TooJung2Die

Master member

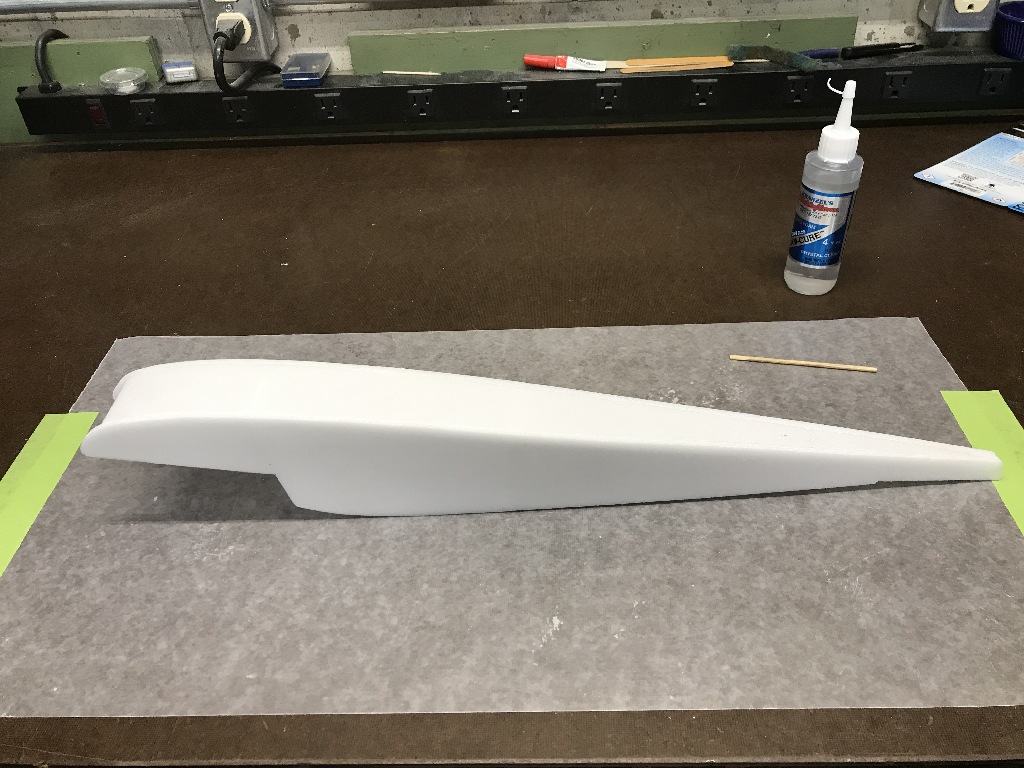

Good timing for the Challenge. I just finished a balsa airplane (Guillow's Lancer) so that means it is time to take a break and build a foamy. The Ranger 30 designed by Carl Goldberg has great memories for me. It was my favorite free-flight airplane when I was a boy. The kit was inexpensive. The build was easy. It flew great and was tough enough to survive many rooftop and treetop landings.

