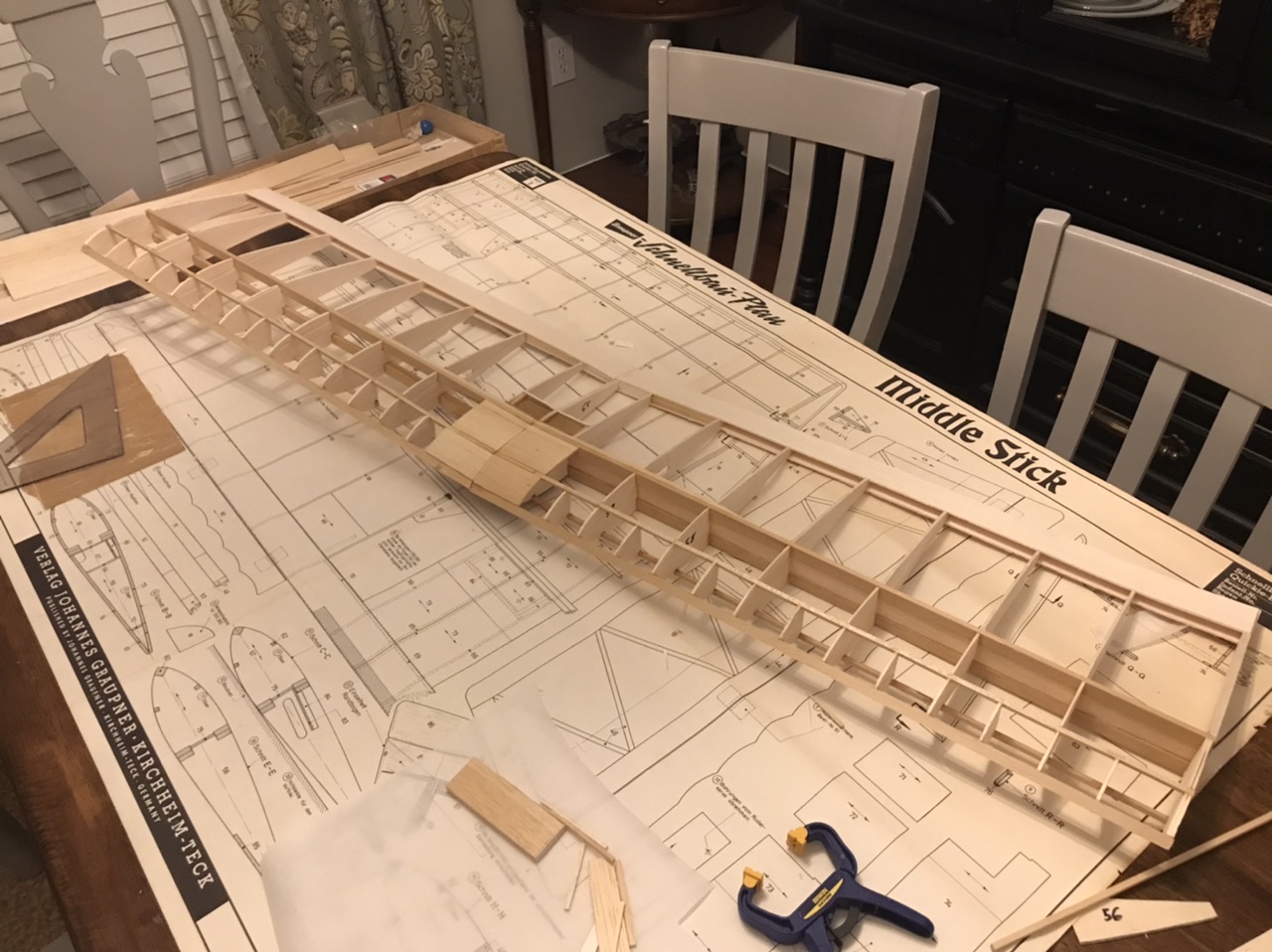

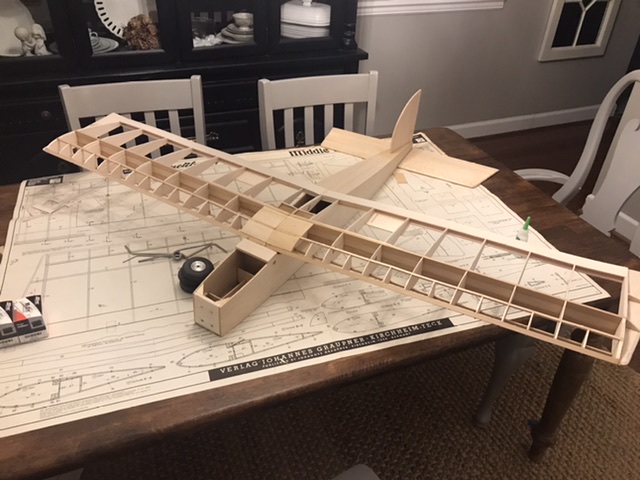

The wing continues to take shape. End formers and plates in place with rounded edges on wings. Horizontal and vertical stabilizers sanded to rounded edges. Placing everything “in place” makes it look a lot like a plane, which is what I am going for.

Servos arrived today (thank you SquirrelTail for the suggestion) and a covering iron is en route.

I decided to take everything to my work where I had a postage scale to check weight to make sure I am on track. The results were as follows (in metric units only despite primarily using Freedom units of measure)

Current plane all in: 736 grams

Fuselage-all: 547 grams

Fuse less tail: 456 grams

Fuse less tail and gear: 261 grams

Gear: 192 grams

Wheels (3): 102 grams

Tail: 88 grams

Horz stab: 23 grams

Wing: 187 grams

Left to install is:

4 servos, wires, push rods, receiver etc: 250 grams

1 2218B motor with mount and ESC: 125 grams

1 4S 2300 MAH battery: 250 grams

Monokote Covering of about 110dm2 (best guess): 170 grams

Other odds/ends and overage: 150 grams

With what I have now plus the budget left to install, I’m at 1,681 grams (3.7 lbs) estimated flying weight. The original plans have the flying weight at around 2,000 grams (4.4 lbs) so I’ll be about 16% underweight as it stands now. I don’t think that’s a problem and I’m pleased to be projected under weight rather than over. We’ll see how close I am to the final weight.

Servos will be a bit of a challenge in the wings for ailerons and will require modifications, will look at that next and then the great sand-off will begin.

Two things truly scare me now; covering with Monokote and flying it for the first time.