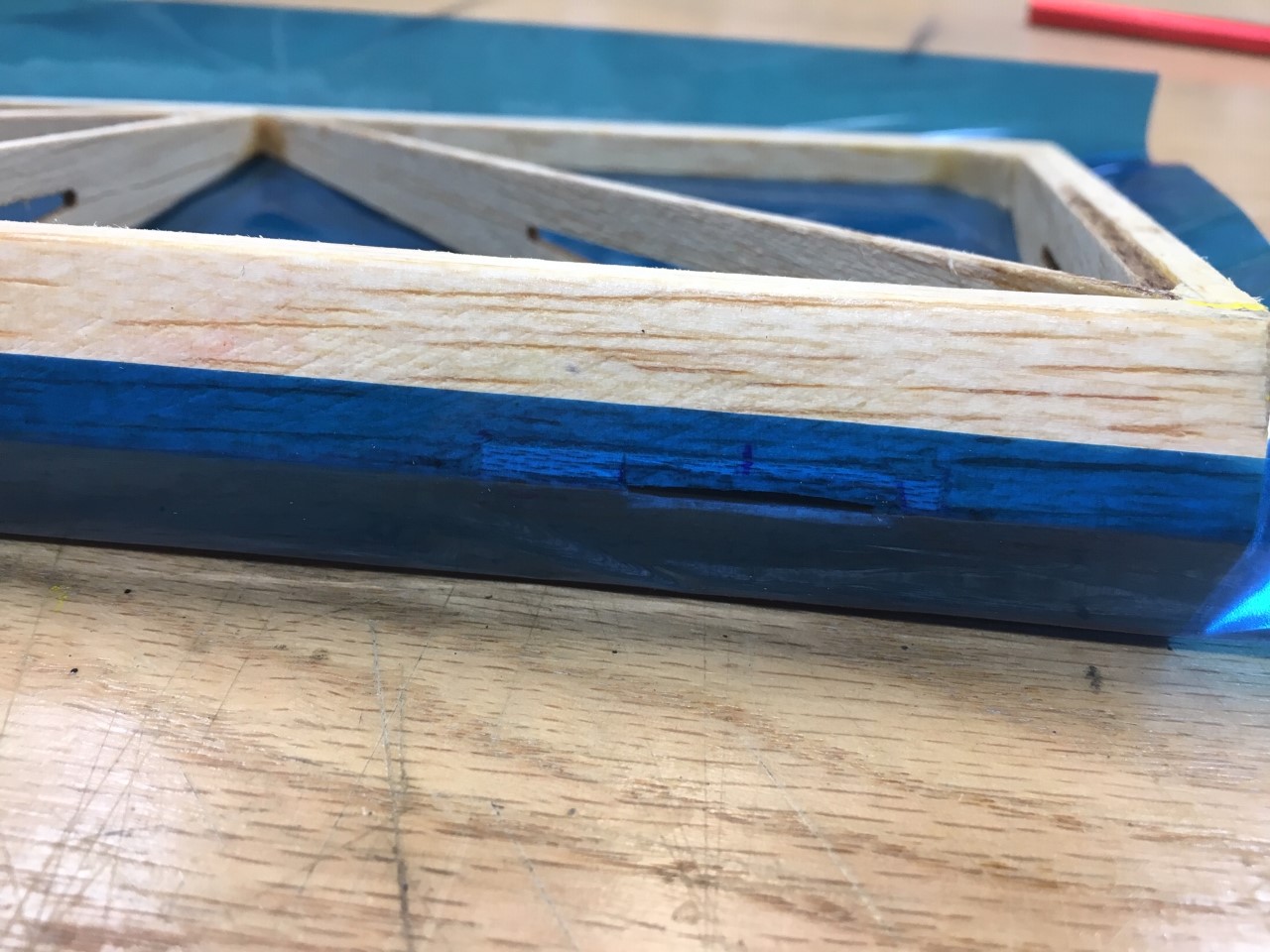

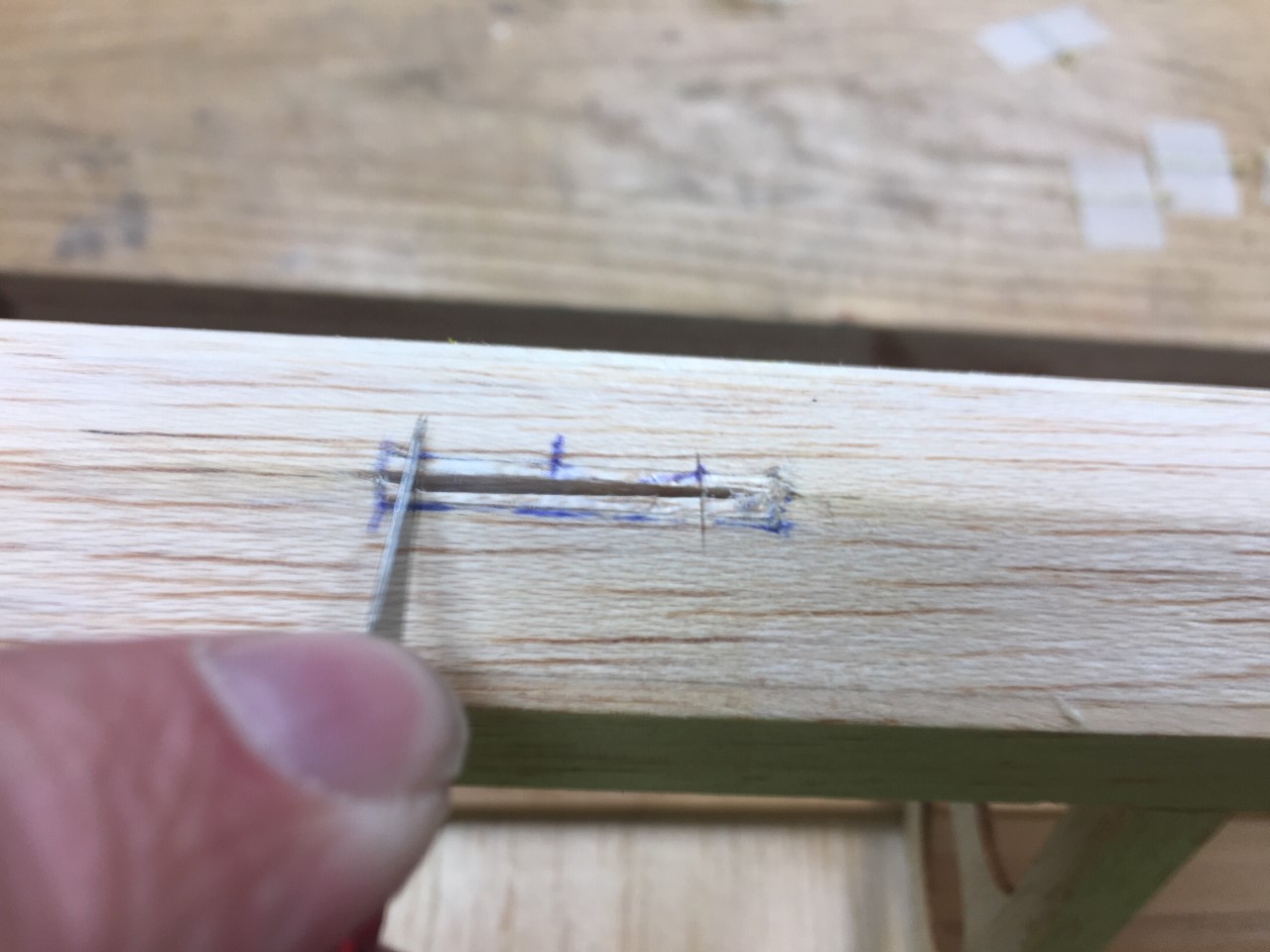

So that wasn't quite the whole story when it comes to hinges like I'm using. That barrel which is the actual hinge joint takes up space between the wing and aileron and gives you a noticeable gap. While it'll still work fine like this, it can easily be improved upon by simply recessing the hinges slightly. To start, insert the hinge and mark where the hinge barrel will sit. (The more visible lines here are from when I fixed the original hinge slots)

