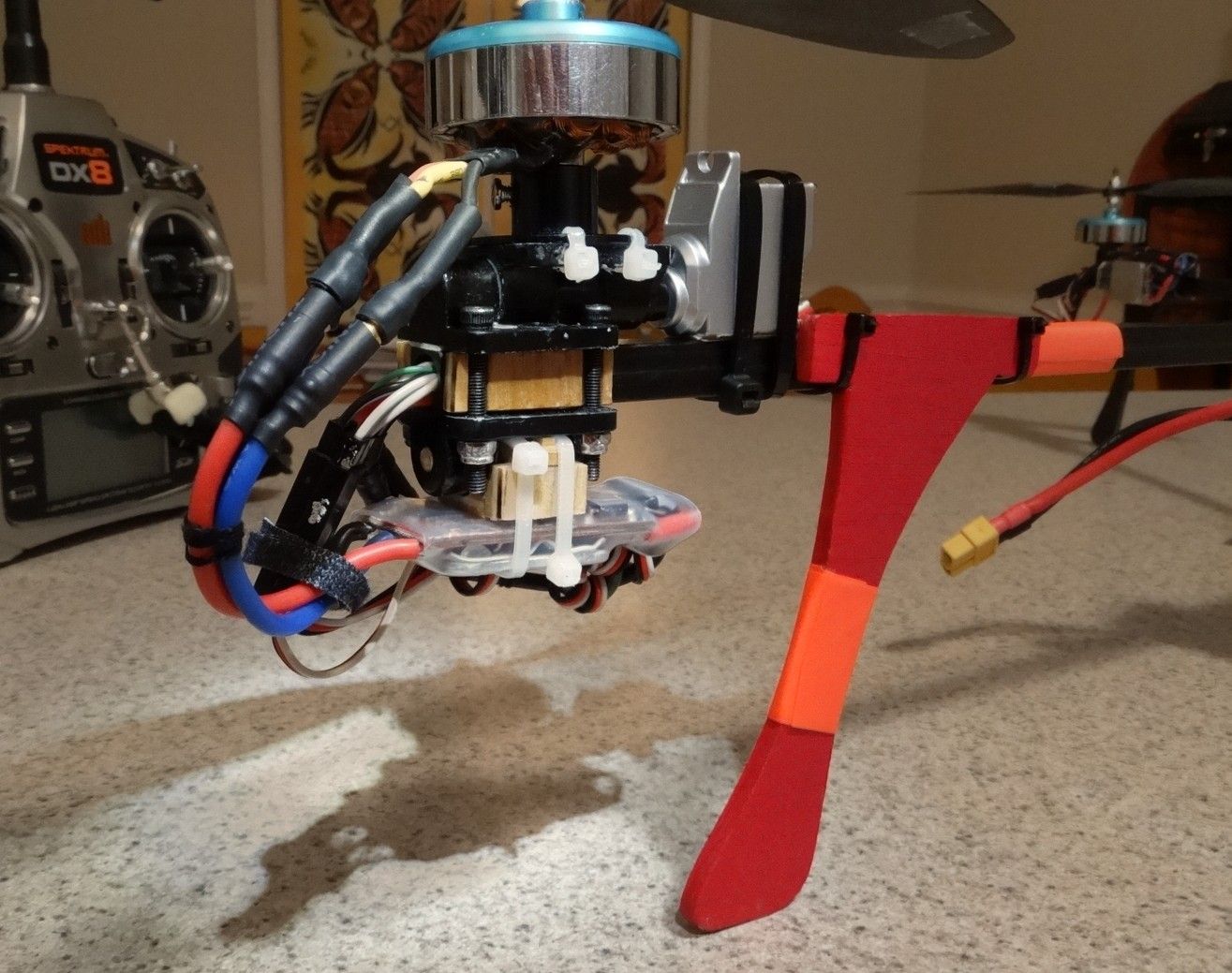

I have just built a new tricopter and the tail moves freely with no stress (it seems) on the servo. I am on the verge of ditching my tri and getting a quad built instead as I have stripped 2 servos in 6 flights.

I thought I'd upgrade to something that seemed a little more durable and ended up with the hitec hs-65mg and still no joy. Does anyone recommend any servos or any tips about where I might be going wrong?

Thanks

Brad.

I thought I'd upgrade to something that seemed a little more durable and ended up with the hitec hs-65mg and still no joy. Does anyone recommend any servos or any tips about where I might be going wrong?

Thanks

Brad.