PsyBorg

Wake up! Time to fly!

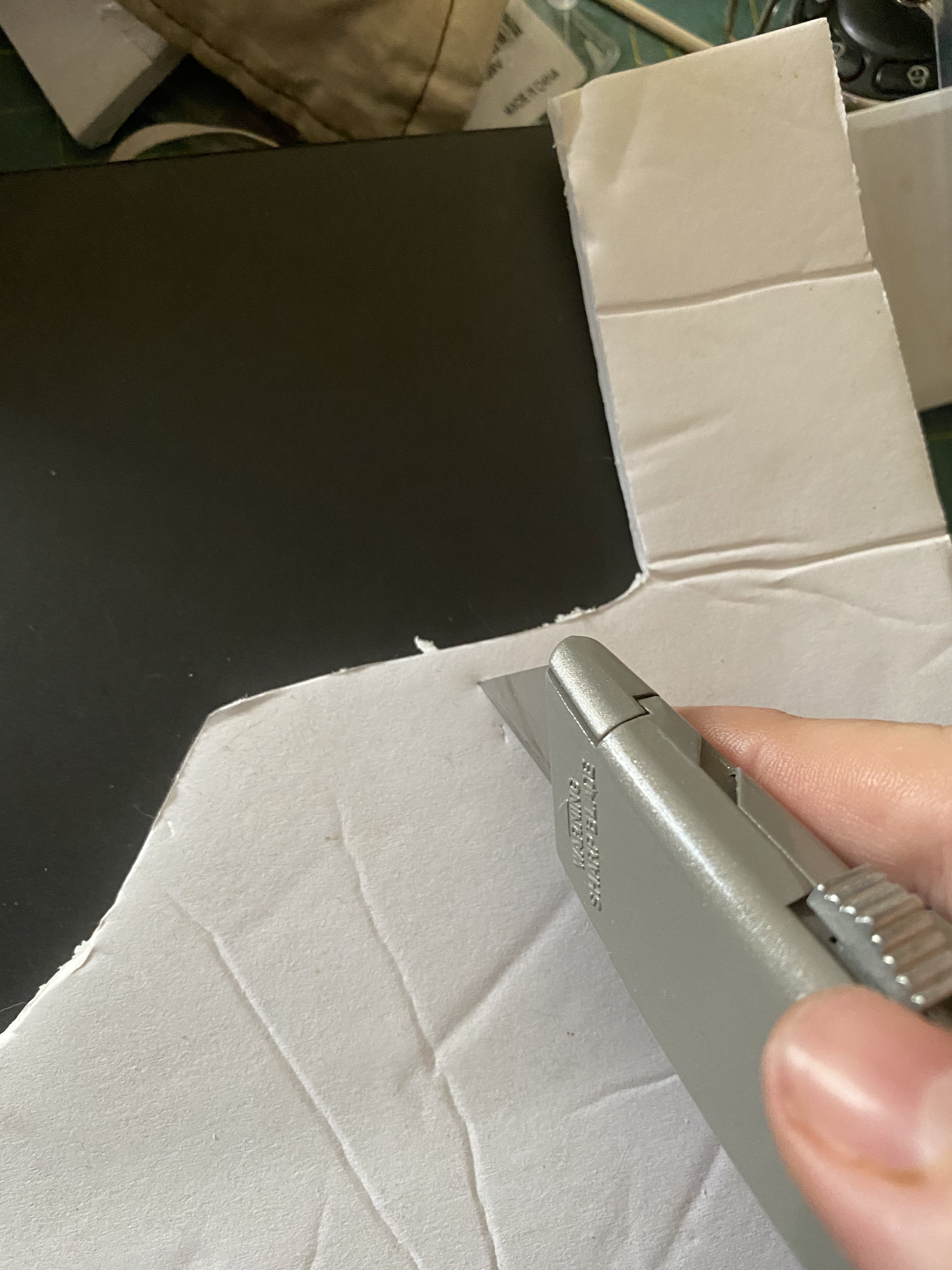

I got to disagree with the angle thing. I think the angle you use depends on the cut you make. when I hold the razor blades I cut straight cuts at 45 degree angle on the blade. For rounded edges I hold straight up and use very short sawing strokes out near the tip of the blade.

The key to ALL cuts is consistent pressure and speed as well as blade sharpness. Granted I am no master builder but I do have the patience to be a semi perfectionist in anything I take on. this was the hardest piece for the edge I built. all done by hand with a single razor blade. In fact I have made five of these now at this point in my attempts to fly.

It all boils down to sharp blade and not rushing to do the job.

The key to ALL cuts is consistent pressure and speed as well as blade sharpness. Granted I am no master builder but I do have the patience to be a semi perfectionist in anything I take on. this was the hardest piece for the edge I built. all done by hand with a single razor blade. In fact I have made five of these now at this point in my attempts to fly.

It all boils down to sharp blade and not rushing to do the job.