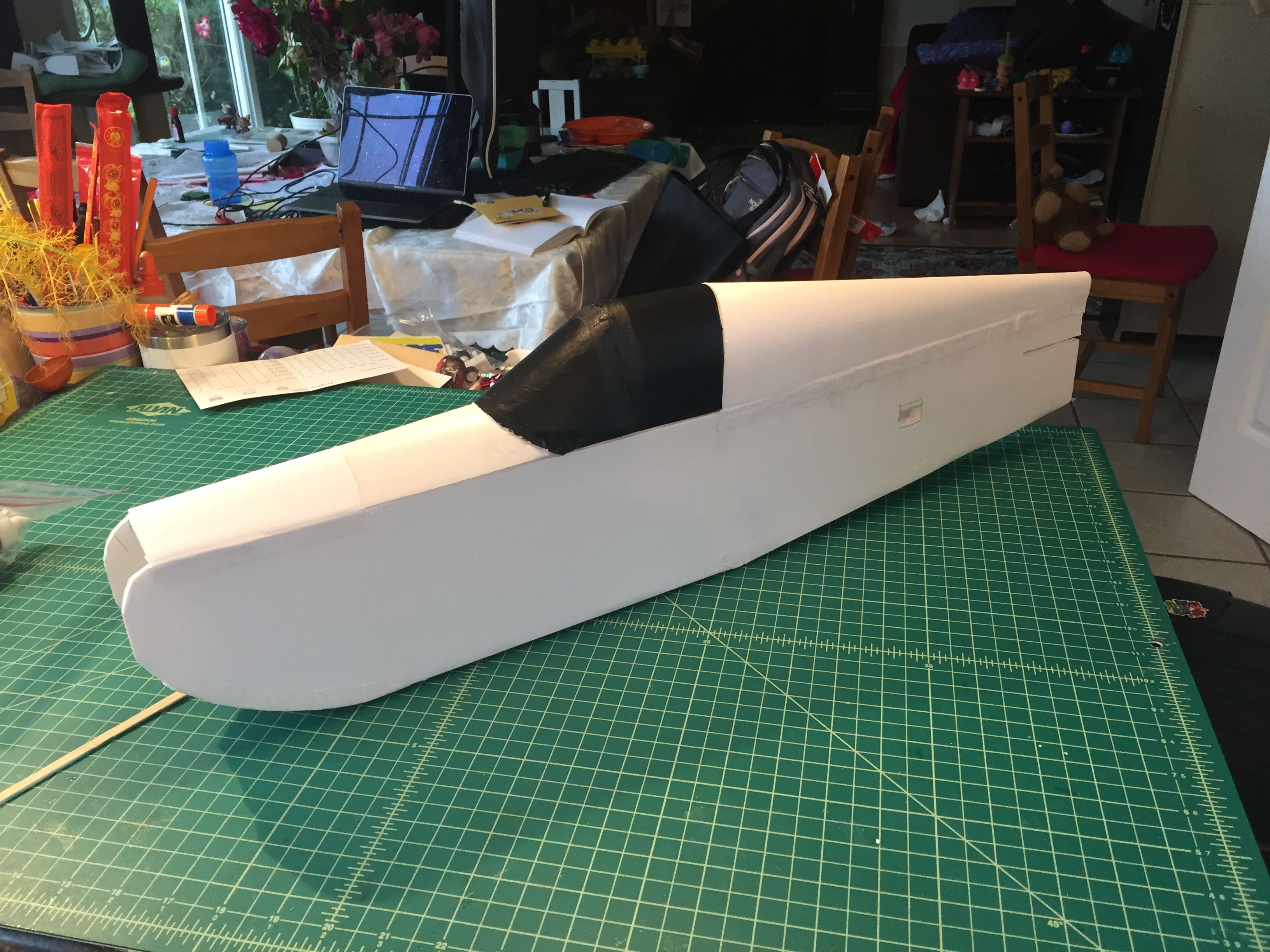

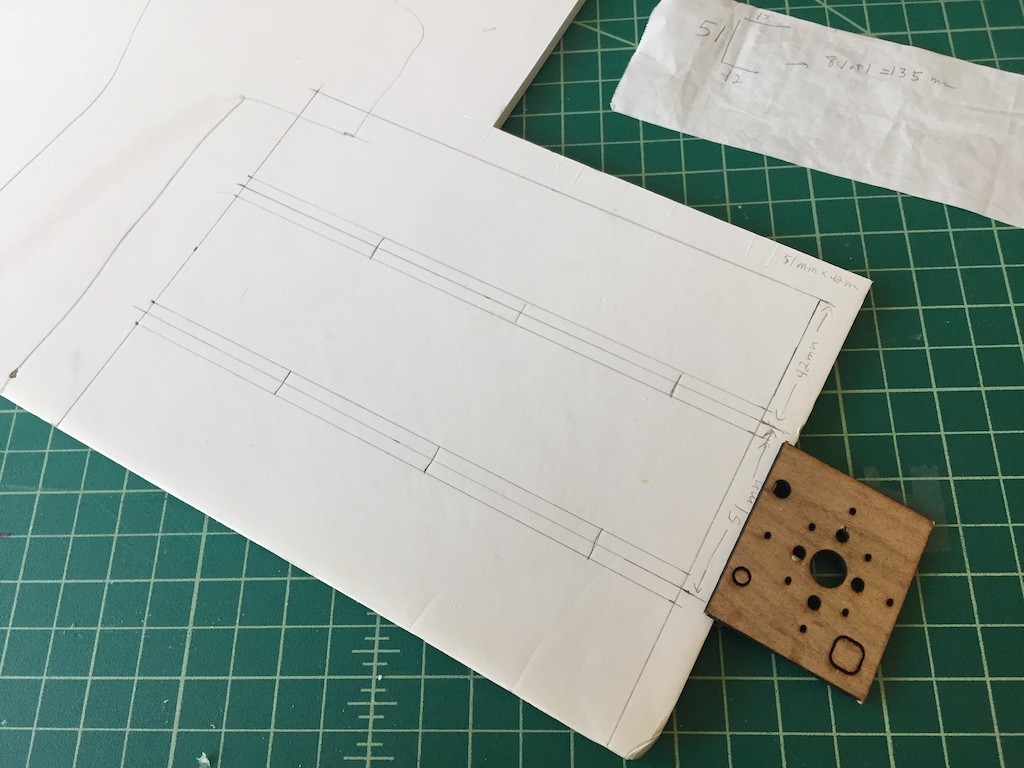

For version 2 of the tail, I'm moving the rudder hinge back half an inch and moving the horizontal stabilizer forward a quarter inch. After some additional modifications to account for the tapered bottom on the fuse, the rudder ends up looking like this:

