You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

FT Mini Guinea Build

- Thread starter fliteadmin

- Start date

nevenelestate

No Agenda FPV

I set mine up on the flap channel, and gave it a mid-open which is level with the bottom of the fuselage, and a full open which is maybe 10deg further down. I also setup the radio with a 3sec travel time so it looks more scale.

Here is a picture of how I rigged it.

I mounted a control horn to the door and then glued a servo to the roof, the pushrod was made to length so that the door was closed when the servo arm is parallel to the servo body. As the servo rotates away from the ceiling of the plane it pushes the door open. I beveled the door side of the hinge, but didn't glue it at first. After the test flight I started to separate the foam from paper on the door so I went back and hot glue sealed the hinge. I also installed a piece of foam as a stopper on the inside of the tail, where the hole is cut for the open only servo (in build plans).It would be good to have a pushrod stopper on the door control horn to make it easier to release the door to be opened manually, but I don't have any more laying around, guess that will be next mod.

Here is a picture of how I rigged it.

I mounted a control horn to the door and then glued a servo to the roof, the pushrod was made to length so that the door was closed when the servo arm is parallel to the servo body. As the servo rotates away from the ceiling of the plane it pushes the door open. I beveled the door side of the hinge, but didn't glue it at first. After the test flight I started to separate the foam from paper on the door so I went back and hot glue sealed the hinge. I also installed a piece of foam as a stopper on the inside of the tail, where the hole is cut for the open only servo (in build plans).It would be good to have a pushrod stopper on the door control horn to make it easier to release the door to be opened manually, but I don't have any more laying around, guess that will be next mod.

Last edited:

JUSS10

I like Biplanes

I did pretty much the exact same thing with mine that I showed. Foam in the inside where the servo hole was so the door closes tight. I also beveled the edges of the foam so the door closes nicer. I intend to ad a spring pressure setup on the servo arm similar to what you see on nitro RC cars for throttle/brake so the door stays under light pressure when closed.

I couldn't figure out how to add a timed open/close on my radio (turnigy 9x) not sure if the stock firmware has that option.

Justin

I couldn't figure out how to add a timed open/close on my radio (turnigy 9x) not sure if the stock firmware has that option.

Justin

nevenelestate

No Agenda FPV

Luckily with the Spektrum radios it was very easy. Just had to change the aircraft type to a wing with ailerons and flaps, that in turn opens up the flaps menu. I adjusted the travels to get the best door closed tight and then set the time to 3 sec travel time.

JLT_GTI

Member

Thinking in building one of theese....

I really would like to build a kit .. but im in europe and shiping prices are killing

I have 2 questions..

-I got "accidentally" (not preciselly what i tought i was ordering) 2 DYS 1306-2300kv motors... they are tiny (13g)... but in their specs i see they can take up to 8A and arround 450g thrust each with 5X3 props .. should they be up to the task with the MiniG?

-I see in the videos that they use JST-HX connector plugs for the power pods and the main battery (Y harness) .... but .. arent JST connectors limited to arround 5A max? some sources said up to 10A but searching in forums most people agree that thye shouldnt handle more than 5A ... even individually they would be overloaded ..but the Y connector for the battery would be handiling twice more power...

Im i missing something here?

I really would like to build a kit .. but im in europe and shiping prices are killing

I have 2 questions..

-I got "accidentally" (not preciselly what i tought i was ordering) 2 DYS 1306-2300kv motors... they are tiny (13g)... but in their specs i see they can take up to 8A and arround 450g thrust each with 5X3 props .. should they be up to the task with the MiniG?

-I see in the videos that they use JST-HX connector plugs for the power pods and the main battery (Y harness) .... but .. arent JST connectors limited to arround 5A max? some sources said up to 10A but searching in forums most people agree that thye shouldnt handle more than 5A ... even individually they would be overloaded ..but the Y connector for the battery would be handiling twice more power...

Im i missing something here?

Last edited:

Lorenzo

Senior Member

-I got "accidentally" (not preciselly what i tought i was ordering) 2 DYS 1306-2300kv motors... they are tiny (13g)... but in their specs i see they can take up to 8A and arround 450g thrust each with 5X3 props .. should they be up to the task with the MiniG?

Those motors will work; they're similar to the Emax MT1806.

Last edited:

JUSS10

I like Biplanes

I'm using the JST connections on my mini guinea and dont seem to have an issue. That said, I can run mine at half throttle all day long and cruise just fine. If I hammer it I have unlimited vertical. I'm running 2200kv motors with 6x4 props.

Does anyone have tip stall issues with this plane or did I screw something up when building it. when I try and bank a turn if my wing goes above say 30 degrees it just falls from the sky. This is my first 4 channel plane so I'm not used to rudder yet. Is that my issue? I'm not making coordinated turns?

I added a mix to my radio to add a little rudder when I turn with the ailerons, hope this will help?

