You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Glassed Viggen

- Thread starter HilldaFlyer

- Start date

-

- Tags

- edf fiberglass viggen waterproof

captron360

Member

FT Viggen

Sounds like fun! I have an older white foam one that I never built. I think I'll build mine along with yours.

Happy landings. Hope we can fly together again.

Ron

Sounds like fun! I have an older white foam one that I never built. I think I'll build mine along with yours.

Happy landings. Hope we can fly together again.

Ron

HilldaFlyer

Well-known member

Hi Ron... This will be great fun to have a building partner... Mine too, is the older version white foam because it is now approaching 1 and half years old. Still in the box... what an ungrateful receiver to wait this long to get to something that was a gift.Sounds like fun! I have an older white foam one that I never built. I think I'll build mine along with yours.

Happy landings. Hope we can fly together again.

Ron

Were you planning on glassing your's too? Do you have the materials? Let me know. The FreeFallRC Podcast guys are building or have built theirs. If not, we'll have four glassed Viggen builds going on. The ThrustMax EDF 70mm was back ordered from HK so if that doesn't get restocked, I'll be looking for a different drive train.

captron360

Member

Hi Dave,

I have the motor and ESC that FlightTest originally said to use. I don't remember off hand what they are. If they have enough thrust I should be all set.

Did you start your build yet? I built one when they first came out. Actually I built 2. I covered the second one with foil tape. It looked nice and lasted a long time.

I have a bunch of fiber glass for the new one. Sounds like fun.

God Bless

Ron

I have the motor and ESC that FlightTest originally said to use. I don't remember off hand what they are. If they have enough thrust I should be all set.

Did you start your build yet? I built one when they first came out. Actually I built 2. I covered the second one with foil tape. It looked nice and lasted a long time.

I have a bunch of fiber glass for the new one. Sounds like fun.

God Bless

Ron

HilldaFlyer

Well-known member

Just started the build an hour an hour ago.

Punched out all the parts, peeled the paper from one side of most pieces, and both off of the pieces that don't have folds.

Used a nifty new hot wire hand cutter to bevel the trailing edges of the elevons to 4 cm from the trailing edge... oooh, that was sweet. Ran a bead of Gorilla glue along the seam in the main wing that shouldn't be there except to help the model fit in the box. Laid the first round of fiberglassing to the fuselage and a few smaller parts. I'll post pictures soon.

Punched out all the parts, peeled the paper from one side of most pieces, and both off of the pieces that don't have folds.

Used a nifty new hot wire hand cutter to bevel the trailing edges of the elevons to 4 cm from the trailing edge... oooh, that was sweet. Ran a bead of Gorilla glue along the seam in the main wing that shouldn't be there except to help the model fit in the box. Laid the first round of fiberglassing to the fuselage and a few smaller parts. I'll post pictures soon.

captron360

Member

Well then I had better get started!

HilldaFlyer

Well-known member

Viggen - Glassed

Viggen - Glassed

Build along by David HilldaFlyer, April 2017

[h=1]Unboxing[/h]

This will be the first model I put together from a FT kit. One of my good friends gave it to me for Christmas over year ago, so it is about time I got with it.

Viggen - Glassed

Build along by David HilldaFlyer, April 2017

[h=1]Unboxing[/h]

This will be the first model I put together from a FT kit. One of my good friends gave it to me for Christmas over year ago, so it is about time I got with it.