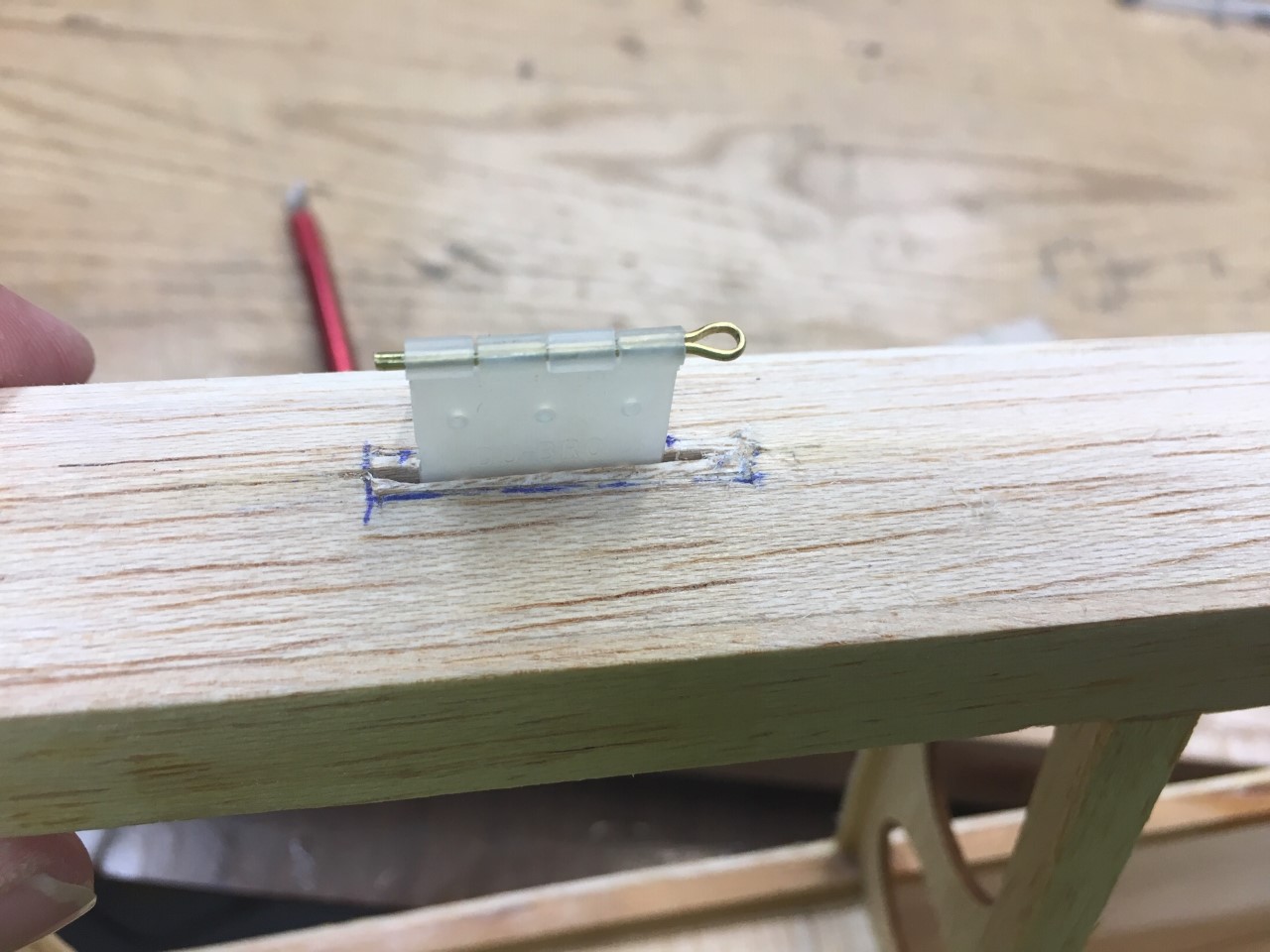

A sharp knife cuts a small slice at the edges of where the hinge will sit.

