DutchTerror

Member

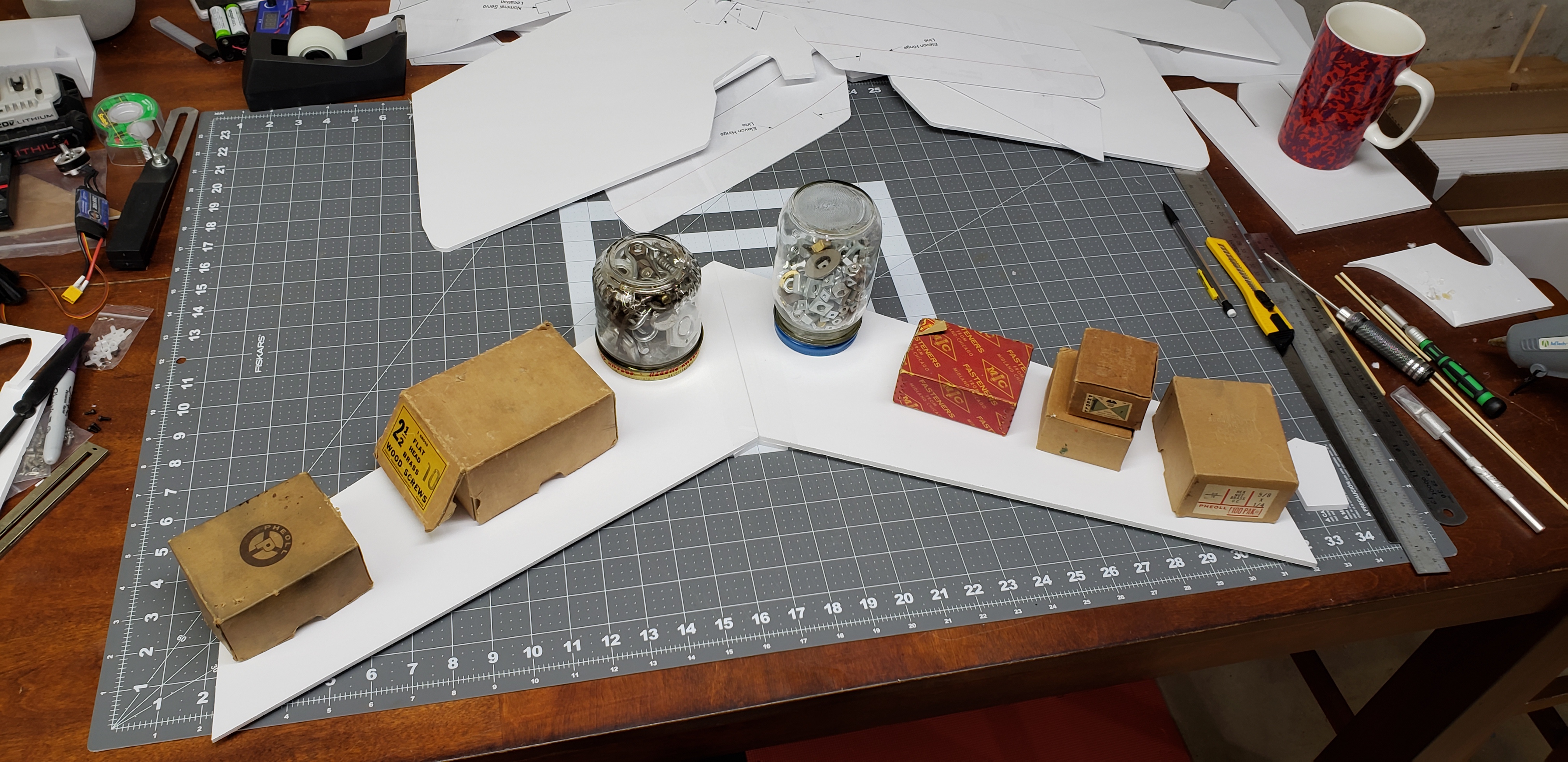

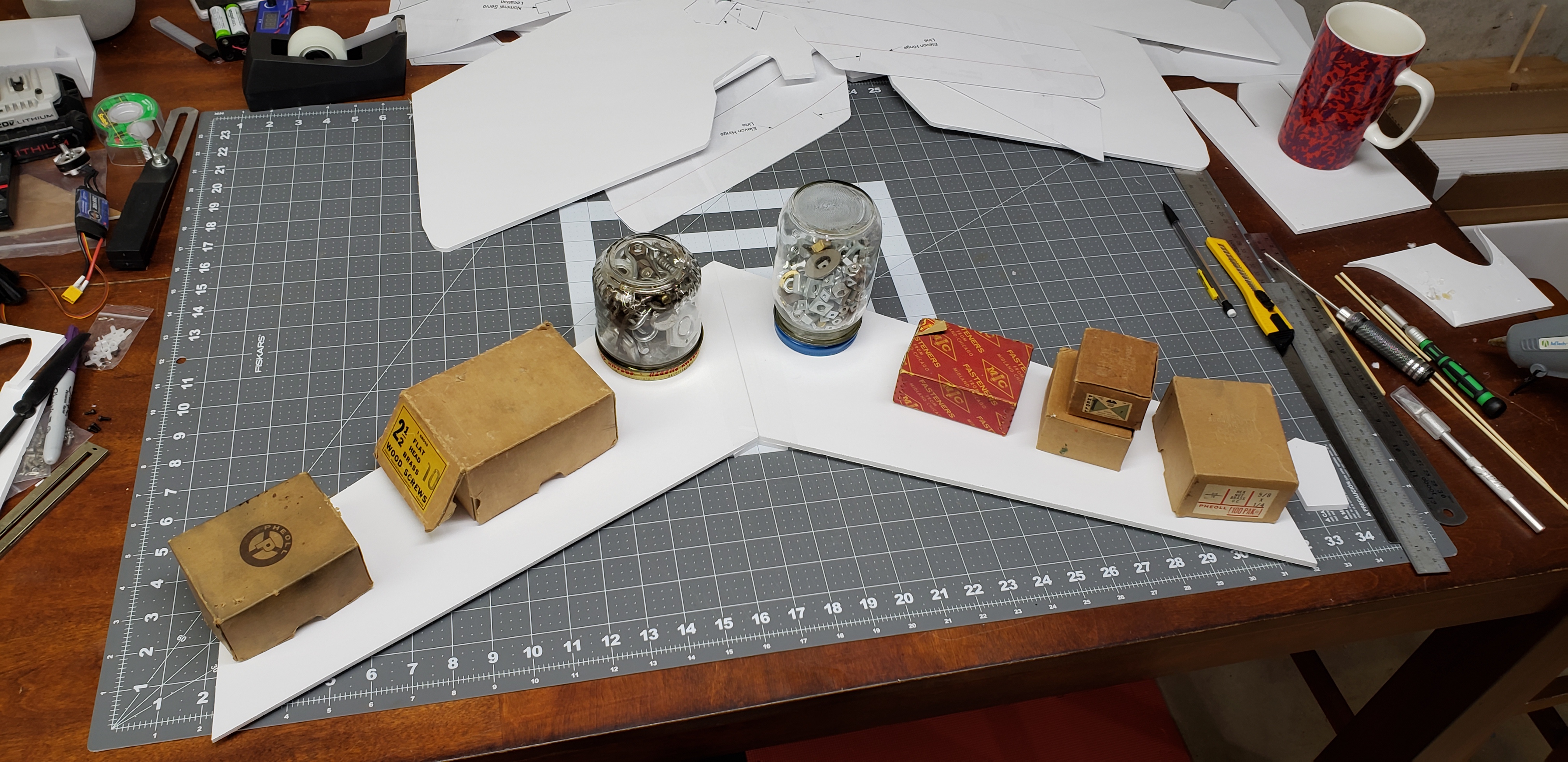

Weather is still crud, so thought I'd mess around with a wing. Wanted to fit the entire width on a sheet of DTFB, so wingspan is 750mm. That takes about 0.25" off of either side of the FB to get a clean edge. Thought about designs a bit, looked at other pics, modified some other plans to fit the size I wanted. Building this as a KFm-6 wing, so who knows how well it will work. Probably better off with a KFm-4, but any dumb thing is better when you overdo it, right? Started laying out the plans and cutting.

Gluing up the first layers. Pretty much all Gorilla Clear on this build. Some of the later sections of electronics housings are Gorilla hot glue.

And more layers, you get the idea.

Finally 5 layers, and I used the technique from @BATTLEAXE to iron down the edges. Bottom leading edge ironed here, top still standard cut. Mock up of the 3D printed motor mount.

Tweaked the pod drawings from FT for their Mighty Mini Arrow to make a two-step housing for camera and electronics. The 600mW VTX stays on the outside for cooling. Pod is cut and inset into the top layer of foam. Also, 9g servos and 3D printed servo horns. I print mostly in PLA, but I coat the finished part in Gorilla Clear to help with strength, delamination, etc.