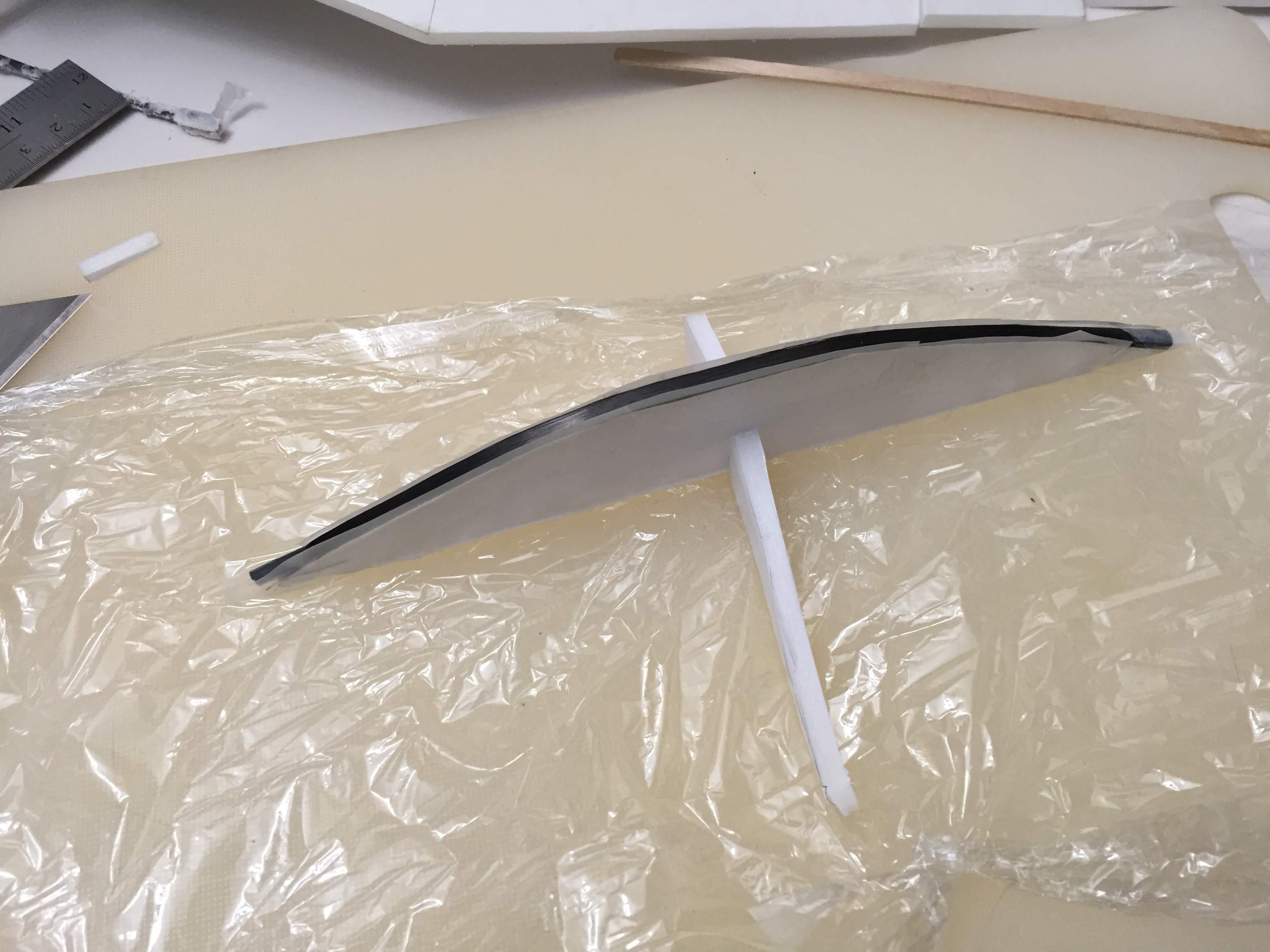

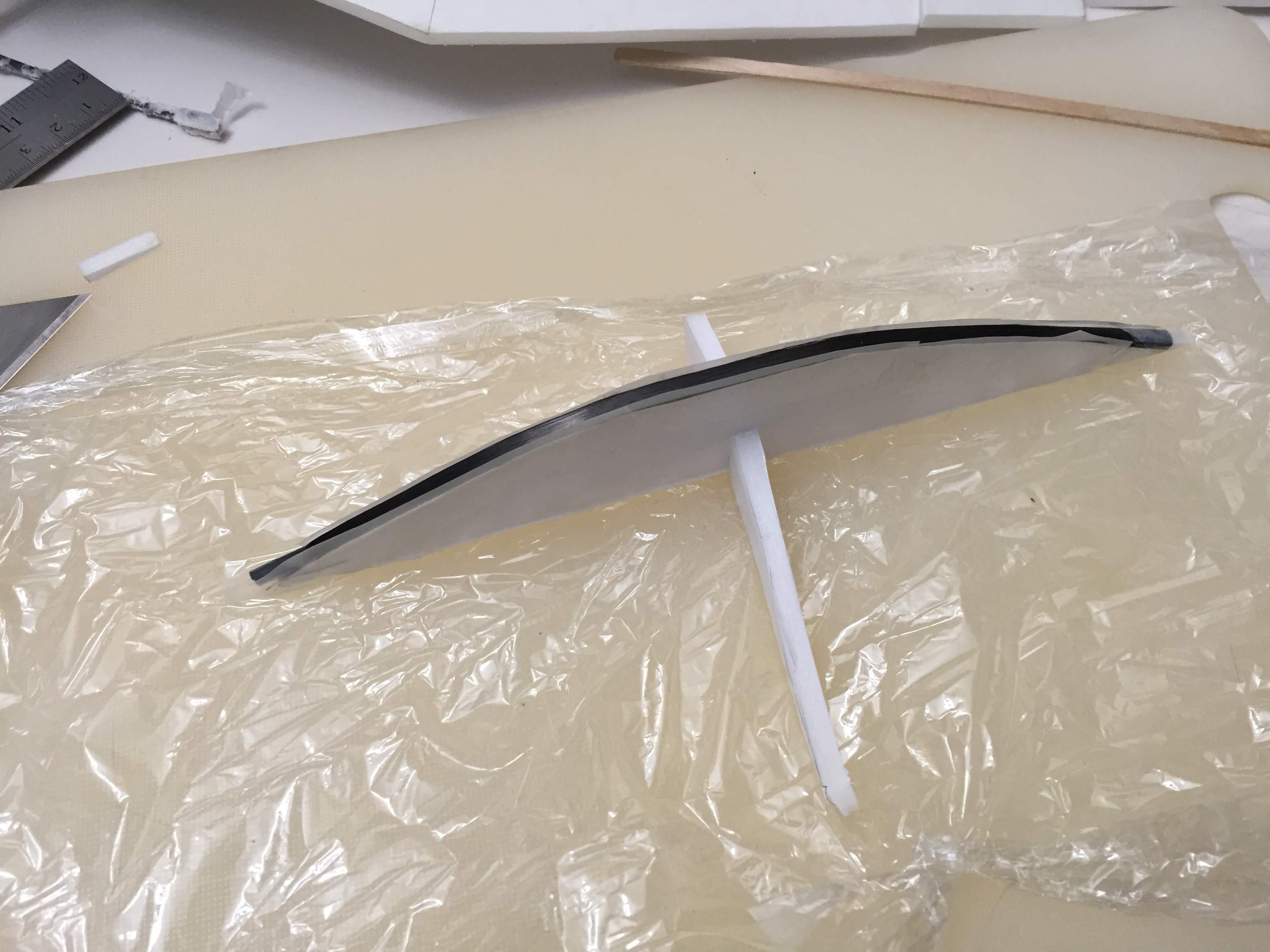

And the horizontal stabilizer looks like this:

Moving the rudder back and the horizontal stabilizer forward makes that V-shaped cutout on the elevator smaller, which should reduce the amount of flex between the two elevator halves.

You may also have noted the curved carbon fiber reinforcement piece in the above photo. I figured, since I had this roll of carbon tow, might as well mold my own reinforcing strips. It took three tries to get to the version in the picture above. On my first try, I cut a slot the elevator and stuffed the dry carbon tow into the slot. The carbon ended up with twists and voids.