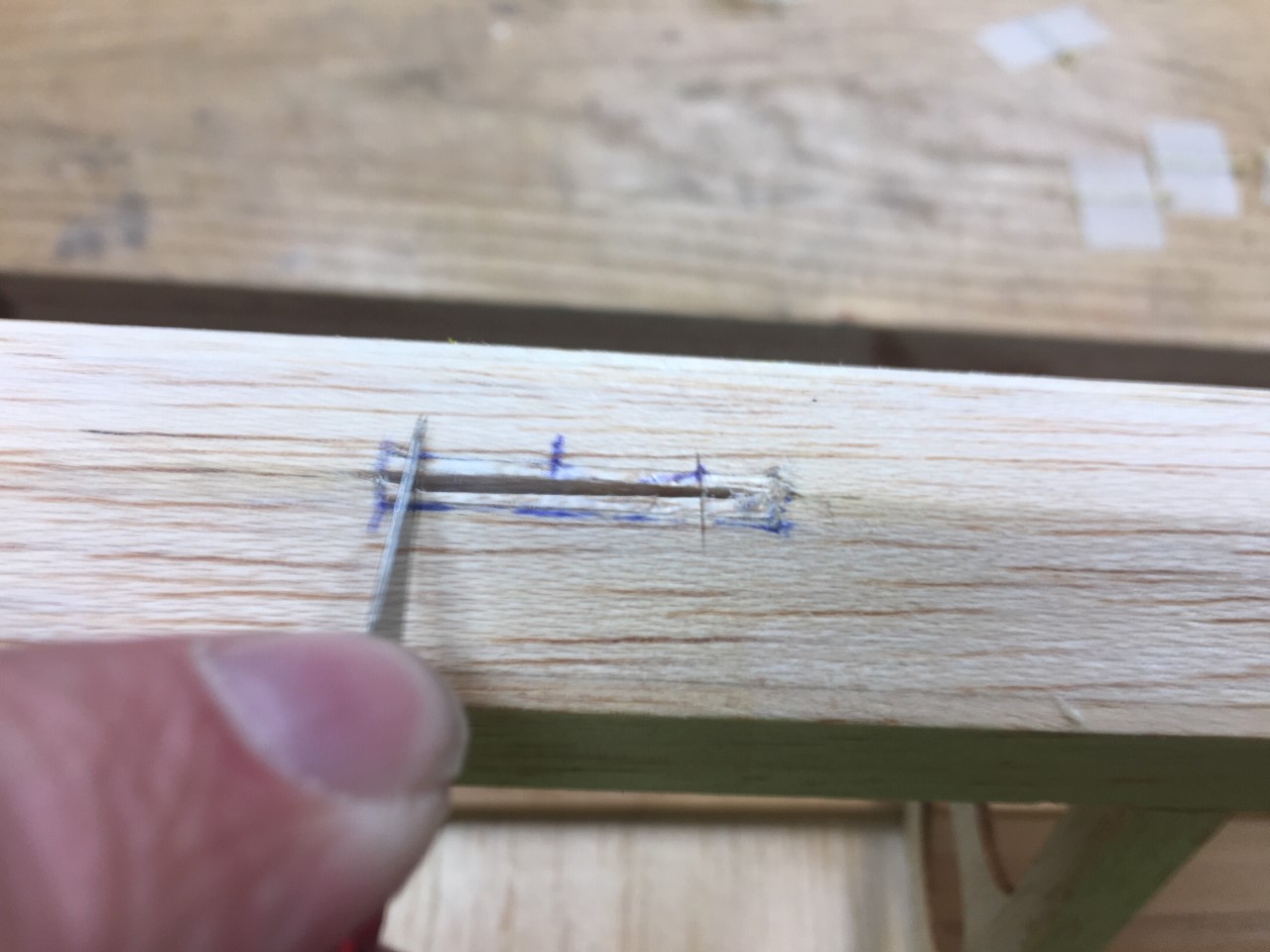

Making very shallow cuts, remove a bit of the surface which will let the hinge sit a little deeper into the wood.

