I haven't covered an airplane with tissue in over 40 years. I did some YouTube research because I might be a little rusty.

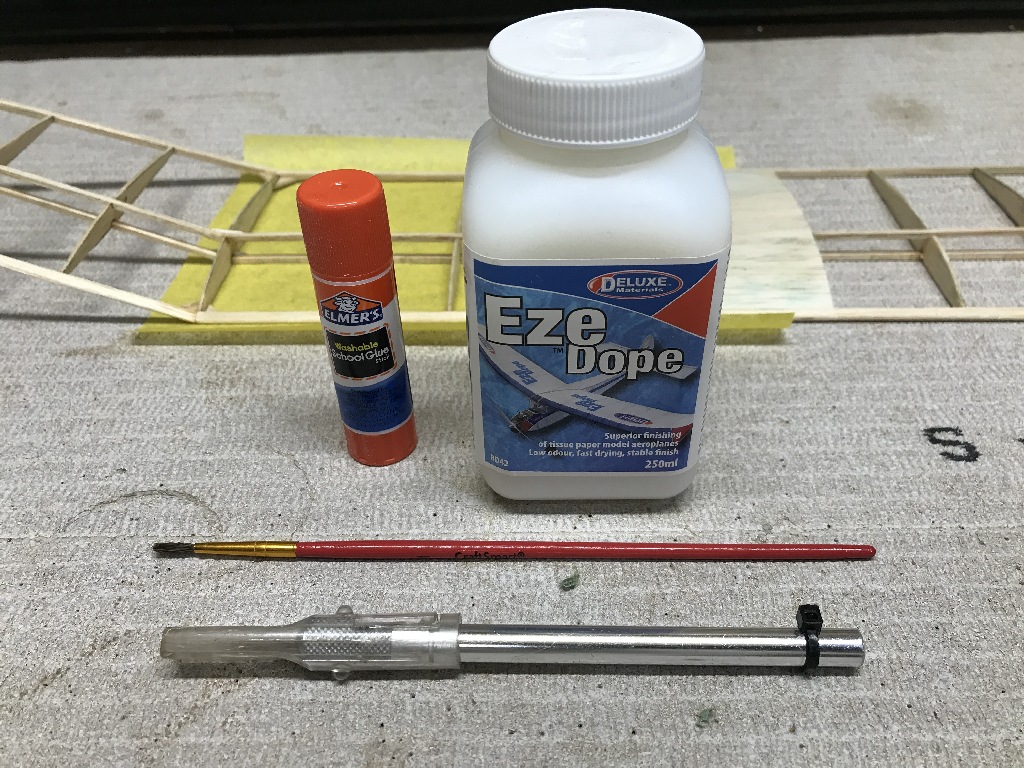

The adhesives are better and easier to use. Since this will be just like I'm doing it for the very first time I'll describe the process step by step. Here's what I gathered together. Using glue stick and Eze dope for tissue covering will be new for me.

