TooJung2Die

Master member

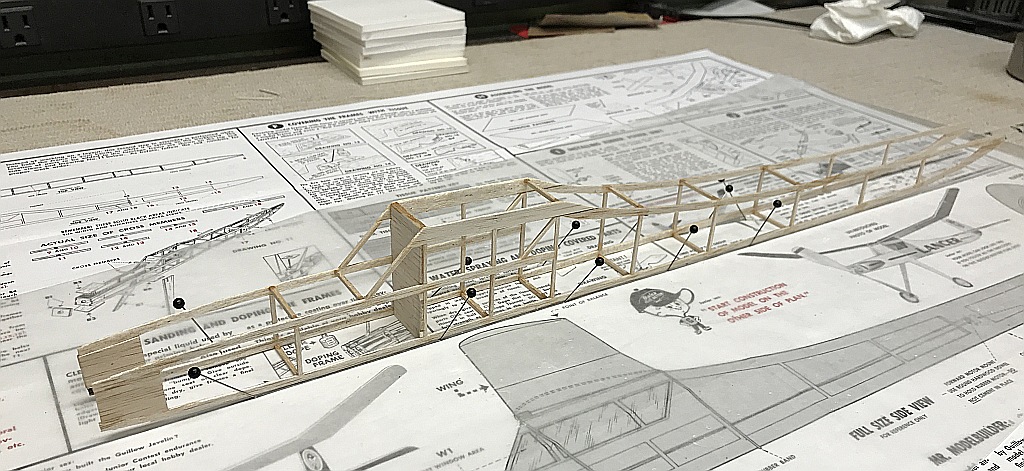

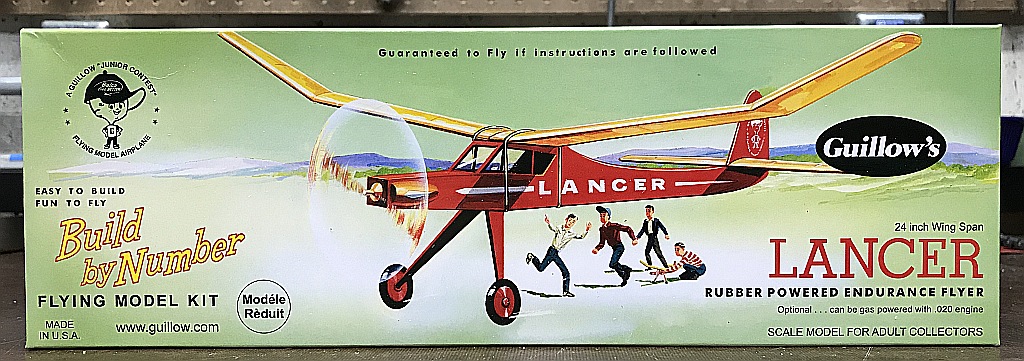

I've been wanting to do this one for years. Our RC club has access to the indoor hockey arena at Hershey Park during the winter. We get one day a week to fly indoors during the winter. This should be a good indoor/outdoor flier after its converted to RC.

