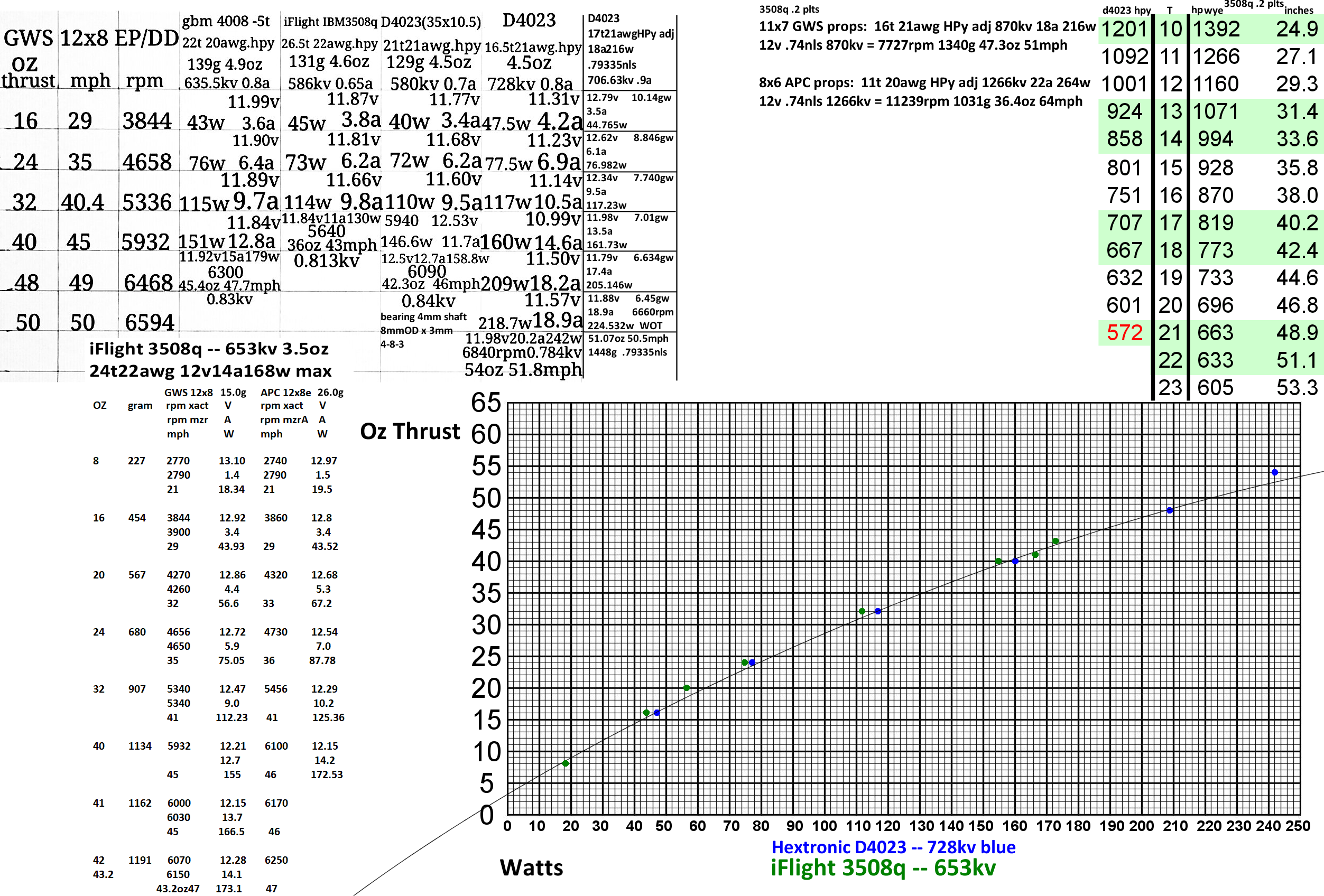

Maybe we still don't know enough about this problem. I got a hextronic d4023 one of 4 that I had rewound then really wished I had checked because the stator rubbed the magnets on the rotor. Kinda like that motor, it's easy to wind with 21awg HP wye gives power limit of 18amps and figured some fixes for it's construction.

Bought some motors un-wound from iflight, used 3 of their pre-made 3.5mm connectors and thought I wound the motor wrong but hadn't made a winding mistake in a long time. Found one of their connectors was not soldered good...cold solder (and this caused funny back and forth oscillation).

Now since you said you disconnected the motor, the resistance, beyond normal cogging, ... could this be rotor and stator scraping like my hobbyking d4023 had?????

Heard of some products like dewalt saws self destructing because of a loose screw floating free in the motor.... something like this in your motor???? should spin free quiet with no noise just magnetic cogging. Could there be a loose part in there, a loose e-clip c-clip on one of the magnets, or the stator glued crooked, THIS really happened.

What if they got one or some of the magnets glued wrong way around, this would work against the controller which tries to deliver the rpms you demand at the throttle, so if it won't go that fast the controller just dumps more power into the motor.

You can measure expected power limits, like I know 2# should take about 110w, 3# takes about 220w w/ my motors 12v a123 batts and 12x8 prop. On the ground 2# static takes about 10amps, 3# takes about 17 to 18amps. Got an ammeter or wattmeter?

BAD solder connections, physical scraping parts, loose parts that don't belong ......

View attachment 144589

View attachment 144590

View attachment 144591

I test my motors the way I intend to use them, thrust and speed static at 2, 2.5, and 3# and power consumed

Hey pictures are really desired, wanted and great on a forum and so is follow-up.... what have you found now?

ProfessorFate

View attachment 144592

View attachment 144593

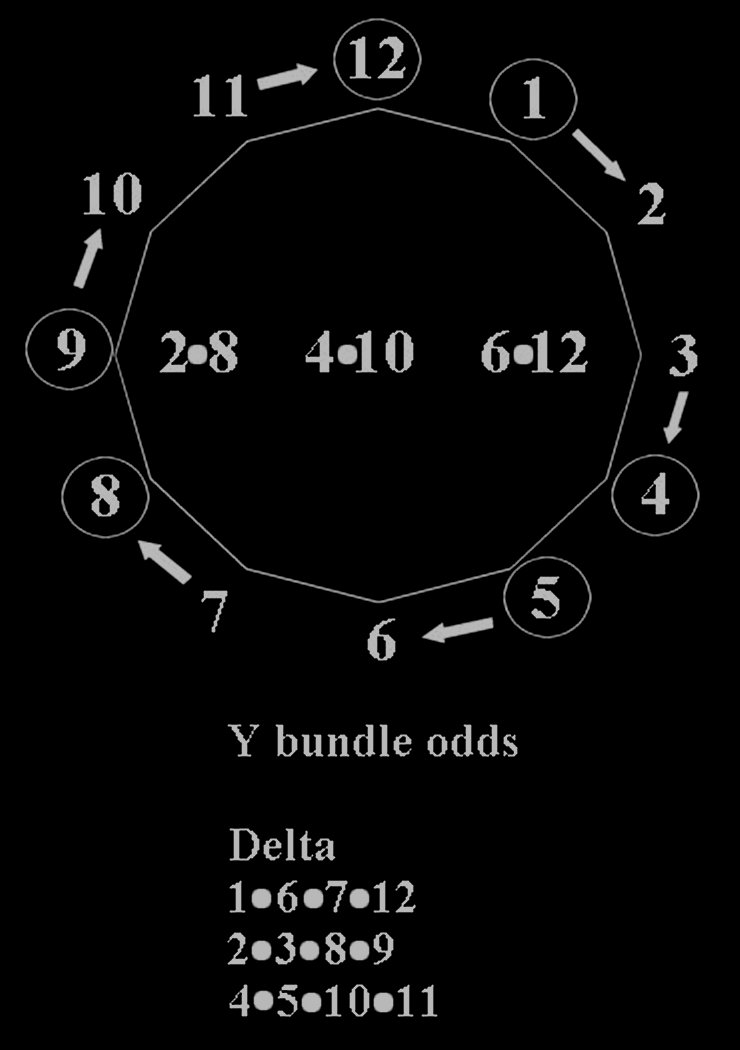

You wanna rewind that motor or another one?

My new favorite wind I made up last month, the Half Parallel dLRK wye adj coil wind ... best ever...separates the fat sloppy even windings, the evens, you wind the odd first, leave the even hanging, wind the next odd head, then wind the even between. Circles are wound CCW.