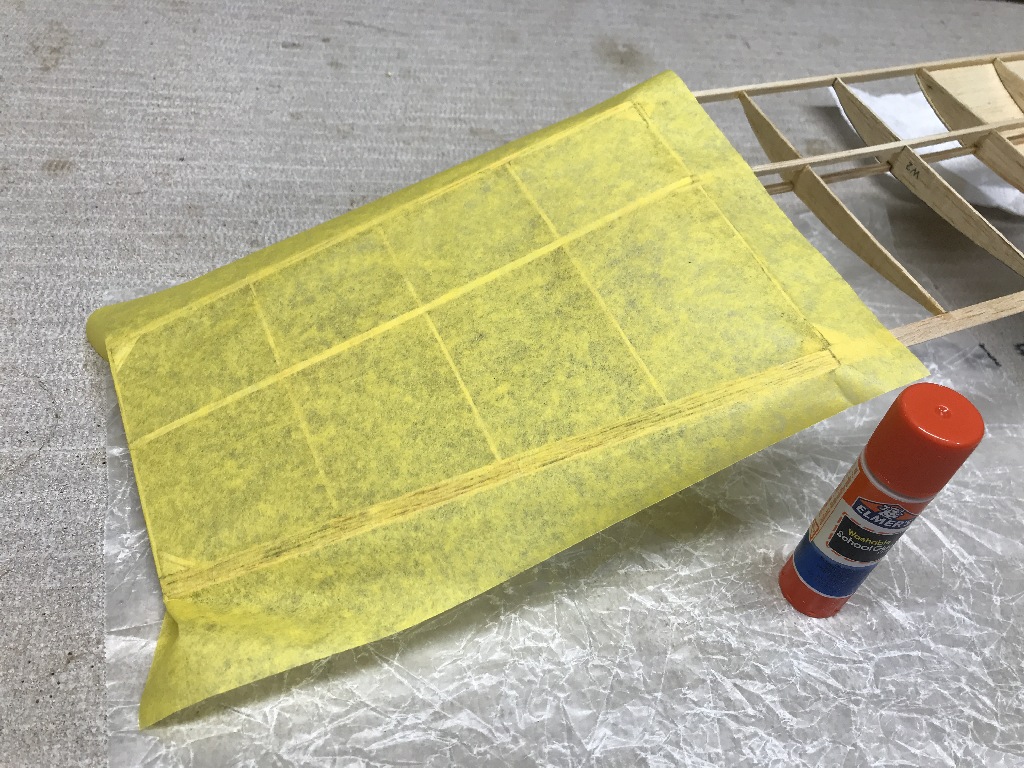

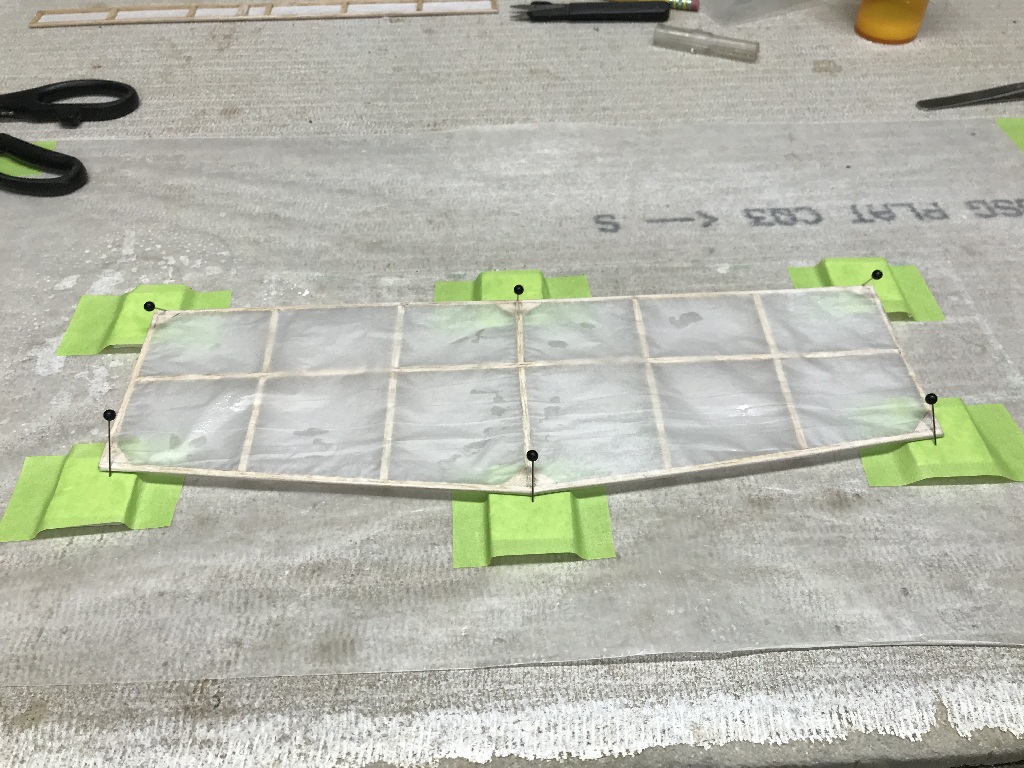

You'll need a blade with a razor edge. Starting on the bottom of the wing cut a piece of tissue 1/2" larger than the area to cover. Lightly rub the glue stick on only the outside edges of the frame you are covering. Don't get glue on the inside ribs or spars. Go around the outside frame twice with the glue stick.

