bracesport

Legendary member

I have been inspired by @thenated0g 's all-things-fibreglass and now especially the Ridge Rat project that he has set a-foot! So as with my Homage to flyboa's DLG's, I am planning to attempt the same thing here!

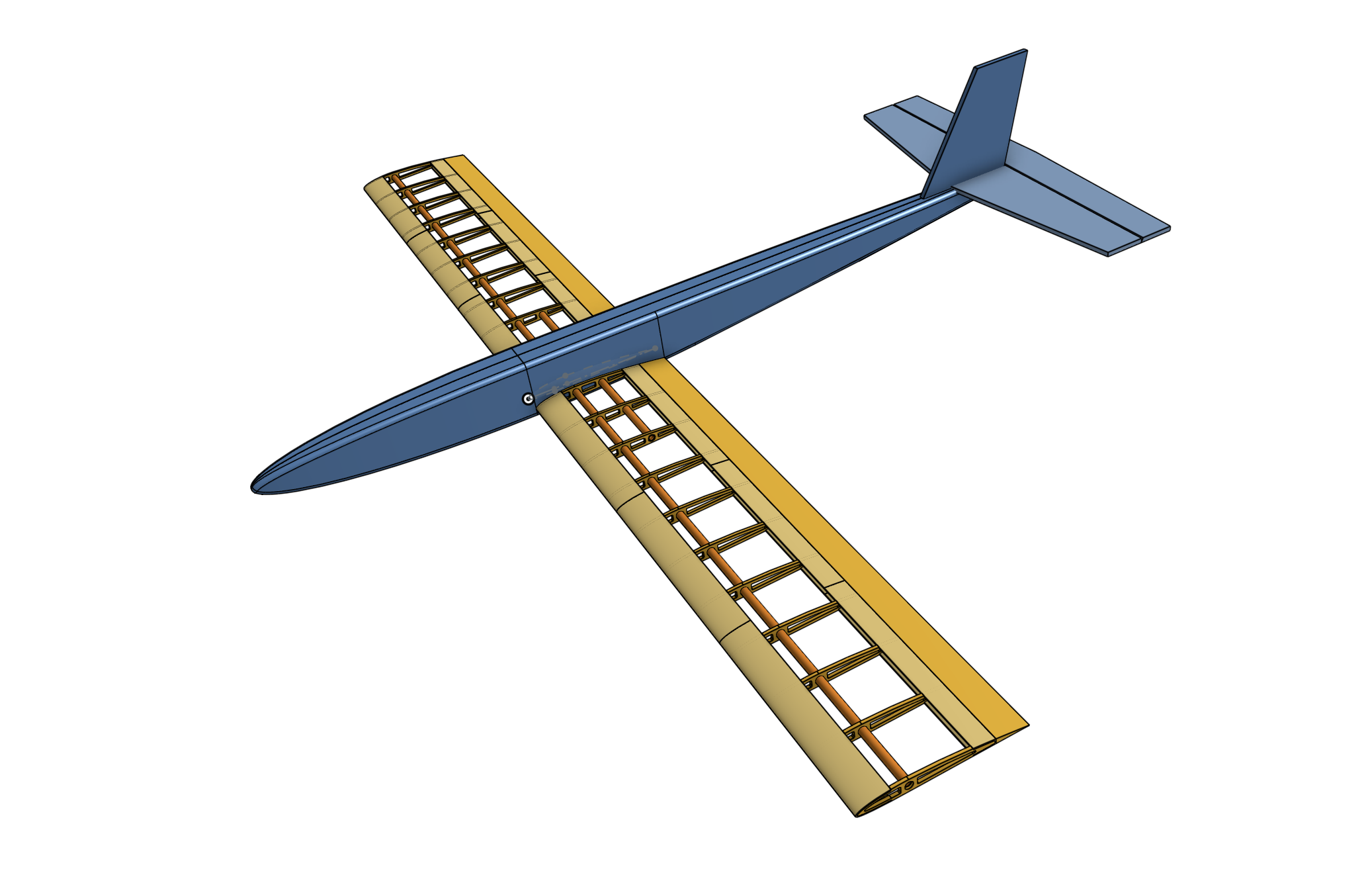

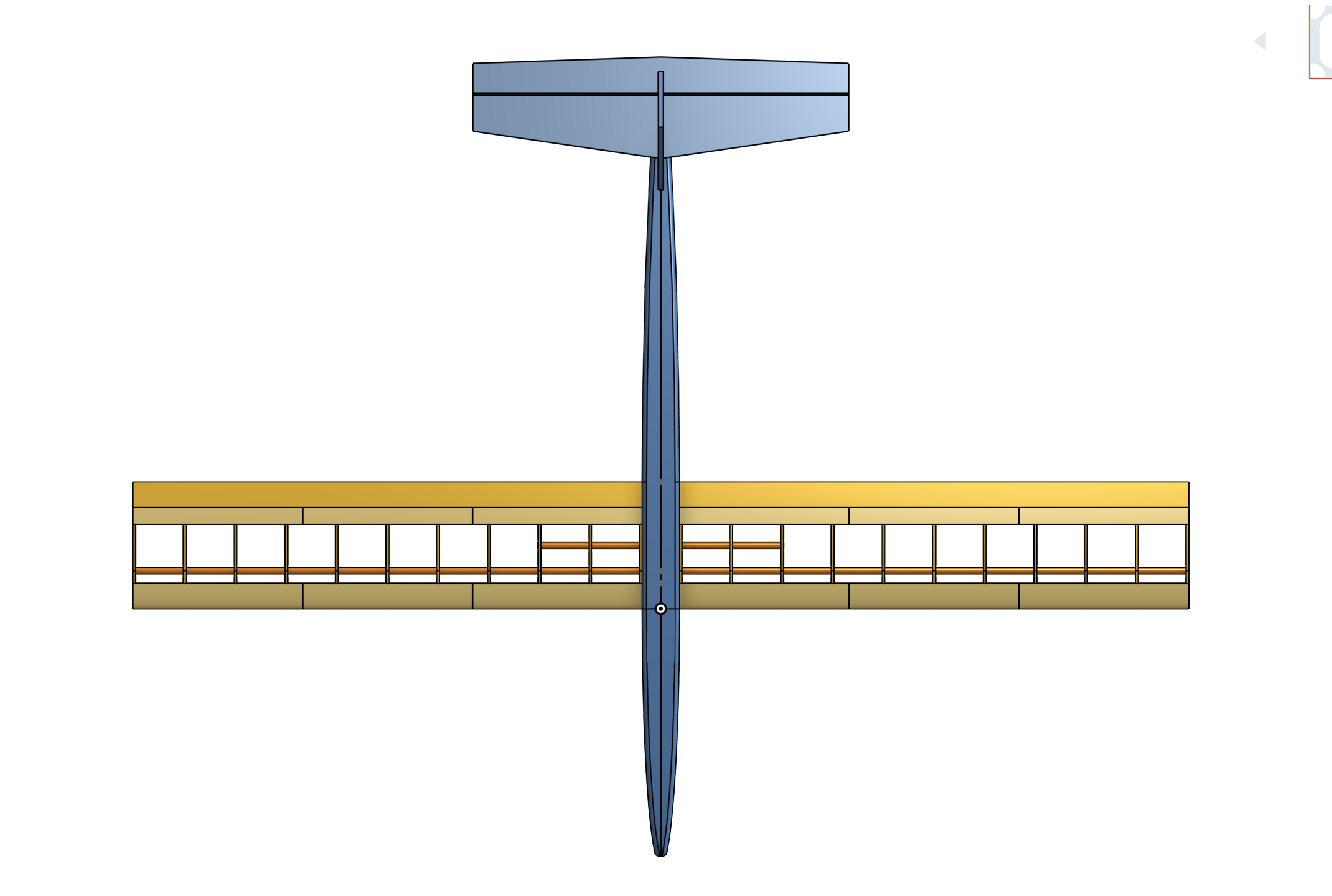

I will try and follow thenated0g's fuse and stabilisers build in FG, But I think I will add my twist with 3D printed wing sections, carbon fibre spars, and a shrink-wrapped skin!

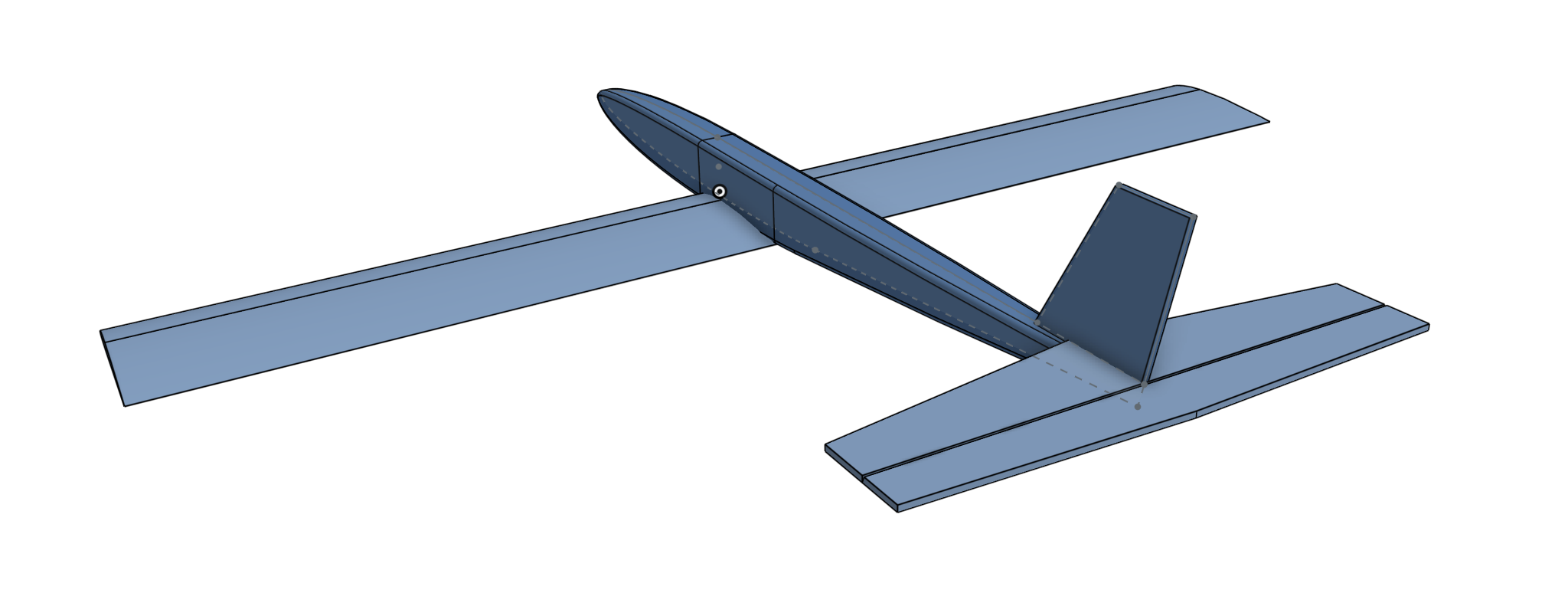

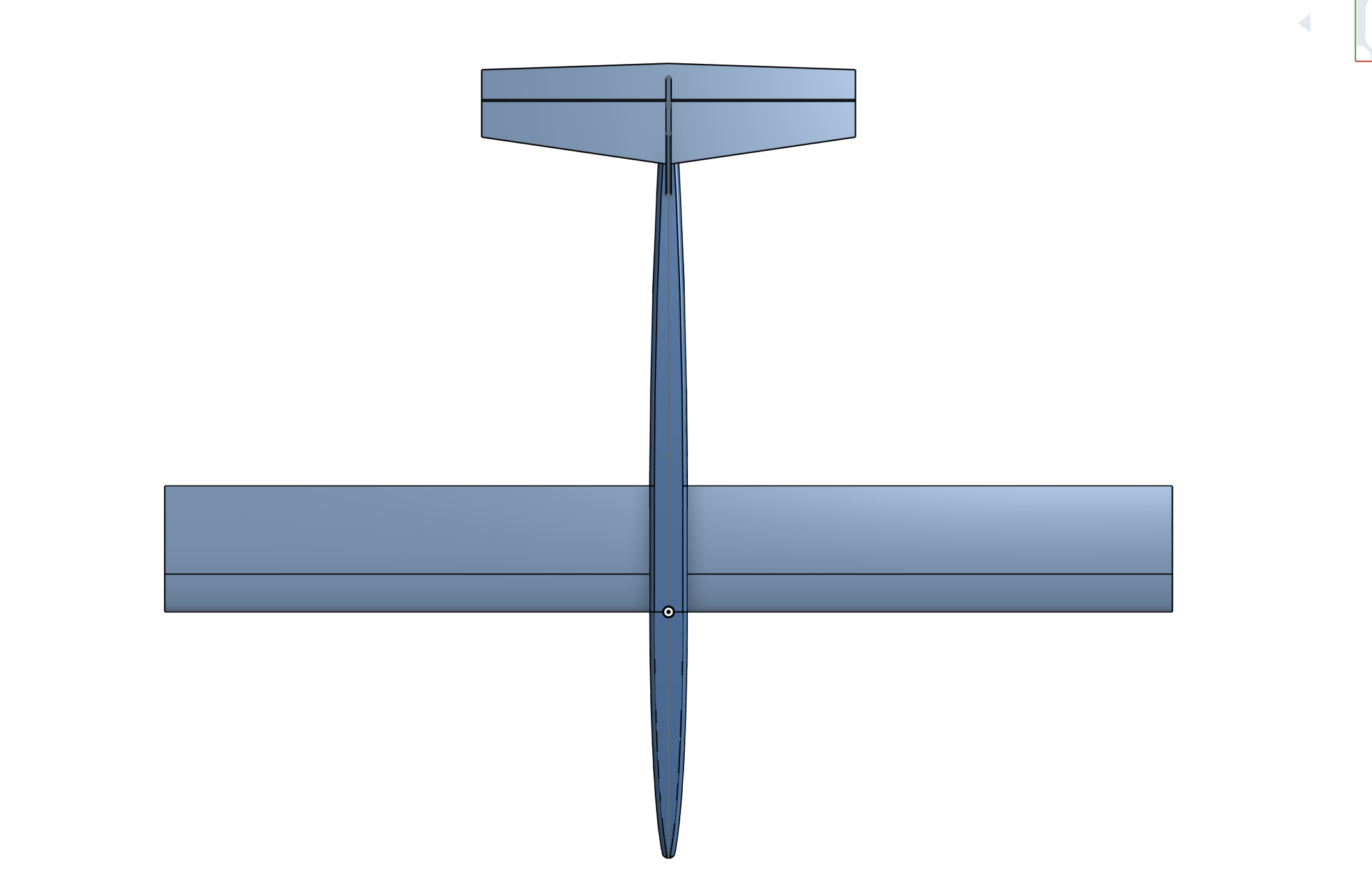

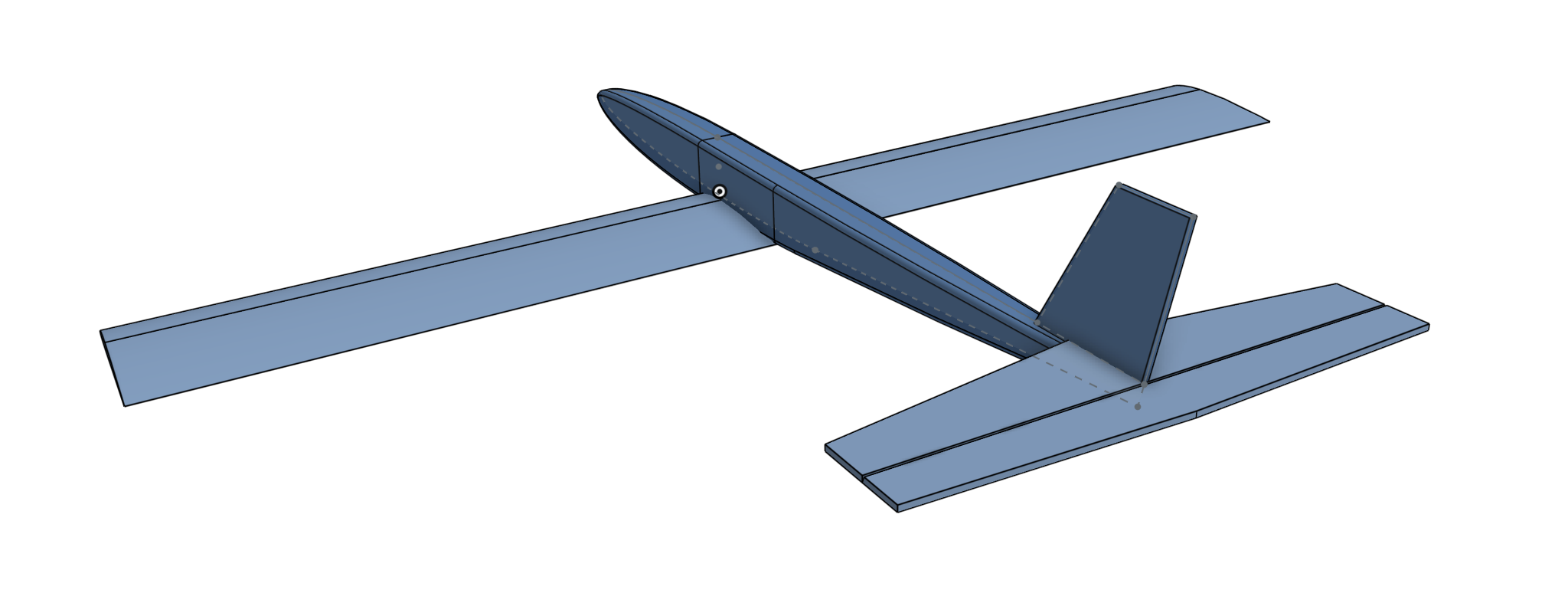

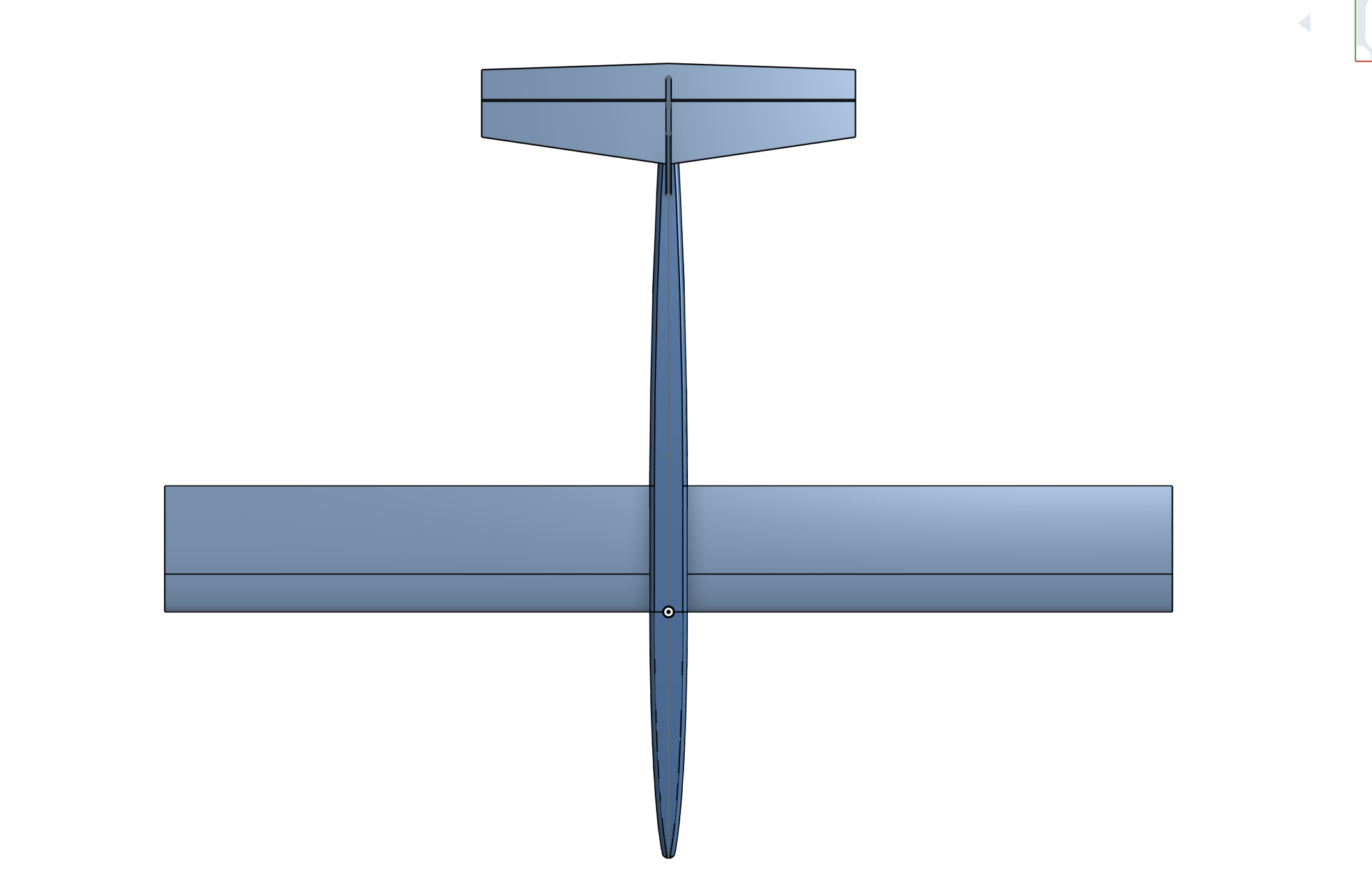

here is my 3D interpretation of the thenated0g's plan - it is a 1.2m wing with a 150mm MH32 chord.

very excited!

I will try and follow thenated0g's fuse and stabilisers build in FG, But I think I will add my twist with 3D printed wing sections, carbon fibre spars, and a shrink-wrapped skin!

here is my 3D interpretation of the thenated0g's plan - it is a 1.2m wing with a 150mm MH32 chord.

very excited!