Justin

Does anyone have tip stall issues with this plane or did I screw something up when building it. when I try and bank a turn if my wing goes above say 30 degrees it just falls from the sky. This is my first 4 channel plane so I'm not used to rudder yet. Is that my issue? I'm not making coordinated turns?

I added a mix to my radio to add a little rudder when I turn with the ailerons, hope this will help?

Justin

JLT_GTI

Member

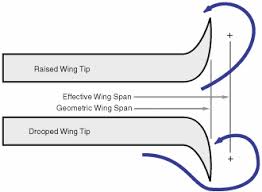

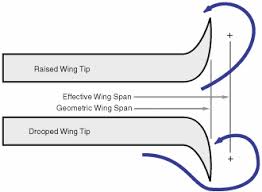

Thats weird... didnt they left the wingtips concave preciselly to avoid tipstalling issues?

One way of have an added protection against tipstall is adding wiglets to the tips.. basically make a fin all the wing chord wich is larger in the trailing edge than in leading edge to keep the airflow there and avoid the nasty wingtip vortex

Both ways (winglet up or winglet down) appear to be similarly effective

for example this a hoerner down winglet

As for JST.. well they do use JST in their planes... i know they can take 5/6A (my Blade 120SR heli has a JST connector and it does arround 5-6A) but most sites say like that never go above that.. and this config should top near 8A ..

Well actually now making calculations my Blade 120SR takes 8m to use a 900mAh battery (its a 950 and it usually ~100mAh left) thats arround 6A but thats a casual flight at 50% throttle.. at full throttle i guess it would top nearly 10A and it uses a normal JST connector... so probably is ok for each motor..

However im going to go with a XT60 for the main battery connector as thats suposed to take motor load X 2 being a twin engine.. i have many arround so not trouble at all

One way of have an added protection against tipstall is adding wiglets to the tips.. basically make a fin all the wing chord wich is larger in the trailing edge than in leading edge to keep the airflow there and avoid the nasty wingtip vortex

Both ways (winglet up or winglet down) appear to be similarly effective

for example this a hoerner down winglet

As for JST.. well they do use JST in their planes... i know they can take 5/6A (my Blade 120SR heli has a JST connector and it does arround 5-6A) but most sites say like that never go above that.. and this config should top near 8A ..

Well actually now making calculations my Blade 120SR takes 8m to use a 900mAh battery (its a 950 and it usually ~100mAh left) thats arround 6A but thats a casual flight at 50% throttle.. at full throttle i guess it would top nearly 10A and it uses a normal JST connector... so probably is ok for each motor..

However im going to go with a XT60 for the main battery connector as thats suposed to take motor load X 2 being a twin engine.. i have many arround so not trouble at all

Last edited:

Christopher14

Driftin' with the wind...

I have used a JST on a 4s setup drawing about 12A, it did get a little bit warm, but it worked great.

JLT_GTI

Member

I have used a JST on a 4s setup drawing about 12A, it did get a little bit warm, but it worked great.

Thanks.

I did some tests yesterday ...got up to 7.4A steady and wires werent even warm .. should be safe with 20AWG

Lorenzo

Senior Member

Man oh man, I just took my freshly built (and painted) Mini Guinea out for its maiden. It banked hard right into the ground just after hand launch. The nose, as designed, took all the punishment and popped like a balloon. First twin-motor lesson learned: snych the timing of the motors! I didn't realize my left was running higher than my right, hence the hard right yaw/bank on takeoff. Time to build a new nose!

Last edited:

Lorenzo

Senior Member

Phew, finally got my first successful flight this afternoon. The weather was perfect and I was actually able to rebuild my original nose cone (though I did order some spares for the future). My first two hand launches were underpowered and it seemed tail heavy (I had the CG set at the recommended location) so the little Guinea just kind of flopped onto the grass (no out-of-control right bank this time though). I set the battery (1300 mAH) about an inch forward and gave it a bit over half throttle with a stronger throw and she climbed out nice and flew like a champ. The Mini Guinea is a lot more speedy than I was anticipating; I'm using Emax MT1806 motors with 6 x 4 props. It flew like it was on rails and has impressive vertical at 3/4 throttle. Next up I will be finishing my paint job, adding the two little vertical stabilizers and installing a cargo door servo.

Last edited:

Christopher14

Driftin' with the wind...

Good job Lorenzo! it looks great.

Lorenzo

Senior Member

Thank you! I actually just finished up the paint job; inspired by TaleSpin, you can check it out here if you like:Good job Lorenzo! it looks great.

http://forum.flitetest.com/showthread.php?14637-TaleSpin-Inspired-Mini-Guinea

Christopher14

Driftin' with the wind...

Lookin good!

nevenelestate

No Agenda FPV

Mini Cargo bay and bottom mounted door servo

After some flights with my first Guinea, a speed build kit, I decided to build a second fuselage to implement some mods.

