Duck

Active member

I gave a few teasers in another thread but I wanted to start a thread to share progress on my flying laser tag gun. I wanted to share progress and collect a few suggestions along the way.

Previous Thread:

https://forum.flitetest.com/index.php?threads/laser-tag-combat-community-suggestions.37994/

Blog Post:

https://executedata.blogspot.com/2020/03/flying-laser-tag-gun.html

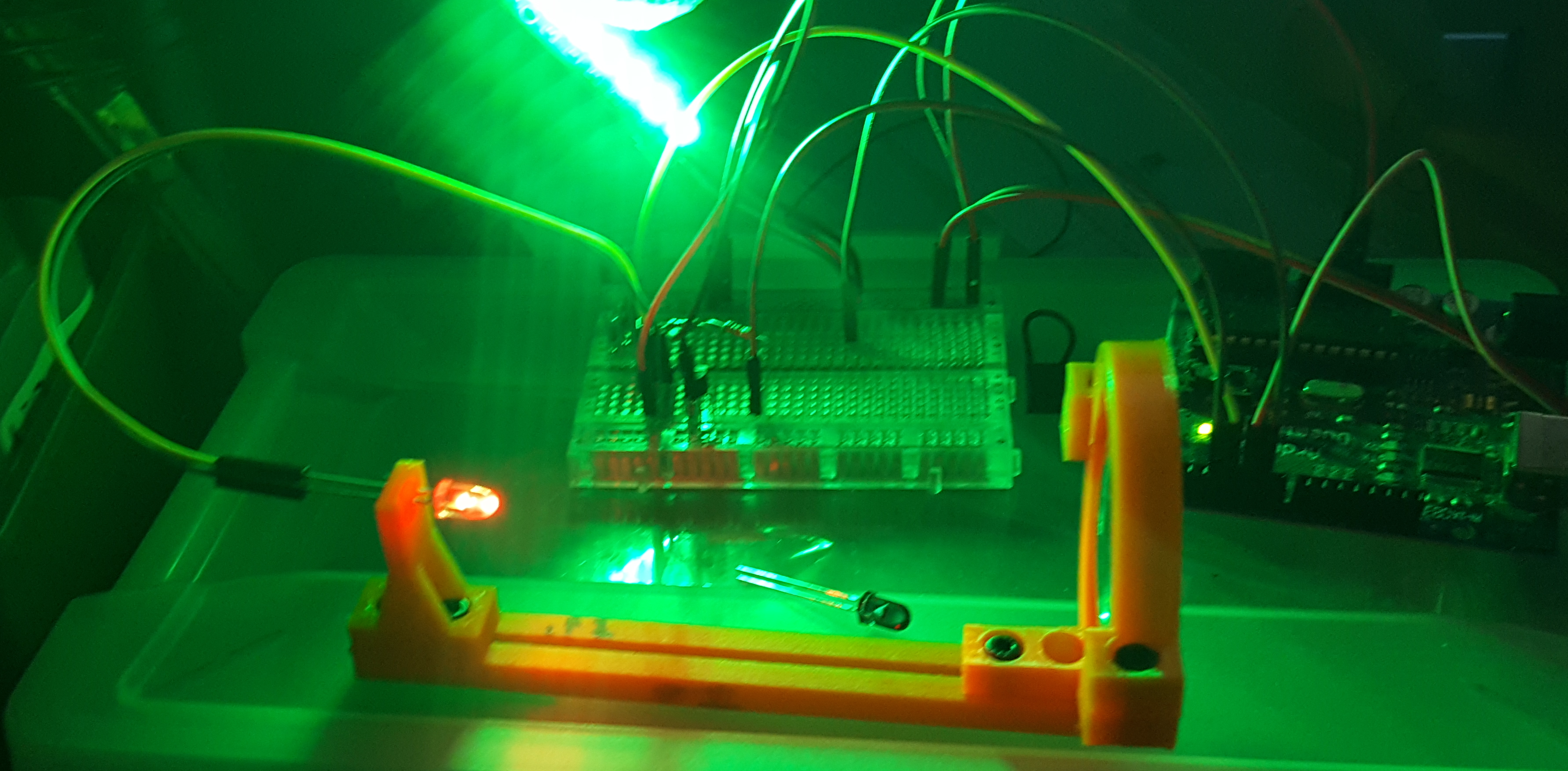

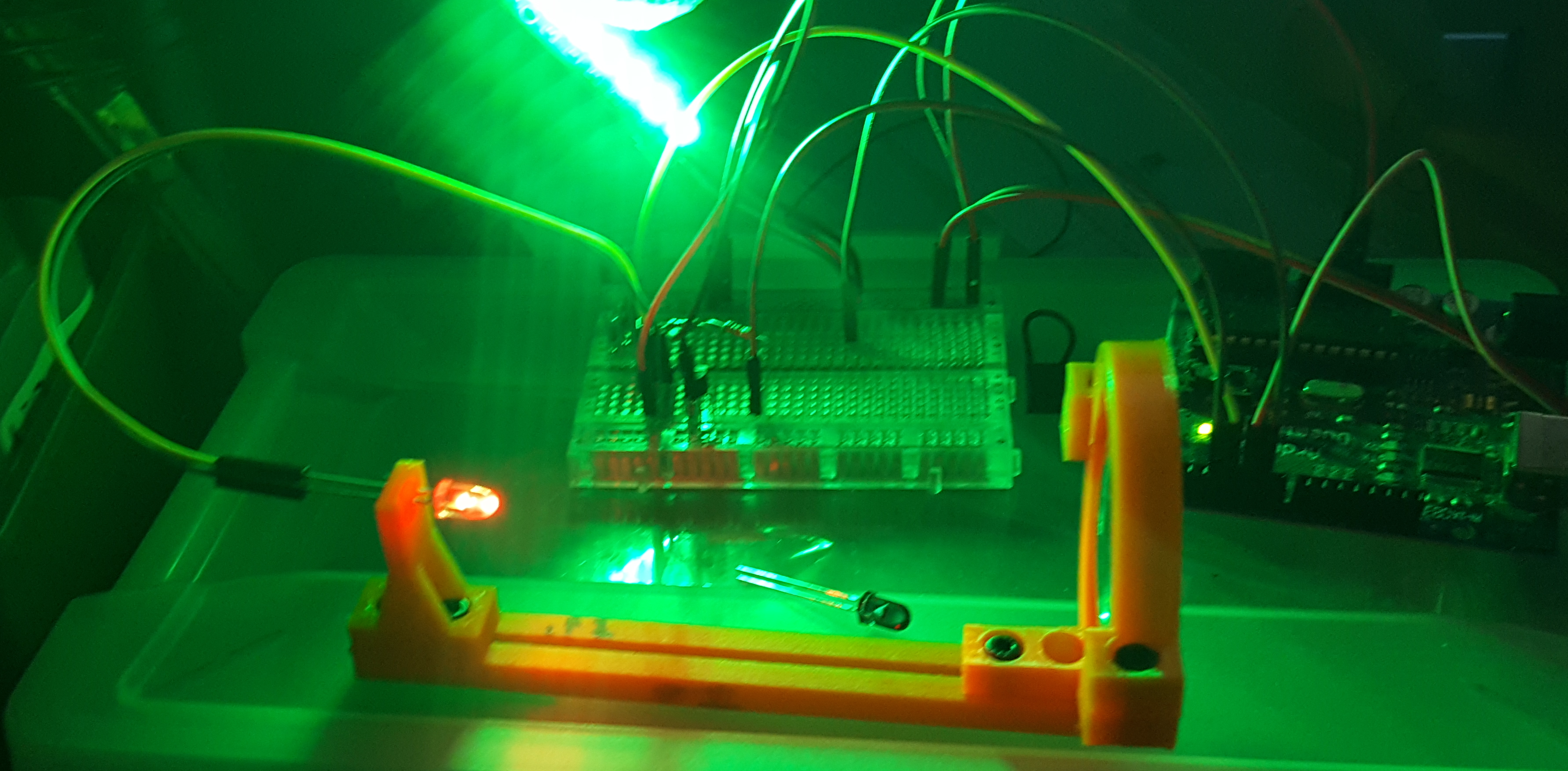

To justify forking the thread, here is an exclusive never before seen shot of the IR TX while I was testing the focus in the dark with a visible light LED.

All the bits are up on github if you want more:

https://github.com/afaucher/Tagger

Previous Thread:

https://forum.flitetest.com/index.php?threads/laser-tag-combat-community-suggestions.37994/

Blog Post:

https://executedata.blogspot.com/2020/03/flying-laser-tag-gun.html

To justify forking the thread, here is an exclusive never before seen shot of the IR TX while I was testing the focus in the dark with a visible light LED.

All the bits are up on github if you want more:

https://github.com/afaucher/Tagger