GrizWiz

Elite member

I have been looking into building a simple and cheap CNC

First, I found the ERC TimSav CNC but, I do not have a 3D printer, so I went to find a shop to buy CNC parts and, I found open builds.

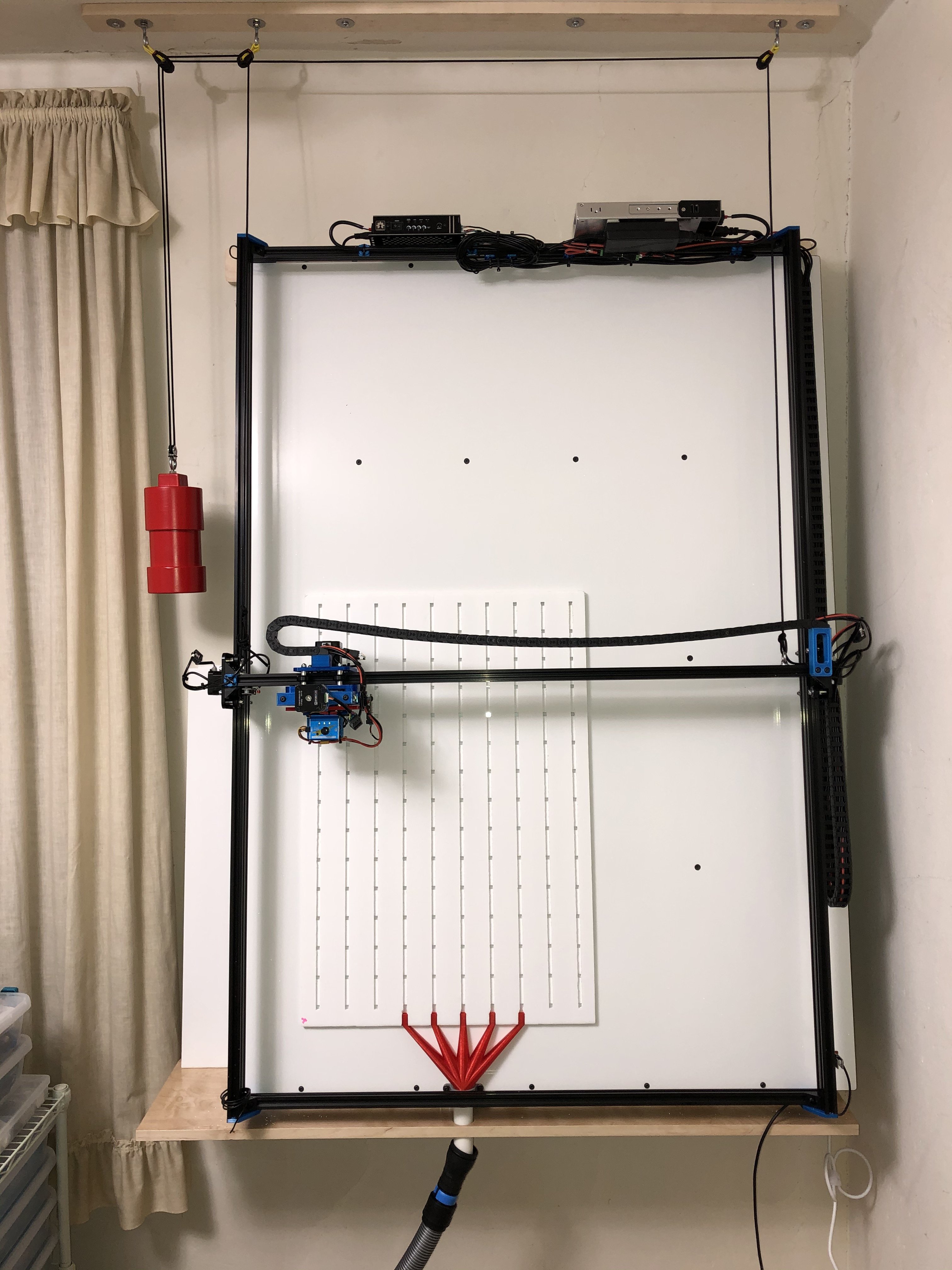

Open builds Acro CNC looked very simple and easy to modify. But it costs a lot for just the frame.

luckily they sell just the plate set by itself for $29.99

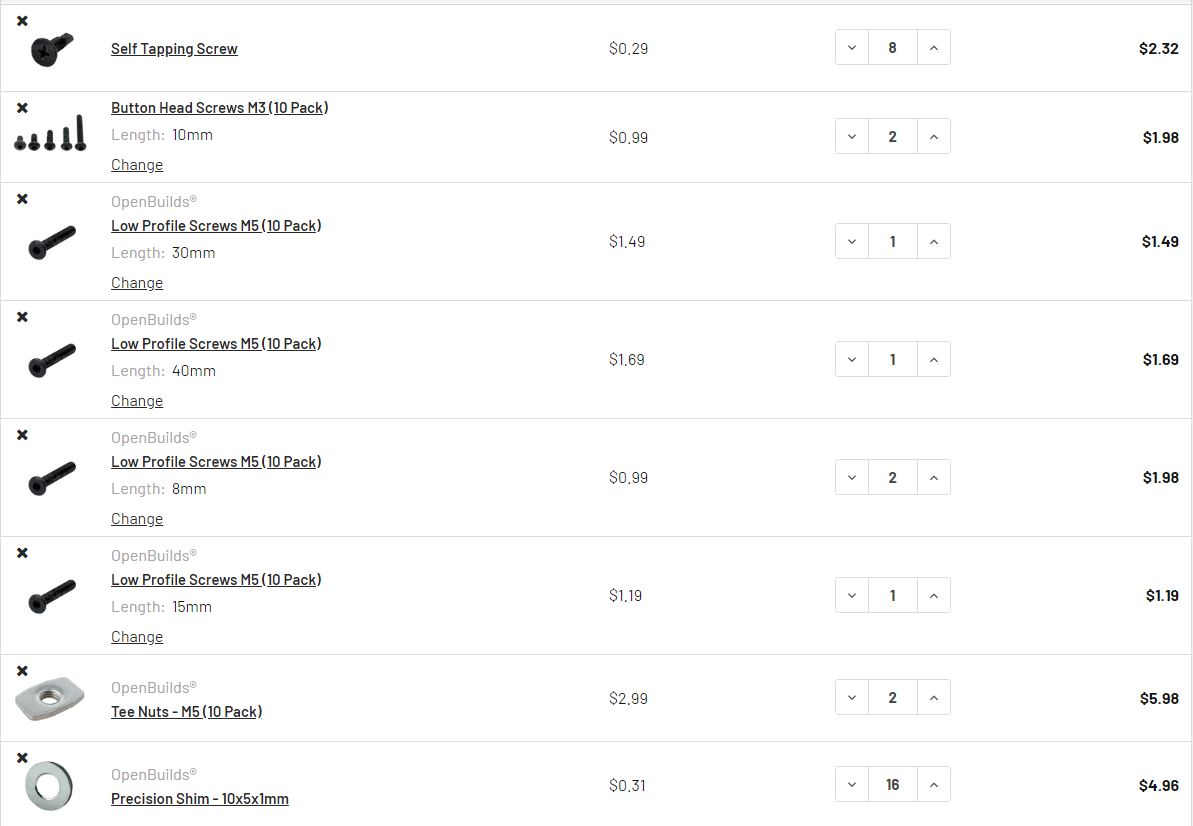

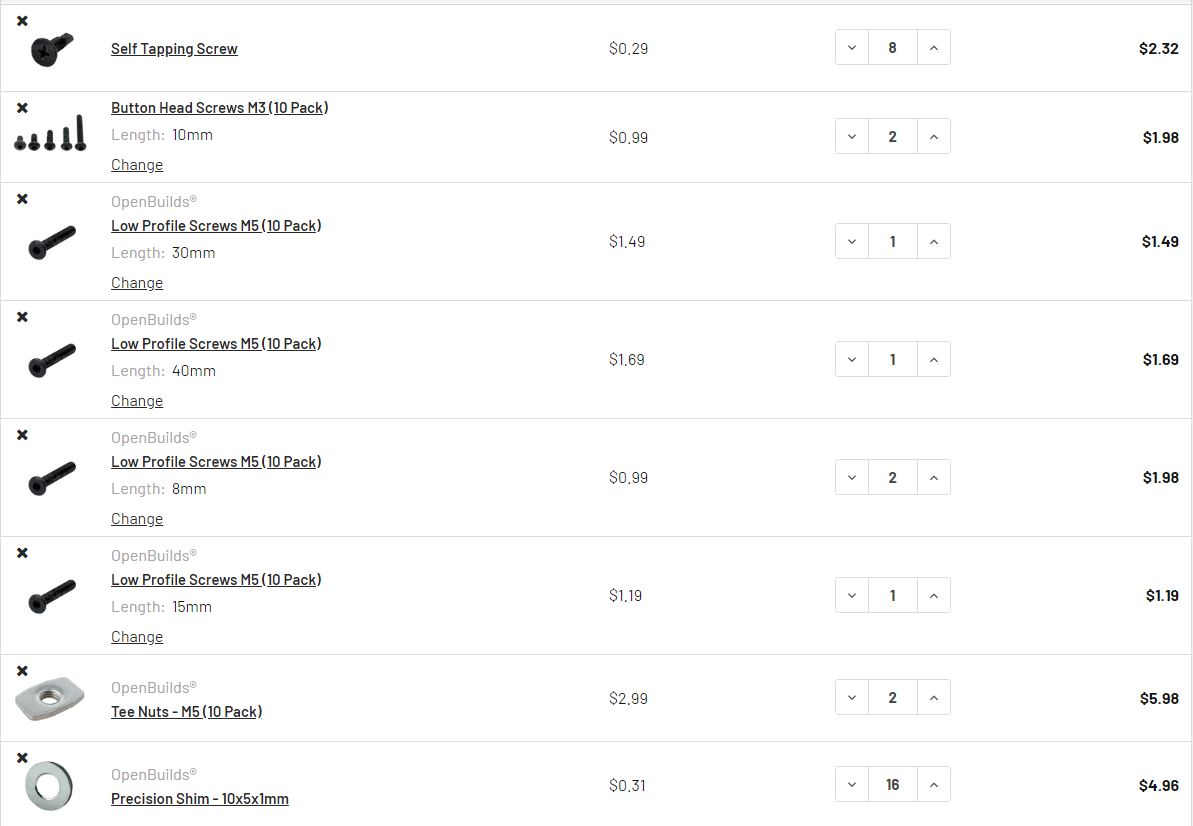

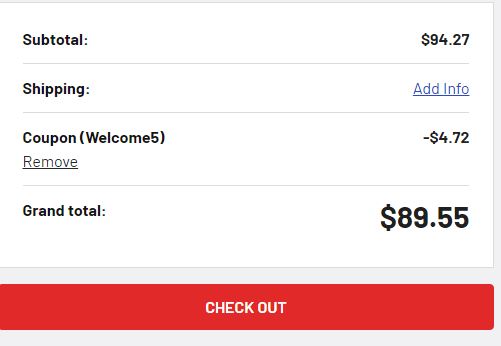

I was able to find all of the screws and other hardware for $36.99

The Extrusions I was going to buy 3 2040 extrusion 2*500mm and 1*1000mm which, I will cut down to 800mm to fit the foam sheet exactly.

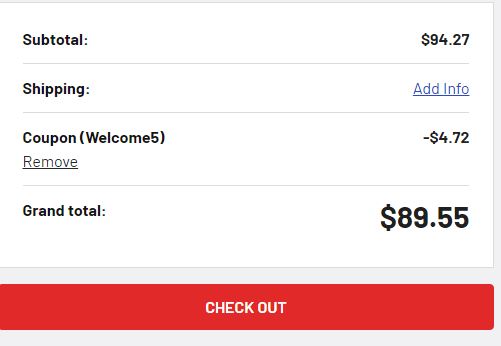

Here is the parts list without electronics

First, I found the ERC TimSav CNC but, I do not have a 3D printer, so I went to find a shop to buy CNC parts and, I found open builds.

Open builds Acro CNC looked very simple and easy to modify. But it costs a lot for just the frame.

luckily they sell just the plate set by itself for $29.99

I was able to find all of the screws and other hardware for $36.99

The Extrusions I was going to buy 3 2040 extrusion 2*500mm and 1*1000mm which, I will cut down to 800mm to fit the foam sheet exactly.

Here is the parts list without electronics