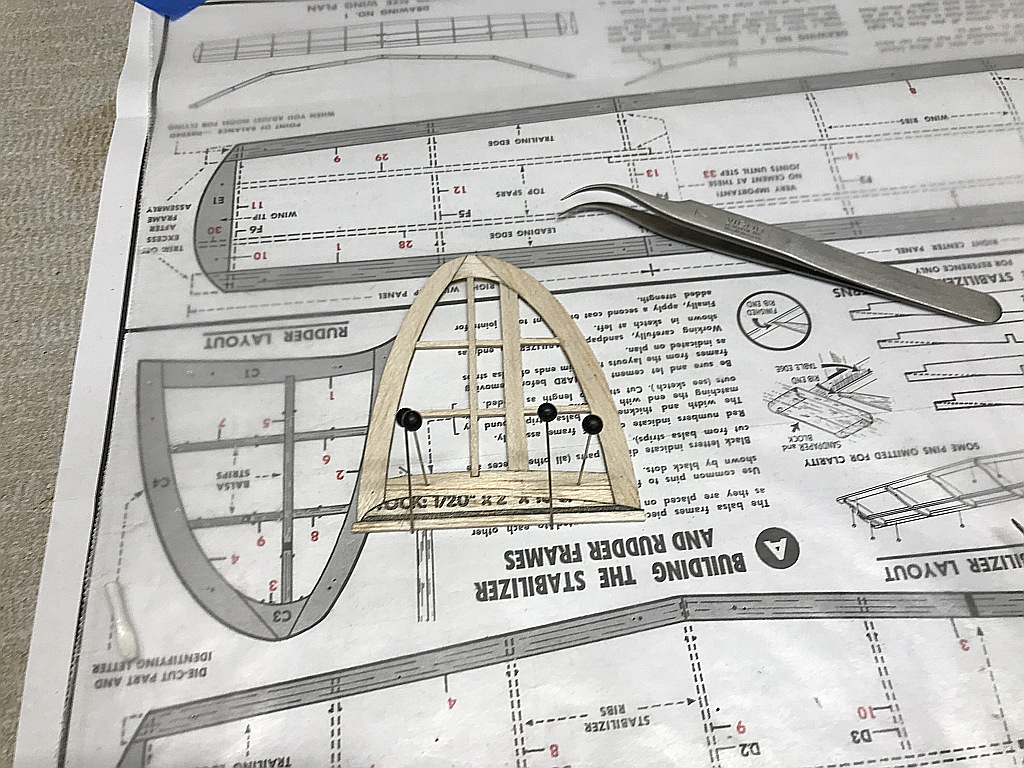

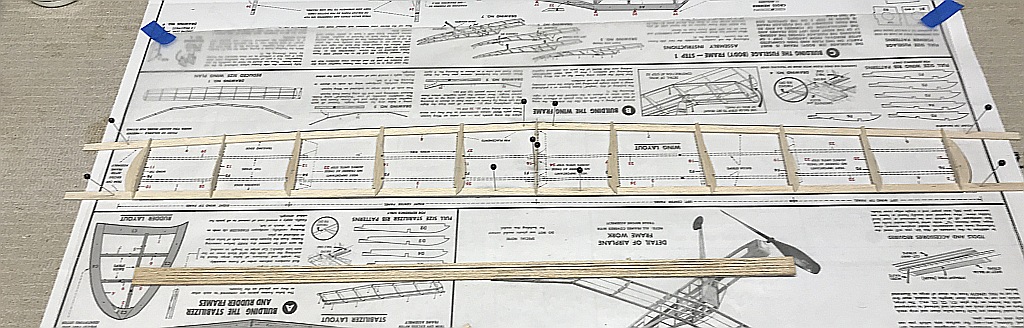

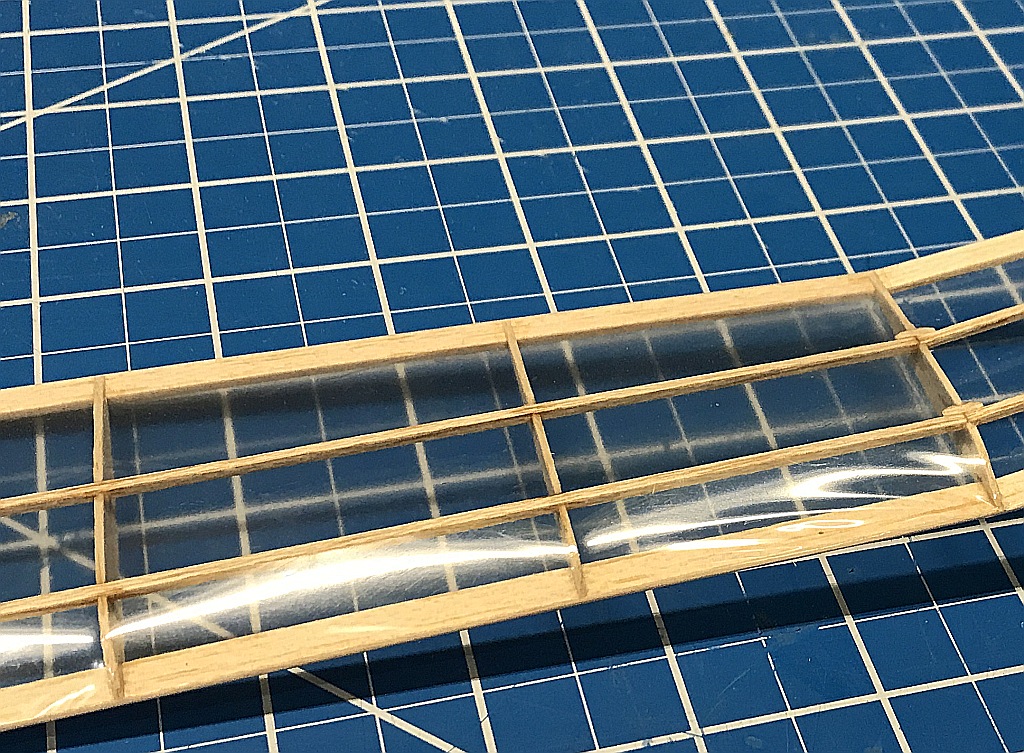

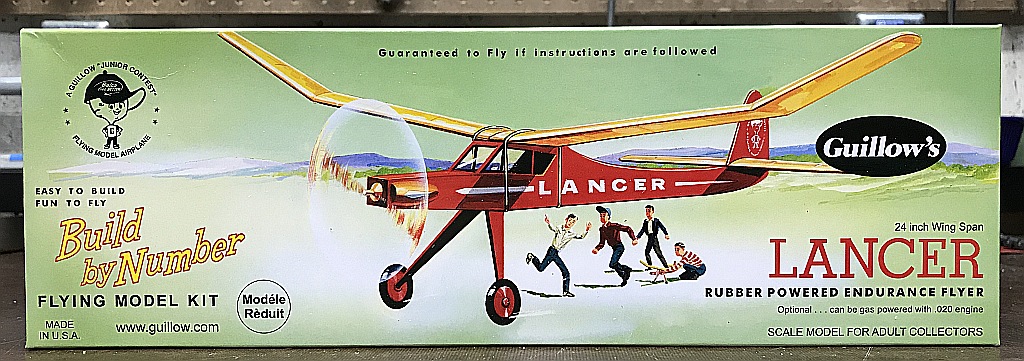

I built this rubber power kit as a boy and it actually flew despite my clumsy build. When you're that young you want to fly it more than build it. The new kit arrived a couple of days ago. I expected a laser cut kit but only the 'C' balsa sheet is laser cut. 'A' and 'B' are die-crushed. Why?