HilldaFlyer

Well-known member

Viggen - Glassed

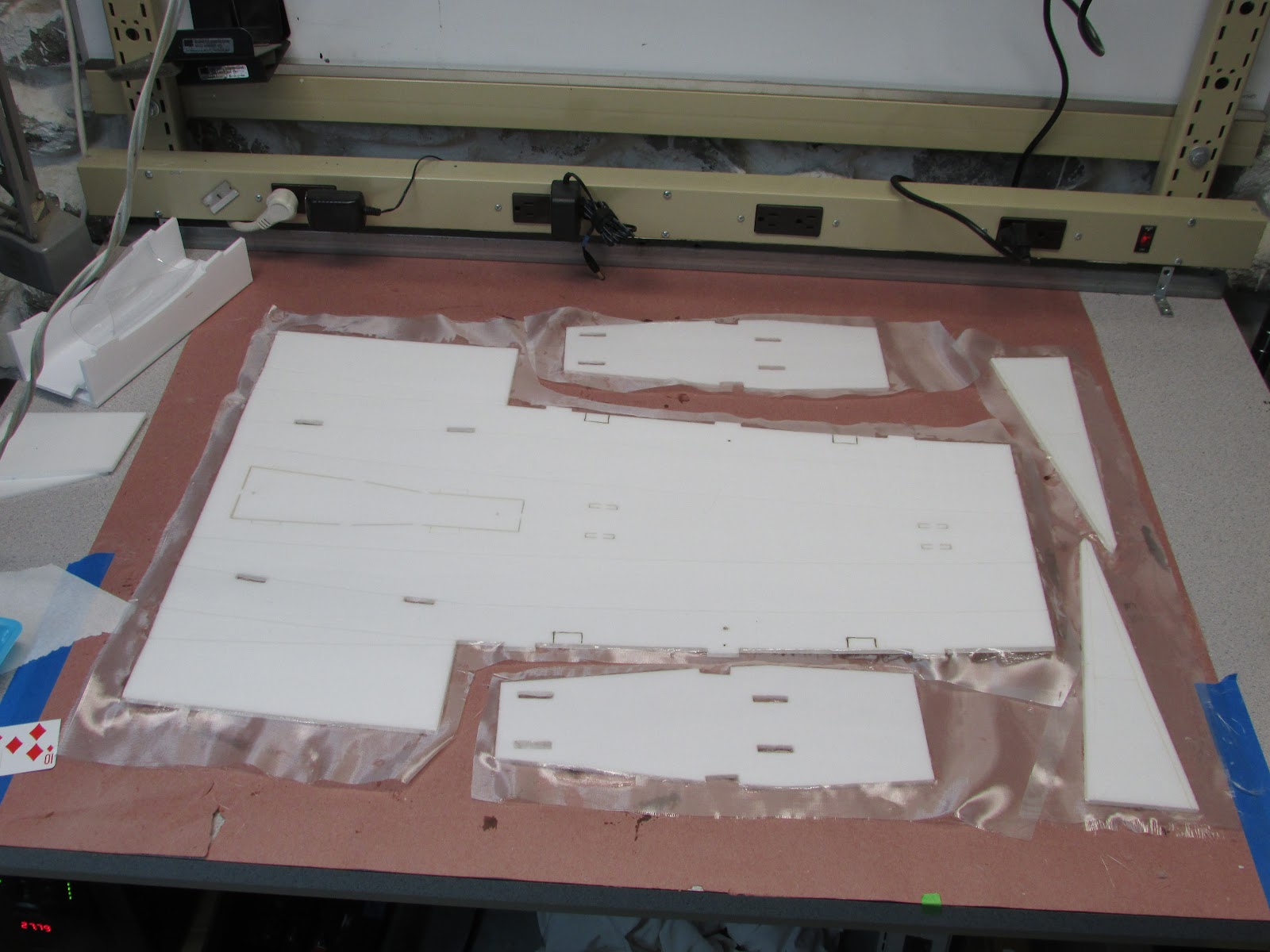

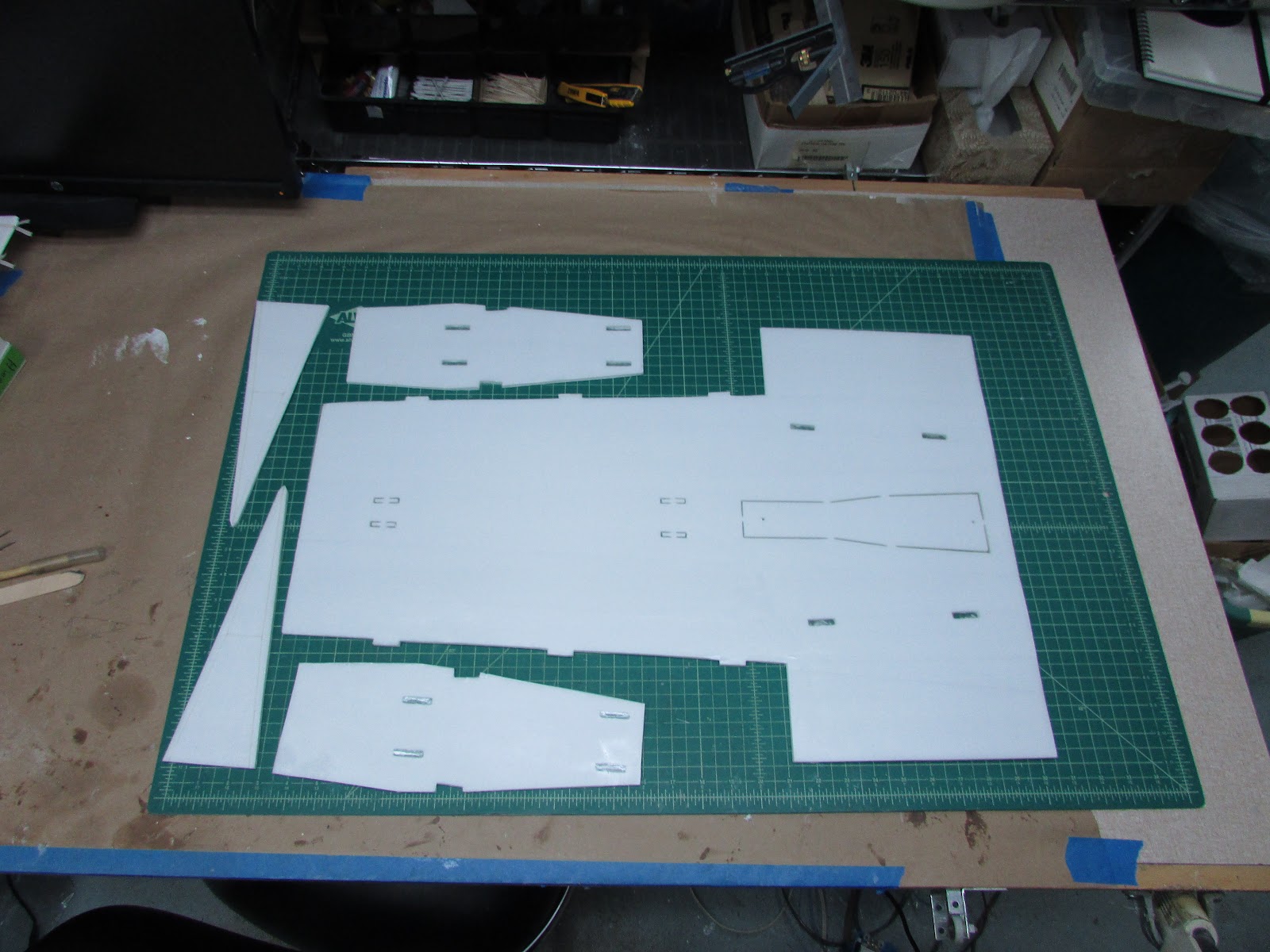

[h=1]Peeling the Paper[/h]

The first chore is to peel the paper from the foam. I’ve chosen to peel the side that has all the partial cuts so that the piece stays together when the first fiberglass skin is applied. Typically when I build a FT model from scratch, I’ll marke where the score cuts go and leave the foam uncut until after the fiberglass skin is applied. I’m curious to find out how fiberglassing over the score cuts will work out. I am anticipating that the epoxy resin will be forced into the seams while squeegeeing the wetting out process and cause the seam to become sealed. Since epoxy is much harder than foam, I imagine it will be nearly impossible to cut along a seam that has been sealed with epoxy. I’m hoping that with a little pressure, the seams will break open along the epoxy foam interface.

[h=1]Peeling the Paper[/h]

The first chore is to peel the paper from the foam. I’ve chosen to peel the side that has all the partial cuts so that the piece stays together when the first fiberglass skin is applied. Typically when I build a FT model from scratch, I’ll marke where the score cuts go and leave the foam uncut until after the fiberglass skin is applied. I’m curious to find out how fiberglassing over the score cuts will work out. I am anticipating that the epoxy resin will be forced into the seams while squeegeeing the wetting out process and cause the seam to become sealed. Since epoxy is much harder than foam, I imagine it will be nearly impossible to cut along a seam that has been sealed with epoxy. I’m hoping that with a little pressure, the seams will break open along the epoxy foam interface.

HilldaFlyer

Well-known member

Viggen - Glassed

[h=1]Fiberglassing the Fuselage - a start[/h]

After the paper is removed from one side, the fiberglass cloth can be wetted out with epoxy. I use a playing card to wet out, smear out and squeegee off the excess epoxy. While that cures…work on something else

My fiberglassing table is only big enough for a single foam sheet, so I have to do the fiberglassing one sheet at a time.

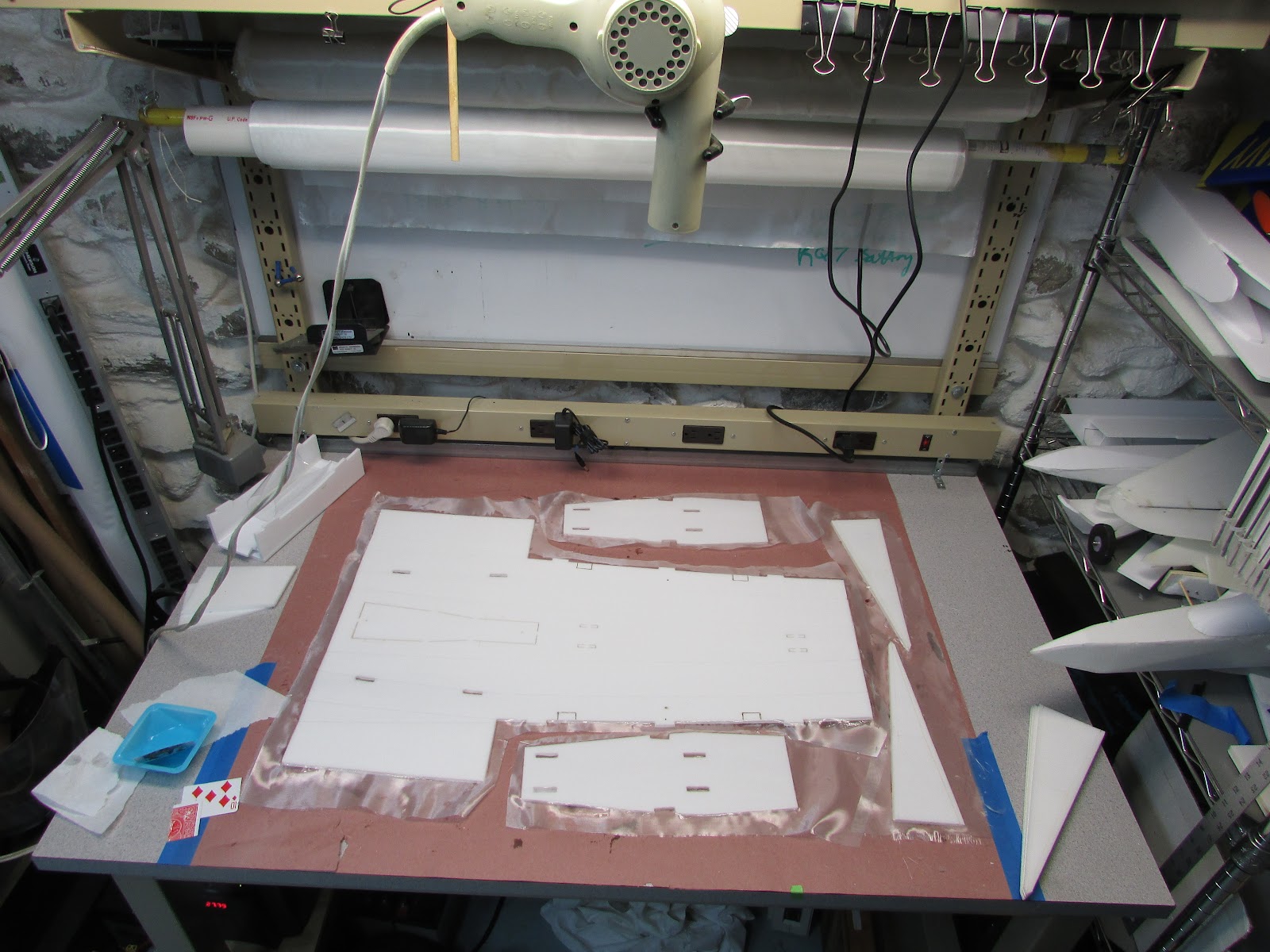

[h=1]Fiberglassing Tips/Trick[/h]