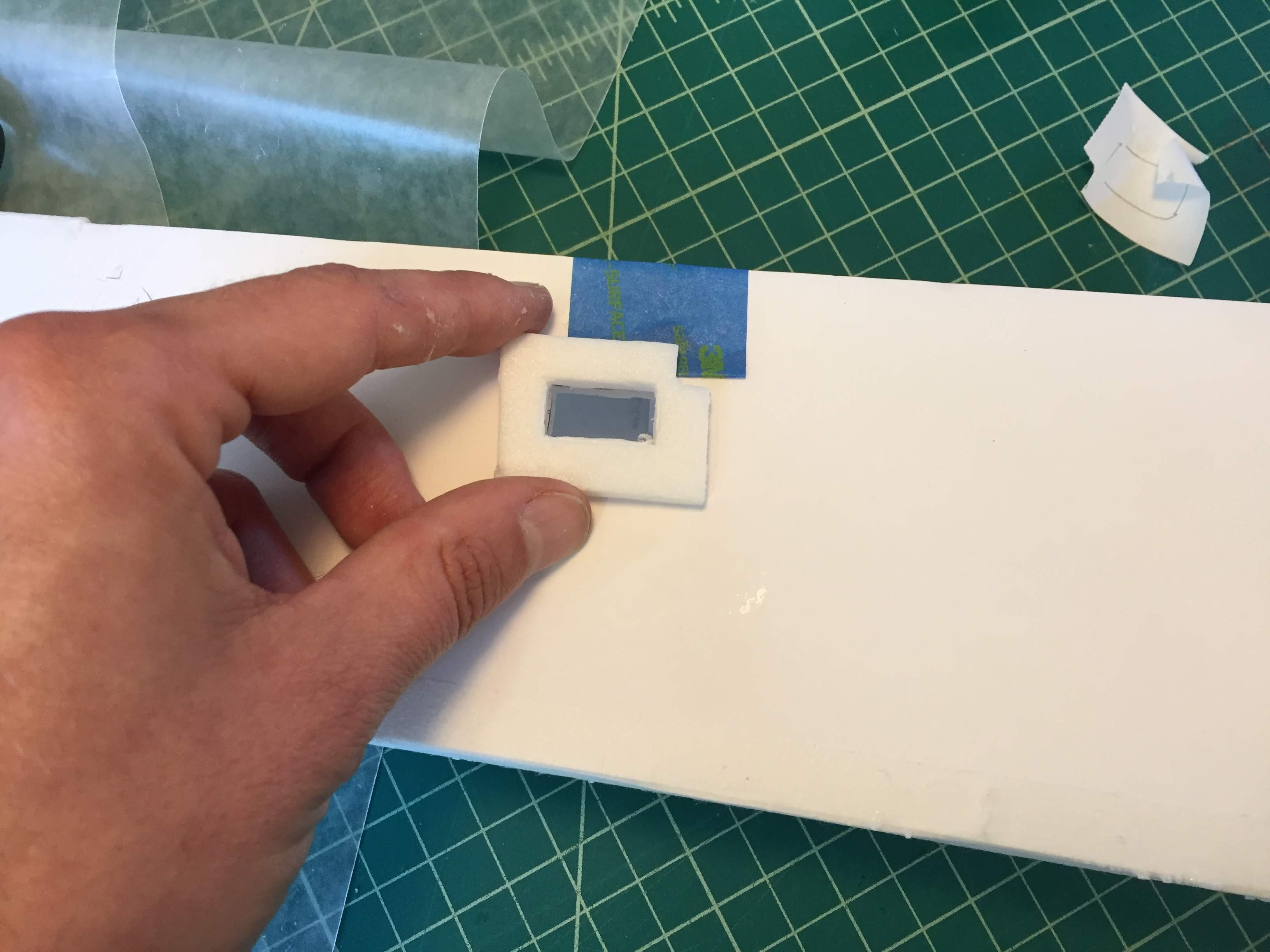

On my second try, I made a two-part mold out of some scrap foam and sandwiched the carbon tow between the two parts:

Then I dribbled epoxy onto the exposed edge of the carbon tow.

Unfortunately the epoxy didn't penetrate all the way to the other side of the mold.

On my third try, I propped up the convex half of the mold with some scrap foam, taped the carbon strip down on top, and applied epoxy directly to the carbon. Then I put the other half of the mold in place until the epoxy partially cured.

After the epoxy had stopped being tacky, I cut the carbon out of the mold, washed away the remaining foam with some acetone, and scraped off the flashing with a razor blade:

