evan

Member

I've done as much research I can with forum searching, but I just wanted to get a solid answer. Do most of you end up having to drill out your linkage stoppers and/or servo horns and/or control surface horns in order to hook up your servo-pushrod set up?

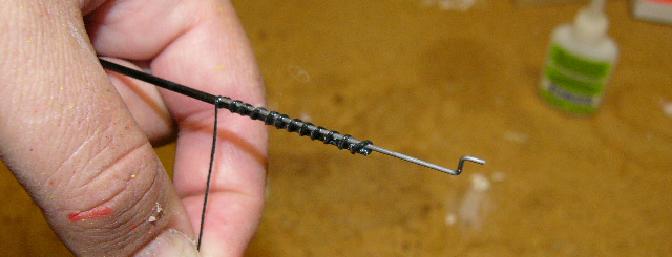

I have both the landscaping flags (which come in at about 1.8-1.9 mm) and the .047" piano wire (1.194 mm). Both of these are too big for the linkage stoppers that come with the LazerToyz FT Swappable components package, despite .047" being the official FT recommended push rod size (see here. I also see that within the last month or so, they've changed from advertising LazerToyz on that page to Uplifting Hobbies. I had some other issues with the LazerToyz package, was it a quality issue?). Additionally, neither size wire, nor the DuBro EZ connectors I got (which fit both wire sizes), nor even the linkage stoppers that came with the kit, nothing fits into the servo horns. So it seems that no matter what I figure out with the linkage stoppers, I'll have to drill out the servo horns. Is that common?

Any tips for a straightforward way of setting up pushrods with having to drill everything out? I'm skeptical of going any smaller than .047" wire, it's already a little more flexible than I'd like, and I'd really prefer to use to larger diameter flags.

And while I'm at it, how is everyone cutting these hardened steel wires? Elsewhere online I've seen everything from bolt-cutters to a Dremel with a metal cutting wheel.

I have both the landscaping flags (which come in at about 1.8-1.9 mm) and the .047" piano wire (1.194 mm). Both of these are too big for the linkage stoppers that come with the LazerToyz FT Swappable components package, despite .047" being the official FT recommended push rod size (see here. I also see that within the last month or so, they've changed from advertising LazerToyz on that page to Uplifting Hobbies. I had some other issues with the LazerToyz package, was it a quality issue?). Additionally, neither size wire, nor the DuBro EZ connectors I got (which fit both wire sizes), nor even the linkage stoppers that came with the kit, nothing fits into the servo horns. So it seems that no matter what I figure out with the linkage stoppers, I'll have to drill out the servo horns. Is that common?

Any tips for a straightforward way of setting up pushrods with having to drill everything out? I'm skeptical of going any smaller than .047" wire, it's already a little more flexible than I'd like, and I'd really prefer to use to larger diameter flags.

And while I'm at it, how is everyone cutting these hardened steel wires? Elsewhere online I've seen everything from bolt-cutters to a Dremel with a metal cutting wheel.