Oh, I think some of you will get a kick out of this. Epoxy resin doesn’t wet out very well at 60 degrees (or less) which is the temperature of my basement, so I use a hair dryer supported above the bench. On low it blows just enough hot air to keep the working surface between 70 degrees on the edges and 85 in the center. Another thing that you may have noticed is that I have a dirty and clean build table. The dirty one is where I do all my cutting, trimming, gluing, sanding and well, just about all of my work. The table above is my “clean” table. Peeling paper from the foam generates a huge amount of static electricity. The foam will suck up all little pieces of stuff on the bench and make the surface bumpy with garbage if it gets in between the fiberglass and foam. The only work I do at this bench is fiberglassing, cutting the fiberglass (Thayercraft.com) into workable sheets (you can see the two 100 yard rolls of fiberglass suspended behind the hair dryer), peeling paper from the foam and a little soldering, you know the kind of work that doesn’t get dust and chips of stuff all over the place.

[h=1]Fiberglassing the Fuselage - a start[/h]

After the paper is removed from one side, the fiberglass cloth can be wetted out with epoxy. I use a playing card to wet out, smear out and squeegee off the excess epoxy. While that cures…work on something else

My fiberglassing table is only big enough for a single foam sheet, so I have to do the fiberglassing one sheet at a time.

[h=1]Fiberglassing Tips/Trick[/h]

Oh, I think some of you will get a kick out of this. Epoxy resin doesn’t wet out very well at 60 degrees (or less) which is the temperature of my basement, so I use a hair dryer supported above the bench. On low it blows just enough hot air to keep the working surface between 70 degrees on the edges and 85 in the center. Another thing that you may have noticed is that I have a dirty and clean build table. The dirty one is where I do all my cutting, trimming, gluing, sanding and well, just about all of my work. The table above is my “clean” table. Peeling paper from the foam generates a huge amount of static electricity. The foam will suck up all little pieces of stuff on the bench and make the surface bumpy with garbage if it gets in between the fiberglass and foam. The only work I do at this bench is fiberglassing, cutting the fiberglass (Thayercraft.com) into workable sheets (you can see the two 100 yard rolls of fiberglass suspended behind the hair dryer), peeling paper from the foam and a little soldering, you know the kind of work that doesn’t get dust and chips of stuff all over the place.

HilldaFlyer

Well-known member

Viggen - Glassed

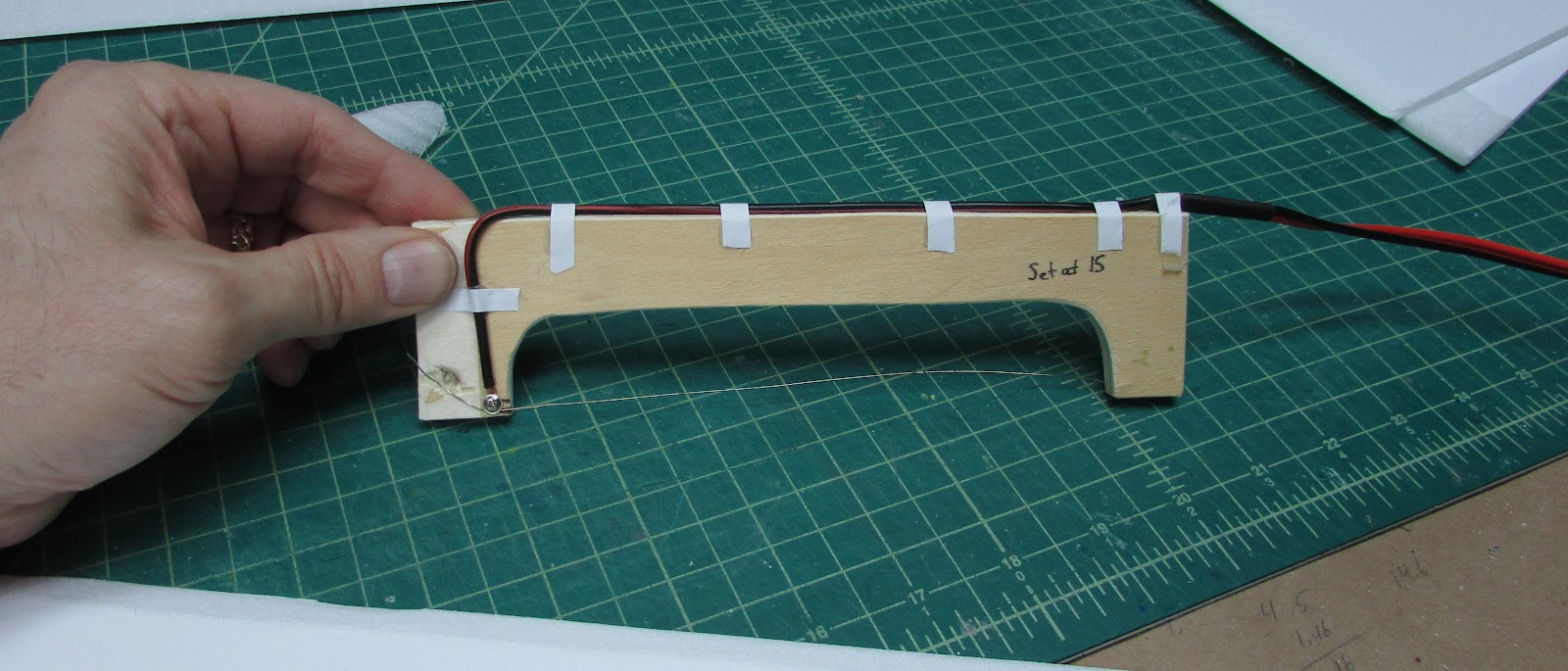

[h=1]Tapering Trailing Edges with a Hot Wire[/h]I like to have tapered trailing edges. I’ve started doing the tapered the trailing edges on my planes for a year now and I really like the increase in the airplane’s perform, so I just have to taper the trailing edges on this rocket. In all of my previous builds I’ve used 80 grit sandpaper glued to the side of a paint stirring stick to sand in the tappers. This is a really, really messy, time consuming and tiring. The little foam dust is charged statically and sticks to shirts, arms, pants, under the table… you get the idea. My shop vac will clean it up, but it is everywhere and just a pain. So, with that in mind, I was thinking there has got to be a better way, so why not do it with a hot wire cutter? I couldn’t think of a reason so I went for it.

This is the first prototype of the handheld hot wire bow, so it isn’t perfect. I made it by cutting a wide “U” out of some ¼” plywood. To opposite sides of the “U” I drilled a small hole and inserted the stripping wire. I used a leftover servo screw to secure the wire in the hole. Before screwing the servo screw down completely, I wrapped the nichrome wire (from Jacob’s Online) around the screw and then finished screwing it in. As I suspected, the wire starts out taunt, but gets loose when heat and pressure are applied. Larger hot wire bows are constructed with springs or made from elastic materials that hold the wire taunt while heating. This design worked fine because it isn’t really important to keep the wire taunt in the rig. The downward pressure against the two non-cutting “rails” keeps the wire pretty straight. I’ll probably upgrade it to have a spring of some sort, but this worked great.

