I finally got around to using the Glowforge laser cutter at the library to cut my Mini Guinea. First a note. The advertised cutting size of the GlowForge is 20" x 12". In reality due to the cutting head needing time to slow down as it approaches the edges, the software will only allow you to cut 19.5" x 11". So when you are organizing your SVG files make sure everything fits into that space. In the case of the Mini Guinea I was able to organize it all into 5 documents that fit those dimensions, however I wasn't able to cut out the tail section since it was more than 11" tall and had to do that manually.

The following are the settings that worked well for me. I used settings that I found on the GlowForge forum as a jumping off point and adjusted after a few test cuts, I suspect everyones GlowForge will need the Power level tweaked up or down 1-2 levels.

| Cut Order | Cut Type | Color | Speed | Power | Passes | Use |

|---|

1

|

Engrave

|

Black

|

500

|

4

|

1

|

Annotating A,B,C Folds, reference lines, etc.

|

2

|

Crease

|

Dark Green

|

200

|

5

|

1

|

For crease lines on wing folds.

|

3

|

50% Score Cut

|

Navy Blue

|

200

|

5

|

2

|

Score Cuts for A,B,C Folds and Bevel Cuts.

|

4

|

Through Cut

|

Bright Green

|

200

|

12

|

2

|

Cut out inset pieces

|

5

|

Through Cut

|

Brown

|

200

|

12

|

2

|

Cut out pieces

|

The color indicated above is how I identified in the SVG file the different types of cuts I wanted GlowForge to perform. If you want a specific order for your cuts, then GlowForge by default will order them as above for the given color, otherwise you will need to reorder them your self. For the most part I think the ordering was unnecessary but it made it easier in the GlowForge UI to know what cuts to make for each. What also made it easier, is after you define the custom cut settings you can save them for use on the other SVG files in your project.

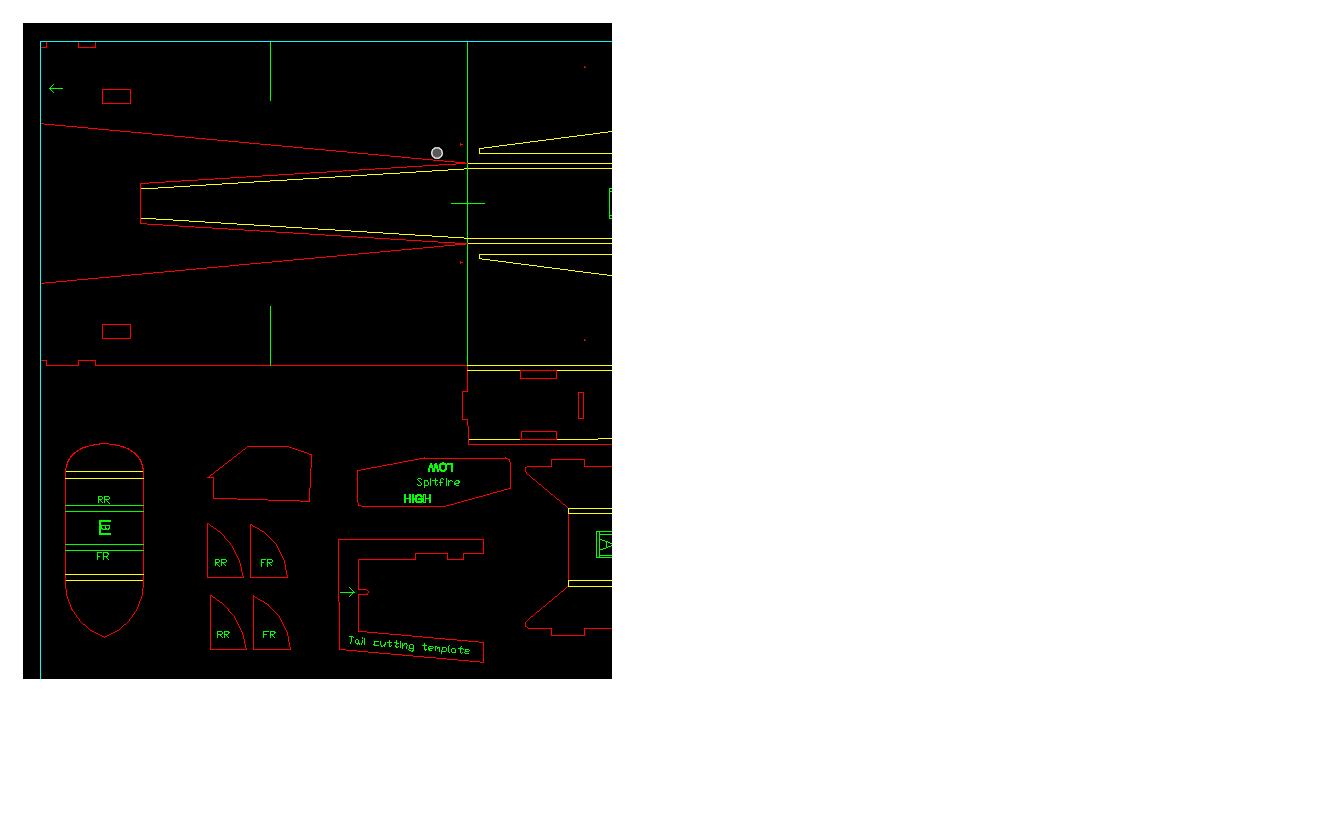

Here is an example of one of my SVGs cut out. I should hopefully start building the plane this weekend.