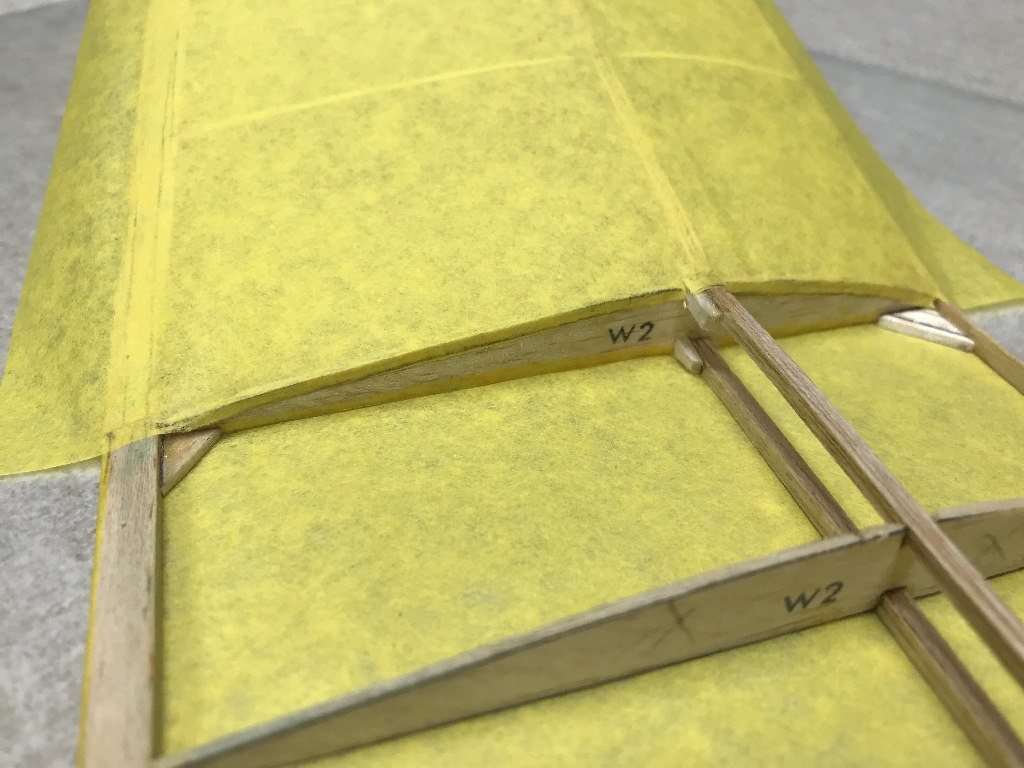

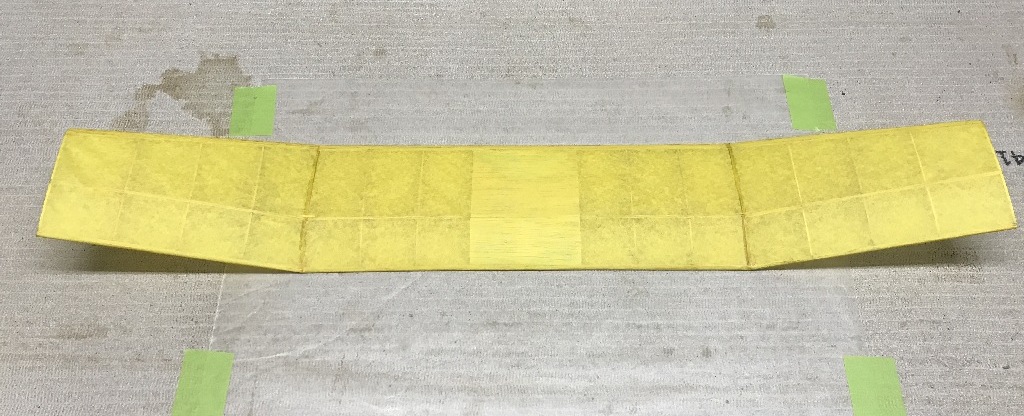

Lay the tissue on the frame and lightly press the tissue into the glue. Pull the excess overhang lightly on areas that are slack or wrinkled. I really like glue stick for this. You can even peel off and reposition the tissue if you have to. When the tissue is smooth and wrinkle free go around the edge again and press the tissue down until it is stuck all the way around.

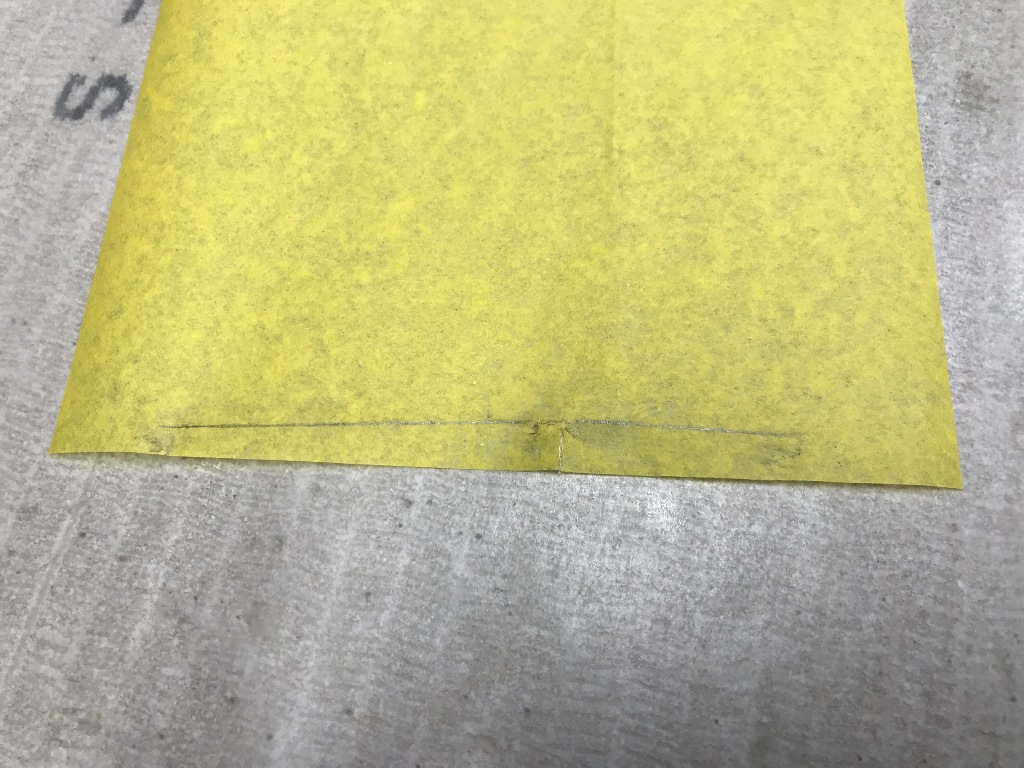

Let the glue stick dry for a few minutes. Then trim off the excess with the razor blade or scissors, leaving about 1/16" all the way around.

Mix one part Eze Dope with two parts water. You can use Elmers glue instead of Eze Dope, same mixture. It will be the consistency of milk. With a small brush paint the tissue edge with the Eze Dope mixture. With your fingers, smooth the edge down over the frame. Brush another coat on just the edge after it is stuck down. I wear surgical gloves for this. It keeps my fingers from sticking to the glue and tissue. It dries fast.

After the bottom of the wing is covered we'll cover the top side.

