Recently i have switched all my build's to fiberglass. Being that i leave the glass to set for a day or 2 i find i have down time when i want to be working on something but cant work on my current project (booby sloper) so i decided to start up another one so i can do stuff while waiting on the epoxy.

One plane i have had on my todo list was the sig ninja or Ridge Rat slope soarer. These were both balsa builds originally. In my conversations with more experienced slopers i was basically told, repeatedly, that they do not compare at all to more modern airfoil ships. Basically unless i was going into the builds to just learn balsa techniques or for nostalgic reasons, just skip them. So i decided to, instead, make a more modern version of them, lets say "inspired by".

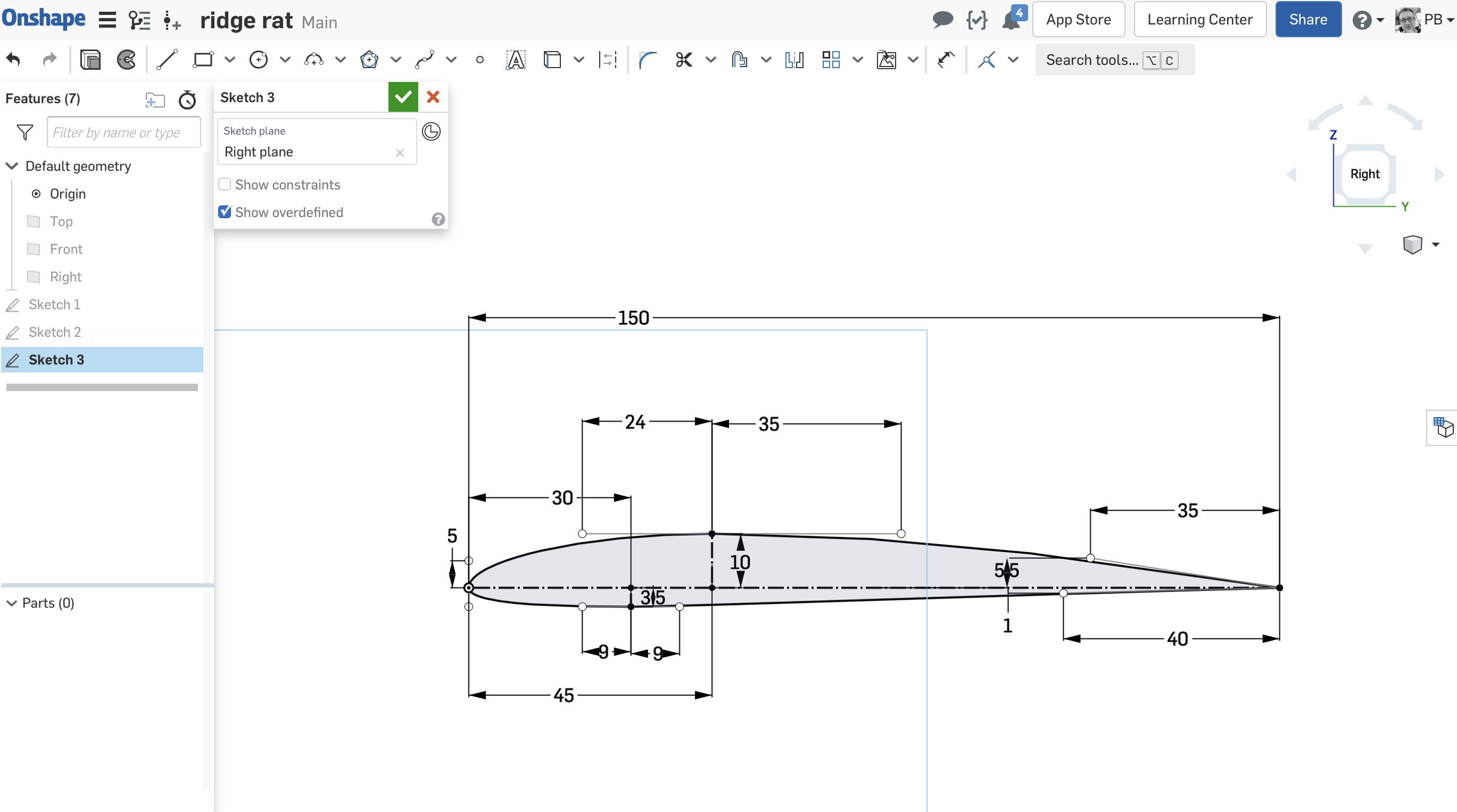

I took the original Ridge Rat plans and started sketching out the main outlines in inkscape.