Before even building the Guinea I wanted to drop stuff from it, having built a opening door on the first attempt and in talking with my friend who also built one, he mentioned partitioning off the cargo bay. I sketched up some plans for a isolated cargo bay, built one fit tested it, then tweaked the design. Cargo bay build 2 worked out better, I cut it out of black foam board (Adams).I designed it to go forward in the haul a little, leave room in the top of the fuselage for the tail servo wires, and the rear wall of the cargo bay is positioned to stop the door from going up into the haul.

Because of the cargo bay I had to move the door servo/linkage. I decided to locate the servo in the bottom of the fuselage and then position the control horn on the bottom of the door. I had to position the servo far enough forward to be ahead of the cargo bay and also decided to center it left/right for CG consideration. I cut a hole a large enough to fit the servo and allow control arm movement. I then cut a piece of foam board a little larger than that hole, cut a notch out for the servo wire, and then glued it to the inside of the fuselage. I positioned the main gear on the door hinge line so that the door control horn could pivot over the axle. Since the servo sticks down below the bottom of the fuselage I added a piece of foam board cut into a U-shape and beveled the leading edge and sides. The video below shows the door movement, still run on the flaps setup on my Spektrum DX6, I currently have the mid position set just below level with the bottom of the fuselage and the full open is just about where the control horn is close to hitting the axle. Once I build another nose, my original nose lived a noble life and died a valiant death, I plan to make the mid position open to the ground like a loading ramp.

I will post up the plans for the cargo bay once I clean them up a bit.

After some flights with my first Guinea, a speed build kit, I decided to build a second fuselage to implement some mods.

Before even building the Guinea I wanted to drop stuff from it, having built a opening door on the first attempt and in talking with my friend who also built one, he mentioned partitioning off the cargo bay. I sketched up some plans for a isolated cargo bay, built one fit tested it, then tweaked the design. Cargo bay build 2 worked out better, I cut it out of black foam board (Adams).I designed it to go forward in the haul a little, leave room in the top of the fuselage for the tail servo wires, and the rear wall of the cargo bay is positioned to stop the door from going up into the haul.

Because of the cargo bay I had to move the door servo/linkage. I decided to locate the servo in the bottom of the fuselage and then position the control horn on the bottom of the door. I had to position the servo far enough forward to be ahead of the cargo bay and also decided to center it left/right for CG consideration. I cut a hole a large enough to fit the servo and allow control arm movement. I then cut a piece of foam board a little larger than that hole, cut a notch out for the servo wire, and then glued it to the inside of the fuselage. I positioned the main gear on the door hinge line so that the door control horn could pivot over the axle. Since the servo sticks down below the bottom of the fuselage I added a piece of foam board cut into a U-shape and beveled the leading edge and sides. The video below shows the door movement, still run on the flaps setup on my Spektrum DX6, I currently have the mid position set just below level with the bottom of the fuselage and the full open is just about where the control horn is close to hitting the axle. Once I build another nose, my original nose lived a noble life and died a valiant death, I plan to make the mid position open to the ground like a loading ramp.

I will post up the plans for the cargo bay once I clean them up a bit.

Last edited:

Lorenzo

Senior Member

I like the external servo - having spent a ridiculous amount of time installing an internal one (mine is a belly lander). I will be doing this on my next guinea. I also have a dx6 with the door on the flaps switch but could not figure out how to apply a slow opening.

Last edited:

nevenelestate

No Agenda FPV

DX6 flap setup

You have to setup the "Aircraft Type" to get the actual "Flap System" menu in the Function List.

In System Setup you select Aircraft Type menu

Then change the wing type to 1 Aileron and 1 Flap, this opens up the Flap menu in the function list.

Then go back to the model and in access the Function List, then scroll down to Flap System

In this menu I setup the Position 0 for closed door position, I started with about 20% so that the door was not closed or over actuating the servo, then dialed in in for a good tight close without stressing the servo. Then adjusted the %s on Position 1 and Position 2.

I also setup the same switch under F-Mode so that I could change the text displayed on the screen, just in case I forget which position is which, or if the acft is too far away to see the door position.

I lIke the external servo, having spent a ridiculous amount of time installing an internal one (mine is a belly lander). I will be doing this on my next guinea. I also have a dx6 with the door on the flaps switch but could not figure out how to apply a slow opening.

You have to setup the "Aircraft Type" to get the actual "Flap System" menu in the Function List.

In System Setup you select Aircraft Type menu

Then change the wing type to 1 Aileron and 1 Flap, this opens up the Flap menu in the function list.

Then go back to the model and in access the Function List, then scroll down to Flap System

In this menu I setup the Position 0 for closed door position, I started with about 20% so that the door was not closed or over actuating the servo, then dialed in in for a good tight close without stressing the servo. Then adjusted the %s on Position 1 and Position 2.

I also setup the same switch under F-Mode so that I could change the text displayed on the screen, just in case I forget which position is which, or if the acft is too far away to see the door position.

Similar threads

- Replies

- 37

- Views

- 2K

- Replies

- 3

- Views

- 233

- Replies

- 3

- Views

- 179