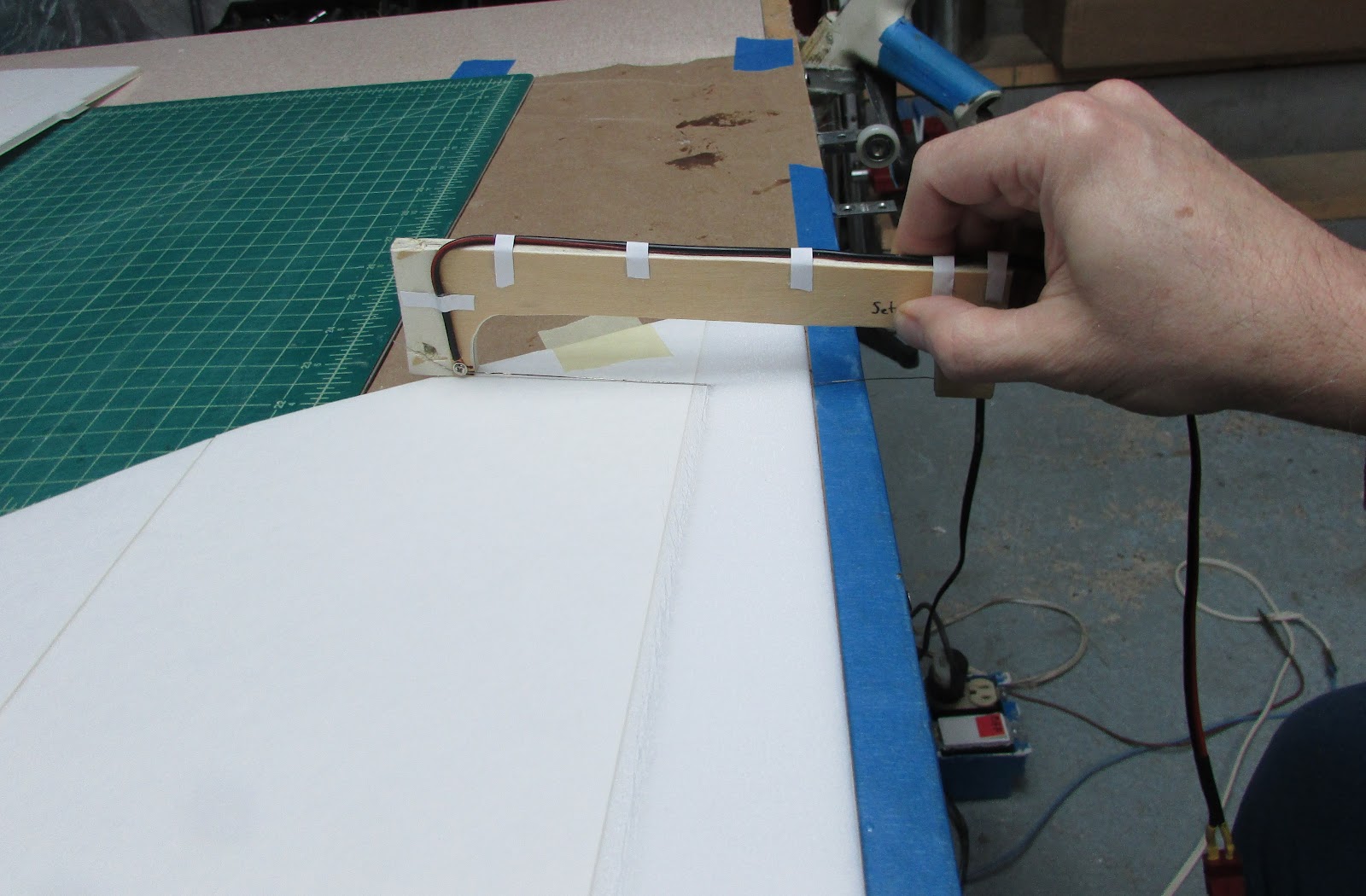

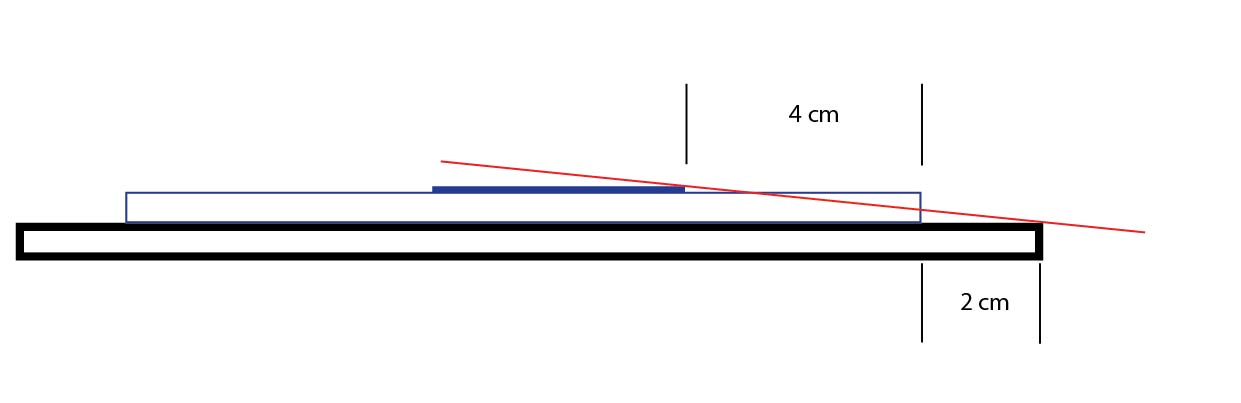

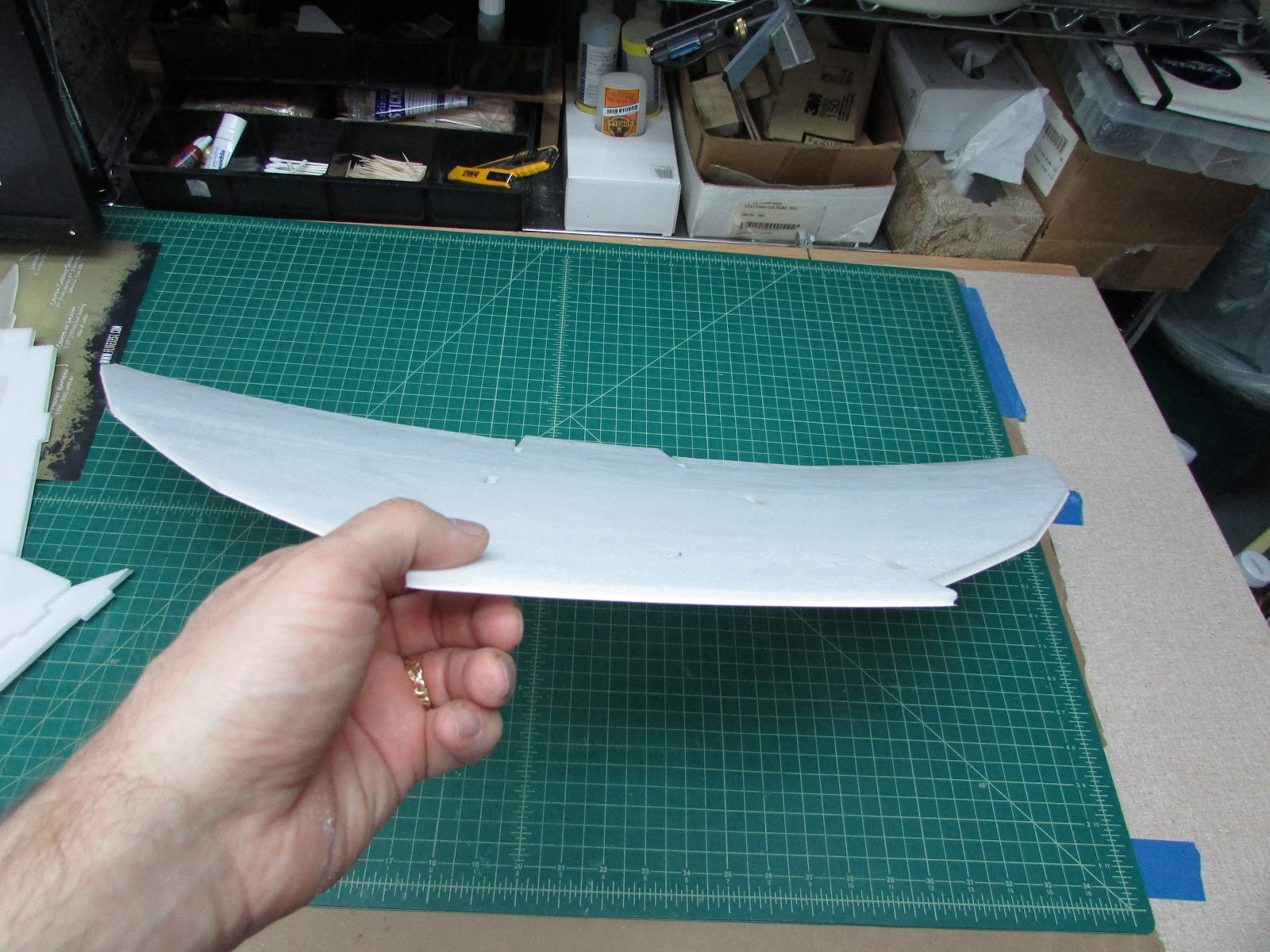

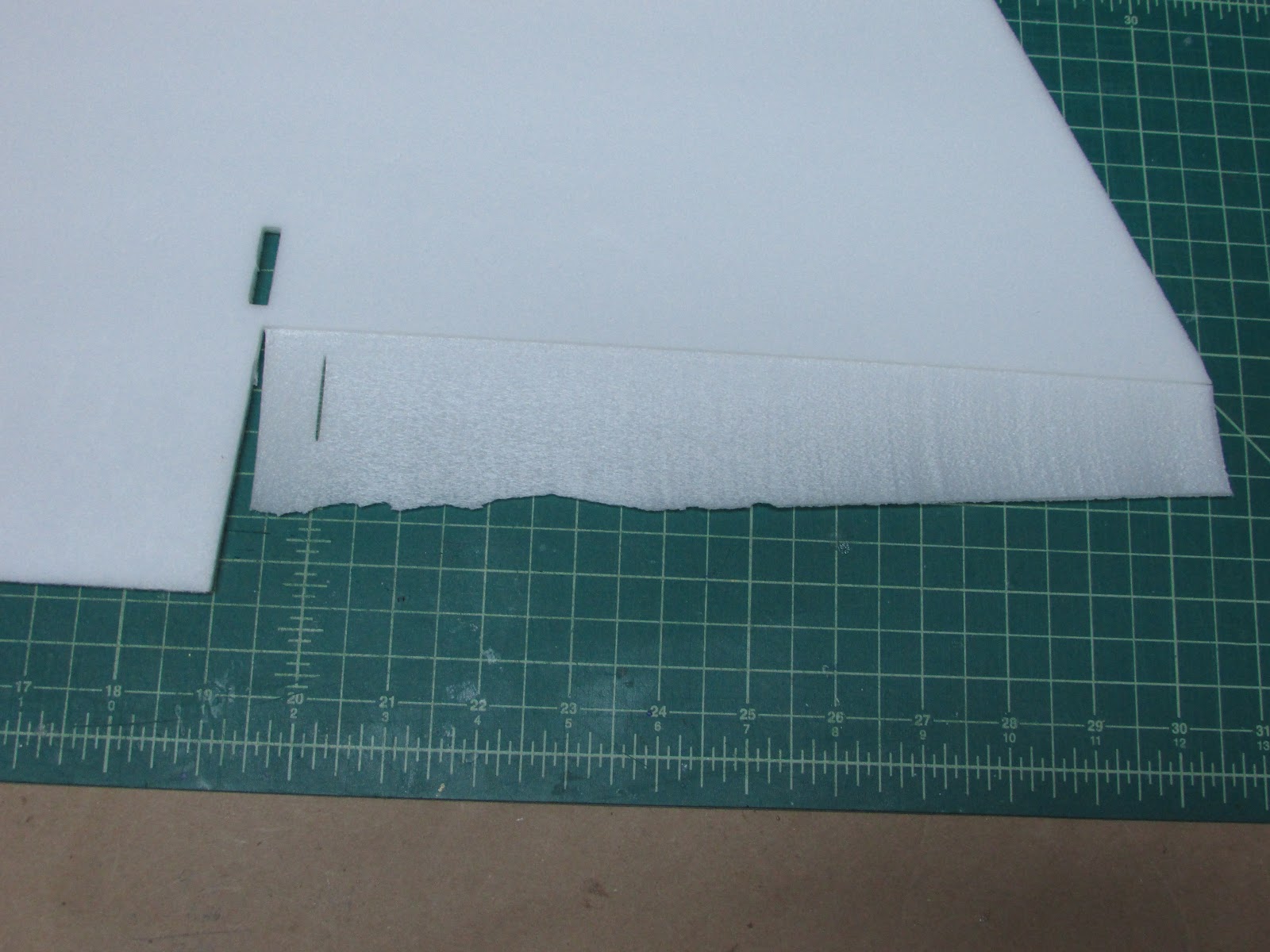

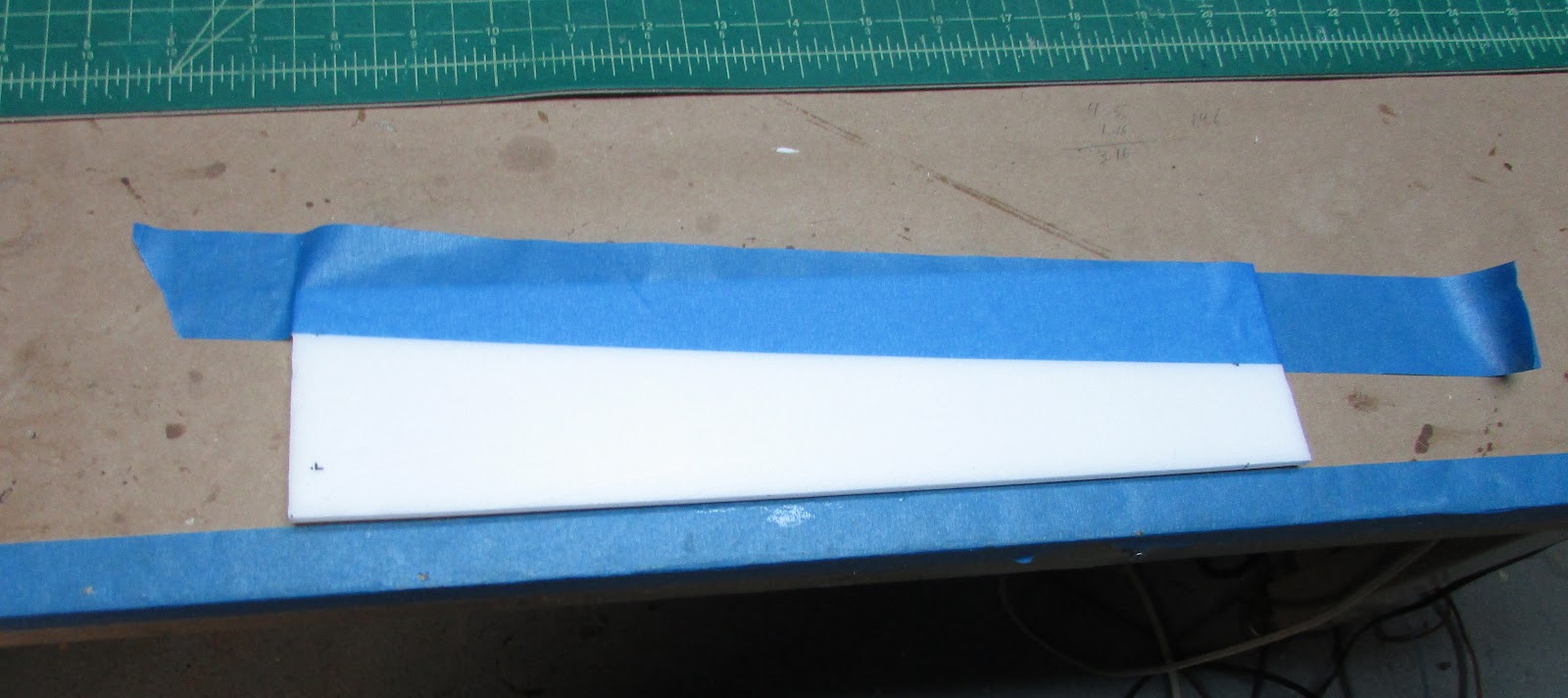

Here is a picture of the right elevon being tapered. There are two “rails” that hold the hot wire at the same distance off the foam. These “rails” are the paper on the foam to the left and the blue tape on the corner edge of the build table on the right. Tape if sufficient to keep the foam from melting as long as you keep moving.

Here is a diagram. I taped the piece of foam to the table 2 cm from the edge of the table and removed the paper 4 cm from the edge of the foam (remove the paper from the elevon). The angle and depth of the cut can be adjusted by taping the foam further or nearer the edge of the table and changing the distance of the paper or tape on the top of the foam is from the edge of the foam. If the foam doesn’t have any paper, I have used masking tape to form the left non-cutting “rail” for the hot wire (represented above by a thick blue line).

[h=1]Tapering Trailing Edges with a Hot Wire[/h]I like to have tapered trailing edges. I’ve started doing the tapered the trailing edges on my planes for a year now and I really like the increase in the airplane’s perform, so I just have to taper the trailing edges on this rocket. In all of my previous builds I’ve used 80 grit sandpaper glued to the side of a paint stirring stick to sand in the tappers. This is a