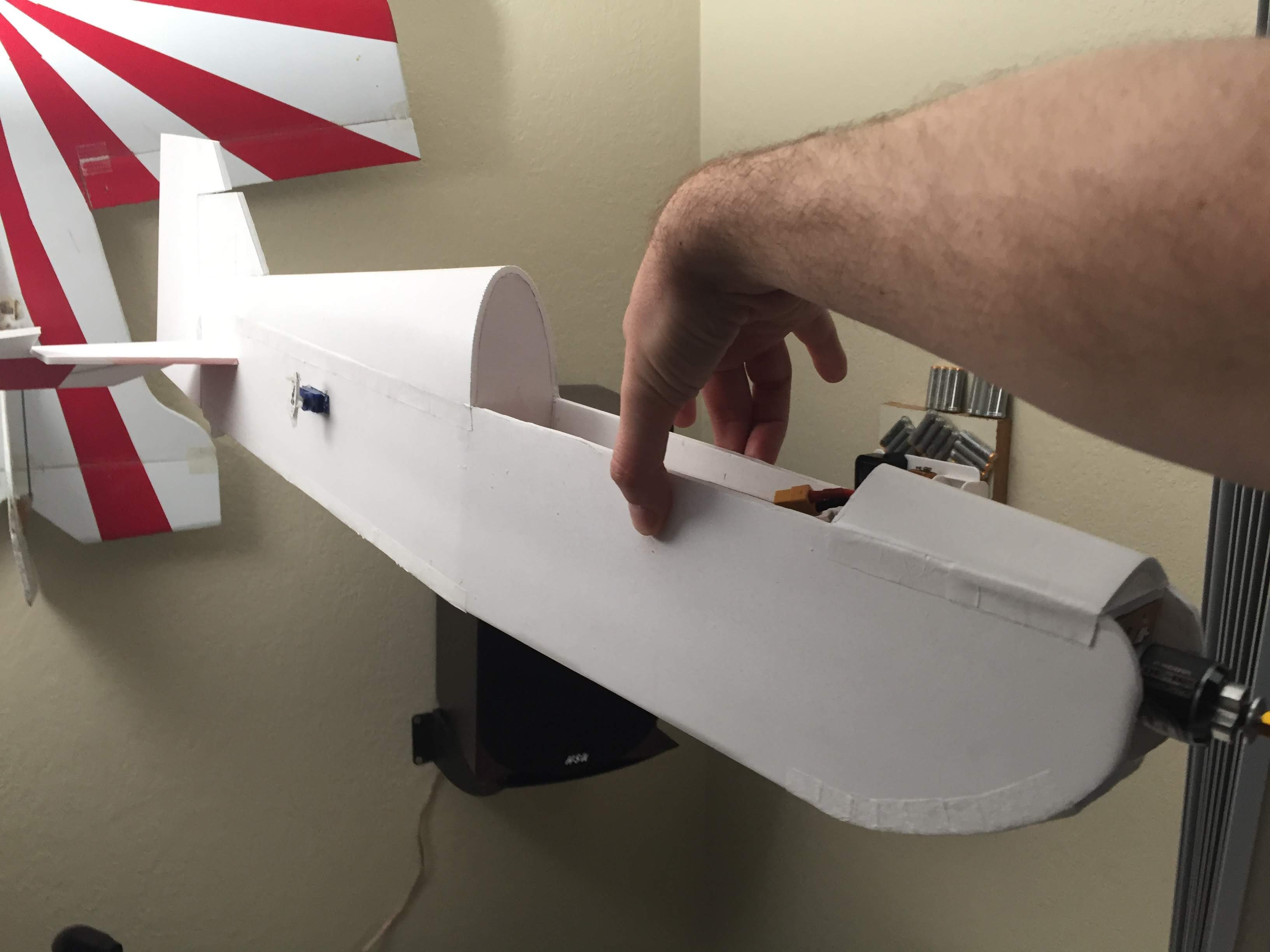

This step left me with a still-flexible curved carbon rod. I cut a slot into the elevator and used some tweezers to push the rod into the slot:

The process of pushing the flexible carbon down with the tweezers left some dents in the foam along the edge. These dents got smaller once I applied epoxy to lock the carbon in place, but there was still a bit of roughness to the edge of the slot:

Next time I'll try letting the epoxy cure completely before inserting the carbon strip.

