basslord1124

Master member

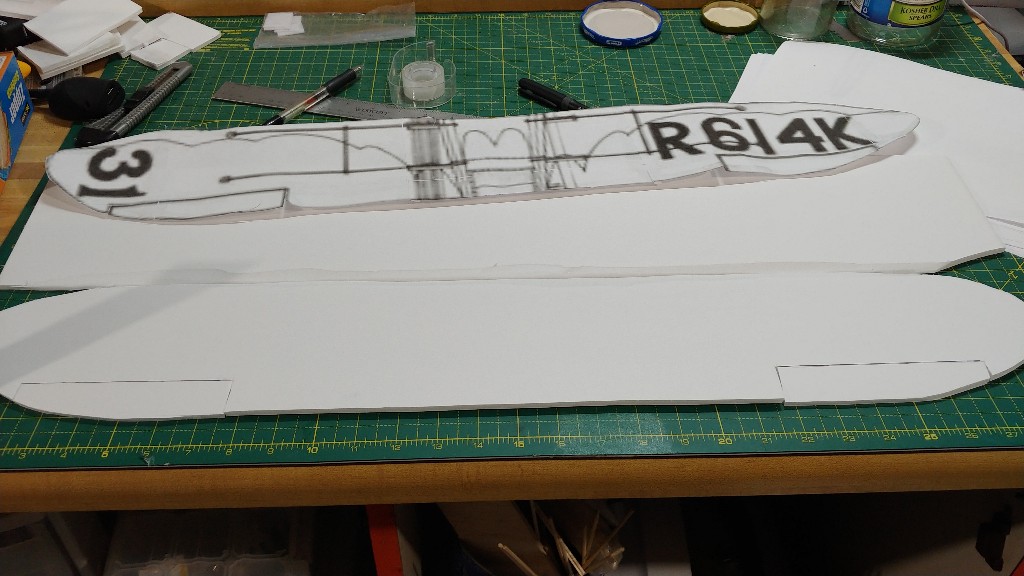

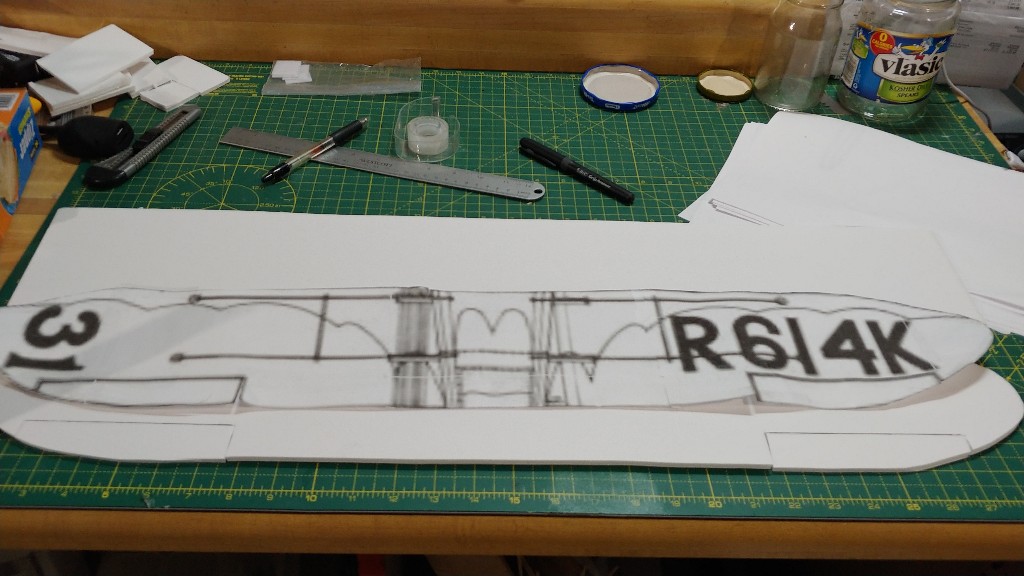

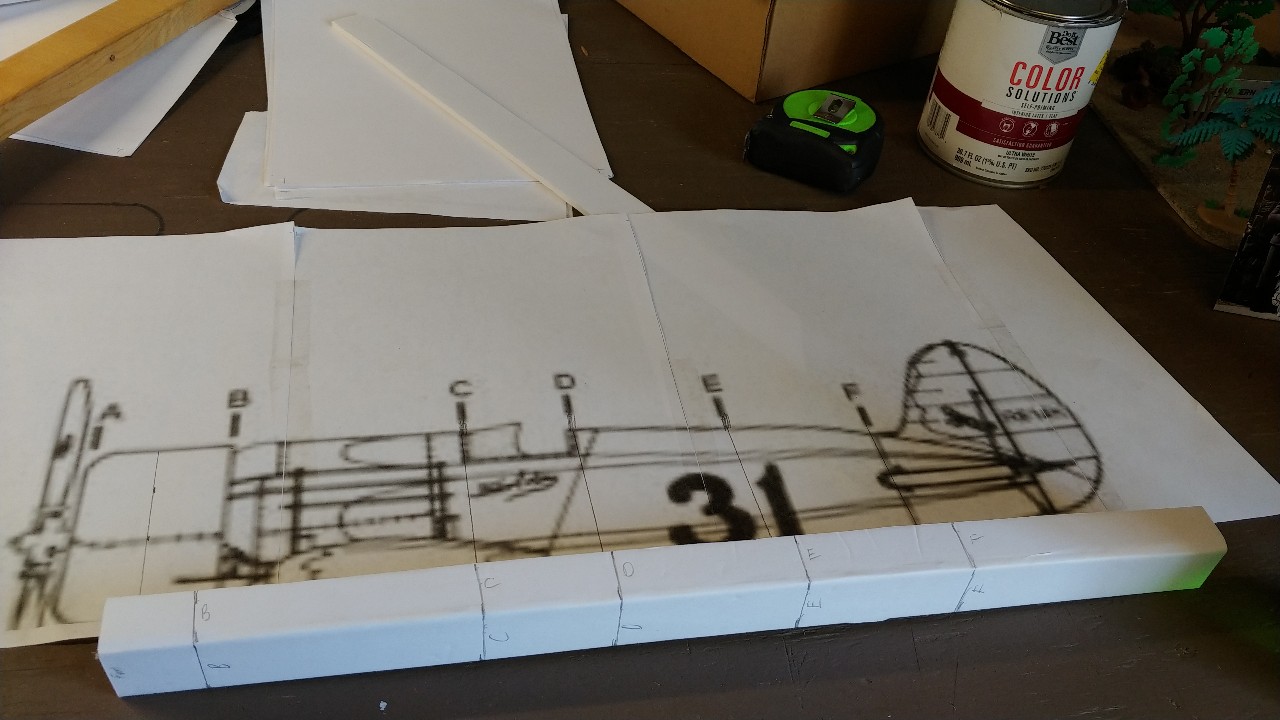

Well I have switched gears on this plane...the following may disappoint some, but I do think it will make things easier for me. Basically I am scratching the idea of doing a larger model (41" currently) and going with something smaller. I'm now aiming for 25"-30".

