buzzbomb

I know nothing!

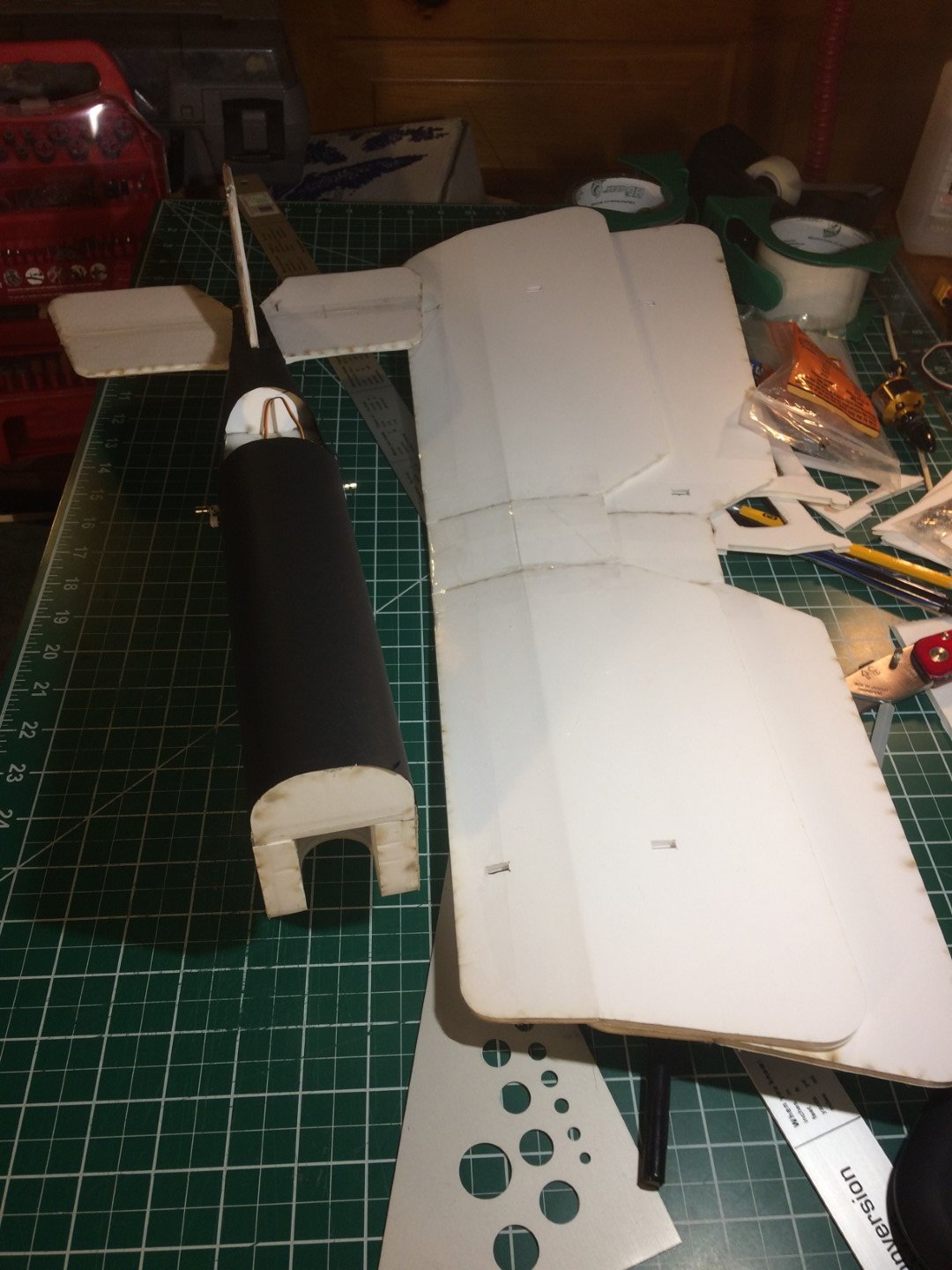

So the SE5 is next on my build list. This is an open call to anyone who wants to join in. Doesn't matter if you've built or flown it before, just so long as you want to build and fly one now.

As usual no time limit and no pressure (except some friendly ribbing now and again).

I'll be building this one for my son, so he and I can engage in some cutthroat ribbon combat with the SE5 and the DR1. Whoots! He doesn't know it yet, but he'll be flying the maiden!

He doesn't know it yet, but he'll be flying the maiden!

Follow along if you wish and join in if you'd like. If you're doing either, please comment when I do something stupid. I wish you could comment before I did something stupid, but that'd be tough to pull off in a forum venue. Oh well.

As usual no time limit and no pressure (except some friendly ribbing now and again).

I'll be building this one for my son, so he and I can engage in some cutthroat ribbon combat with the SE5 and the DR1. Whoots!

Follow along if you wish and join in if you'd like. If you're doing either, please comment when I do something stupid. I wish you could comment before I did something stupid, but that'd be tough to pull off in a forum venue. Oh well.