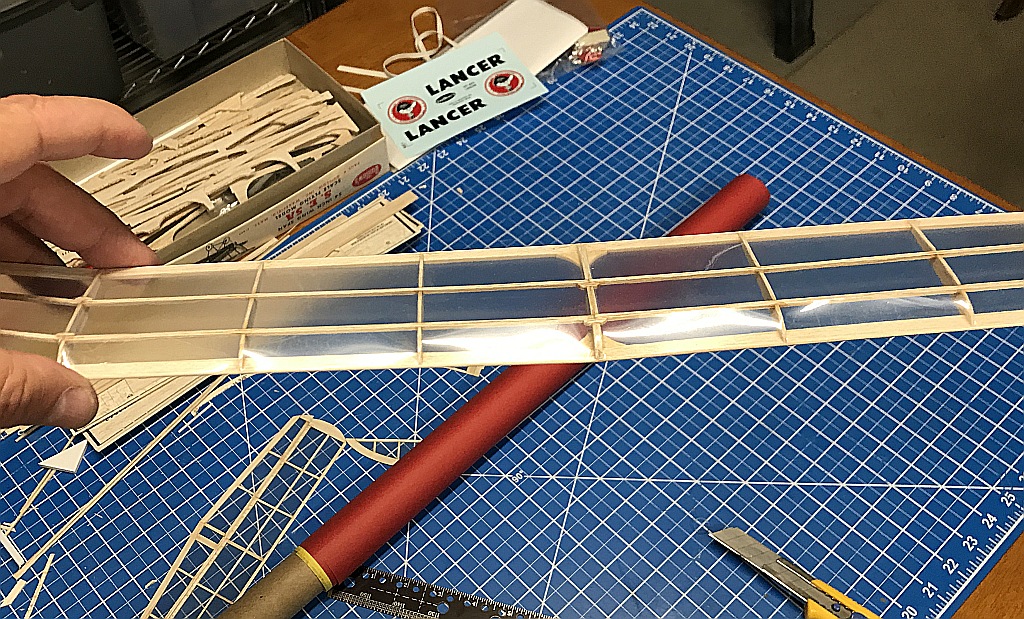

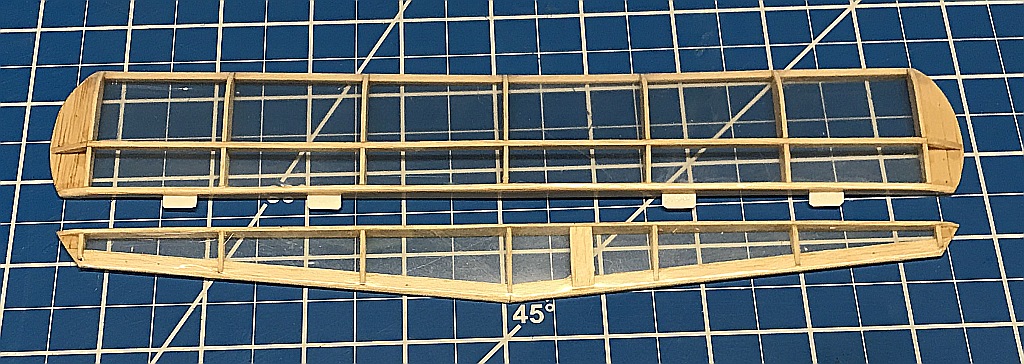

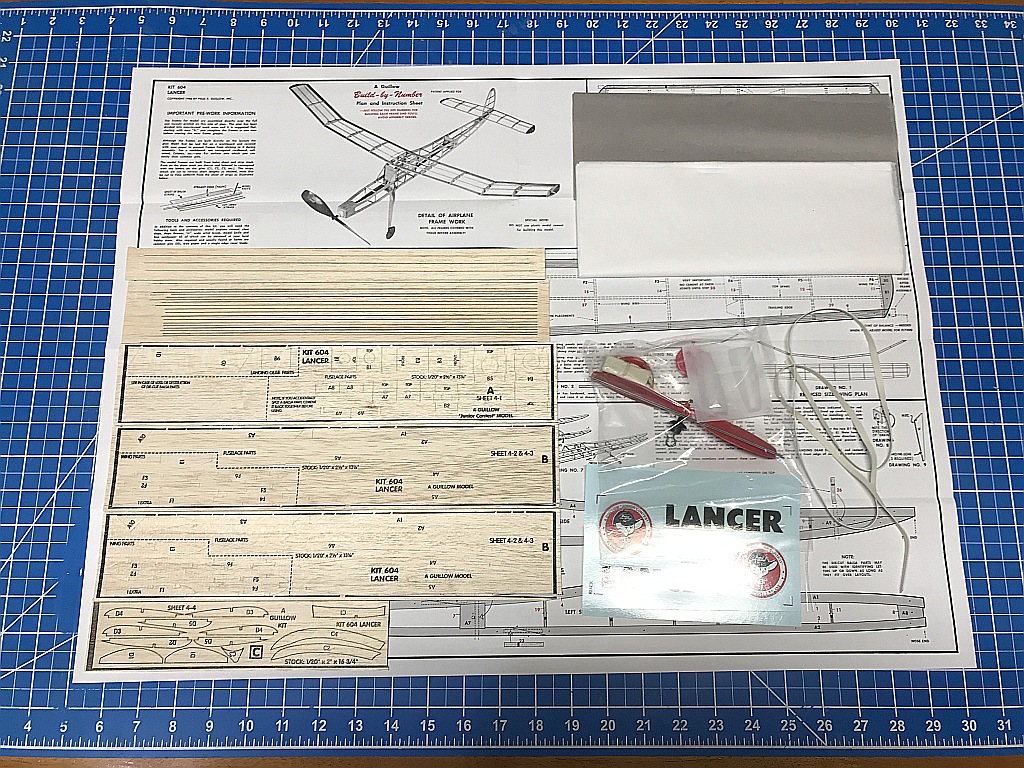