I liked the overall shape of the fuselage, but decided to stretch out the nose to get more weight out front. The Tail feathers i left exactly the same and the distance between the trailing edge of the main wing and leading edge of the horizontal stabilizer i also left the same. I left the original wingspan of 48 inches the same but i shortened the root from over 9 inches to 6 inches and used a thinner, newer, airfoil: MH32

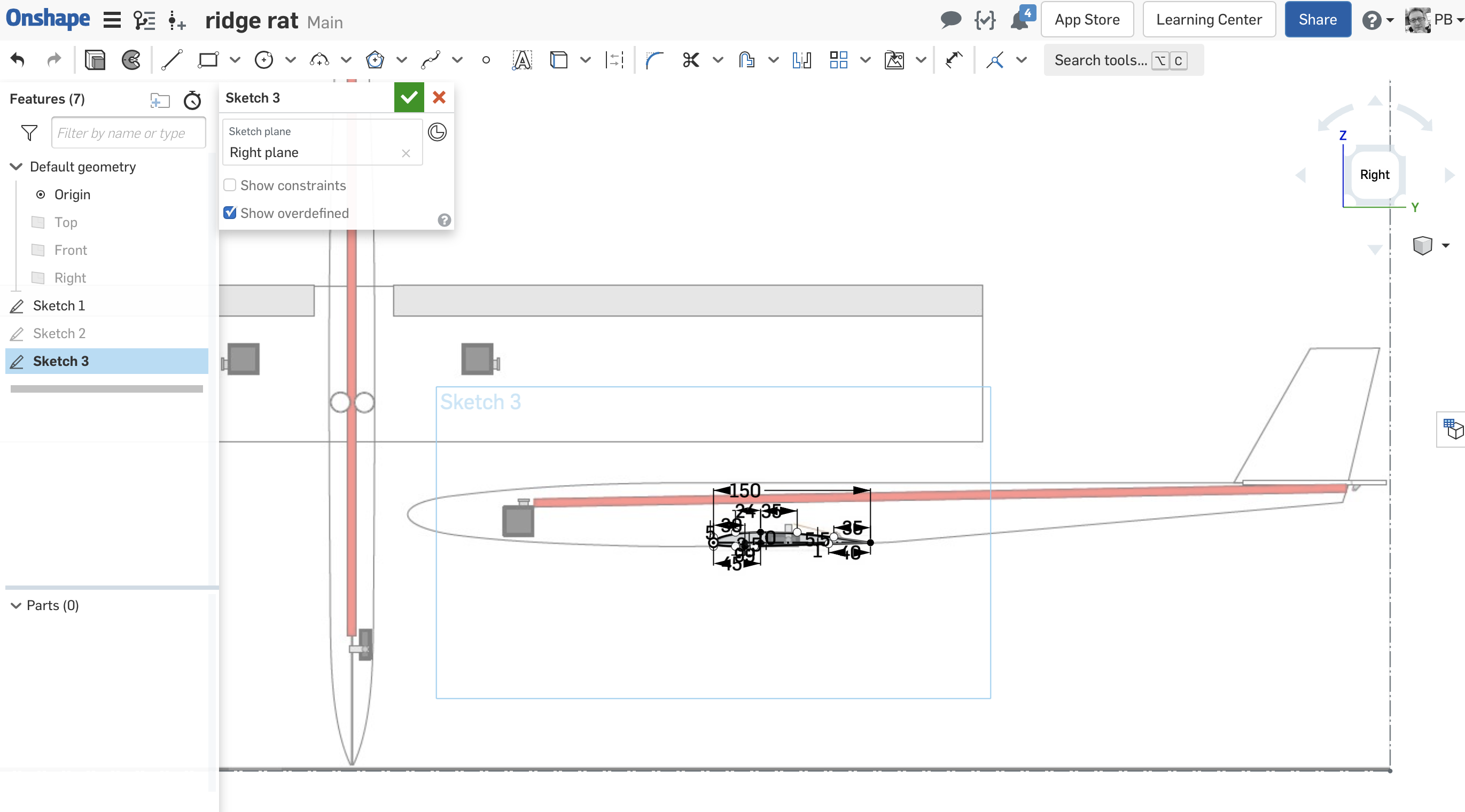

In the picture above the red is some double wall pushrods that will allow me to put the elevator servo forward in the nose.

The two circles in the center of the wing represent carbon tubing i may put to hold copper pipe ballast.

