Did a bit of playing over the weekend. Still haven't wired in my analog power control or aligned the mirrors...but wanted to give the new lens a bit of a try.

Turns out the focus is higher not lower with this lens...in fact it's high enough I'm a little worried about the head being able to clear the material. I'm surprised as it's a 2"/50.8mm focal length lens which is what I thought the stock lens was as well. I had to raise my cutting bed about 6-7mm from where I had it to get into the focal point. (I still need to work out a more permanent bed as well, for now I'm just resting a piece of cardboard on top of the stock bed mounts and have a layer of DTFB on top of that to get to the focal point.)

I haven't yet swapped to the upgraded mirrors...though inspecing the stock mirror while swapping the laser head I'm really itching to now. Wow is the stock mirror iffy. At first I thought it was dirty...but it's actually just a really uneven coating with a number of flaws. I didn't get any photos of it...but...yeah it's pretty bad.

I also haven't aligned the mirrors yet - I was waiting on a new pair of safety goggles before I did...but I'm also waiting on a chance to do it when my daughter is out of the house just out of an abundance of caution. I can't really do it when she's asleep because it's just too loud running the machine.

So with the machine still in barely working order I continued to do a few tests for fun.

After a couple of test cuts I got DTFB cutting about as well as I think it's going to:

I still prefer my needle cutter since it has zero under cutting...but this seems to be about the same as the under cutting I saw on the quick build kits I've tried. This was two passes at 110mm/sec and 30% power. I could probably keep fiddling to get it even better...but since I don't really plan on cutting foam board with this very often if at all (unless I expand the size of the machine...and even then I'm not sure.) I'm calling this good enough for my needs.

Next I gave engraving a bit of a try. I haven't had any luck at all with greyscale engraving in lightburn. Not sure what I'm doing wrong but it doesn't fire the laser at all at any point when I enable greyscale. So I must still be missing something. With dithering though I was able to get surprisingly decent results on my first try:

The original image wasn't the greatest:

And it seems like the dark parts got a bit over exposed...but overall for a first try I'm pretty happy. It may look better done larger so more detail would should. Hard to tell from the photo but this test was only about 1" across.

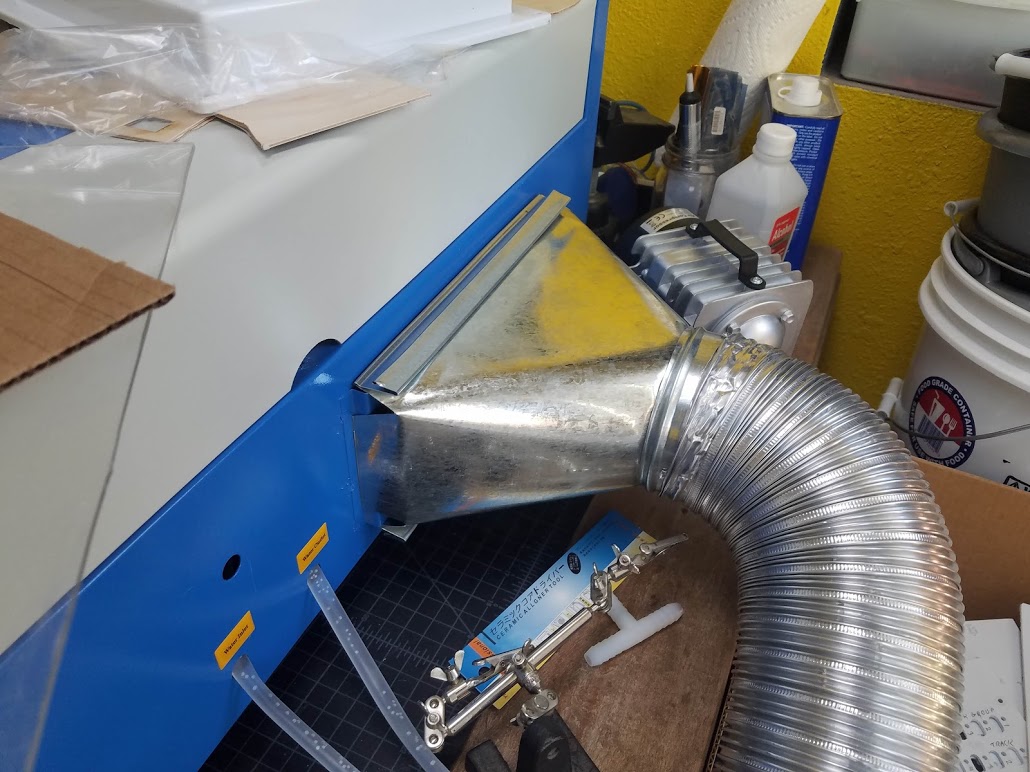

And my cut around it wasn't quite powerful enough to get through the 1/8" ply. It was just a random guess anyway...and I really want the air assist hooked up before I push cutting things too much more.

Even so I decided to do a few power tests. In lightburn I did a 10x10 grid. The cut itself is setup as 20mm/sec@60% power (which maxes out at about 15ma - I could push it a bit higher but I'd rather treat the tube gentle and try to give it as long of a life as possible) I then used the shape properties to change the power percentage starting at 10% on the left and going up 10% each square to 100%. Note - this is % of the actual cut setting. So it's 10% of 60% for the left most squares. Once I have my analog power control in I can set my max power limit with that and use 100% for the base setting here which would be less confusing.

Going up I increased the speed by 10mm/sec each row. So it starts at 20mm/sec and goes up - the top row is 110mm/sec because I suck at math and didn't think this through then didn't want to start over to get 10mm/sec-100mm/sec range to appease my OCD

I stuck in a piece of "standard amazon box cardboard" and let it rip:

My daughter had fun pushing out as many of the squares as she could. But off the machine only the 20mm/sec@30% power piece actually fell out by itself. A few of the 100% squares and the 50%, 60% squares came out with a gentle touch - the rest she had to actually push on.

But this doesn't make much sense to me. Why would some of the higher power cuts not do as well? Something just seems really non-intuitive here. I'm not going to loose any sleep trying to figure it out until I have things more dialed in. Maybe the mirror alignment means that at some points it's not getting full power.

Also - note the uncut corners on the lower power squares. I think I may have too high of accelerations in smoothie causing the motion to be quicker than the laser can keep up with at lower powers....still need to experiment more to figure that out.

I repeated the same test on a piece of single thickness Jimmy Dean biscuit and gravy bowl box (I had a craving and didn't want to take the time to make it from scratch - don't judge!):

As I expected this was able to cut reliably at lower powers and higher speeds - though it's still showing a lot of the same "issues" with higher power cuts not always being better. Also my daughter didn't get to try and remove any of these yet. Most of them just fell out by themselves...but I did tap the sheet against the table a few times to encourage more to drop. I suspect that quite a few more of these would be easily removed as well.

I did one more power test like this on some frisket material. That did NOT go well. The slower speeds were way too much and before the 5th square was cut I had to stop it and put out the fire. Will have to do a grid with faster speeds and lower powers before I try that again!

I also did a test cut on some 3mm thick white craft foam. With my 3watt diode laser I can cut 3mm black foam beautifully at fast speeds and low power...but even at it's highest power and low speeds it couldn't even mark white foam. The CO2 laser had no such issues. In fact instead I had the same issue I did with DTFB in that it cut too well. Will need the same kind of faster lower power multiple pass cuts to do it accurately without melting a 1mm wide kerf. I didn't get a photo of that though so you'll have to use your imagination.