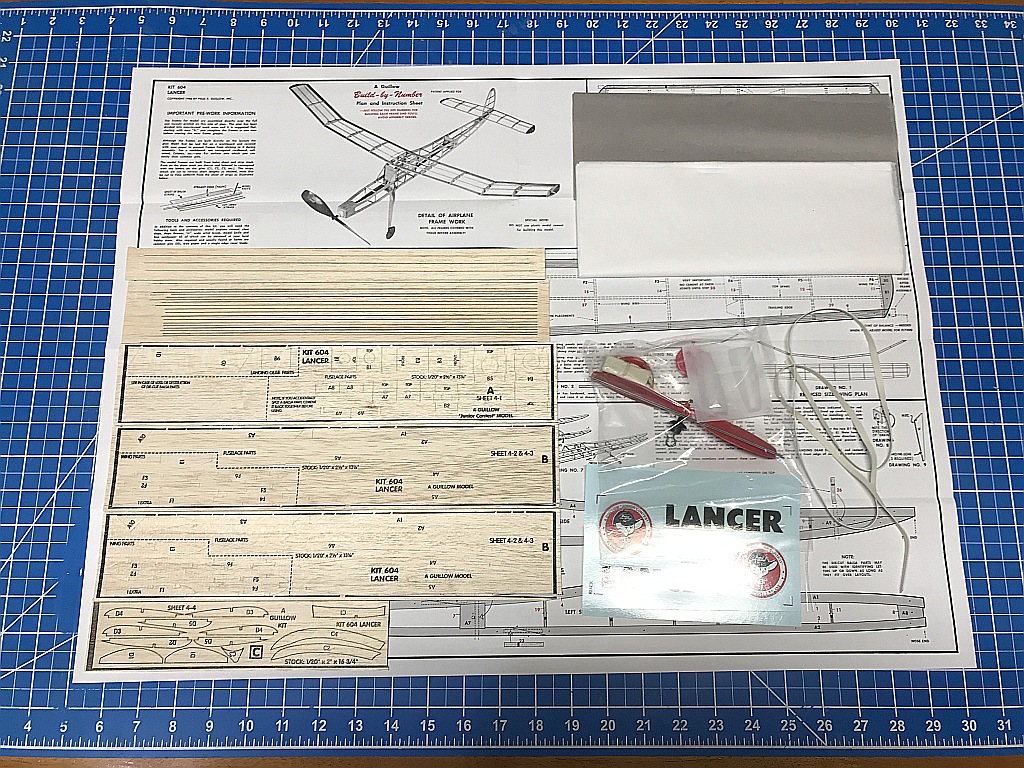

Here are the contents of the kit. This is so simple compared to what I have built recently.