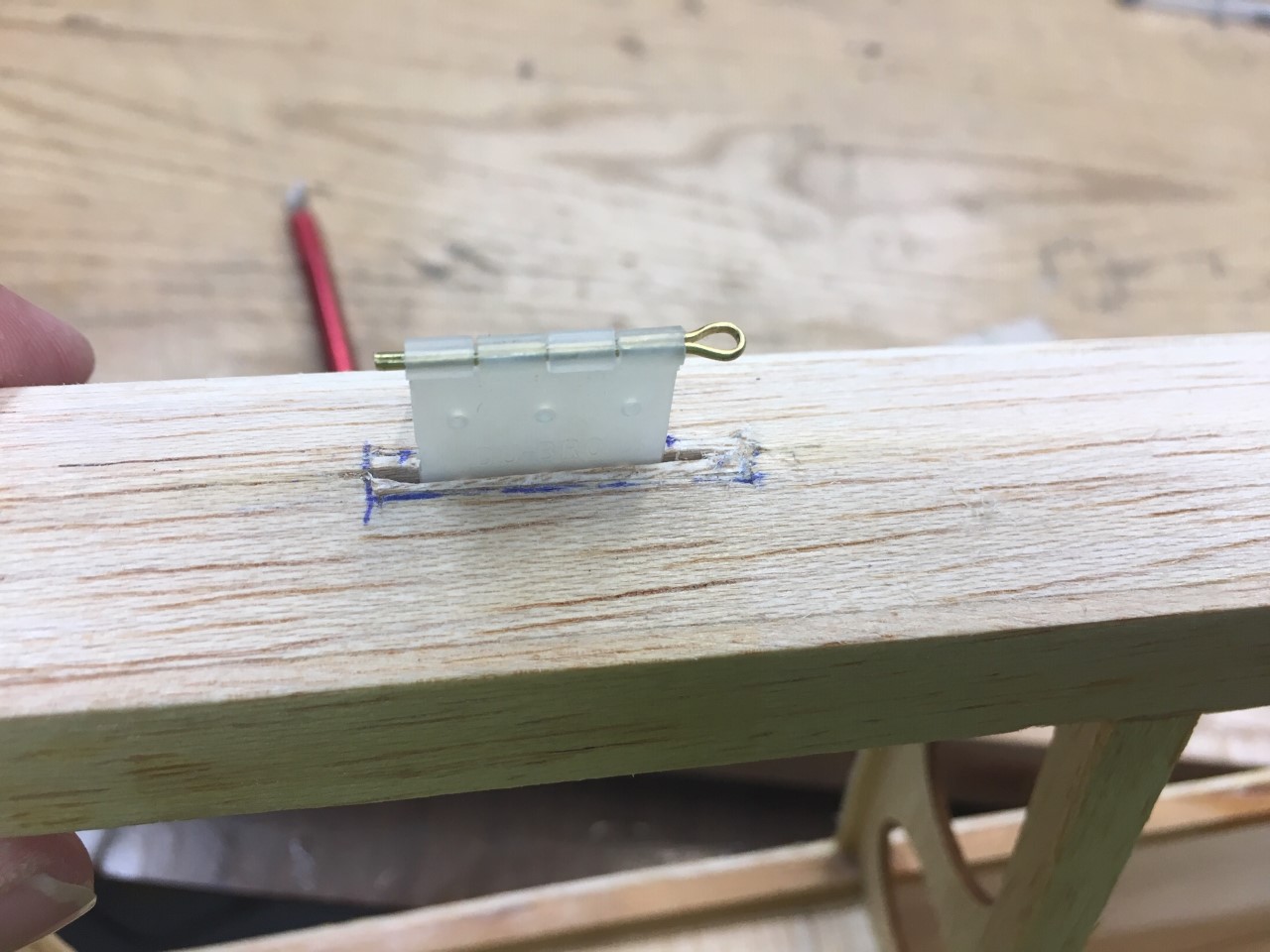

Like this. It doesn't take much, maybe 1mm or less.

In doing this for all hinges I've now got a tighter fit from the aileron to the wing. Note that the hinges won't be permanently installed until the surfaces are covered.

There is still plenty of deflection for the aileron. Note that I did sheet the outside end of the aileron to match the newly sheeted outside end of the wing.

A sharp knife cuts a small slice at the edges of where the hinge will sit.

Making very shallow cuts, remove a bit of the surface which will let the hinge sit a little deeper into the wood.

Like this. It doesn't take much, maybe 1mm or less.

In doing this for all hinges I've now got a tighter fit from the aileron to the wing. Note that the hinges won't be permanently installed until the surfaces are covered.

There is still plenty of deflection for the aileron. Note that I did sheet the outside end of the aileron to match the newly sheeted outside end of the wing.