You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

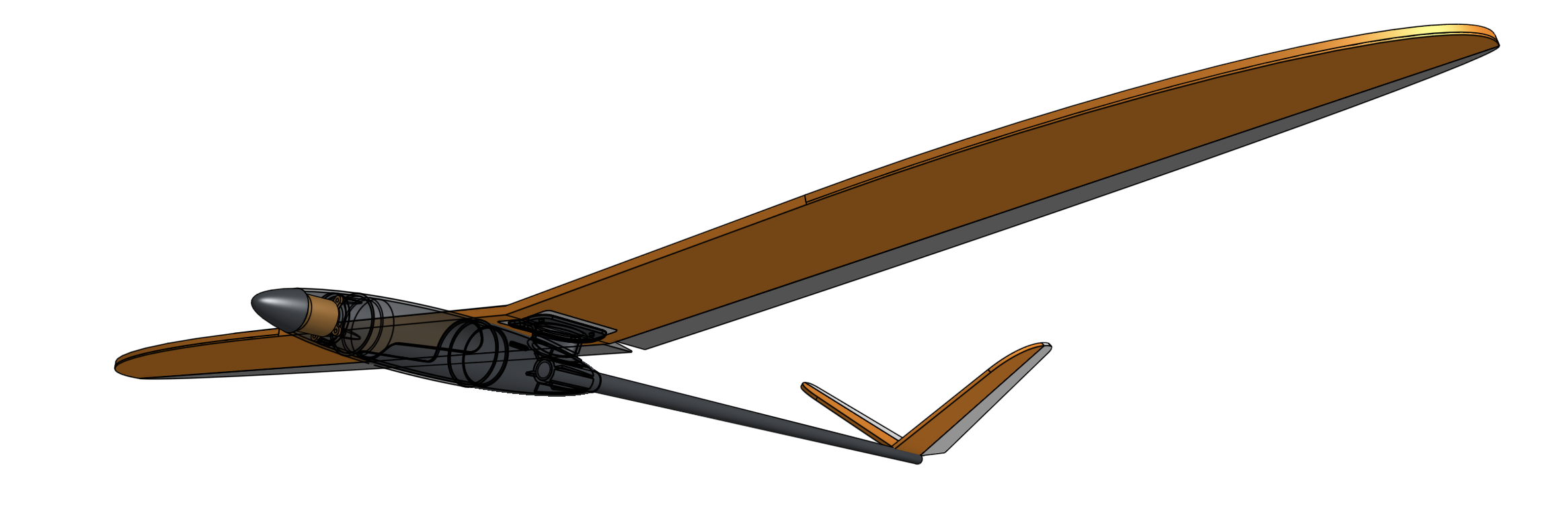

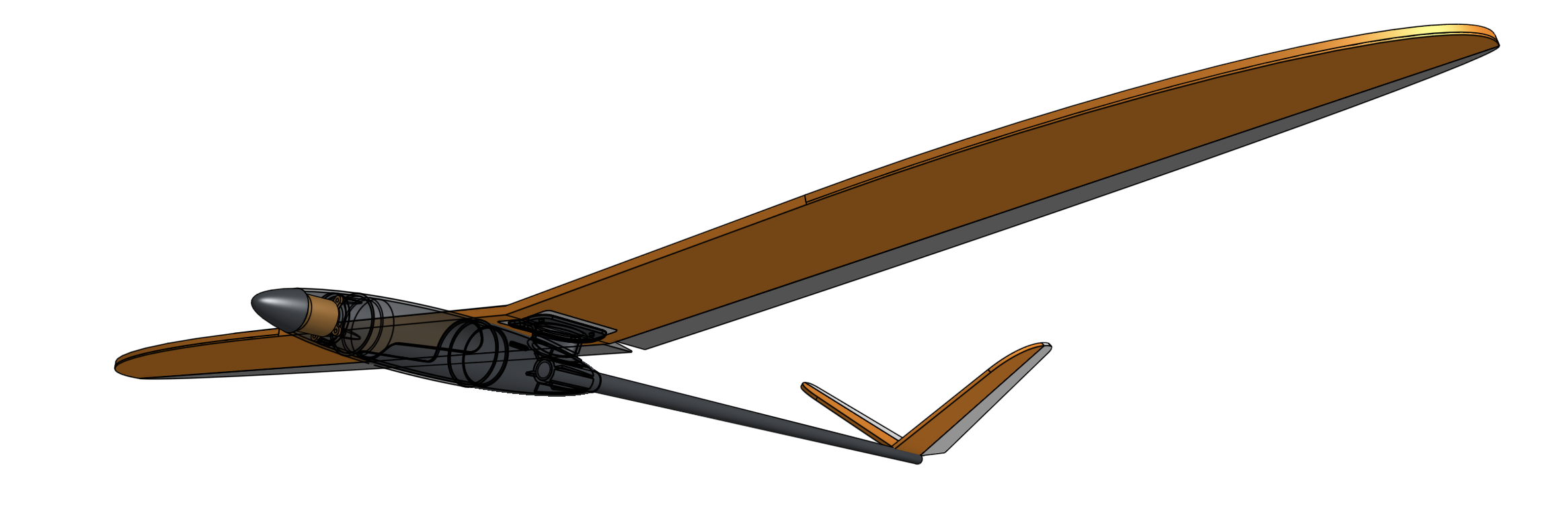

Foam wing DLG electric

- Thread starter bracesport

- Start date

bracesport

Legendary member

That plane is really shaping up great.

I really like the look of your 3d printed pod and tail parts.

Would you ever consider sharing them ?

Absolutely I would! Let’s see if it works! Also they are easy to modify to fit specific booms etc!

bracesport

Legendary member

Awesome. Looking forward to see this in the air.

I seem to be only able to grab an hour at a time just at the moment, but am getting there with the painting. In parallel, I've been reassembling my trainer glider with ailerons instead of the rudder so I can have a crack, and probably a crash flying bank and yank! I am way ahead of myself building vs flying skills (except on the sim). Envious of Brisbane weather!

bracesport

Legendary member

The V tail mount is glued on and I made a bit more progress on painting prep. The motor mount needs to be fitted and then trimmed at the edges to fit under the cowl, and once that is done I will dry fit the components.

I also ordered some new servos, extension leads, control horns and pushrods. Previously I made my own control horns but I ended up with too much slop, so with this one, I will try and be a tad more precise.

I also ordered some new servos, extension leads, control horns and pushrods. Previously I made my own control horns but I ended up with too much slop, so with this one, I will try and be a tad more precise.