really, really messy, time consuming and tiring. The little foam dust is charged statically and sticks to shirts, arms, pants, under the table… you get the idea. My shop vac will clean it up, but it is everywhere and just a pain. So, with that in mind, I was thinking there has got to be a better way, so why not do it with a hot wire cutter? I couldn’t think of a reason so I went for it.

This is the first prototype of the handheld hot wire bow, so it isn’t perfect. I made it by cutting a wide “U” out of some ¼” plywood. To opposite sides of the “U” I drilled a small hole and inserted the stripping wire. I used a leftover servo screw to secure the wire in the hole. Before screwing the servo screw down completely, I wrapped the nichrome wire (from Jacob’s Online) around the screw and then finished screwing it in. As I suspected, the wire starts out taunt, but gets loose when heat and pressure are applied. Larger hot wire bows are constructed with springs or made from elastic materials that hold the wire taunt while heating. This design worked fine because it isn’t really important to keep the wire taunt in the rig. The downward pressure against the two non-cutting “rails” keeps the wire pretty straight. I’ll probably upgrade it to have a spring of some sort, but this worked great.

Here is a picture of the right elevon being tapered. There are two “rails” that hold the hot wire at the same distance off the foam. These “rails” are the paper on the foam to the left and the blue tape on the corner edge of the build table on the right. Tape if sufficient to keep the foam from melting as long as you keep moving.

