MaxTheFliteFreak

Active member

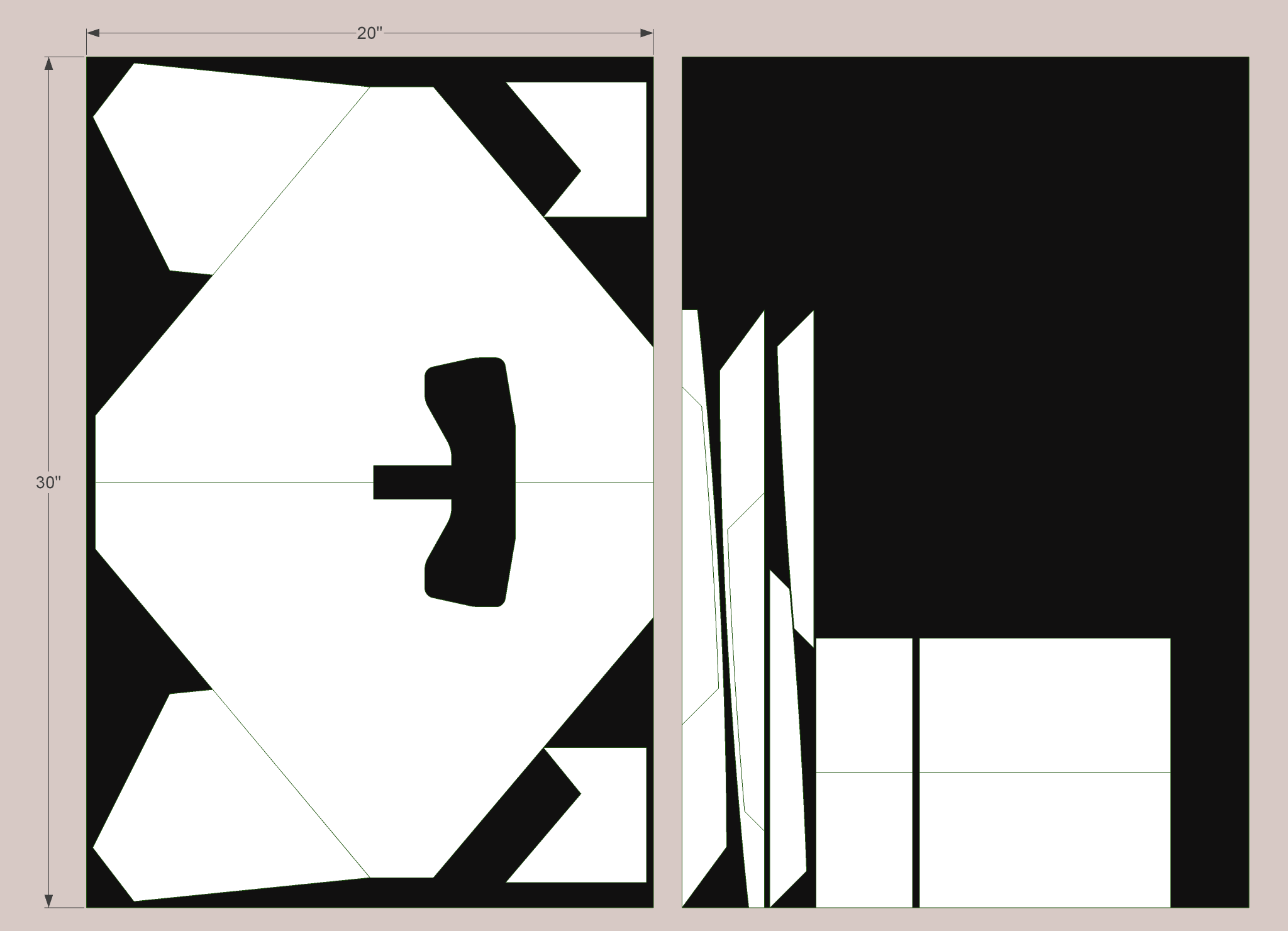

Hi, I am taking a whack at my first scratch built master series style plane and I have a problem. How do I calculate how big a sheet of skin should be? Any help would be much appreciated and thanks in advance!

P.S. My foamboard is 5mm thick if that helps.

Haply flying!

P.S. My foamboard is 5mm thick if that helps.

Haply flying!