bracesport

Legendary member

Update V tail design.

Slop in a horn will drive you to madness . . . Or CA.

It's actually a fairly popular trick to CA the Z-bend into the horn with a medium CA (so it gap-fills), wait for it to cure, then break the joint loose. The CA won't bond well to the wire, but sticks to the glass/plastic/wood horn -- a little twist, and the wire breaks free into a hole precisely the diameter of the wire.

It's actually a fairly popular trick to CA the Z-bend into the horn with a medium CA (so it gap-fills), wait for it to cure, then break the joint loose. The CA won't bond well to the wire, but sticks to the glass/plastic/wood horn -- a little twist, and the wire breaks free into a hole precisely the diameter of the wire.

bracesport

Legendary member

Slop in a horn will drive you to madness . . . Or CA.

It's actually a fairly popular trick to CA the Z-bend into the horn with a medium CA (so it gap-fills), wait for it to cure, then break the joint loose. The CA won't bond well to the wire, but sticks to the glass/plastic/wood horn -- a little twist, and the wire breaks free into a hole precisely the diameter of the wire.

Nice tip! you the man! Funnily enough, the new pushrods and control horns arrived today and there is definitely a miss match in the hole size vs the wire size!

I need to buy some CA - never really used the stuff!

Last edited:

buzzbomb

I know nothing!

I didn't like it because I agree with it. I liked because you just taught it to me. Thanks.Slop in a horn will drive you to madness . . . Or CA.

It's actually a fairly popular trick to CA the Z-bend into the horn with a medium CA (so it gap-fills), wait for it to cure, then break the joint loose. The CA won't bond well to the wire, but sticks to the glass/plastic/wood horn -- a little twist, and the wire breaks free into a hole precisely the diameter of the wire.

I didn't like it because I agree with it. I liked because you just taught it to me. Thanks.

One of the benefits of flying a glider competition -- the first time contestant probably won't do well, but hanging around the other contestants, you'll certainly get better at it.

That's one of several tricks I've seen as desperate pilots are racing to make their planes airworthy again before the next round.

If you ever get a chance to fly in one, don't pass it up.

bracesport

Legendary member

Today I ordered an FS i6s to see if that will help me fly!

My JR X378 is pretty old school and although I've hacked it from mode 1 to mode 2 I'm not sure if it will cut the mustard when I try and do some mixes. Hopefully, it will help me have the steering in the right hand, and if that works out my son can learn on the FS i6s!

My JR X378 is pretty old school and although I've hacked it from mode 1 to mode 2 I'm not sure if it will cut the mustard when I try and do some mixes. Hopefully, it will help me have the steering in the right hand, and if that works out my son can learn on the FS i6s!

Last edited:

bracesport

Legendary member

The motor mount was a tad wide and I just managed to squeeze in the bolts and trim the edges so the cowl will fit. The motor mount is bolted from the inside with some epoxy on the thread to keep the nuts on! Next time I would make some internal bosses and screw bolts directly from the front.

Today I made some good progress on the wings, the painting is getting there, so I decided to cut the Ailerons free of the wing in preparation for attaching them with a silicone hinge. Cutting through the wing exposed the internal foam so I put some epoxy along the edges to give the silicone something to stick to. A bit more sanding and painting (still a few pinholes to fill) and they should be good to go! I'm going for a matt charcoal grey finish with some yellow fluoro somewhere underneath.

I was surprised how many blades I used to cut through the fibreglass even though there is only one layer of very fine glass on each surface. I cut the ailerons out on an angle, and my plan is to swap the left for the right which will bring the ailerons together with the wing creating a V between them for the hinge. My trailing edge is a tad thick so that will also go on the list for the second wing build!

Today I made some good progress on the wings, the painting is getting there, so I decided to cut the Ailerons free of the wing in preparation for attaching them with a silicone hinge. Cutting through the wing exposed the internal foam so I put some epoxy along the edges to give the silicone something to stick to. A bit more sanding and painting (still a few pinholes to fill) and they should be good to go! I'm going for a matt charcoal grey finish with some yellow fluoro somewhere underneath.

I was surprised how many blades I used to cut through the fibreglass even though there is only one layer of very fine glass on each surface. I cut the ailerons out on an angle, and my plan is to swap the left for the right which will bring the ailerons together with the wing creating a V between them for the hinge. My trailing edge is a tad thick so that will also go on the list for the second wing build!

bracesport

Legendary member

My plan was to make a silicone hinge but it was a disaster, the tape on the back side was not sticky enough to prevent migration of the silicone underneath the tape, and the goop in the V was a nightmare to smooth. I gave up and wiped off all the silicone with turpentine.

I jumped online and was looking at the CA hinges again, as it was time for a plan B! Sadly its the weekend and I was impatient to get this done so I searched the garage for something flexible. In the end, I had an epiphany to use small cable ties cut into pieces. Using a cold chisel I dented the middle to thin them out even further, and there was an added bonus with the teeth allowing for better glueing.

I first marked and set the hinge positions with a small nail pushed into the foam followed by a drill large enough to match the hinge size. Next, I glued the hinges into the wing side with 5min epoxy, then assembled the aileron onto hinges to finish. There is a little resistance in the aileron but it does not feel restrictive, and once the servos are in place we will see! If they need to be tweaked I will file them a bit or touch them with the tip of a soldering iron!

The wing halves are not too bad if I have to say so myself - time to join them together!