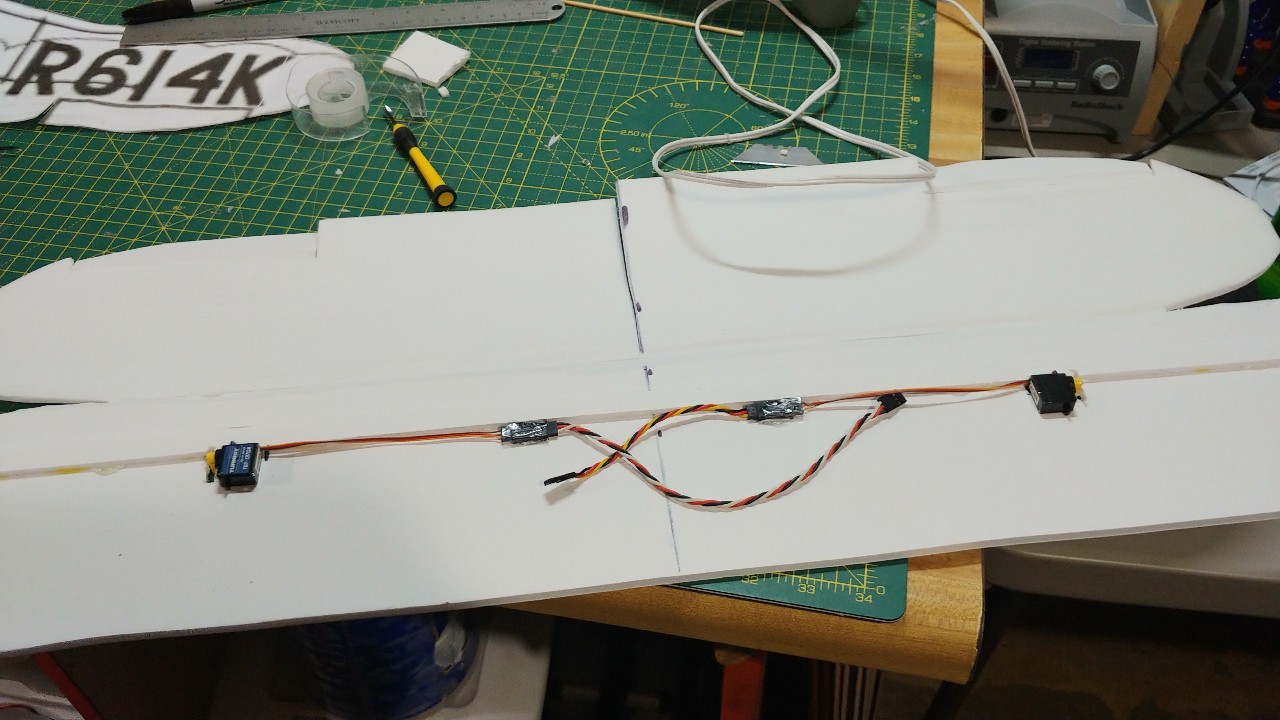

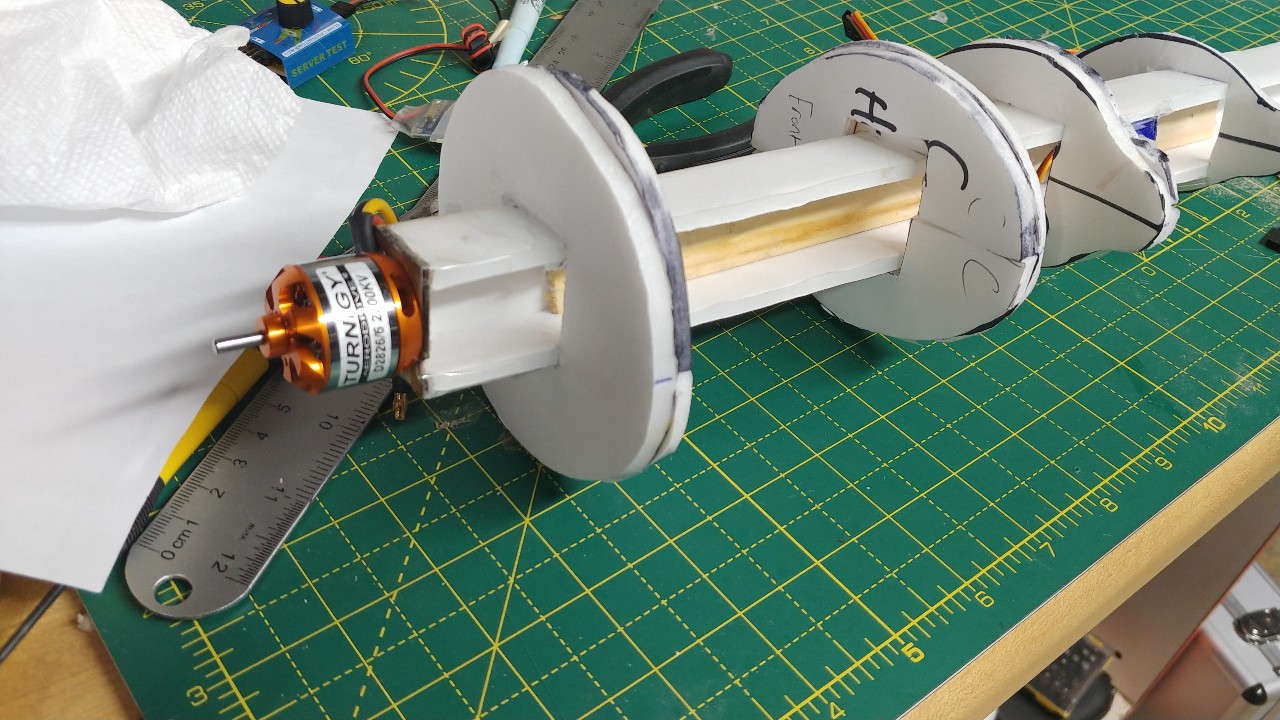

Main reason being is that I currently have a motor and ESC that would be suited for that size. I thought about keeping it for when I do the FT22 build, but figured this plane was more important right now. PLUS, I sorta hated the way the diagram looked all blown up like that. Most of the existing diagrams are in the 25"-30" size model anyways. This also saves me from having to order new gear amidst this pandemic going on (although I still may have to order servos) which would be safer in the long run anyways.

Main reason being is that I currently have a motor and ESC that would be suited for that size. I thought about keeping it for when I do the FT22 build, but figured this plane was more important right now. PLUS, I sorta hated the way the diagram looked all blown up like that. Most of the existing diagrams are in the 25"-30" size model anyways. This also saves me from having to order new gear amidst this pandemic going on (although I still may have to order servos) which would be safer in the long run anyways.