Jon

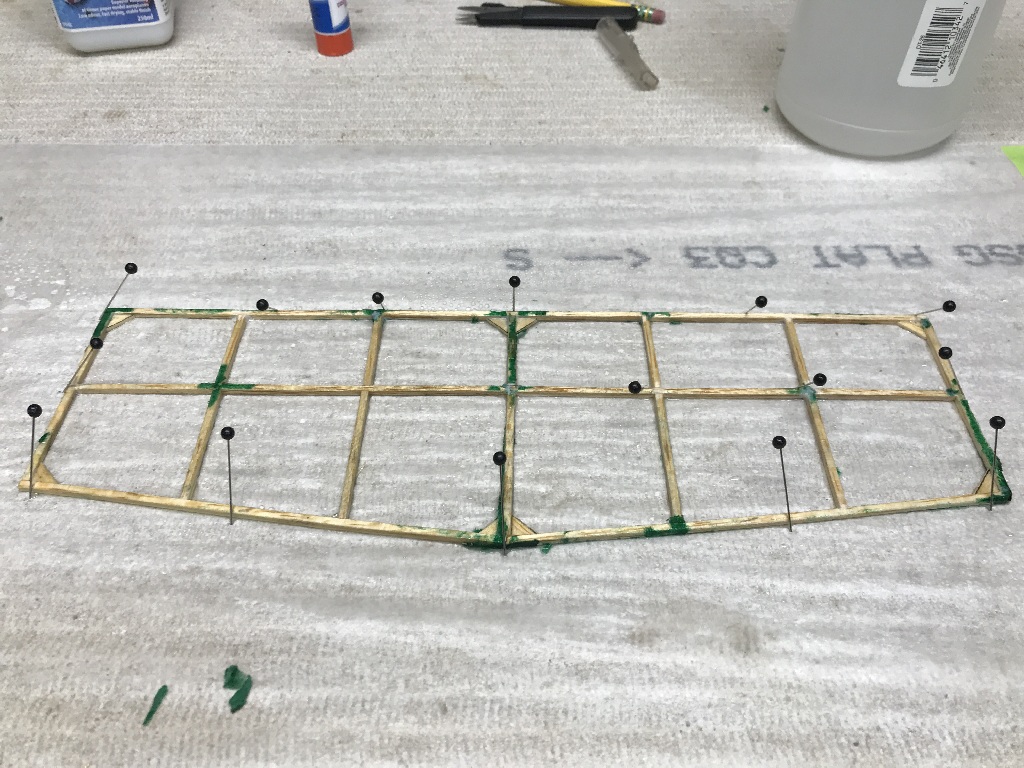

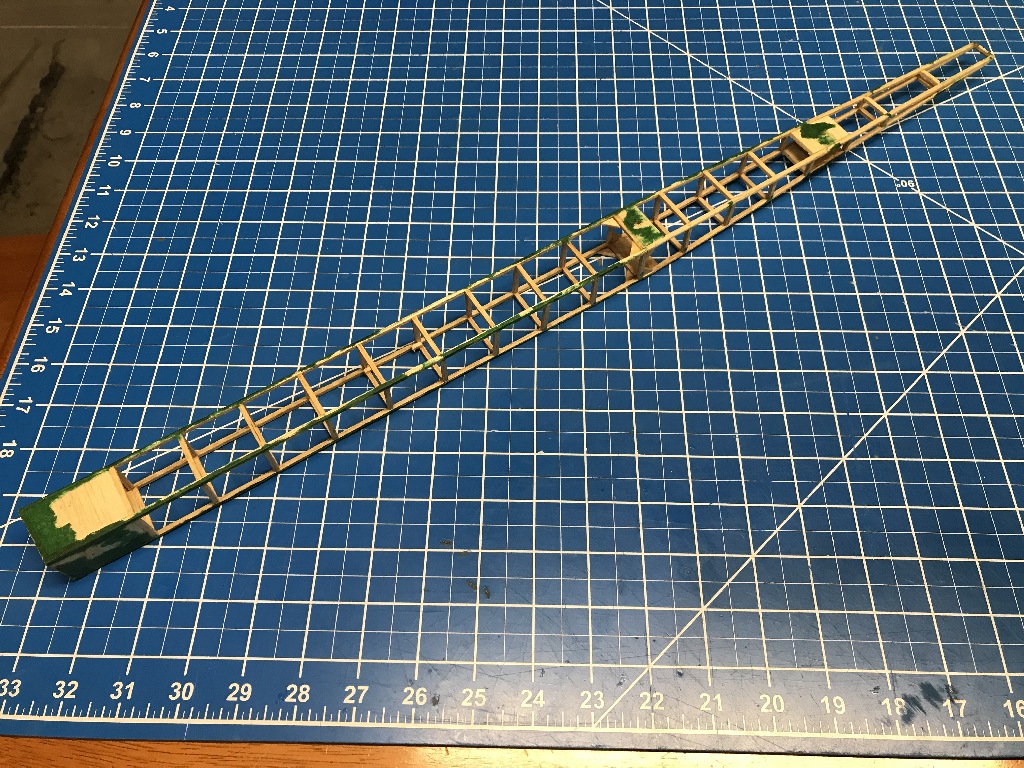

It is an old Peck Polymers "One Nite 28" designed by Bob Peck. A FB was going to throw this away. It looks like he did a quality build so I rescued it to see what I can do with it. The One Nite line of rubber powered airplanes has been around for a very long time. Probably thousands were built and flown. This 28" version is still sold as the "Almost 30" kit by the new Peck Polymers.

It is an old Peck Polymers "One Nite 28" designed by Bob Peck. A FB was going to throw this away. It looks like he did a quality build so I rescued it to see what I can do with it. The One Nite line of rubber powered airplanes has been around for a very long time. Probably thousands were built and flown. This 28" version is still sold as the "Almost 30" kit by the new Peck Polymers.