I jumped online and was looking at the CA hinges again, as it was time for a plan B! Sadly its the weekend and I was impatient to get this done so I searched the garage for something flexible. In the end, I had an epiphany to use small cable ties cut into pieces. Using a cold chisel I dented the middle to thin them out even further, and there was an added bonus with the teeth allowing for better glueing.

I first marked and set the hinge positions with a small nail pushed into the foam followed by a drill large enough to match the hinge size. Next, I glued the hinges into the wing side with 5min epoxy, then assembled the aileron onto hinges to finish. There is a little resistance in the aileron but it does not feel restrictive, and once the servos are in place we will see! If they need to be tweaked I will file them a bit or touch them with the tip of a soldering iron!

The wing halves are not too bad if I have to say so myself - time to join them together!

Next time . . . packing tape.

Seriously.

It's not a pretty solution and for full length it may be a pain to apply smoothly, but you get a solid hinge that -- so long as the tape hasn't been nicked -- is both strong and flexible. the acrylic glue on them also sticks to composites better than practically any adhesive I know.

Integrated tape hinges are better, but after the layup they're no longer an option, and nearly everyone I know uses packing tape, even as their long-term repairs.

Seriously.

It's not a pretty solution and for full length it may be a pain to apply smoothly, but you get a solid hinge that -- so long as the tape hasn't been nicked -- is both strong and flexible. the acrylic glue on them also sticks to composites better than practically any adhesive I know.

Integrated tape hinges are better, but after the layup they're no longer an option, and nearly everyone I know uses packing tape, even as their long-term repairs.

bracesport

Legendary member

My FT style trainer has taped hinges and they work well, but with the glider, I'm looking for a clean finish and there is still more painting to do!

The summer break is coming in less than a week so its time to ramp up and get this thing done!

It was amazing to get the ailerons in yesterday as it makes the wing feel real. I now have everything I need except the tail!

Tucked away in a box I have a Bixler 3 wing and two Bixler 2 tails (spare parts) that I bought on a whim from Hobby King. My plan was to use them on my next foam trainer before I try the Glider. I am now wondering if I can make a V tail from one of the Bixler tails to get this thing finished! My only concern is the Bixler parts are thicker than the usual tails you see on a DLG/glider but if they work on a Bixler they should work on a glider - right?

The summer break is coming in less than a week so its time to ramp up and get this thing done!

It was amazing to get the ailerons in yesterday as it makes the wing feel real. I now have everything I need except the tail!

Tucked away in a box I have a Bixler 3 wing and two Bixler 2 tails (spare parts) that I bought on a whim from Hobby King. My plan was to use them on my next foam trainer before I try the Glider. I am now wondering if I can make a V tail from one of the Bixler tails to get this thing finished! My only concern is the Bixler parts are thicker than the usual tails you see on a DLG/glider but if they work on a Bixler they should work on a glider - right?

Last edited:

Those tails should work just fine, assuming they have sufficient stiffness for the task. If you're going for an energetic glider (quick climb up, slow float down), go for it, just watch for flutter if you have to dive out of a thermal. In this case, drag from fat tails is only an issue if your powersystem is undersized for the launch -- at high speeds it's bad, at low it'll do.

If you're going for a warm/hotliner . . . I'd say go ahead and get her flying, but don't push her hard until you've replaced them with something better suited. Speed is fun, but flutter kills.

Speaking of painting (and well, another "next time"), yet another advantage of using mylars in the layup -- ever wonder how they get all those pretty colors on composite wings? If you give the mylars a *LIGHT* coat or two of rattle-can paint before you build the layup on top of them, the paint will melt into the epoxy as it sets, giving you a polished, painted look right out of the bag.

If you choose to build out stiffer composite tails (you will, eventually), I'd HIGHLY recommend hinge tape in the layup, and paint on the layup.

For tails, because they are so thin, you can also get away with a variant of "Wax Paper Bagging" and delay the purchase of a vacuum pump. Effectively you make your layup, then instead of a vacuum bag, you place it between LARGE stacks of paper towels, then compress the lot. The squish in the towels will force the outer layers of your layup to conform tightly to your core. The original post I learned from has been 404'ed to the ravages of time, but nothing is ever truly deleted:

https://web.archive.org/web/20060424032518/http://www.sjsf.org/waxpaper/waxpaper.htm

From my lessons learned, wax paper isn't ideal -- it needs to be an impervious layer, thin enough to conform, which won't chemically bond to the epoxy . . . but the smoother the better. I've had fair luck with some acetate/cellophane wrapping papers (bonus, you can get the epoxy to steal their paint if you pick the right side), and saran-wrap (Kitchen cling wrap won't stick or bond, but it's a pain to get all the wrinkles out). Kitchen parchment works too, but it will leave a fine mat finish instead of high gloss most plastics will do. If you go with wax paper, make sure you do the layup on the waxed side.

If you're not certain if a plastic sheeting you have is suited to the task, dribble a bit of epoxy on the plastic, then let it cure. If the blob peals easily off the plastic once fully set, it'll do the same in your final piece. if it *almost* peals off easy, you can hedge your bets by waxing the plastic with neutral shoe polish (or molding wax, if you want the fancy stuff).

If you're going for a warm/hotliner . . . I'd say go ahead and get her flying, but don't push her hard until you've replaced them with something better suited. Speed is fun, but flutter kills.

Speaking of painting (and well, another "next time"), yet another advantage of using mylars in the layup -- ever wonder how they get all those pretty colors on composite wings? If you give the mylars a *LIGHT* coat or two of rattle-can paint before you build the layup on top of them, the paint will melt into the epoxy as it sets, giving you a polished, painted look right out of the bag.

If you choose to build out stiffer composite tails (you will, eventually), I'd HIGHLY recommend hinge tape in the layup, and paint on the layup.

For tails, because they are so thin, you can also get away with a variant of "Wax Paper Bagging" and delay the purchase of a vacuum pump. Effectively you make your layup, then instead of a vacuum bag, you place it between LARGE stacks of paper towels, then compress the lot. The squish in the towels will force the outer layers of your layup to conform tightly to your core. The original post I learned from has been 404'ed to the ravages of time, but nothing is ever truly deleted:

https://web.archive.org/web/20060424032518/http://www.sjsf.org/waxpaper/waxpaper.htm

From my lessons learned, wax paper isn't ideal -- it needs to be an impervious layer, thin enough to conform, which won't chemically bond to the epoxy . . . but the smoother the better. I've had fair luck with some acetate/cellophane wrapping papers (bonus, you can get the epoxy to steal their paint if you pick the right side), and saran-wrap (Kitchen cling wrap won't stick or bond, but it's a pain to get all the wrinkles out). Kitchen parchment works too, but it will leave a fine mat finish instead of high gloss most plastics will do. If you go with wax paper, make sure you do the layup on the waxed side.

If you're not certain if a plastic sheeting you have is suited to the task, dribble a bit of epoxy on the plastic, then let it cure. If the blob peals easily off the plastic once fully set, it'll do the same in your final piece. if it *almost* peals off easy, you can hedge your bets by waxing the plastic with neutral shoe polish (or molding wax, if you want the fancy stuff).

bracesport

Legendary member

hehe. lots of great info there Dan! I appreciate it.

As a designer/engineer I am always looking ahead to what I would do differently on a future project. My building skills in this RC hobby are a 'first time' for everything at the moment, and sadly my building is getting ahead of my flying time! What I have learned is that you can make a half decent model with some simple techniques and its a lot of fun!

As a designer/engineer I am always looking ahead to what I would do differently on a future project. My building skills in this RC hobby are a 'first time' for everything at the moment, and sadly my building is getting ahead of my flying time! What I have learned is that you can make a half decent model with some simple techniques and its a lot of fun!

bracesport

Legendary member

I had an idea for completing the graphics - hi Viz modern camo - still tossing up between red and dazzle orange!

Similar threads

- Replies

- 15

- Views

- 761

- Replies

- 3

- Views

- 375