran into was that even my 20 guage JST pigtail with braided wires wont fit the VBat through-holes. I assume this is the situation where you want a flat pad instead. What are the best ways to connect these on the FC? Is my JST pigtail idea silly? How would this normally be hooked up for a wing?

I came up with a few options but each has drawbacks. I was hoping to get some sage advice to point me in the right direction.

1. Do I just need higher gauge pigtails?

2. Should I trim some braid off and make it fit?

3. Should I just use some solid copper wire that fits and splice that to the pigtail?

Board

https://www.readymaderc.com/products/details/rmrc-seriously-dodo-flight-controller-rev-3b

Thanks!