Mad_Mechanic

Well-known member

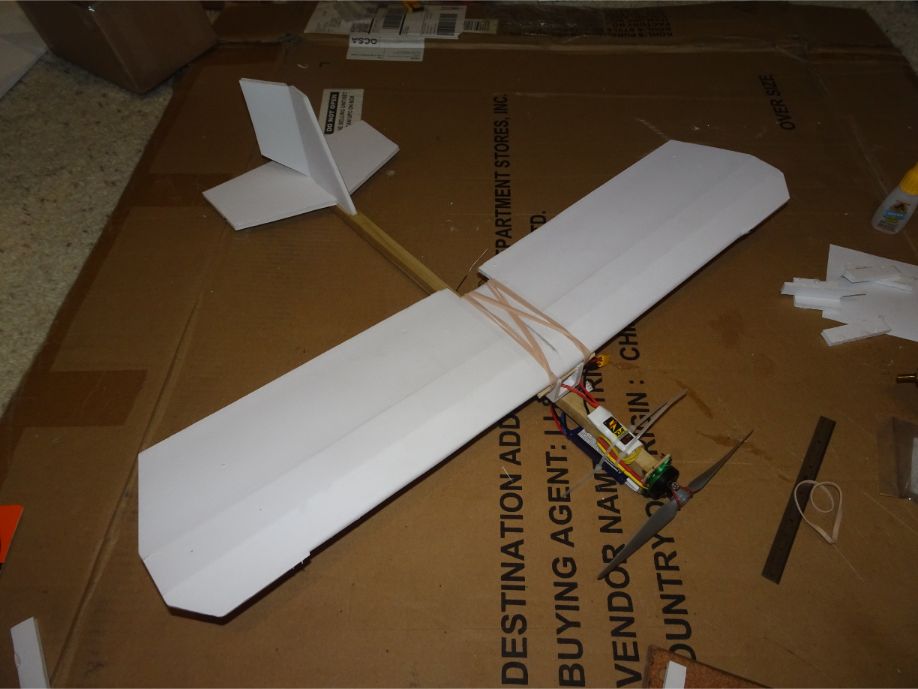

So the other night I was watching the old Flite Test video on the eRC Micro Stik and I thought it was pretty cool. So I started looking into parts and ideas of how I could build an FT inspired 'Stik' plane.

Today on my lunch break I threw together this design in SolidWorks. It's based around a 1/2" wood dowel (thinking something like Pine or Basswood), wing and control surfaces are dollar store foam board. If my estimations are correct, I can get all the wing and tail surfaces from 1 piece of foam board.

Wings have nominally 5-deg dihedral on each side.

Wingspan is nominally 24in, with an 8in wide elevator (1/3 wingspan) and 4in tall rudder (1/2 elevator).

I'm letting SolidWorks do all the math for the CG. The foamboard density I used was 0.062 g/cm^3. All the electronics bits I applied the manufacturer's stated weights. I was aiming for the balance point to be about 1/3 back from the leading edge. I chose 1/3 because that's what Josh Bixler says he uses for most of his designs.

Electronics are as follows:

FrSky RX4R receiver (4-channel, ~2.4g)

2x HexTronik HXT500 servos (~6.2g each)

Turnigy 1811-2000Kv motor (~11g)

Turnigy Plus 6A ESC w/ BEC (~6g)

Turnigy 2s 460mAh LiPo (~31g)

*Was planning on a 300mAh, but I needed more nose weight

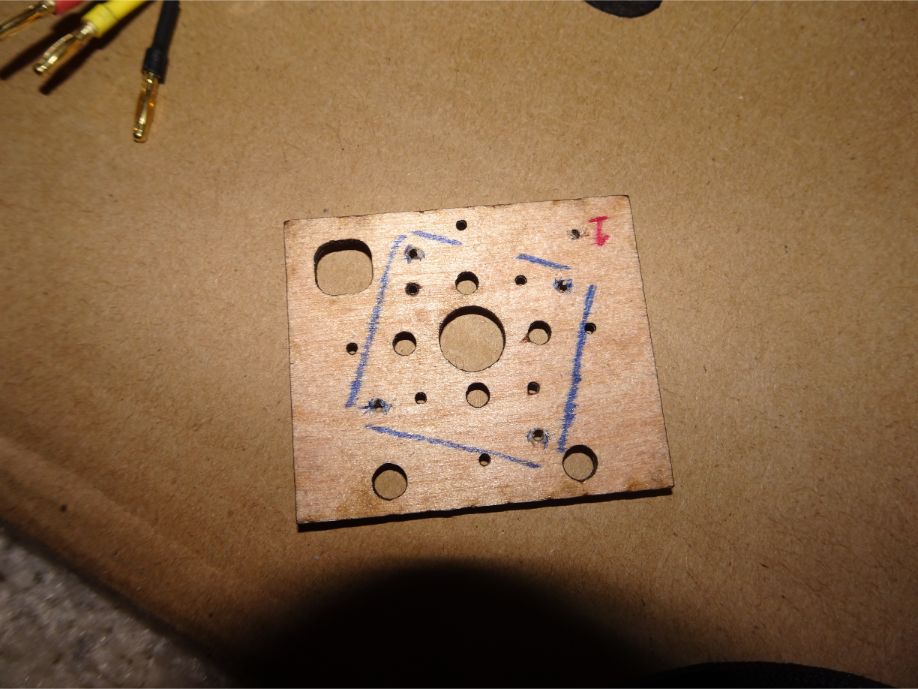

Here is how all the electronics package:

The motor description states that it will work with 6x3 up to 7x3 props with a nominal thrust of 150-165g

According to SolidWorks mass calculations, I'm right around 135g as shown. This of course doesn't account for hot glue, which I will have to use sparingly.

I already have most of the electronics parts on order from the HobbyKing USA warehouse, unfortunately the motor is currently on backorder so I can't get to excited.

Thoughts?

Today on my lunch break I threw together this design in SolidWorks. It's based around a 1/2" wood dowel (thinking something like Pine or Basswood), wing and control surfaces are dollar store foam board. If my estimations are correct, I can get all the wing and tail surfaces from 1 piece of foam board.

Wings have nominally 5-deg dihedral on each side.

Wingspan is nominally 24in, with an 8in wide elevator (1/3 wingspan) and 4in tall rudder (1/2 elevator).

I'm letting SolidWorks do all the math for the CG. The foamboard density I used was 0.062 g/cm^3. All the electronics bits I applied the manufacturer's stated weights. I was aiming for the balance point to be about 1/3 back from the leading edge. I chose 1/3 because that's what Josh Bixler says he uses for most of his designs.

Electronics are as follows:

FrSky RX4R receiver (4-channel, ~2.4g)

2x HexTronik HXT500 servos (~6.2g each)

Turnigy 1811-2000Kv motor (~11g)

Turnigy Plus 6A ESC w/ BEC (~6g)

Turnigy 2s 460mAh LiPo (~31g)

*Was planning on a 300mAh, but I needed more nose weight

Here is how all the electronics package:

The motor description states that it will work with 6x3 up to 7x3 props with a nominal thrust of 150-165g

According to SolidWorks mass calculations, I'm right around 135g as shown. This of course doesn't account for hot glue, which I will have to use sparingly.

I already have most of the electronics parts on order from the HobbyKing USA warehouse, unfortunately the motor is currently on backorder so I can't get to excited.

Thoughts?