SgtHavoc

New member

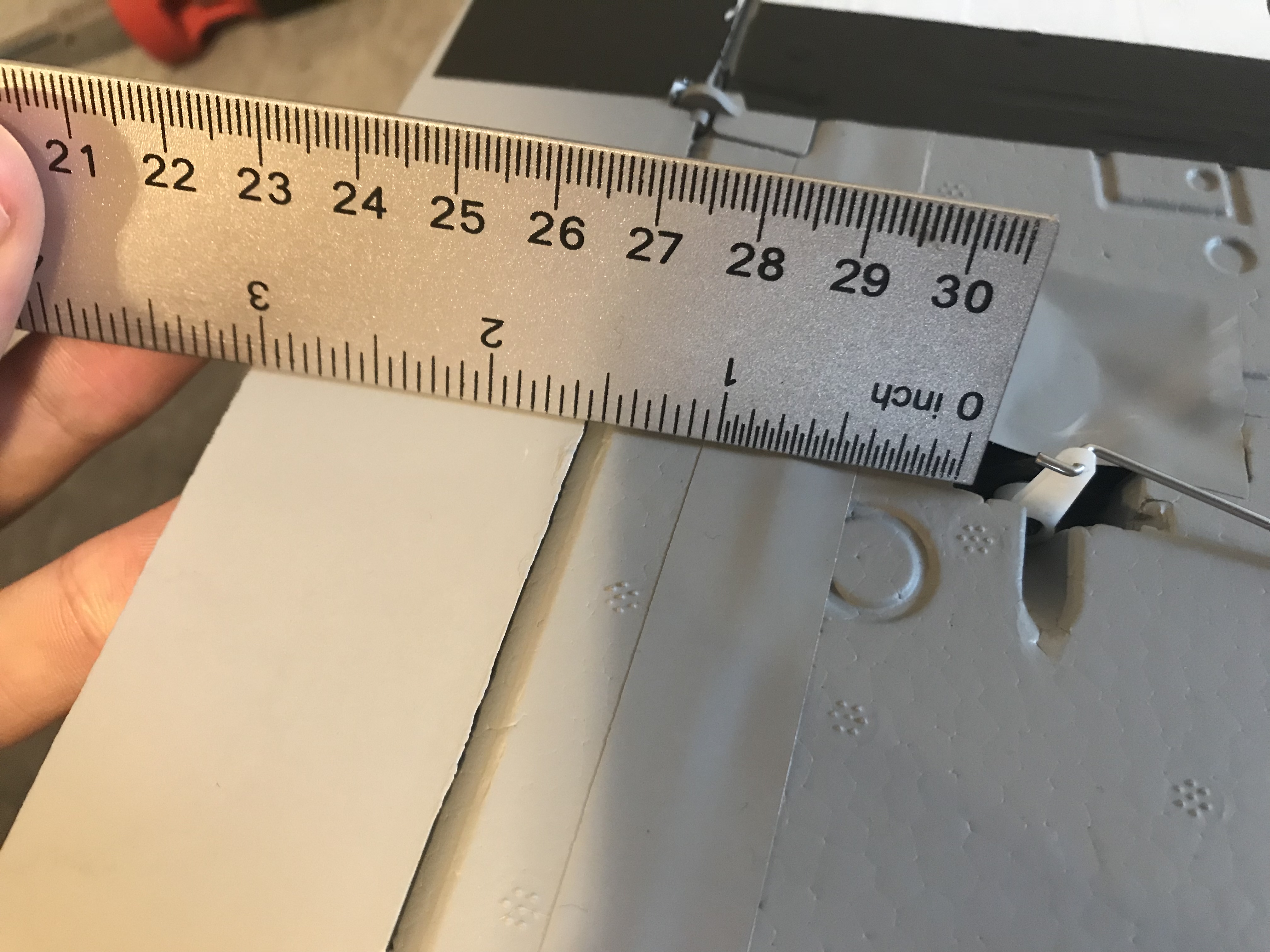

I recently bought a Durafly Spitfire Mk24 V2 from HobbyKing, and assembly was going fine until I had trouble with the flap servos. They were pretty close to being centered, but one flap was clearly not matching the other. The servo arms have an S on one end, and an adjustable eyelet at the other. After fussing with screwing them in and out, and trying to make sure I hadn't messed up some radio settings, I realized that though the arms provided are identical, there is about a 5/16th of an inch difference between the servo horn and the flight control horn, even with the control rods screwed in or out to their maximum adjustment.

In essence, the servo slots are not identically placed on this plane, and the provided servo arms cannot be adjusted to match. Has anyone else experienced this? Is there anything that I can do other than drive an hour to the hobby shop and buy new arms and bend them myself? Also, I can't seem to get a screwdriver in to adjust the servo horn without stripping the screw.

Left wing length approximately 1 and 5/8ths

Right wing length approximately 1 and 15/16ths

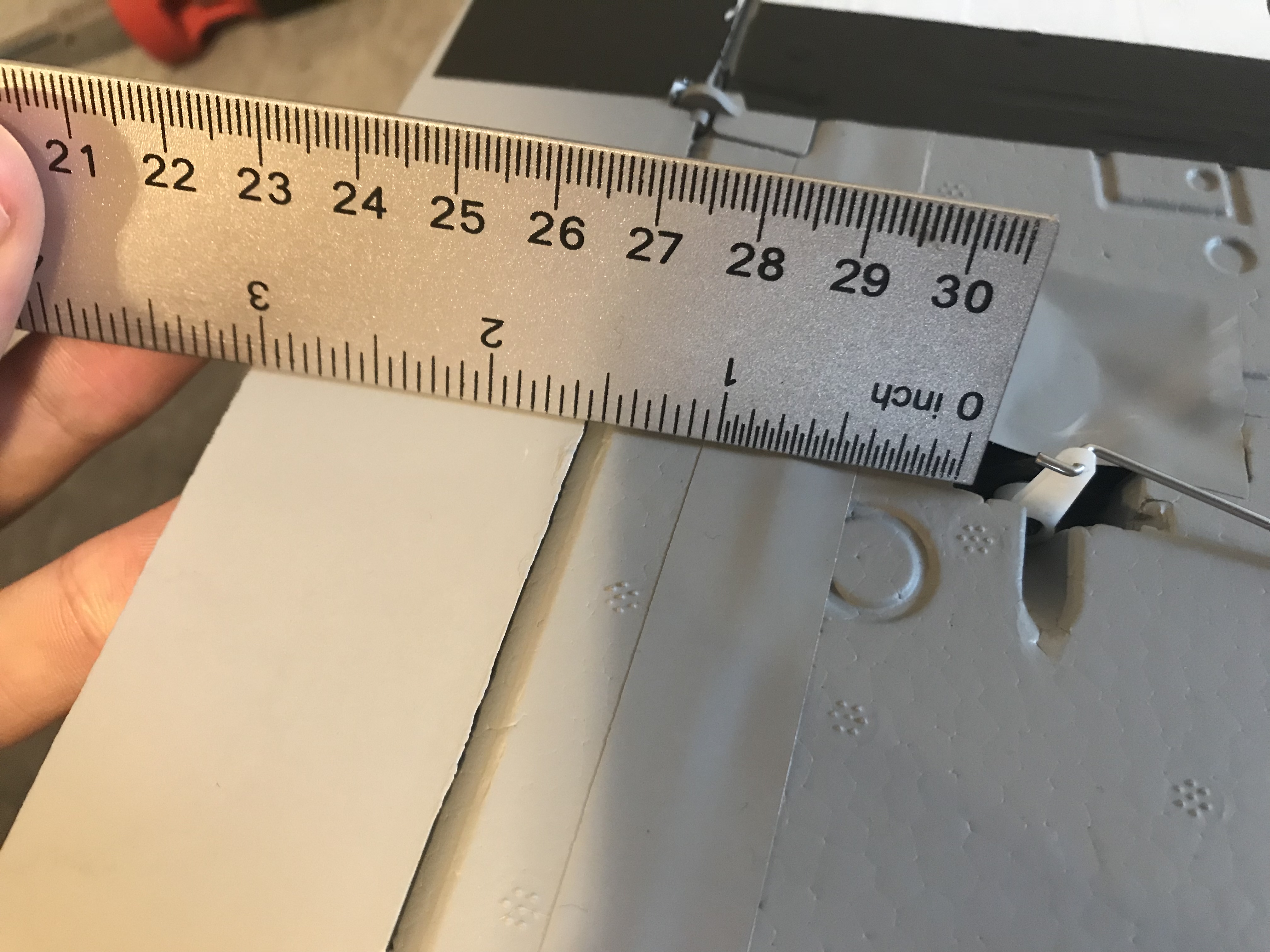

About 1 and 3/8ths

About 1 and 3/8ths

About 1 and 9/16ths

About 1 and 9/16ths

In essence, the servo slots are not identically placed on this plane, and the provided servo arms cannot be adjusted to match. Has anyone else experienced this? Is there anything that I can do other than drive an hour to the hobby shop and buy new arms and bend them myself? Also, I can't seem to get a screwdriver in to adjust the servo horn without stripping the screw.

Left wing length approximately 1 and 5/8ths

Right wing length approximately 1 and 15/16ths