Here is a diagram. I taped the piece of foam to the table 2 cm from the edge of the table and removed the paper 4 cm from the edge of the foam (remove the paper from the elevon). The angle and depth of the cut can be adjusted by taping the foam further or nearer the edge of the table and changing the distance of the paper or tape on the top of the foam is from the edge of the foam. If the foam doesn’t have any paper, I have used masking tape to form the left non-cutting “rail” for the hot wire (represented above by a thick blue line).

Michael9865

Elite member

I love the way you are tapering your elevons. I will have to try that on my Kfir. Thank you!

HilldaFlyer

Well-known member

Smooth, straight and no sanding dust!! BonusI love the way you are tapering your elevons. I will have to try that on my Kfir. Thank you!

HilldaFlyer

Well-known member

Viggen - Glassed

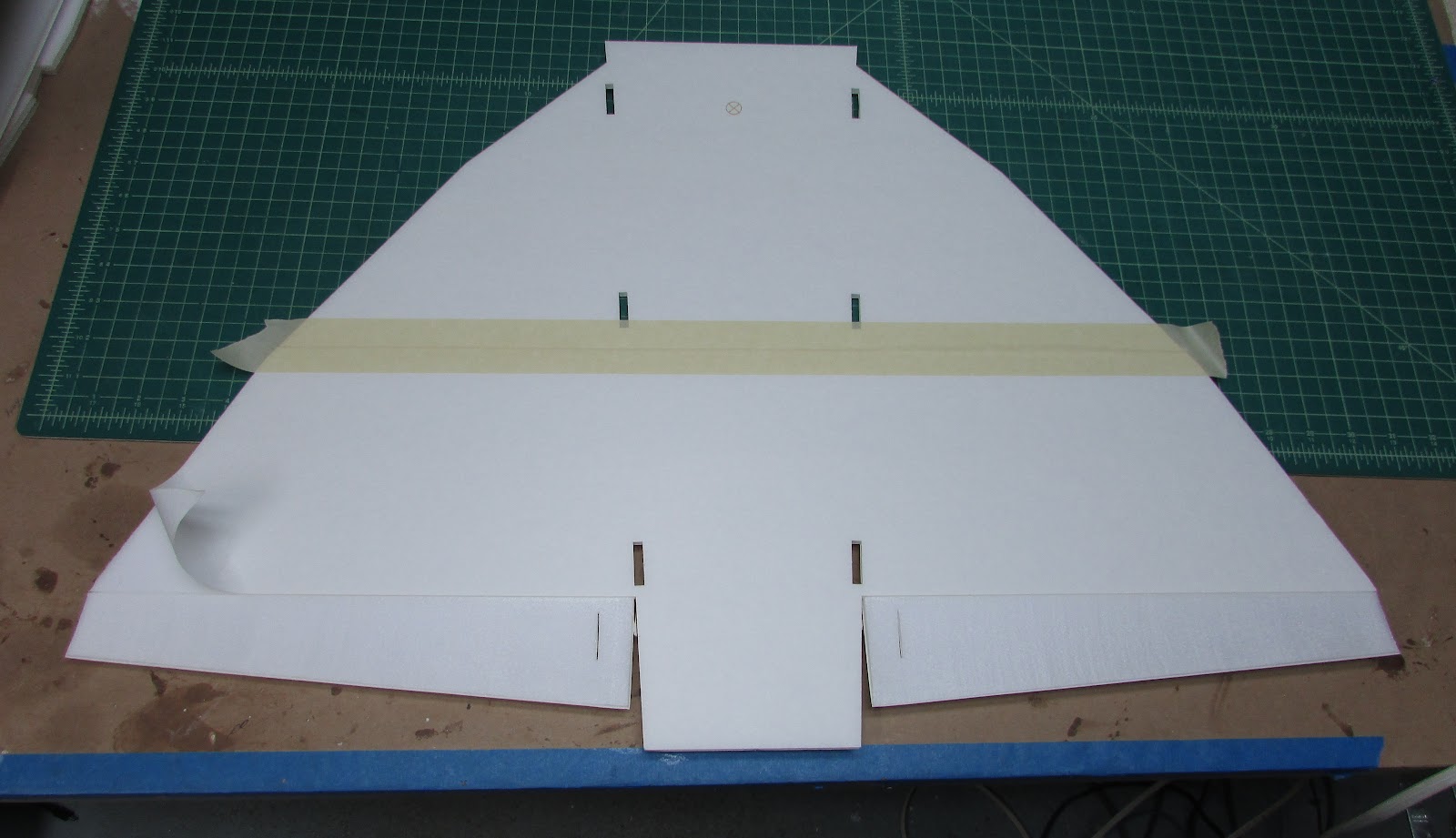

[h=1]Main Wing [/h]

The wing panel is cut in half (score cut) in order to fold it to fit in the shipping box. This seam needs to be joined. I left the paper on both sides (I peeled a little section so you could see the paper was still on), opened the seam using the paper on the back as a hinge, ran a bead of Gorilla glue along the seam, pressed it flat on the table and and taped it. Add a little weight to keep it flat while the glue cures.

