CapnBry

Elite member

Yeah! I have only had one "Wait... what am I doing?" moment which is where you said that the slightly larger of the two hatch formers goes to the front but I didn't know which end was the front. I skipped forward in the video real quick to see. If that's the only question I'm going to have on this whole build and I've never done this before, then the instructions must be top notch. One minor issue in the plans: in the tiled plans you have Fuselage Mold F twice, but the one on page A6 (Mold E) is labeled correctly on the full size page.@CapnBry That’s wonderful man!!! Glad the instructions are sufficient so far and thanks for posting the stl, this community is awesome!

Lunch break! I also quickly messed around with creating 3D printed versions of the formers, since cutting curves on small parts can be a little perilous for me.

It would definitely save a lot of time but the tradeoff is weight. All the DTFB formers are 0.4-0.7g each. Printed in ABS with 10% hex infill and 1x 0.6mm perimeter they weigh up to 2.3g. That would add 12-16g of weight to the plane which would be OK for a larger build but this whole thing only weighs 137g so far with 2 of the servos so that's a significant increase.

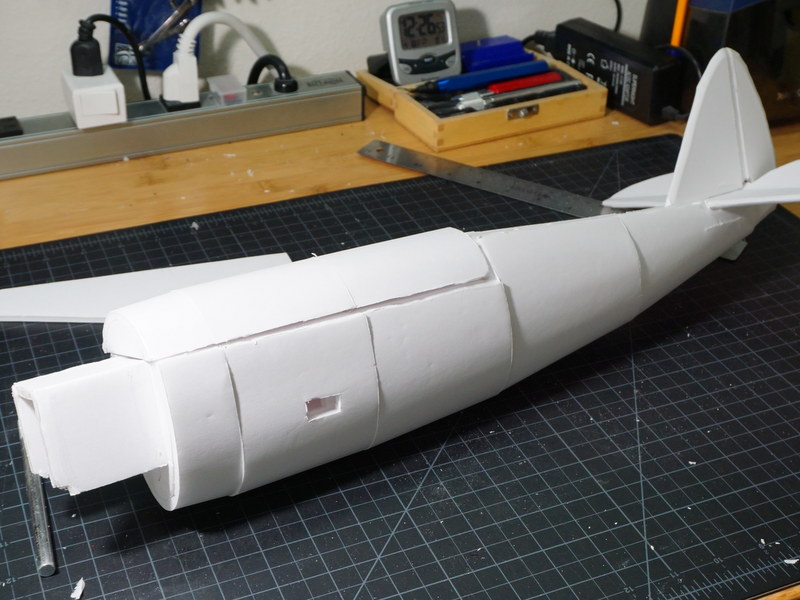

I was able to remove the cowl from my build with a little denatured alcohol and an eyedropper to break down the glue. Heck yeah, right side up!

I had a little bit of a rough time with the larger mold pieces. A tip I would give to new people is to jump forward and do the hatch first, since the smaller size makes the molds easier to form and give you some practice before getting to the fuselage. It didn't come out too bad though.

To smooth them out, I considered getting some body filler or super-light spackle but it seemed easier to just coat the seams with paper and some spray glue. I think I'll be able to sand out some of the wrinkles that came from me being overzealous on the curve in the front too. I should have just done like I did near the tail where I just cut strips from the scrap mold paper.