Motor mount holds the 2205 2300KV motor and 20A ESC. Inside the pod lives the F411-Wing, FS-iA6B receiver (iBus), Hawkeye Firefly Split 4K camera, and the battery. GPS module not yet pictured, but it should arrive today.

Belly shot for those interested. Still need to add the wingtip stabilizers, add some tape reinforcement on the LE and belly protection, color for identification, etc.

Gluing up the first layers. Pretty much all Gorilla Clear on this build. Some of the later sections of electronics housings are Gorilla hot glue.

And more layers, you get the idea.

Finally 5 layers, and I used the technique from @BATTLEAXE to iron down the edges. Bottom leading edge ironed here, top still standard cut. Mock up of the 3D printed motor mount.

Tweaked the pod drawings from FT for their Mighty Mini Arrow to make a two-step housing for camera and electronics. The 600mW VTX stays on the outside for cooling. Pod is cut and inset into the top layer of foam. Also, 9g servos and 3D printed servo horns. I print mostly in PLA, but I coat the finished part in Gorilla Clear to help with strength, delamination, etc.

Motor mount holds the 2205 2300KV motor and 20A ESC. Inside the pod lives the F411-Wing, FS-iA6B receiver (iBus), Hawkeye Firefly Split 4K camera, and the battery. GPS module not yet pictured, but it should arrive today.

Belly shot for those interested. Still need to add the wingtip stabilizers, add some tape reinforcement on the LE and belly protection, color for identification, etc.