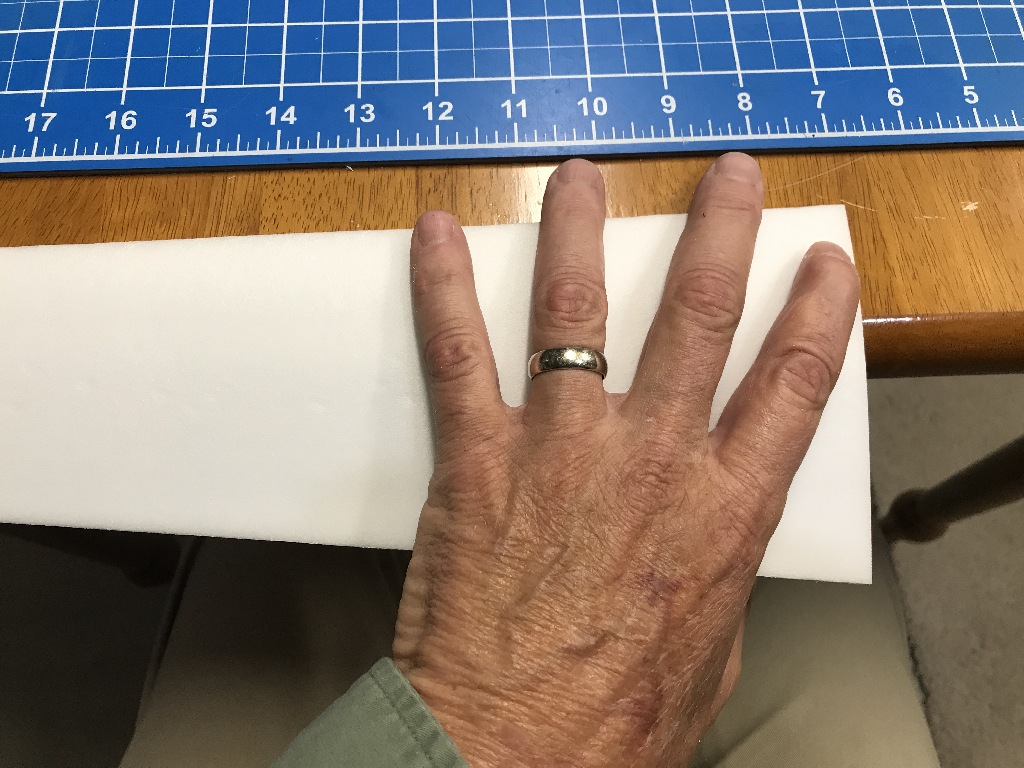

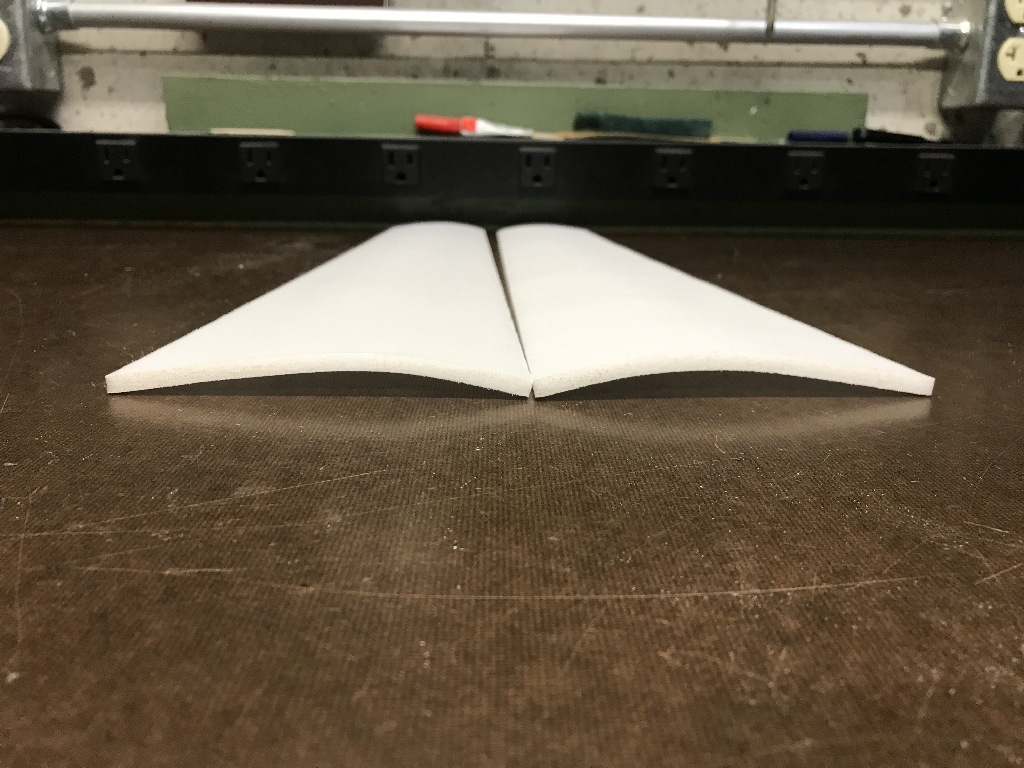

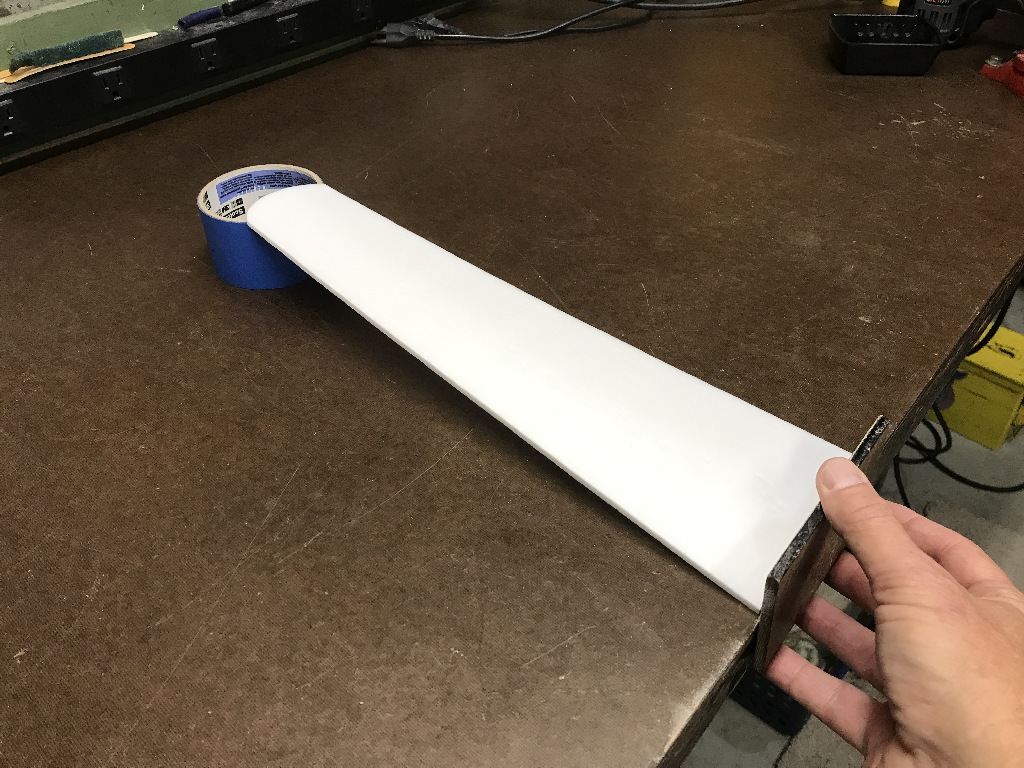

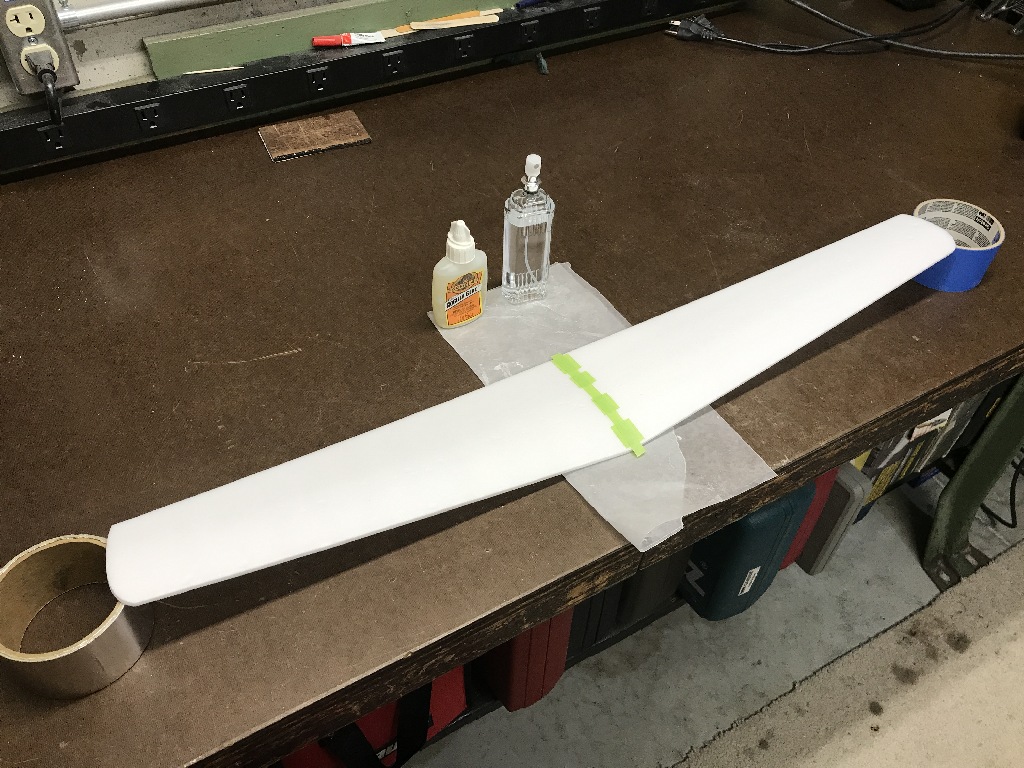

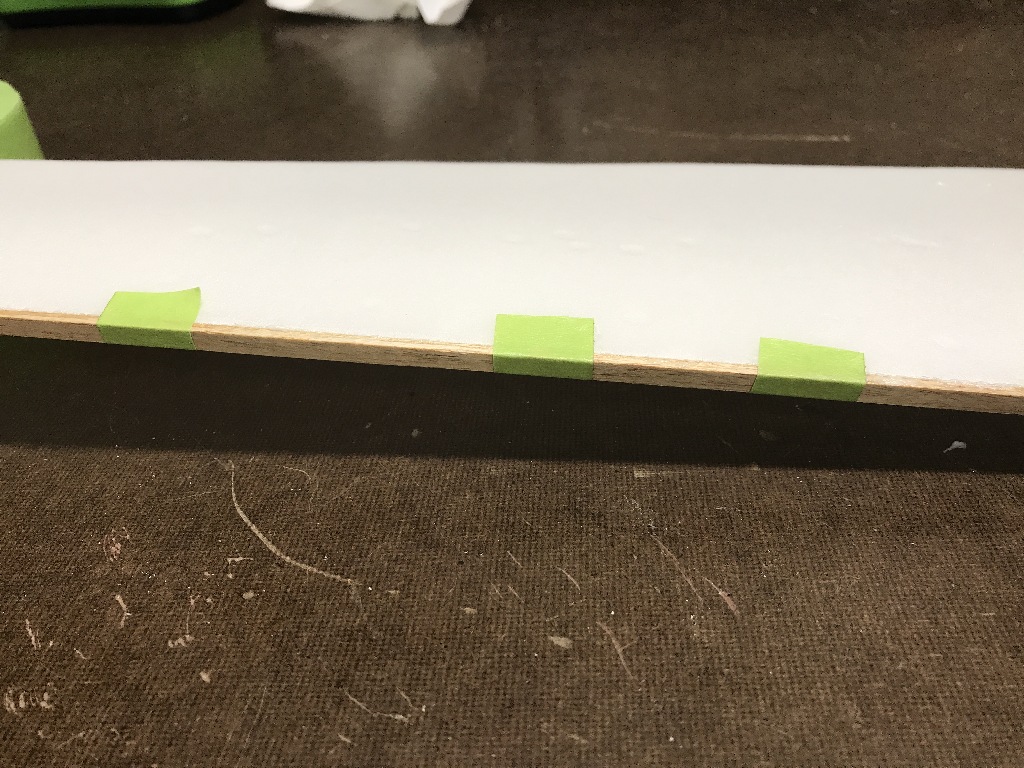

There is another thread I started back in 2015 for this airplane (Ranger 30). With a lot of help from this community we built several great flying 'A' pack 3 channel and 4 channel Rangers. It was built using Flite Test techniques. This time the build will go in a different direction. I want to build it as if the foam was balsa sheet. Since the original airplane is all balsa sheet this should be a natural for foam board. All paper will be removed. I'm going for an indoor venue ultra-light. Carbon fiber or balsa may be added for strength.

Link to the Challenge: FTFC20 Classic to Modern Forum Challenge!

Jon

A nice example of the original balsa wood kit:

Original instructions and balsa templates:

There is another thread I started back in 2015 for this airplane (Ranger 30). With a lot of help from this community we built several great flying 'A' pack 3 channel and 4 channel Rangers. It was built using Flite Test techniques. This time the build will go in a different direction. I want to build it as if the foam was balsa sheet. Since the original airplane is all balsa sheet this should be a natural for foam board. All paper will be removed. I'm going for an indoor venue ultra-light. Carbon fiber or balsa may be added for strength.

Link to the Challenge: FTFC20 Classic to Modern Forum Challenge!

Jon

A nice example of the original balsa wood kit:

Original instructions and balsa templates:

Attachments

Last edited: