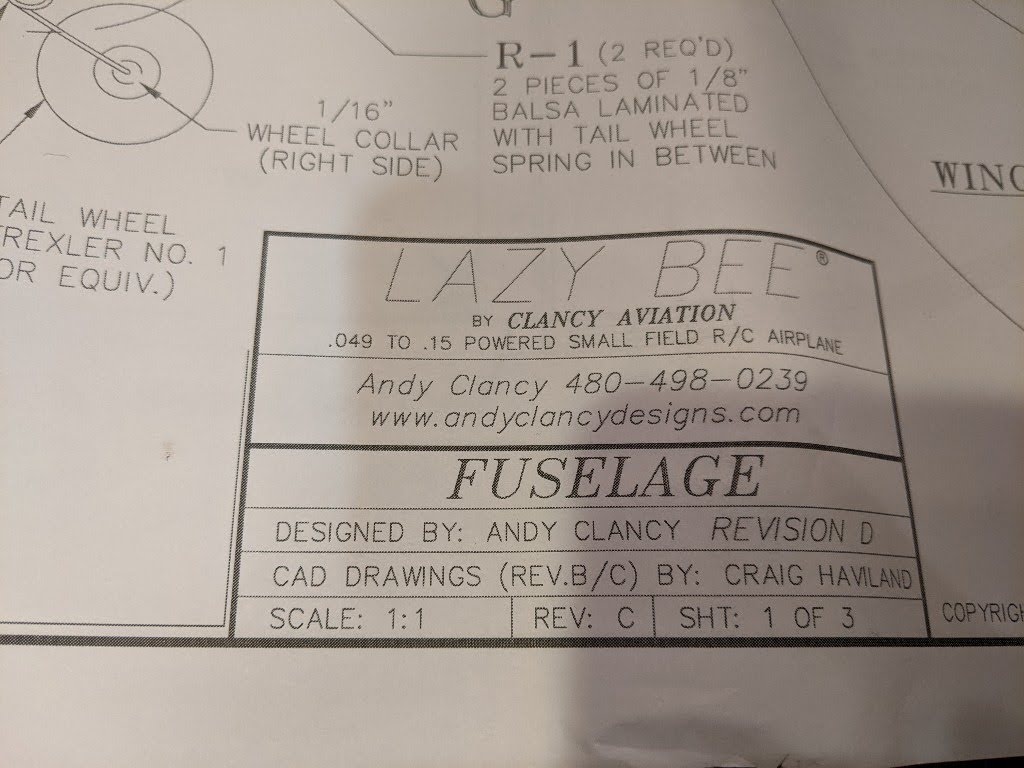

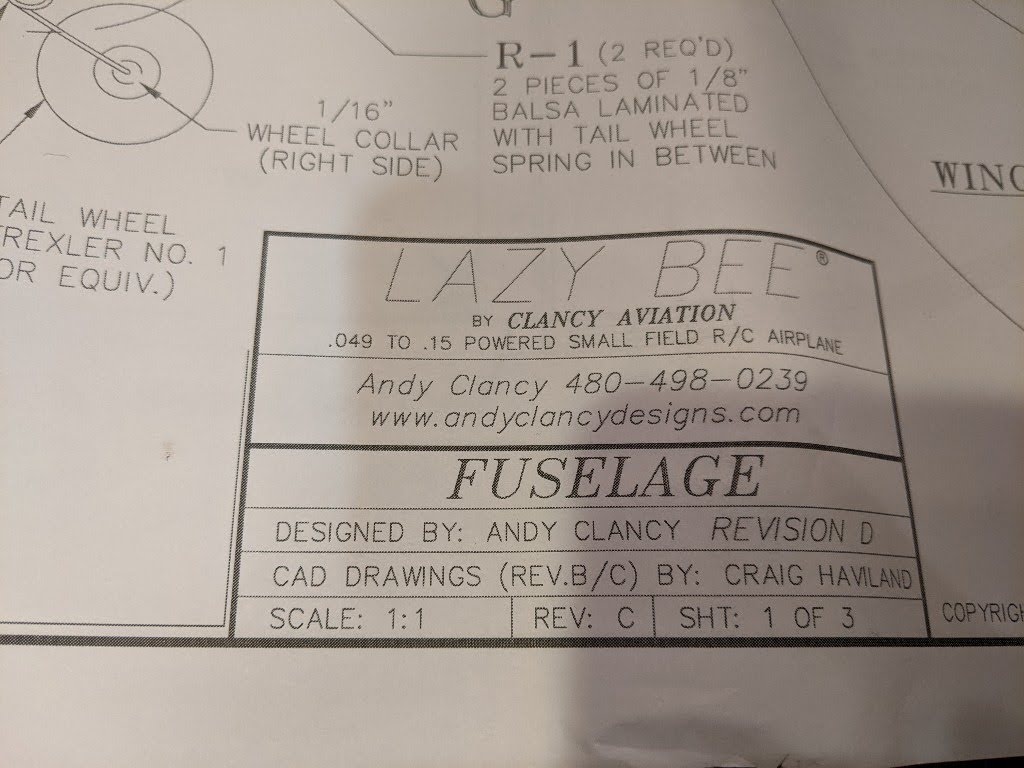

Next project - one of Clancy Aviation's newly release, 2020 Lazy Bee kits! https://www.andyclancydesigns.com/

I picked up one of the first batch of "Original Lazy Bee" kits which means 3 channel - no ailerons on this girl. The post-man did his best to mash up the shipping tube, but everything inside arrived safely anyway. Inside are a full size set of plans, a bundle of sticks, a bundle of laser cut balsa sheets, some laser cut plywood, a small bundle of bamboo dowels & some landing gear wires, and instructions. I'll share a picture of the instruction book too - it's a classic hand-drawn late 90's "To Build a Bee" handbook, and a couple pages of a 2020 Laser Kit update instructions too.

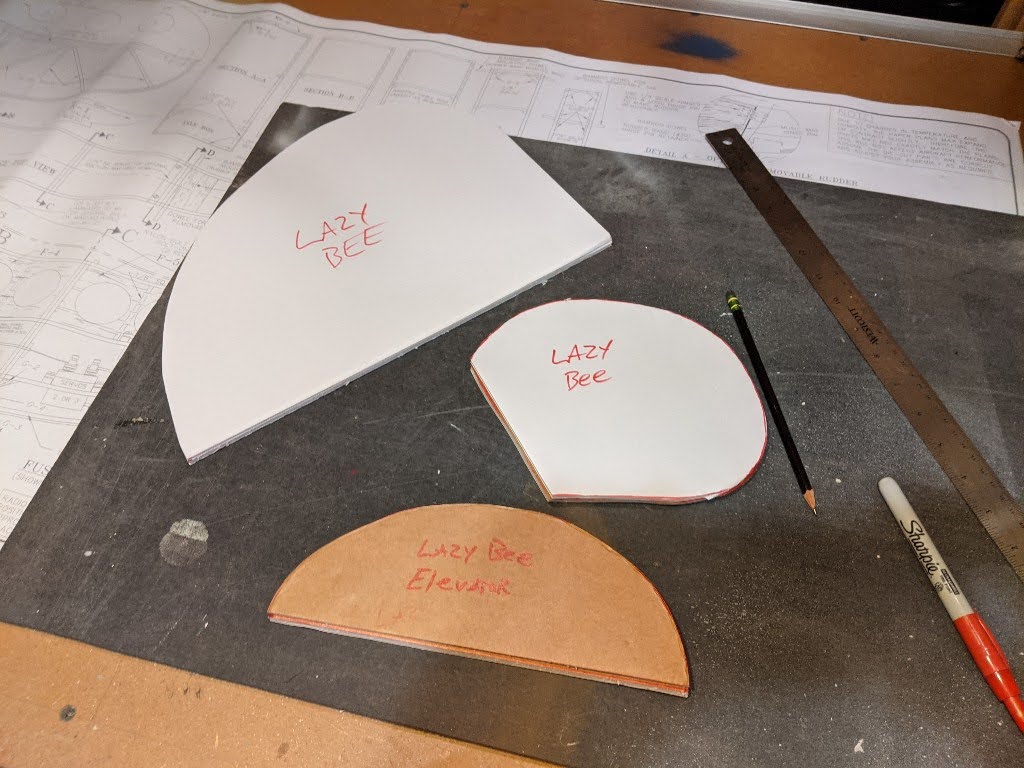

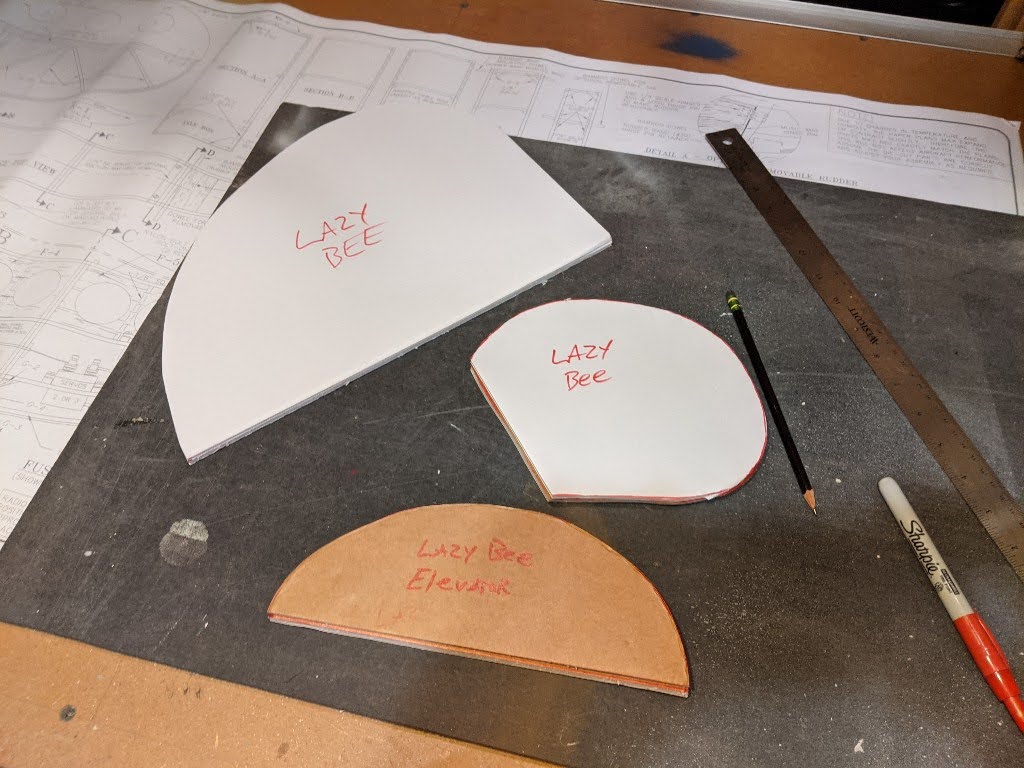

After reading all the way through the instructions, I am following his recommended build order and getting started on the laminations first. That starts with tracing the lamination form shapes onto foamboard (two layers hot-glued together in this case).