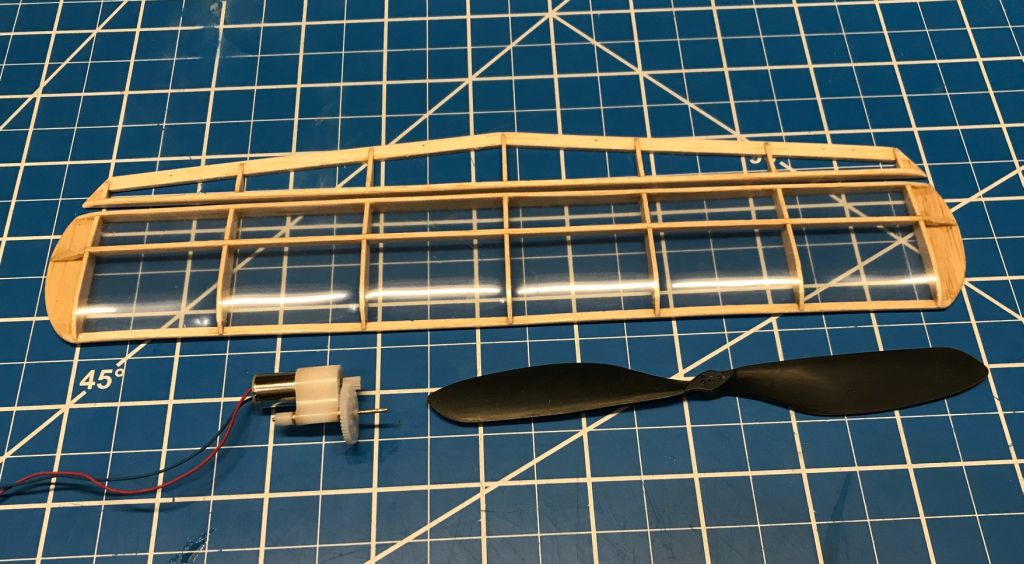

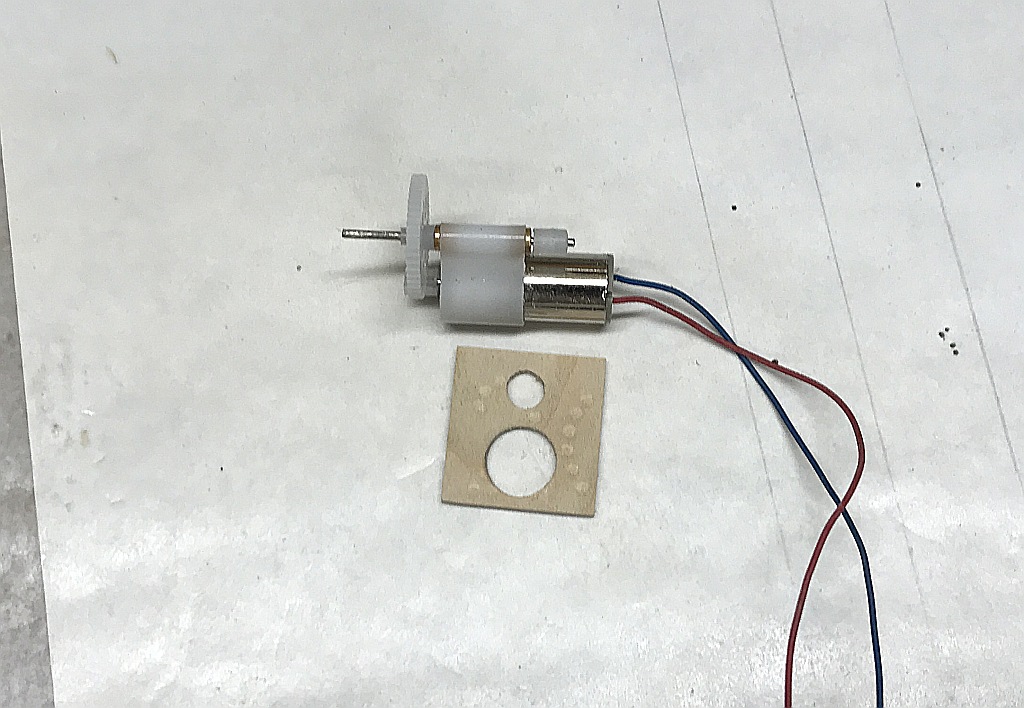

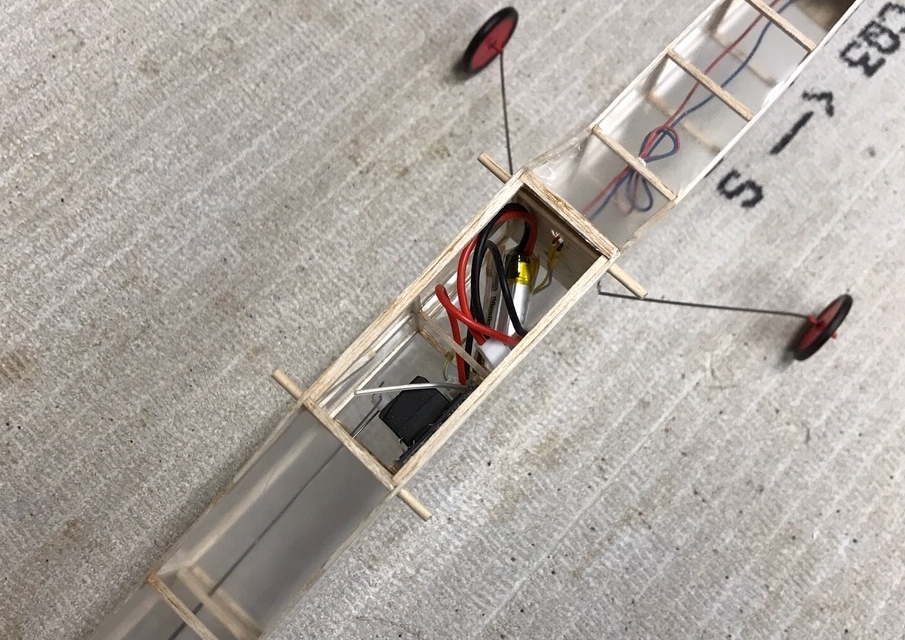

The electronics are coming from the WLToys F949 Cessna 182. The Cessna has a 19" wingspan and weighs 2 ounces ready to fly. It was bought bind-n-fly without a transmitter because WLToys binds with my Flysky FS-i6 transmitter. Turns out the Cessna is such a blast to fly I can't bring myself to sacrifice it yet. I ordered another Rx brick and motor gearbox separate. The build will have to commence without the electronics. I will be taking my time and enjoying the build. RC conversions require lots of thinking ahead.

Jon

I built this rubber power kit as a boy and it actually flew despite my clumsy build. When you're that young you want to fly it more than build it. The new kit arrived a couple of days ago. I expected a laser cut kit but only the 'C' balsa sheet is laser cut. 'A' and 'B' are die-crushed. Why?

Here are the contents of the kit. This is so simple compared to what I have built recently.

The electronics are coming from the WLToys F949 Cessna 182. The Cessna has a 19" wingspan and weighs 2 ounces ready to fly. It was bought bind-n-fly without a transmitter because WLToys binds with my Flysky FS-i6 transmitter. Turns out the Cessna is such a blast to fly I can't bring myself to sacrifice it yet. I ordered another Rx brick and motor gearbox separate. The build will have to commence without the electronics. I will be taking my time and enjoying the build. RC conversions require lots of thinking ahead.

Jon

Last edited: