bracesport

Legendary member

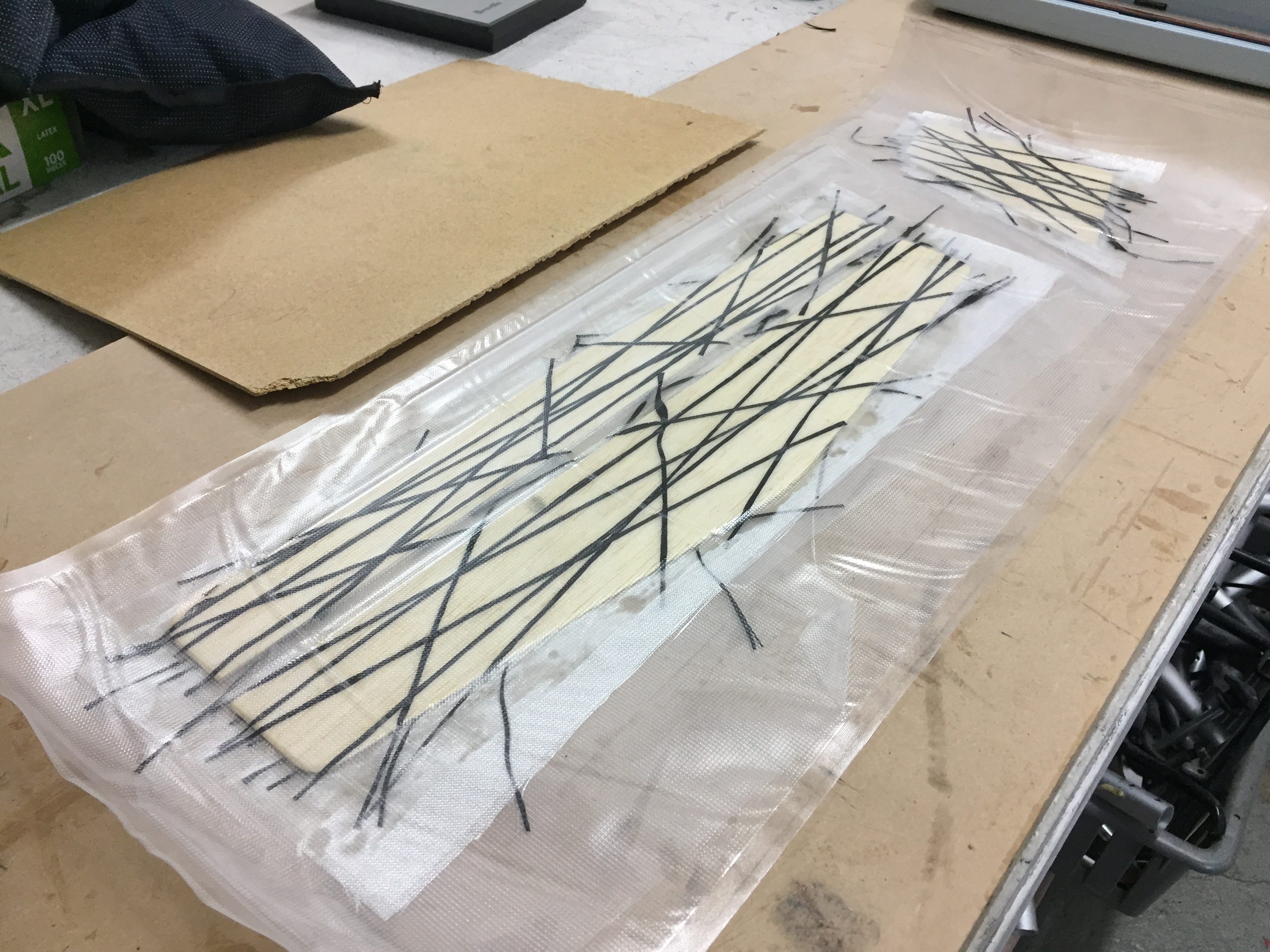

Now to the fuse!

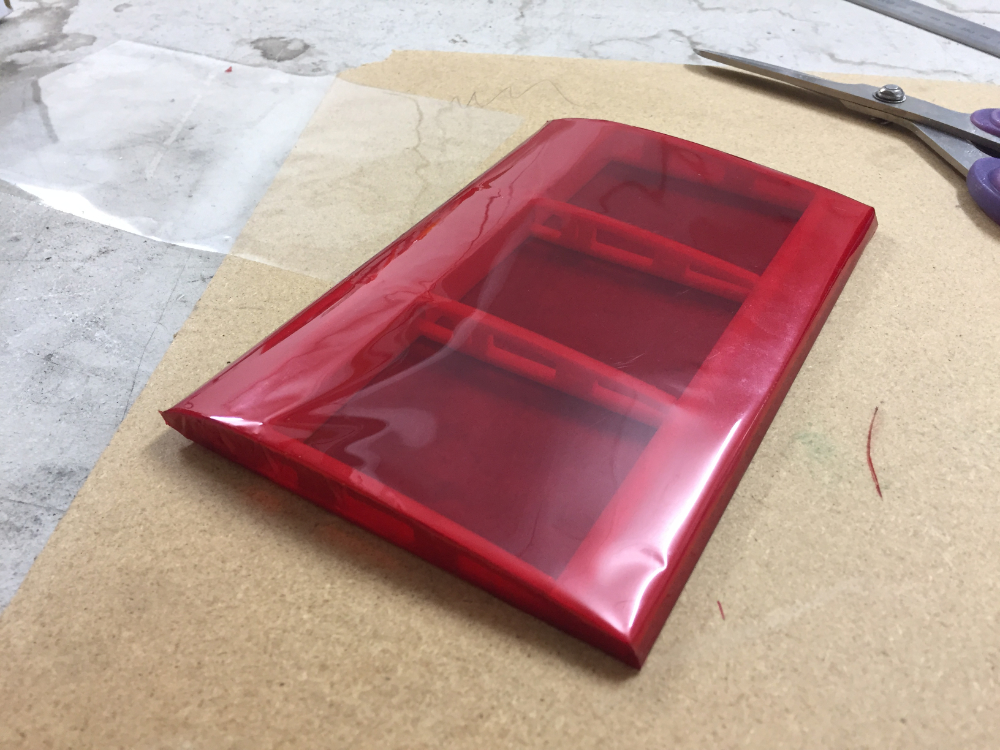

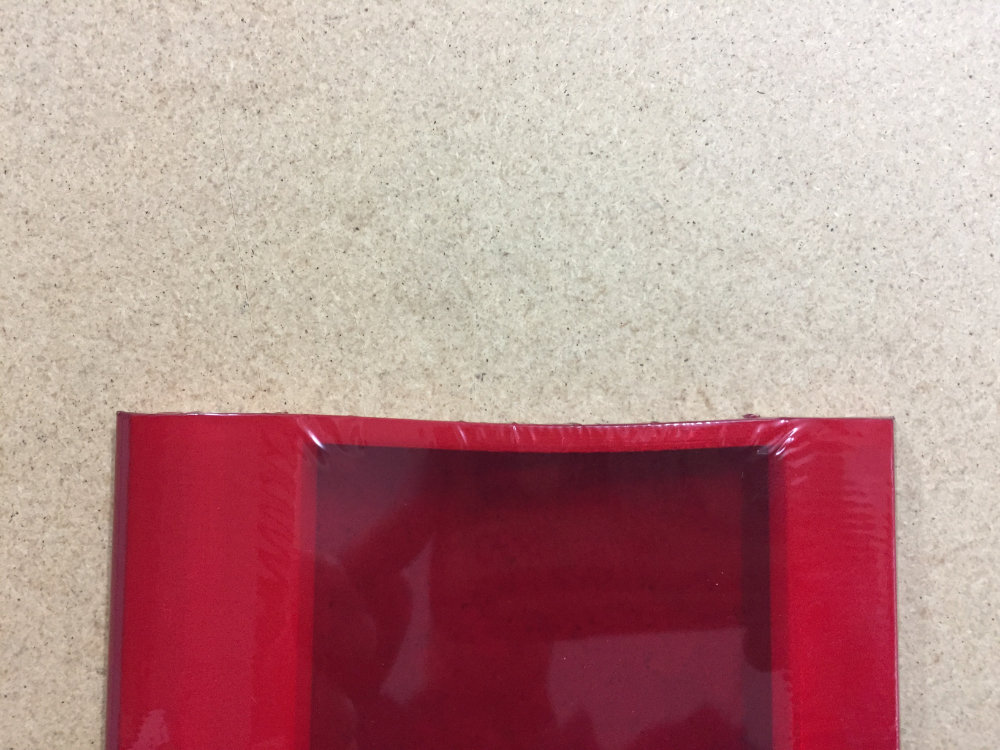

I can confirm the cling wrap worked well - better than the Vac bag I think - the nose worked a treat with the wire tie holding the sausage closed while the epoxy set - I think it only requires a small amount of sanding an filling to tidy it up!

Knowing what I know now I think I could have done a better job overall - not having enough braid was the first issue requiring two goes at it - the fuse volume at the thickest point was a tad bid which meant the braid was tough to fit - all fixable on a v2!

I can confirm the cling wrap worked well - better than the Vac bag I think - the nose worked a treat with the wire tie holding the sausage closed while the epoxy set - I think it only requires a small amount of sanding an filling to tidy it up!

Knowing what I know now I think I could have done a better job overall - not having enough braid was the first issue requiring two goes at it - the fuse volume at the thickest point was a tad bid which meant the braid was tough to fit - all fixable on a v2!