After the glue cured for an hour or so, I peeled the paper and tape off. The Gorilla glue was almost cured but was still tacky. When I peeled the paper, the glue that oozed out between the paper and tape peeled off with the paper. I was really impressed with how clean the seam was. No glue bump.

Peel the paper from the other side. It is ready for fiberglass.

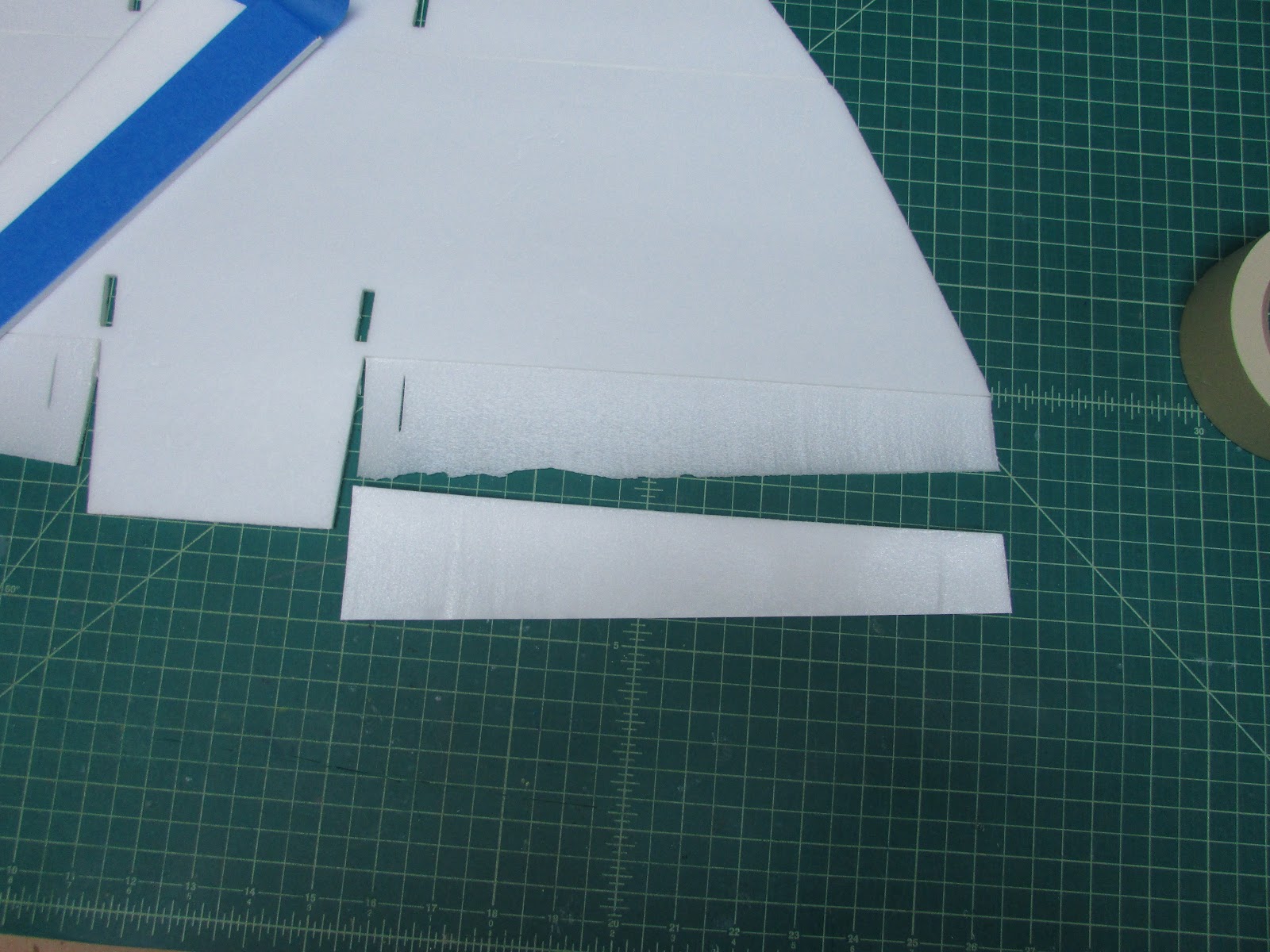

When I peeled the paper from the other side of the wing panel, the thin foam on the tapered elevon peeled off with the paper.

I made another one by cutting out a small piece of foam

and tapering it with the hot wire, so there was no loss except for time.

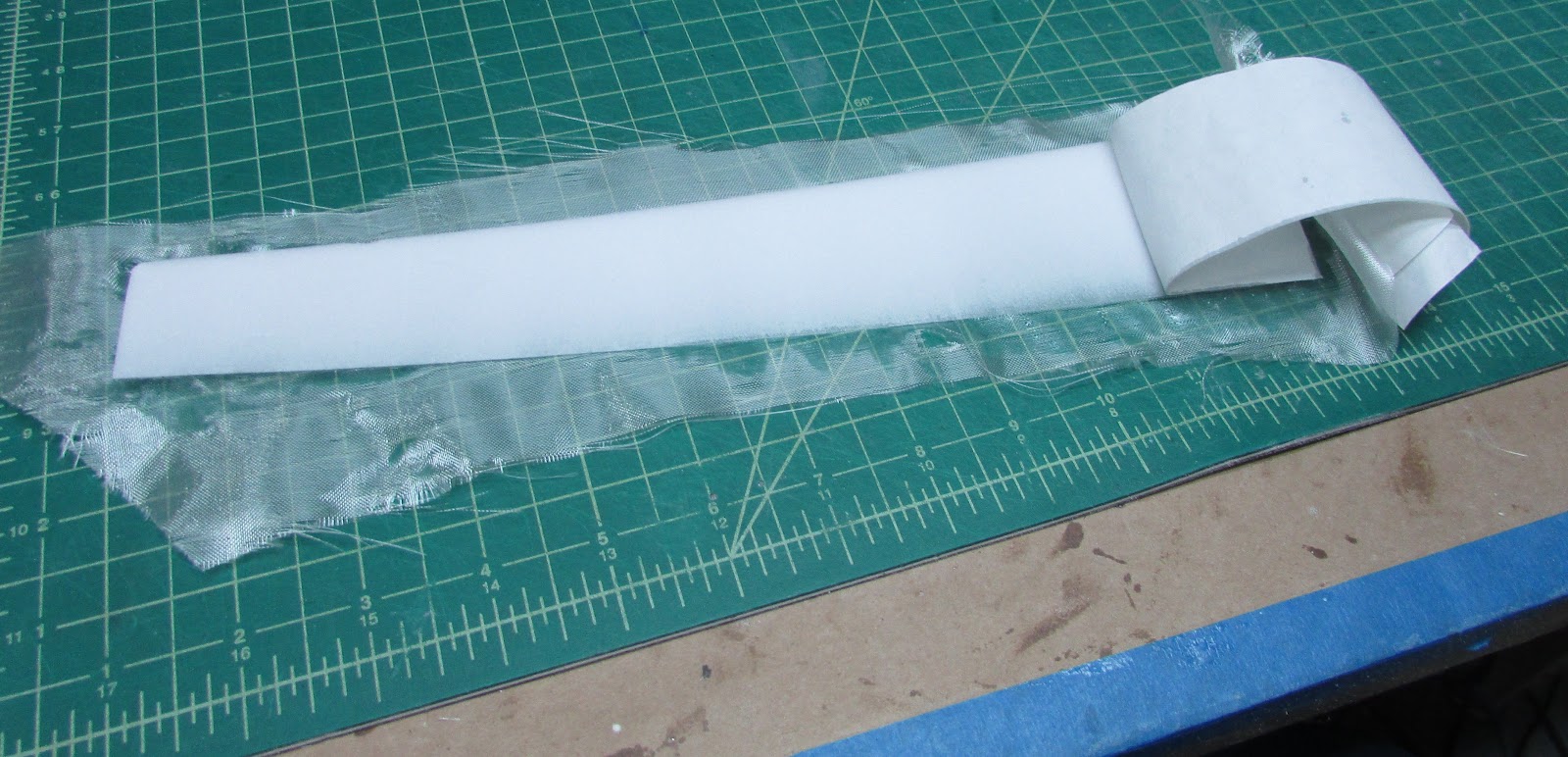

Here is the new elevon next to the torn one.

[h=1]Main Wing [/h]

The wing panel is cut in half (score cut) in order to fold it to fit in the shipping box. This seam needs to be joined. I left the paper on both sides (I peeled a little section so you could see the paper was still on), opened the seam using the paper on the back as a hinge, ran a bead of Gorilla glue along the seam, pressed it flat on the table and and taped it. Add a little weight to keep it flat while the glue cures.

After the glue cured for an hour or so, I peeled the paper and tape off. The Gorilla glue was almost cured but was still tacky. When I peeled the paper, the glue that oozed out between the paper and tape peeled off with the paper. I was really impressed with how clean the seam was. No glue bump.

Peel the paper from the other side. It is ready for fiberglass.

When I peeled the paper from the other side of the wing panel, the thin foam on the tapered elevon peeled off with the paper.

I made another one by cutting out a small piece of foam

and tapering it with the hot wire, so there was no loss except for time.

Here is the new elevon next to the torn one.

HilldaFlyer

Well-known member

Viggen - Glassed

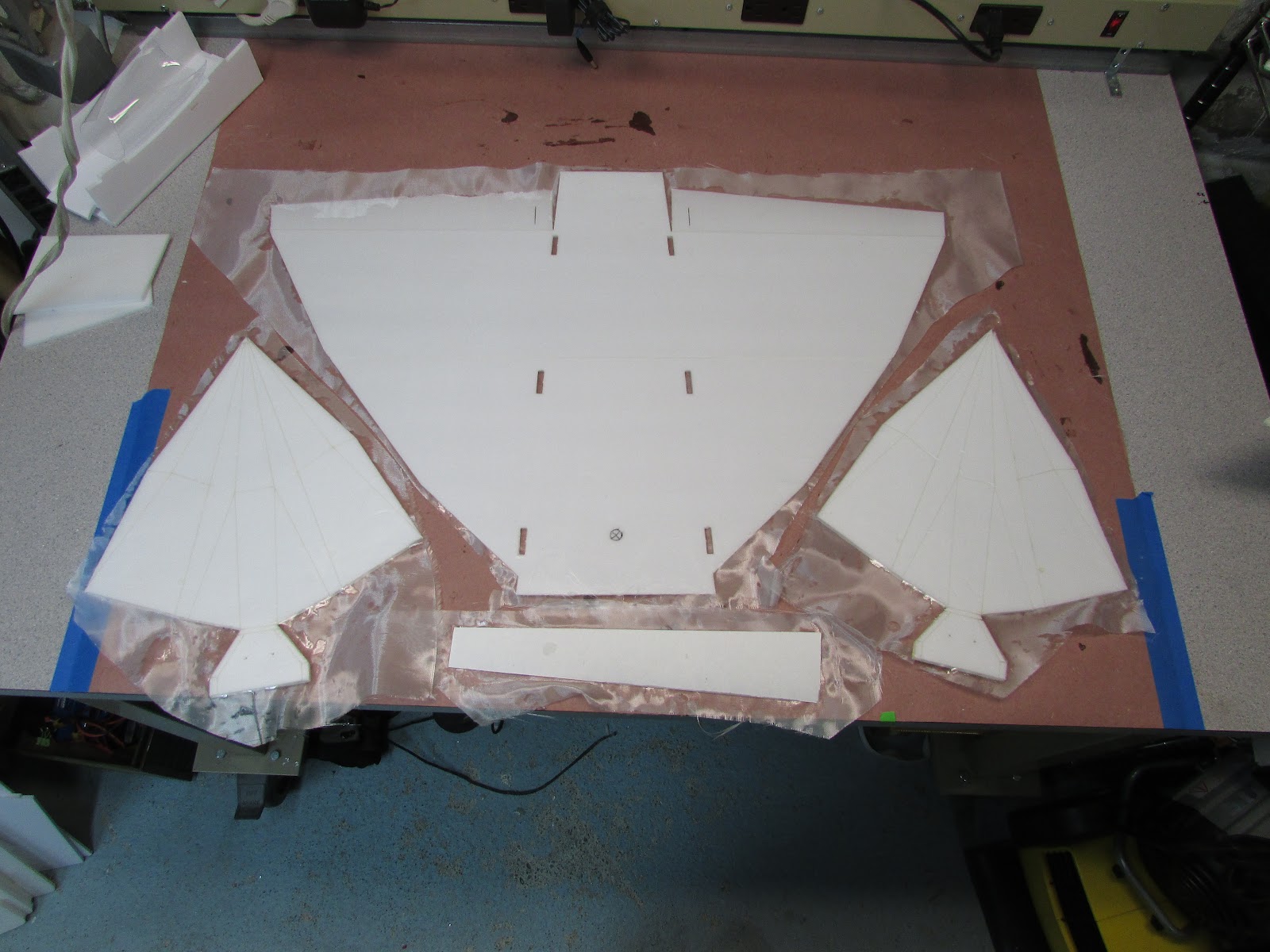

[h=1]Fiberglassing the opposite side[/h]

The parts that were already fiberglassed on one side were turned over. If the paper was still on, it was removed and then skinned as before.

The fiberglassed parts were trimmed and sanded.

Glassing the nose cones and wing panel.

The verdict is in, glassing the one side before removing paper from the second side stabilizes the foam and prevents it from peeling. Razor sharp trailing edges on the elevons.

Glassing the rest of the pieces.

Trimming and sanding.

Last set of parts to glass. Then the build begins.

[h=1]Fiberglassing the opposite side[/h]

The parts that were already fiberglassed on one side were turned over. If the paper was still on, it was removed and then skinned as before.

The fiberglassed parts were trimmed and sanded.

Glassing the nose cones and wing panel.

The verdict is in, glassing the one side before removing paper from the second side stabilizes the foam and prevents it from peeling. Razor sharp trailing edges on the elevons.

Glassing the rest of the pieces.

Trimming and sanding.

Last set of parts to glass. Then the build begins.

enjoy your builds man keep it up!

HilldaFlyer

Well-known member

Do you have any data about the weight difference between the paper covered foam and the glass covered foam? This is the first time I have seen this.

Sure do... so glad you asked. Check out the article Super Strong Waterproof Foam Core. You should find what your looking for in there. I've been getting better at the glassing and on a warm day when the resin is thin, I can squeegee it pretty easily and skin both sides with 0.73 oz/yd cloth and come in at about 10% less than with the paper. However, this is not typical in the winter when the epoxy is pretty thick.

HilldaFlyer

Well-known member

Alwaysenjoy your builds man keep it up!

Similar threads

- Replies

- 3

- Views

- 528

- Replies

- 23

- Views

- 5K

- Replies

- 5

- Views

- 844

- Replies

- 10

- Views

- 1K