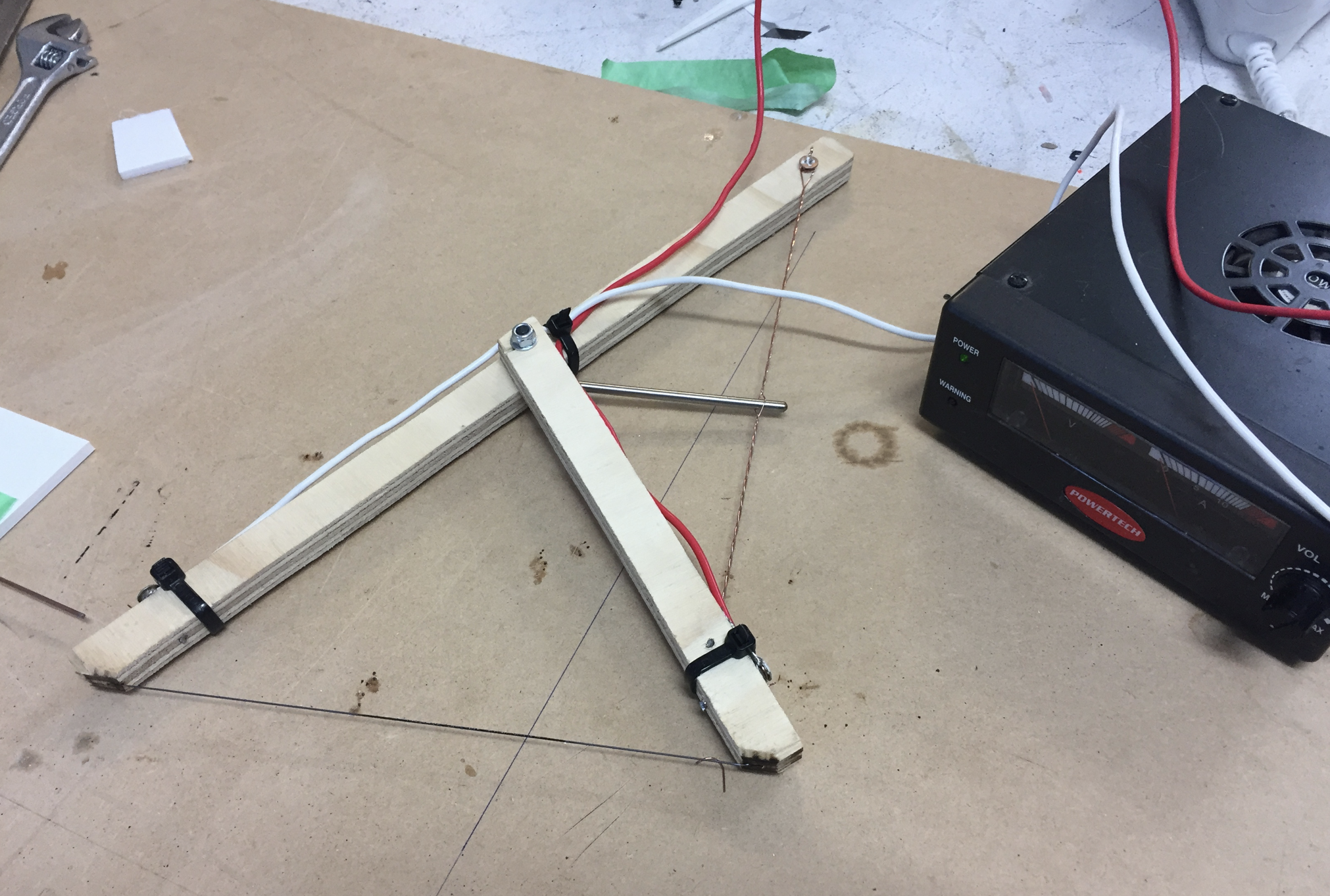

The wings will be hot cut out of some white lab cooler insulation foam and than vacuum bagged with one layer of 6oz s-glass (30% stronger than E glass and 15% stiffer)

The fuselage will be 2 layers of 1" pink foam that i will cut down to shape. It will be fiberglassed with one layer of 12oz fiberglass sleeving material. The tail feathers will be some kind of composite layer of blasa, fiberglass, and/or carbon fiber cloth.

END OF LINE

One plane i have had on my todo list was the sig ninja or Ridge Rat slope soarer. These were both balsa builds originally. In my conversations with more experienced slopers i was basically told, repeatedly, that they do not compare at all to more modern airfoil ships. Basically unless i was going into the builds to just learn balsa techniques or for nostalgic reasons, just skip them. So i decided to, instead, make a more modern version of them, lets say "inspired by".

I took the original Ridge Rat plans and started sketching out the main outlines in inkscape.

I liked the overall shape of the fuselage, but decided to stretch out the nose to get more weight out front. The Tail feathers i left exactly the same and the distance between the trailing edge of the main wing and leading edge of the horizontal stabilizer i also left the same. I left the original wingspan of 48 inches the same but i shortened the root from over 9 inches to 6 inches and used a thinner, newer, airfoil: MH32

In the picture above the red is some double wall pushrods that will allow me to put the elevator servo forward in the nose.

The two circles in the center of the wing represent carbon tubing i may put to hold copper pipe ballast.

The wings will be hot cut out of some white lab cooler insulation foam and than vacuum bagged with one layer of 6oz s-glass (30% stronger than E glass and 15% stiffer)

The fuselage will be 2 layers of 1" pink foam that i will cut down to shape. It will be fiberglassed with one layer of 12oz fiberglass sleeving material. The tail feathers will be some kind of composite layer of blasa, fiberglass, and/or carbon fiber cloth.

END OF LINE