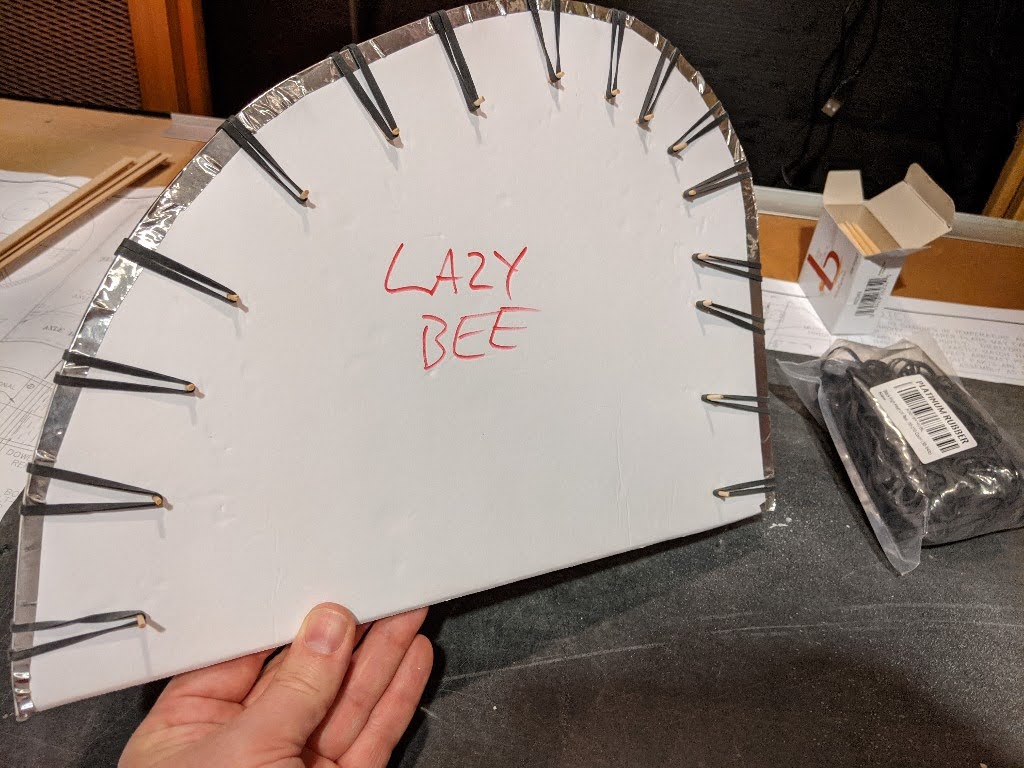

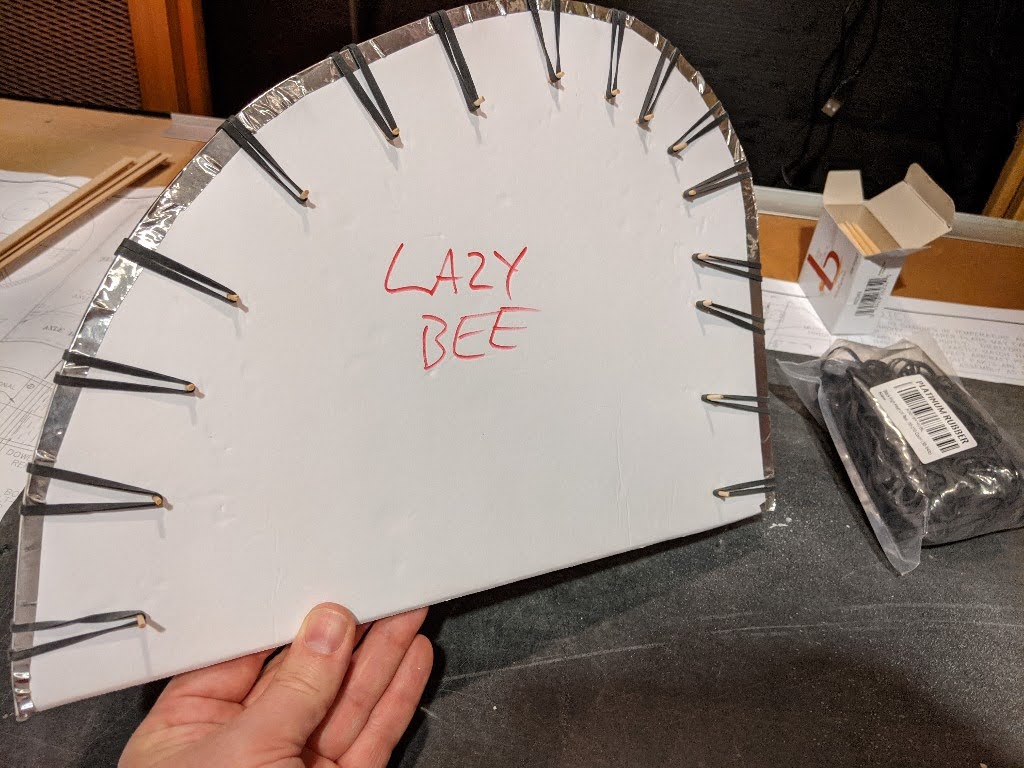

Then covering the edges with some sort of waterproof tape - aluminum ducting tape cause it was at the top of the tape stack.

Next I stretched a rubber band around the edge and figured out where a toothpick would give a moderate amount of tension (maybe stretched to 1/3 additional length). Snapped a bunch of toothpicks in half and made sure they all hooked up nicely.

Finally some balsa get's involved! 1/8" x 1/2" strips in this case - I squirted them down with an ammonia/water mix (windex works great too) and rubbed that into the wood for a moment (and pulled the rubber bands off the template). Then starting from the most flat edge of the template that still gets wood, I bent and rubber banded my way around the form.

I did two strips first, and then did the second two strips on top of that so there is a layer of rubber bands trapped in the middle. Hopefully that won't cause some weird indentations in the wood, but I don't think the bands are stretched tightly enough for that.

Time to let this dry overnight - and do it a bunch more time on the other forms too.

I picked up one of the first batch of "Original Lazy Bee" kits which means 3 channel - no ailerons on this girl. The post-man did his best to mash up the shipping tube, but everything inside arrived safely anyway. Inside are a full size set of plans, a bundle of sticks, a bundle of laser cut balsa sheets, some laser cut plywood, a small bundle of bamboo dowels & some landing gear wires, and instructions. I'll share a picture of the instruction book too - it's a classic hand-drawn late 90's "To Build a Bee" handbook, and a couple pages of a 2020 Laser Kit update instructions too.

After reading all the way through the instructions, I am following his recommended build order and getting started on the laminations first. That starts with tracing the lamination form shapes onto foamboard (two layers hot-glued together in this case).

Then covering the edges with some sort of waterproof tape - aluminum ducting tape cause it was at the top of the tape stack.

Next I stretched a rubber band around the edge and figured out where a toothpick would give a moderate amount of tension (maybe stretched to 1/3 additional length). Snapped a bunch of toothpicks in half and made sure they all hooked up nicely.

Finally some balsa get's involved! 1/8" x 1/2" strips in this case - I squirted them down with an ammonia/water mix (windex works great too) and rubbed that into the wood for a moment (and pulled the rubber bands off the template). Then starting from the most flat edge of the template that still gets wood, I bent and rubber banded my way around the form.

I did two strips first, and then did the second two strips on top of that so there is a layer of rubber bands trapped in the middle. Hopefully that won't cause some weird indentations in the wood, but I don't think the bands are stretched tightly enough for that.

Time to let this dry overnight - and do it a bunch more time on the other forms too.