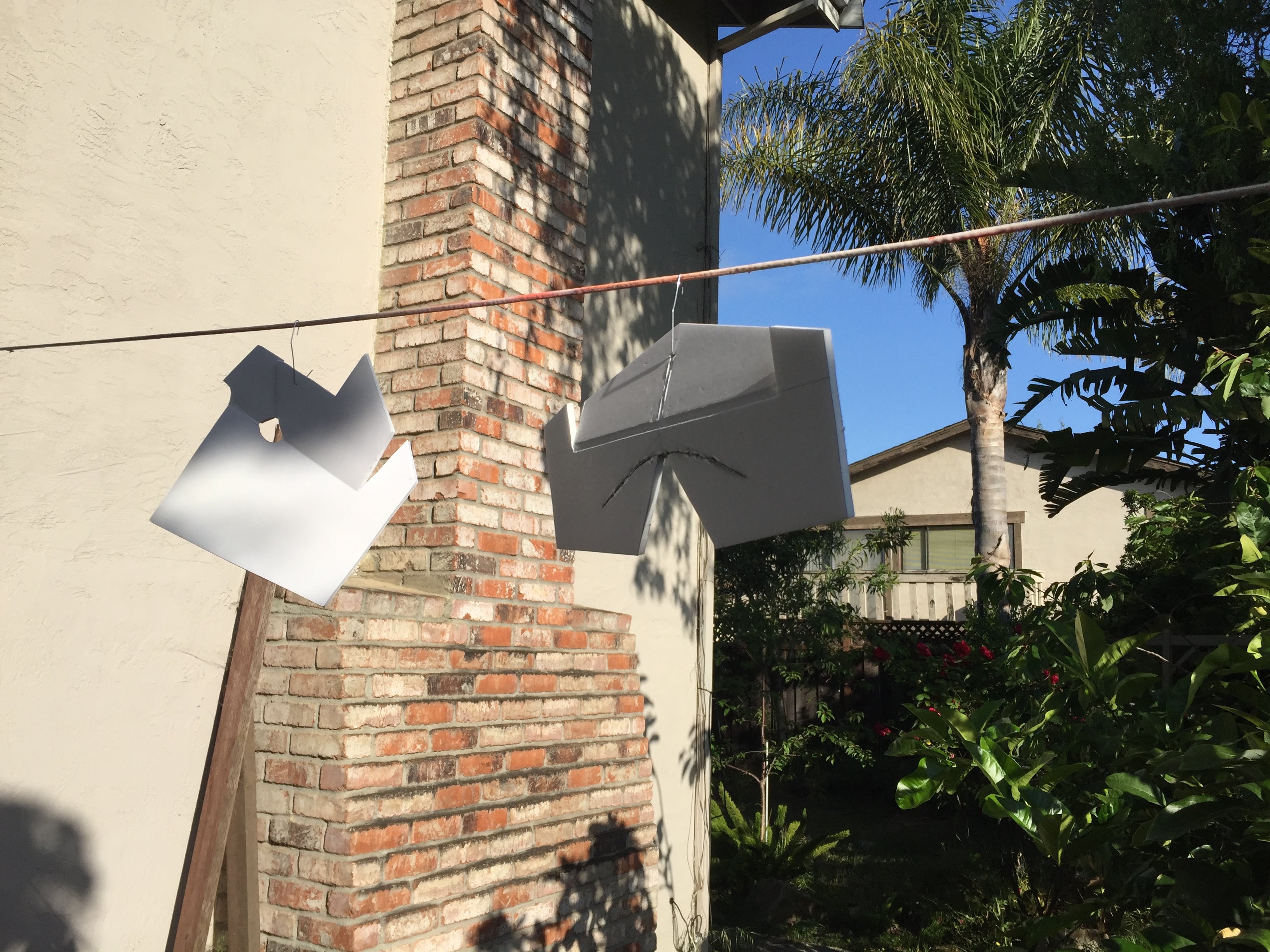

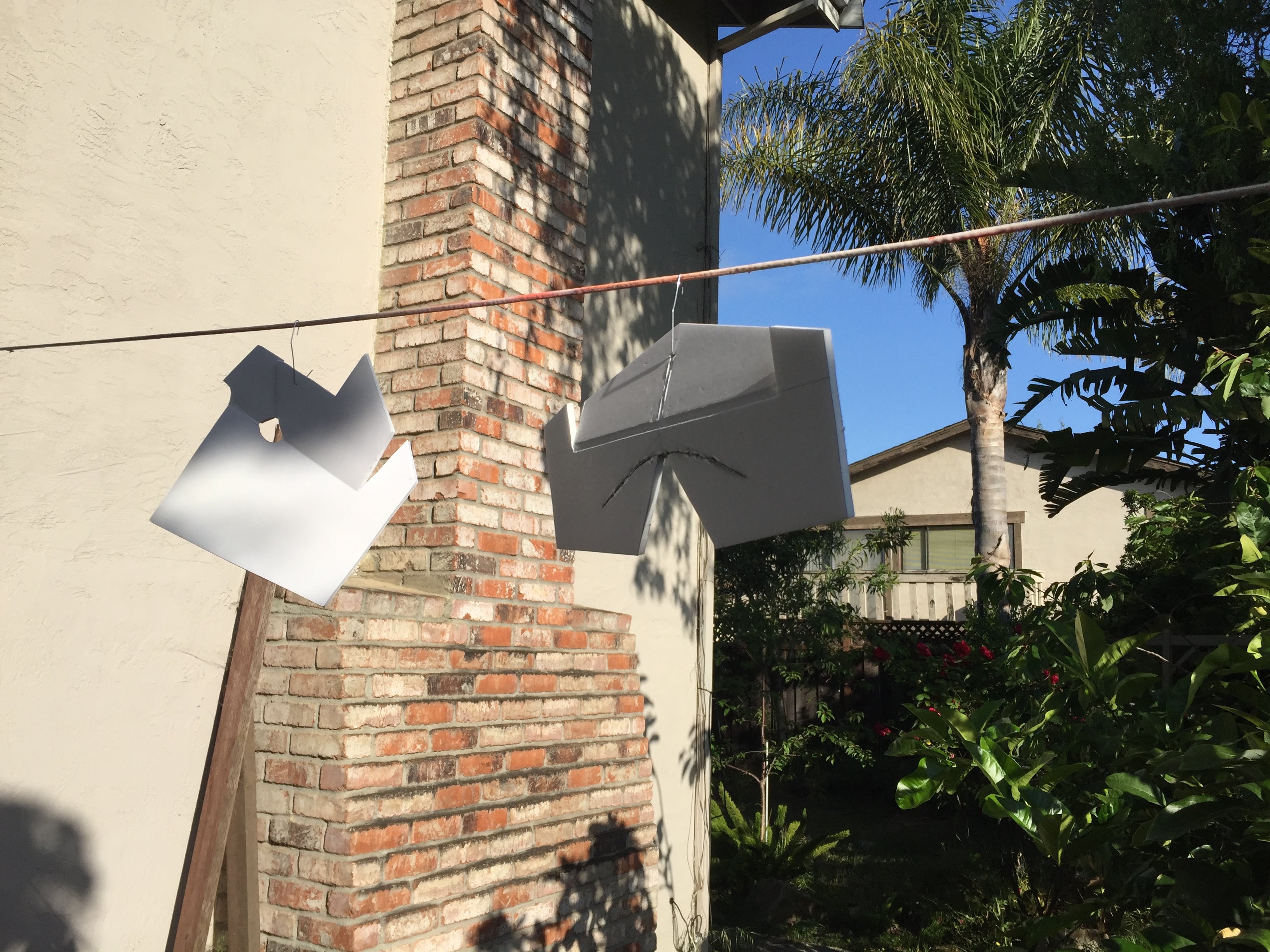

After the reinforcement had set up, it was time for a minimal paint job. I started with a light dusting of white spray paint to seal the paper:

Then I painted a checker pattern on the bottom of the horizontal stabilizer:

And the horizontal stabilizer looks like this:

Moving the rudder back and the horizontal stabilizer forward makes that V-shaped cutout on the elevator smaller, which should reduce the amount of flex between the two elevator halves.

You may also have noted the curved carbon fiber reinforcement piece in the above photo. I figured, since I had this roll of carbon tow, might as well mold my own reinforcing strips. It took three tries to get to the version in the picture above. On my first try, I cut a slot the elevator and stuffed the dry carbon tow into the slot. The carbon ended up with twists and voids.

On my second try, I made a two-part mold out of some scrap foam and sandwiched the carbon tow between the two parts:

Then I dribbled epoxy onto the exposed edge of the carbon tow.

Unfortunately the epoxy didn't penetrate all the way to the other side of the mold.

On my third try, I propped up the convex half of the mold with some scrap foam, taped the carbon strip down on top, and applied epoxy directly to the carbon. Then I put the other half of the mold in place until the epoxy partially cured.

After the epoxy had stopped being tacky, I cut the carbon out of the mold, washed away the remaining foam with some acetone, and scraped off the flashing with a razor blade:

This step left me with a still-flexible curved carbon rod. I cut a slot into the elevator and used some tweezers to push the rod into the slot:

The process of pushing the flexible carbon down with the tweezers left some dents in the foam along the edge. These dents got smaller once I applied epoxy to lock the carbon in place, but there was still a bit of roughness to the edge of the slot:

Next time I'll try letting the epoxy cure completely before inserting the carbon strip.

After the reinforcement had set up, it was time for a minimal paint job. I started with a light dusting of white spray paint to seal the paper:

Then I painted a checker pattern on the bottom of the horizontal stabilizer: